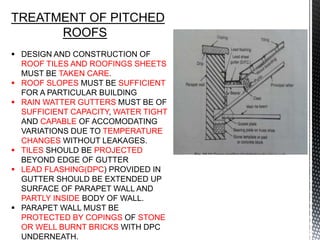

This document discusses various methods of damp proofing buildings to prevent damage from moisture. It describes different materials that can be used for damp proof courses (DPC) like bitumen felts, mastic, and concrete. Methods are grouped into treatments for foundations, basements, floors, walls, roofs, and pitched roofs. Key steps include installing DPCs, drainage, waterproof plasters and membranes, and properly sloping surfaces to prevent water accumulation. Maintaining continuity of DPCs and properly detailing features like parapets is also important for effective damp proofing.