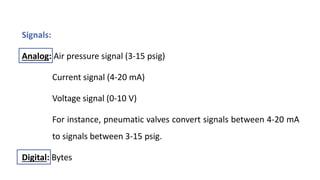

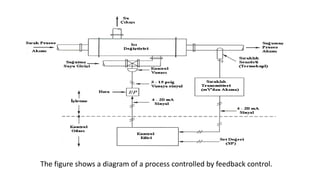

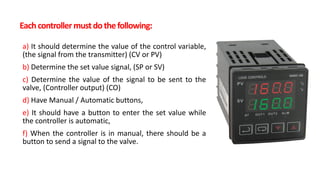

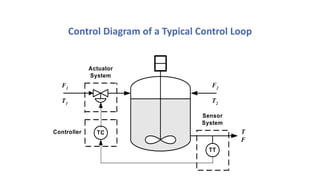

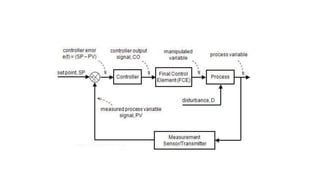

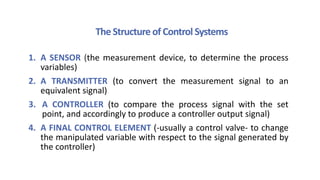

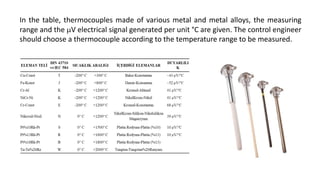

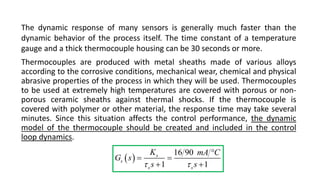

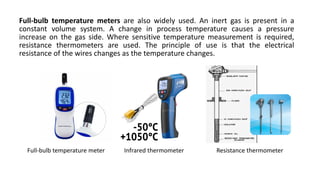

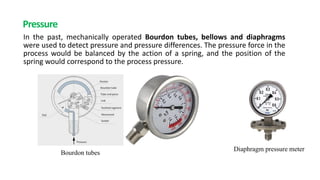

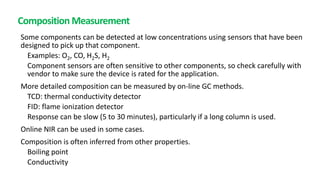

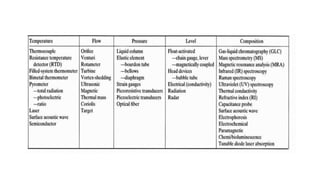

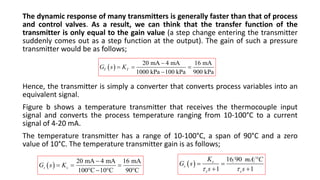

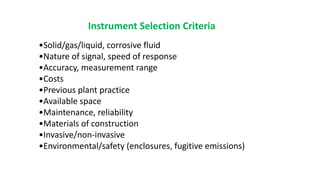

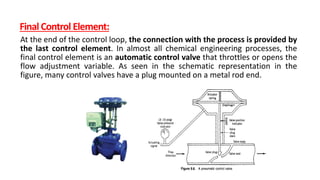

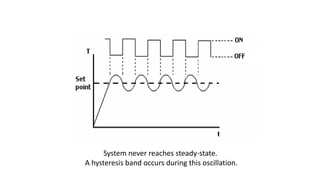

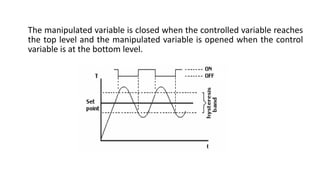

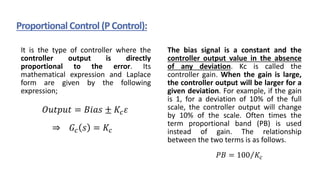

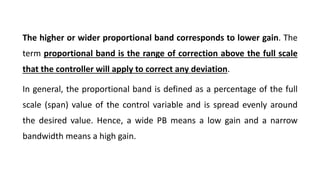

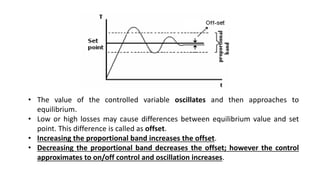

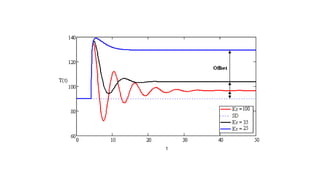

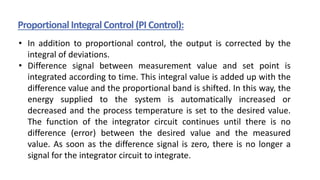

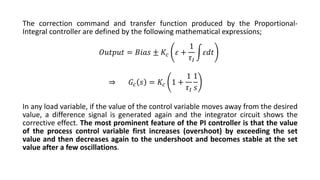

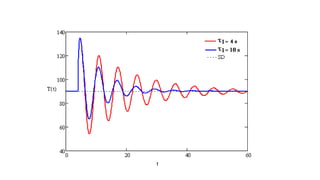

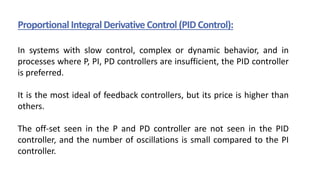

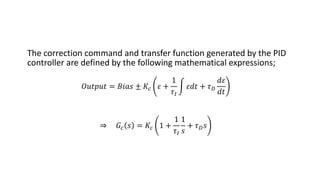

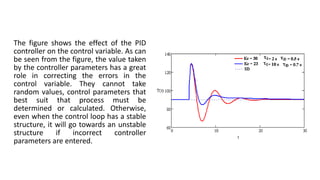

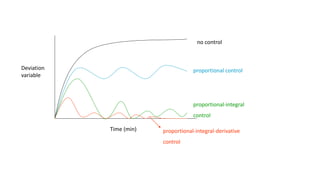

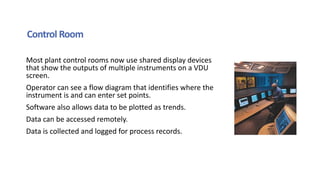

The document outlines the evolution of process control systems from mechanical and pneumatic devices to modern digital monitoring and control systems. It details the components of control loops, including sensors, transmitters, controllers, and final control elements, emphasizing the differences between analog and digital signals and control strategies. Additionally, it elaborates on various measurement devices and their principles, such as thermocouples and pressure meters, and discusses control methods like on-off, proportional, and PID controllers.