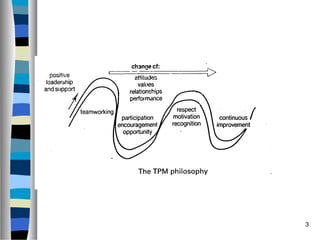

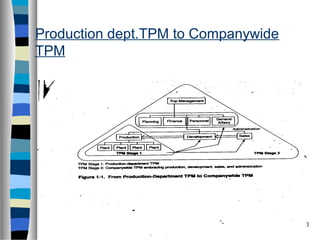

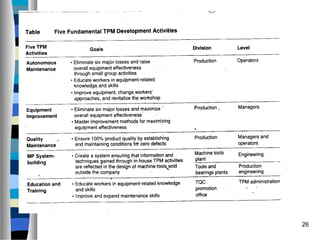

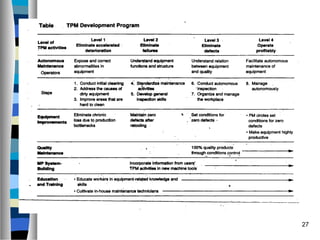

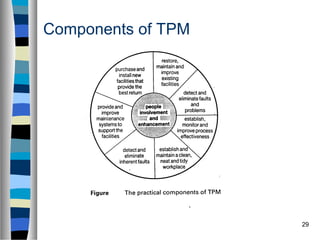

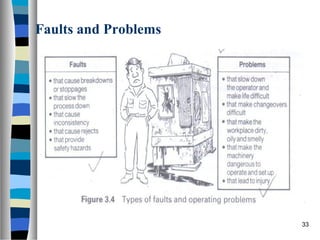

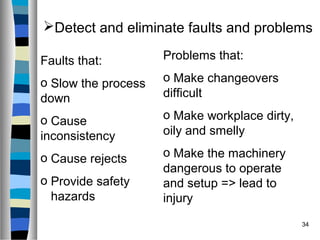

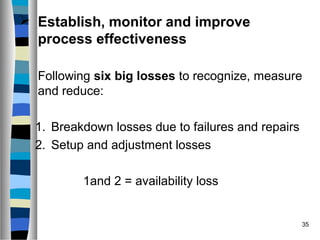

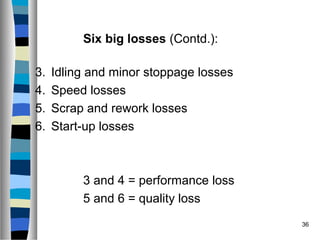

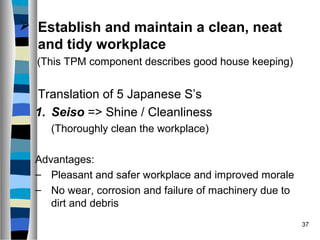

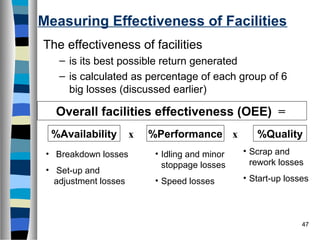

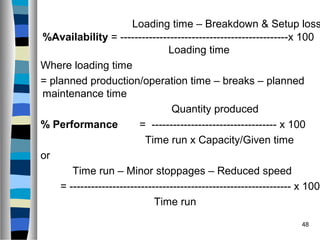

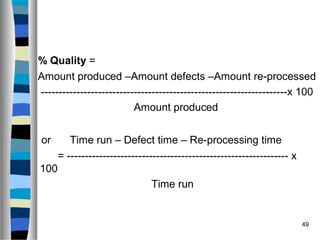

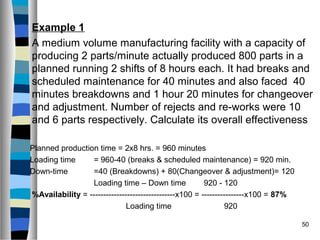

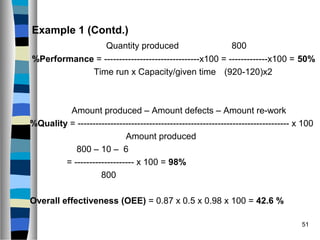

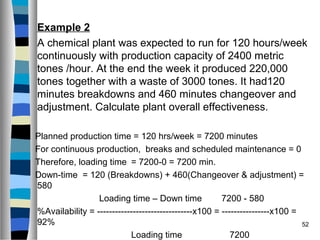

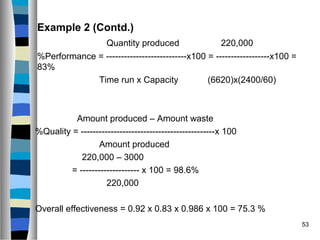

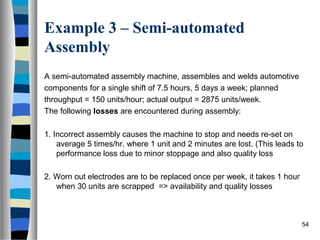

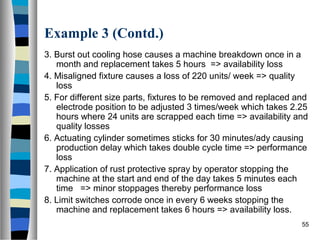

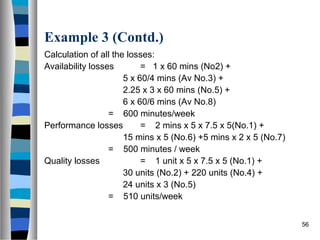

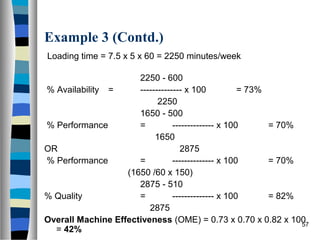

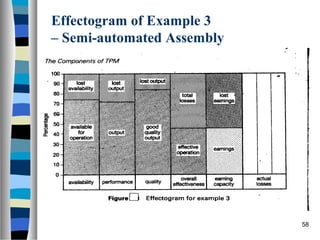

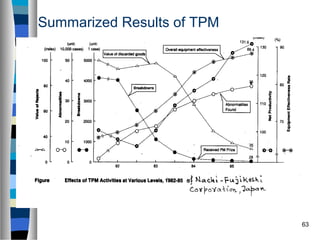

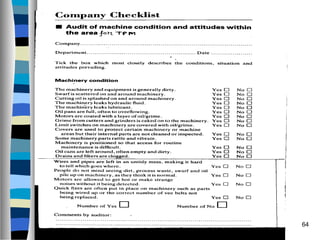

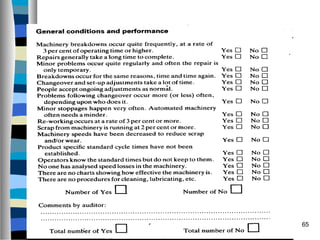

This document provides an introduction and overview of Total Productive Maintenance (TPM). It discusses that TPM is both a philosophy and collection of techniques aimed at maximizing the effectiveness of business facilities and processes through zero breakdowns, accidents, and defects. The key aspects of TPM covered include its origins in Japan, its role in companies, fundamental activities like autonomous maintenance and equipment improvement, components like maintaining clean and tidy workplaces, and measuring facility effectiveness using overall equipment effectiveness. Examples are also provided to demonstrate how to calculate availability, performance, quality, and overall equipment effectiveness.