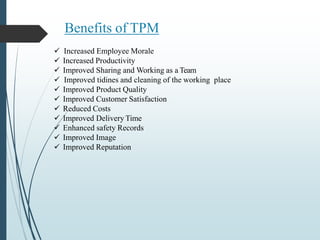

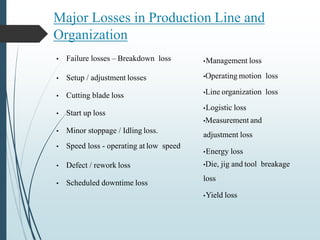

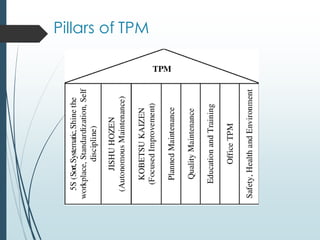

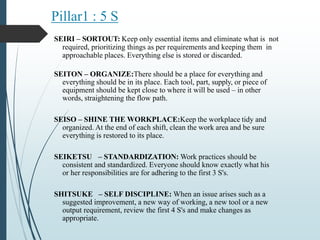

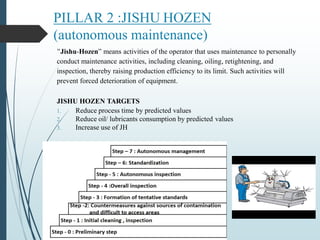

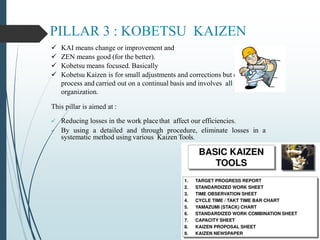

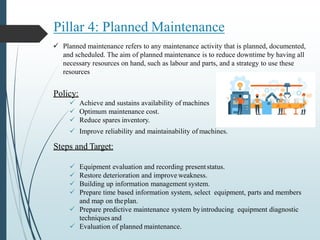

This document discusses Total Productive Maintenance (TPM), which aims to maximize equipment effectiveness through the involvement of all employees. It outlines the history and objectives of TPM, as well as its eight pillars: 5S, Autonomous Maintenance, Focused Improvement, Planned Maintenance, Quality Maintenance, Training, Safety and Health, and Office TPM. Implementing TPM through these pillars can provide benefits such as increased productivity, improved quality, reduced costs, and enhanced employee morale and job satisfaction.