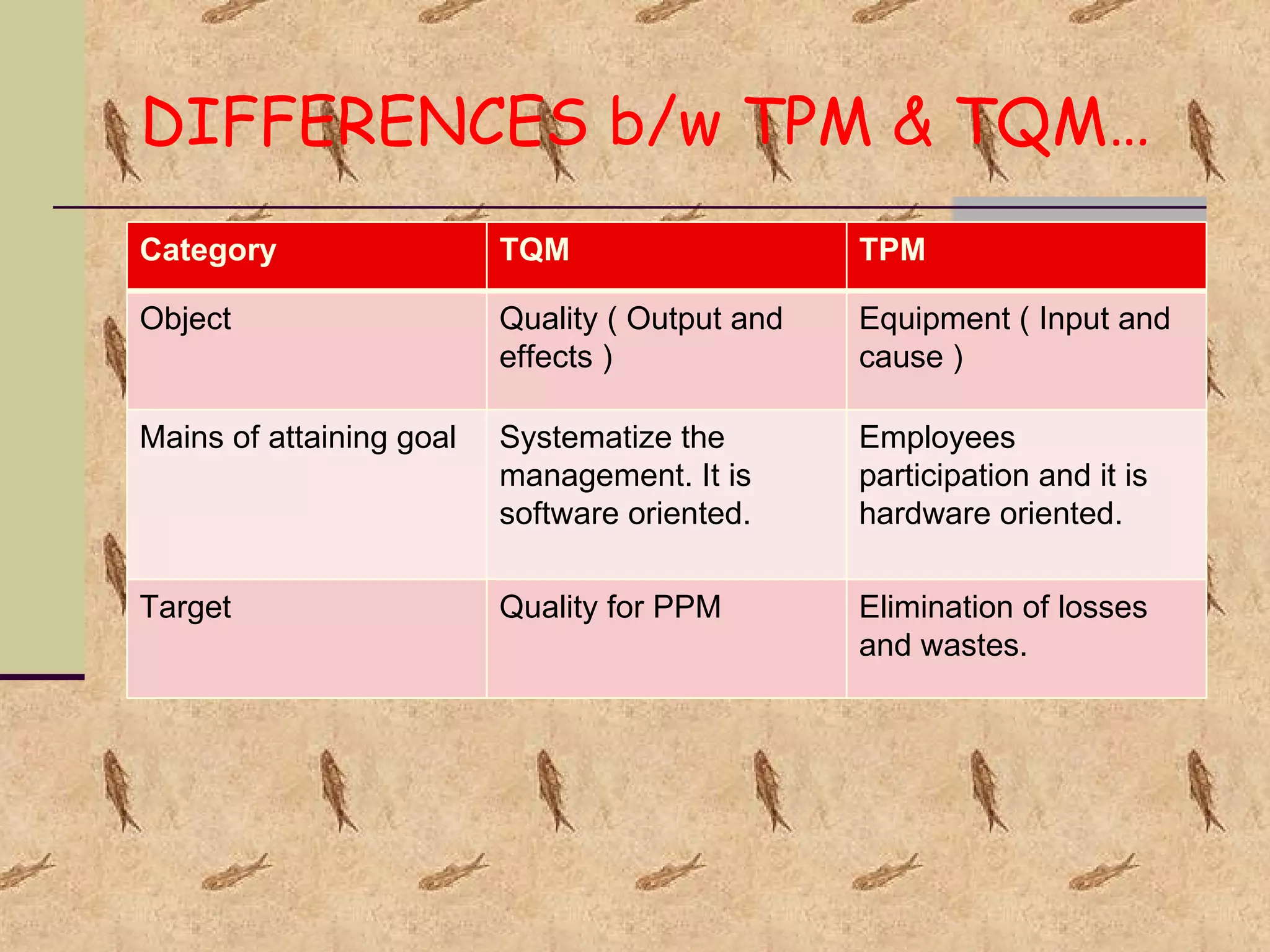

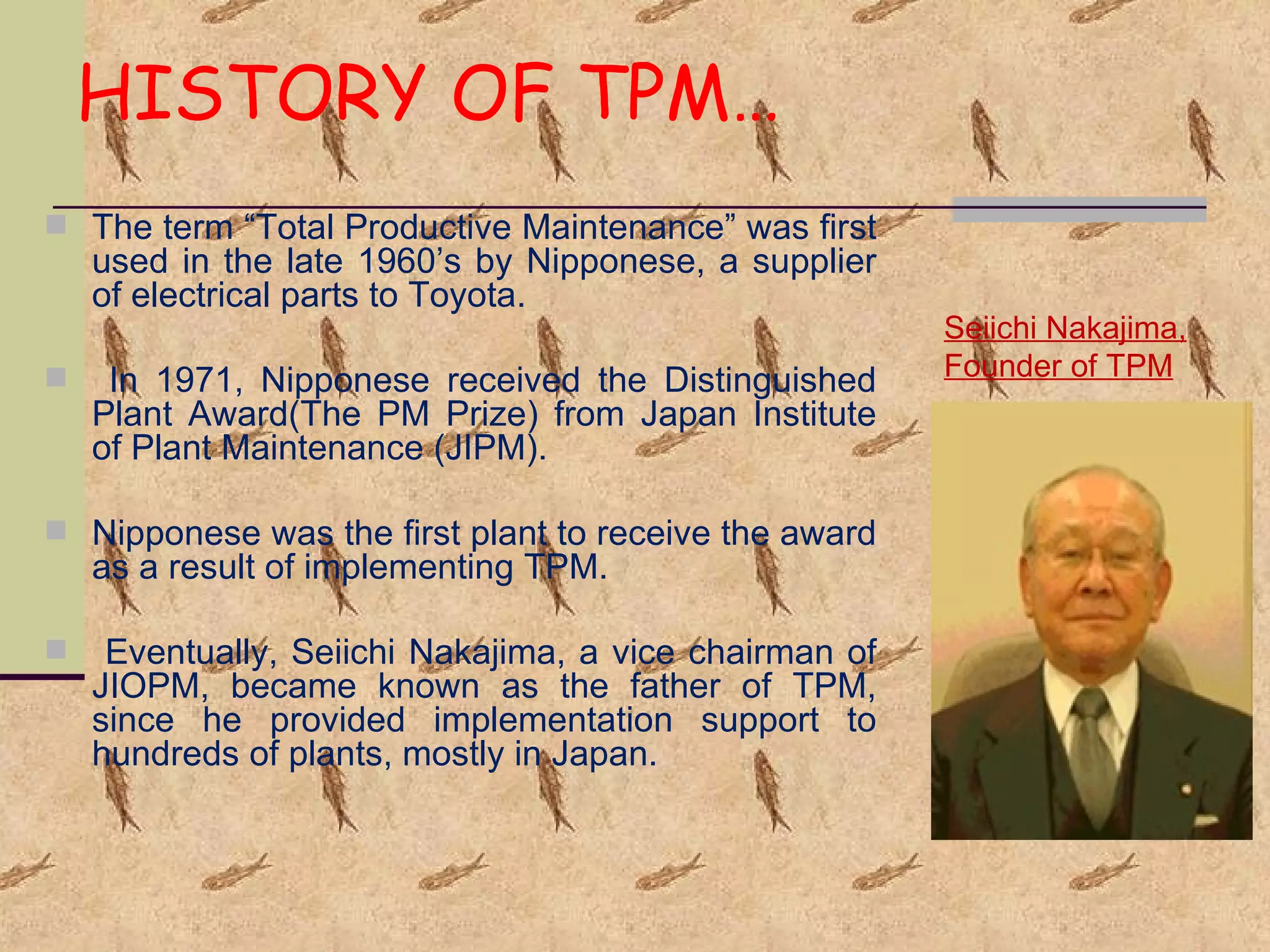

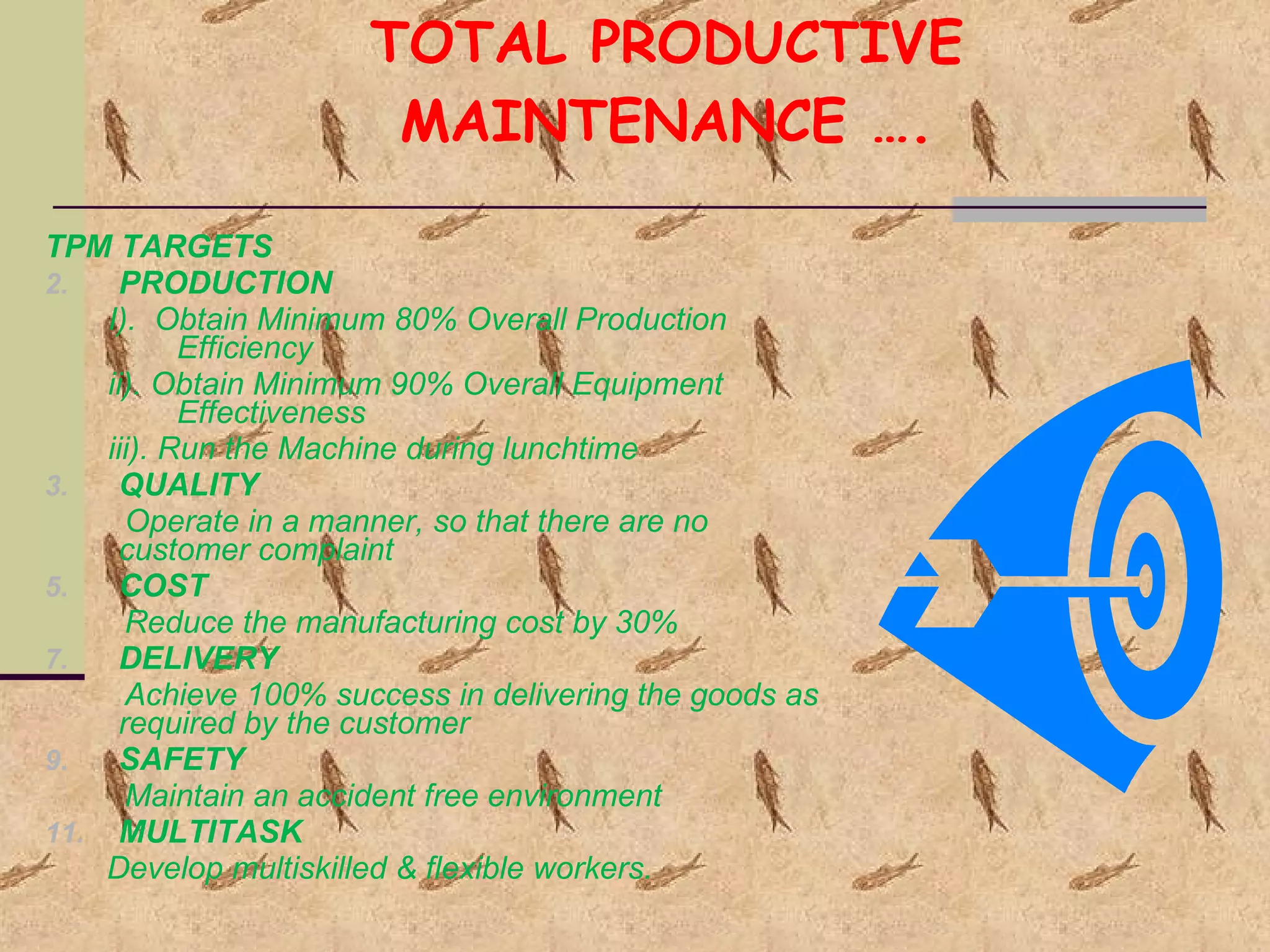

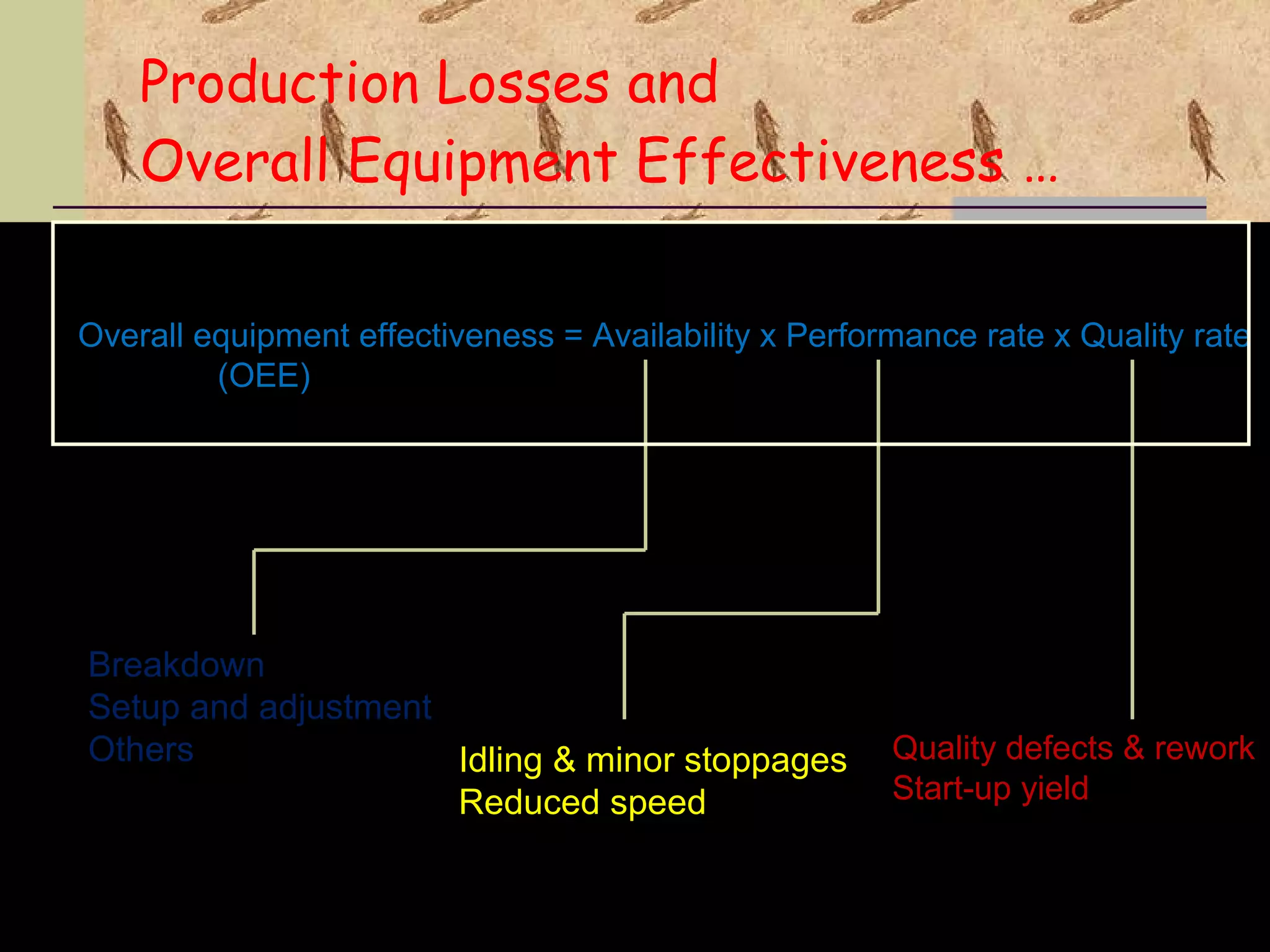

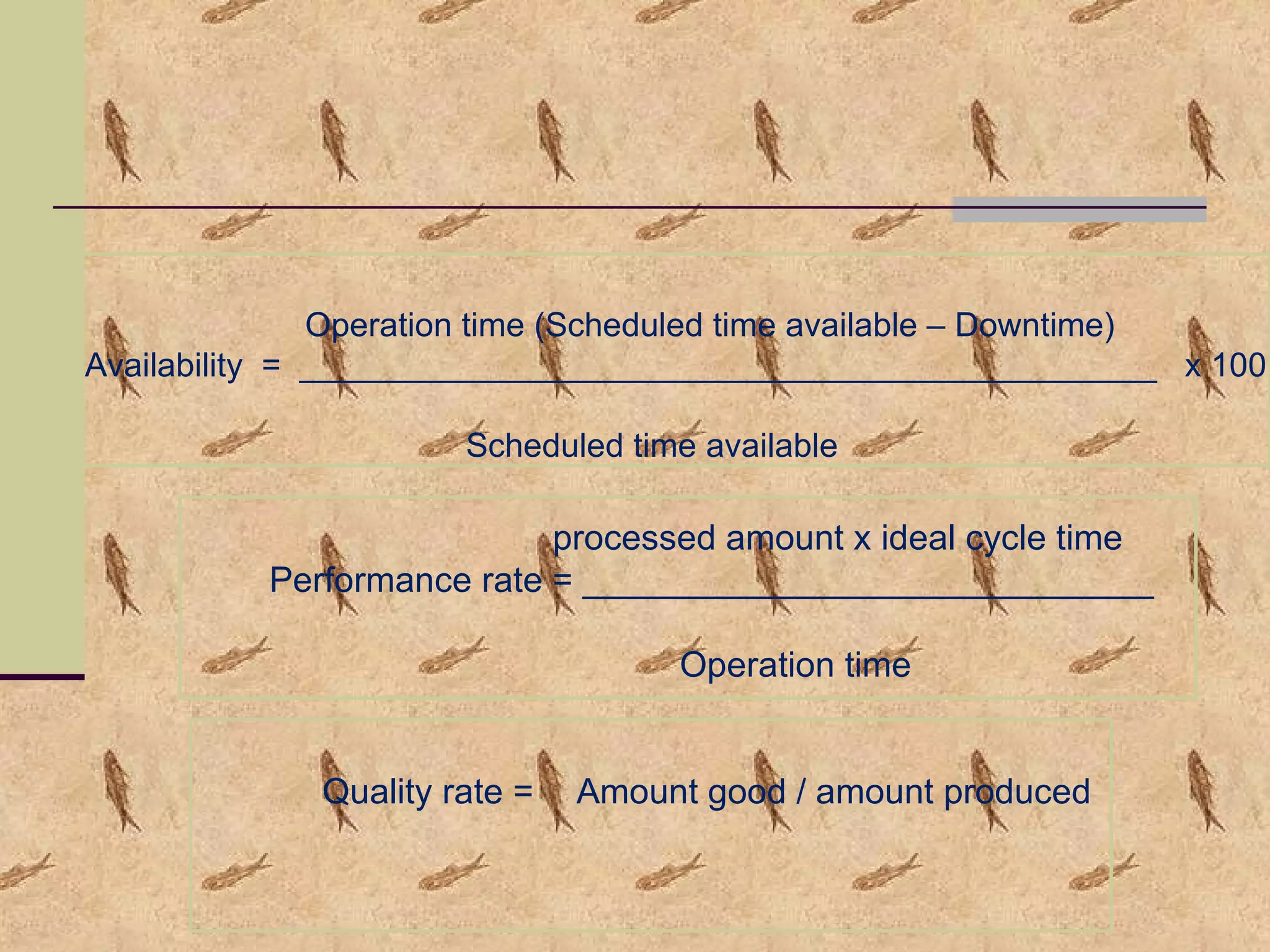

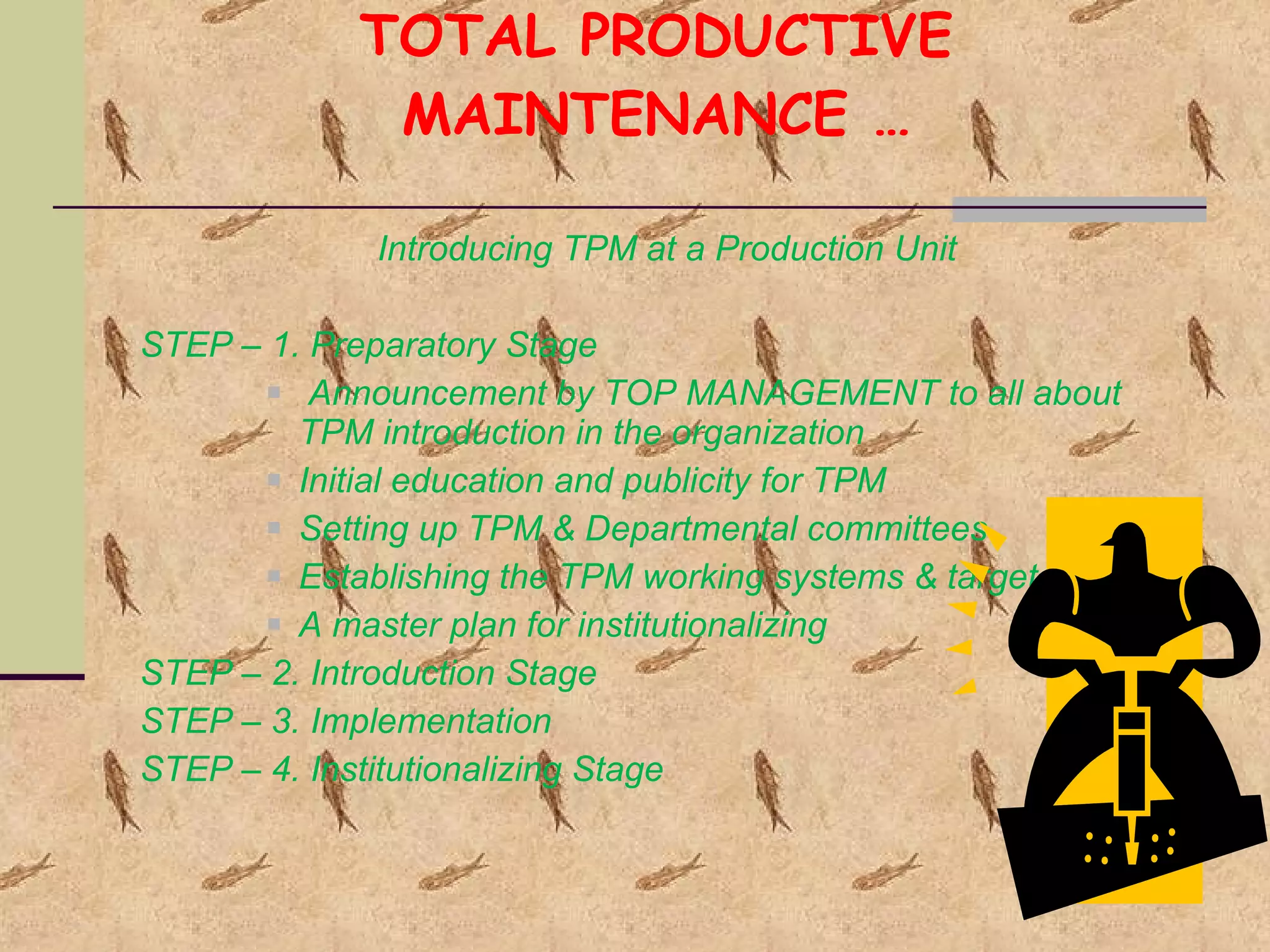

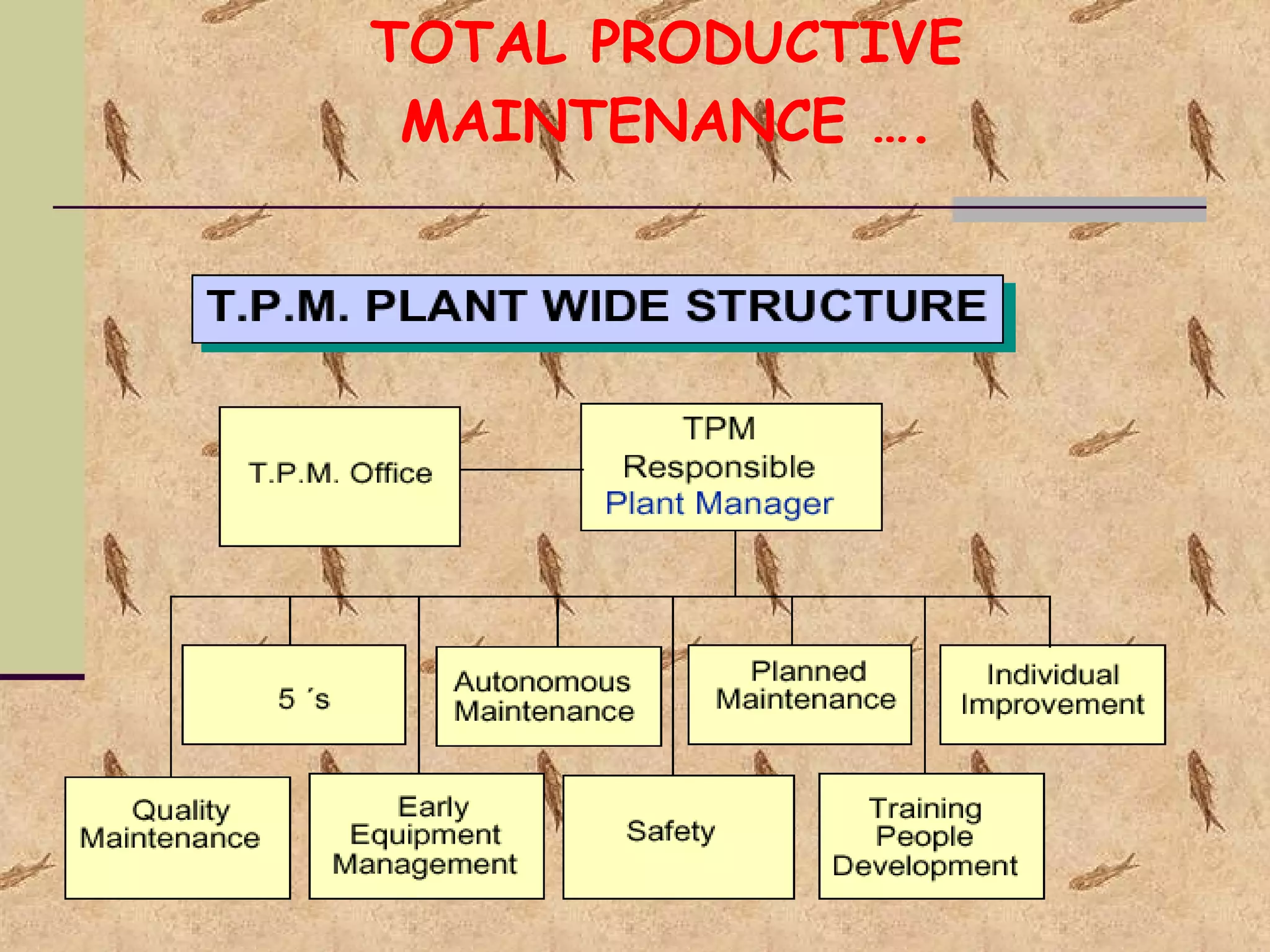

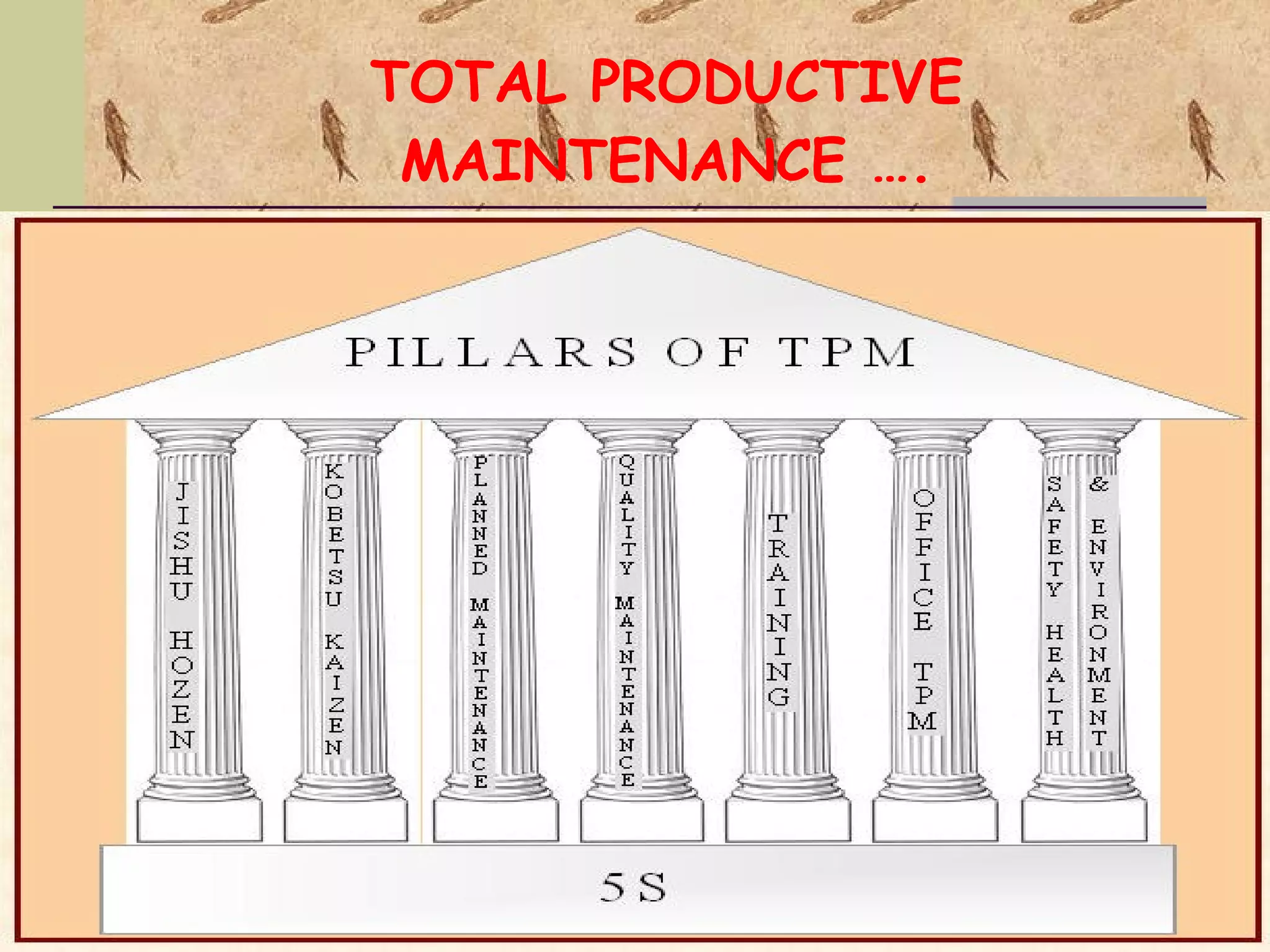

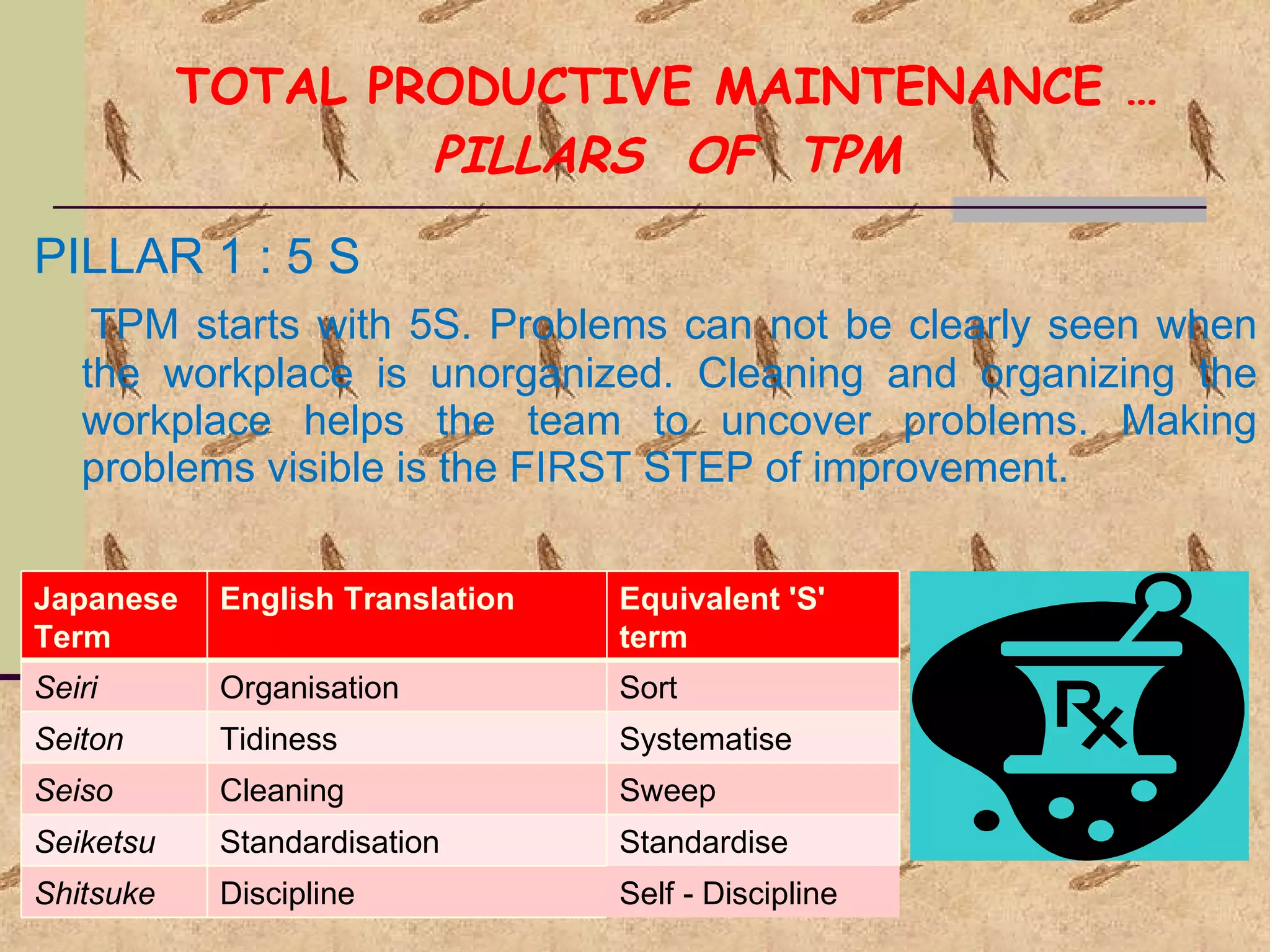

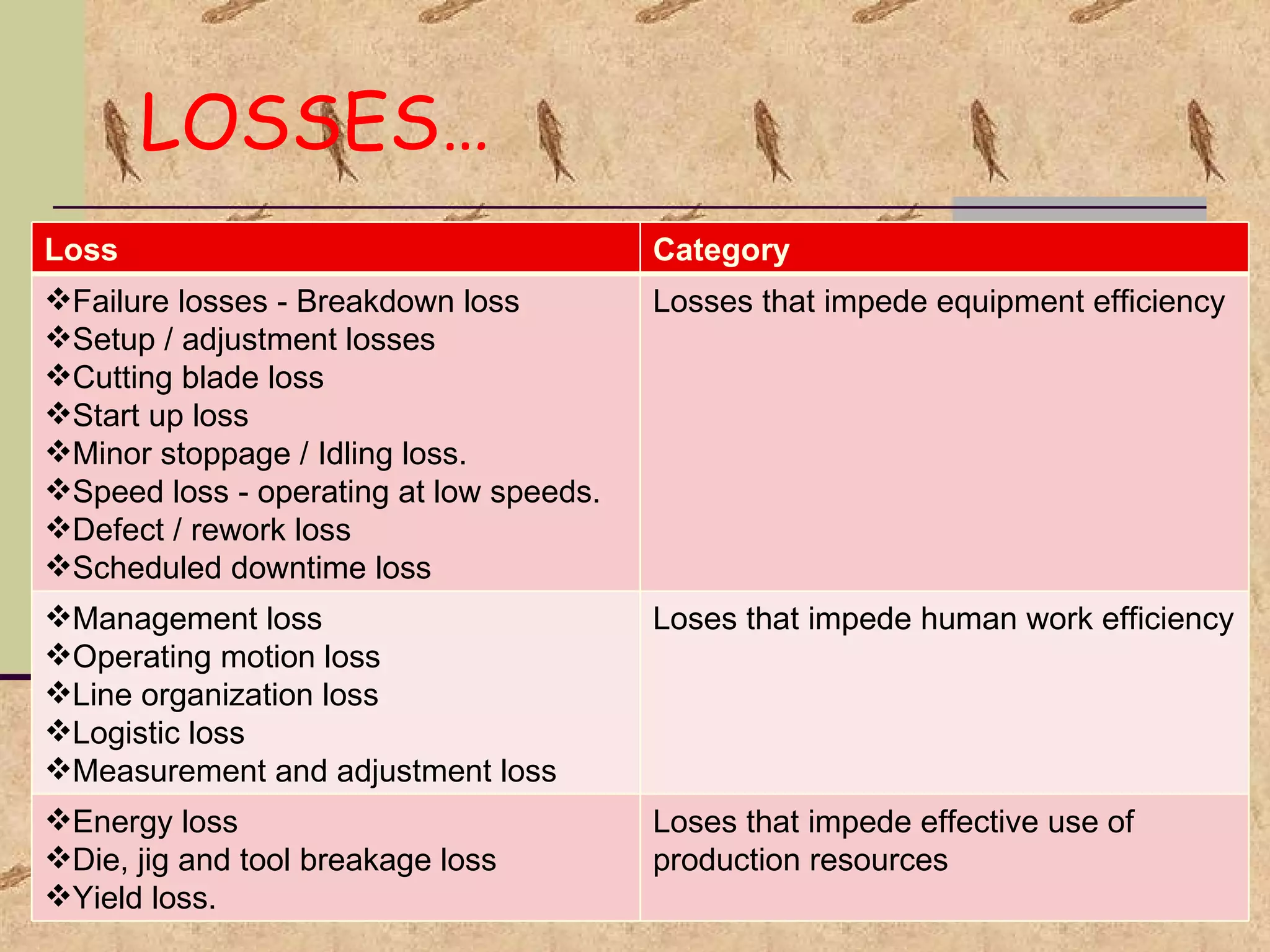

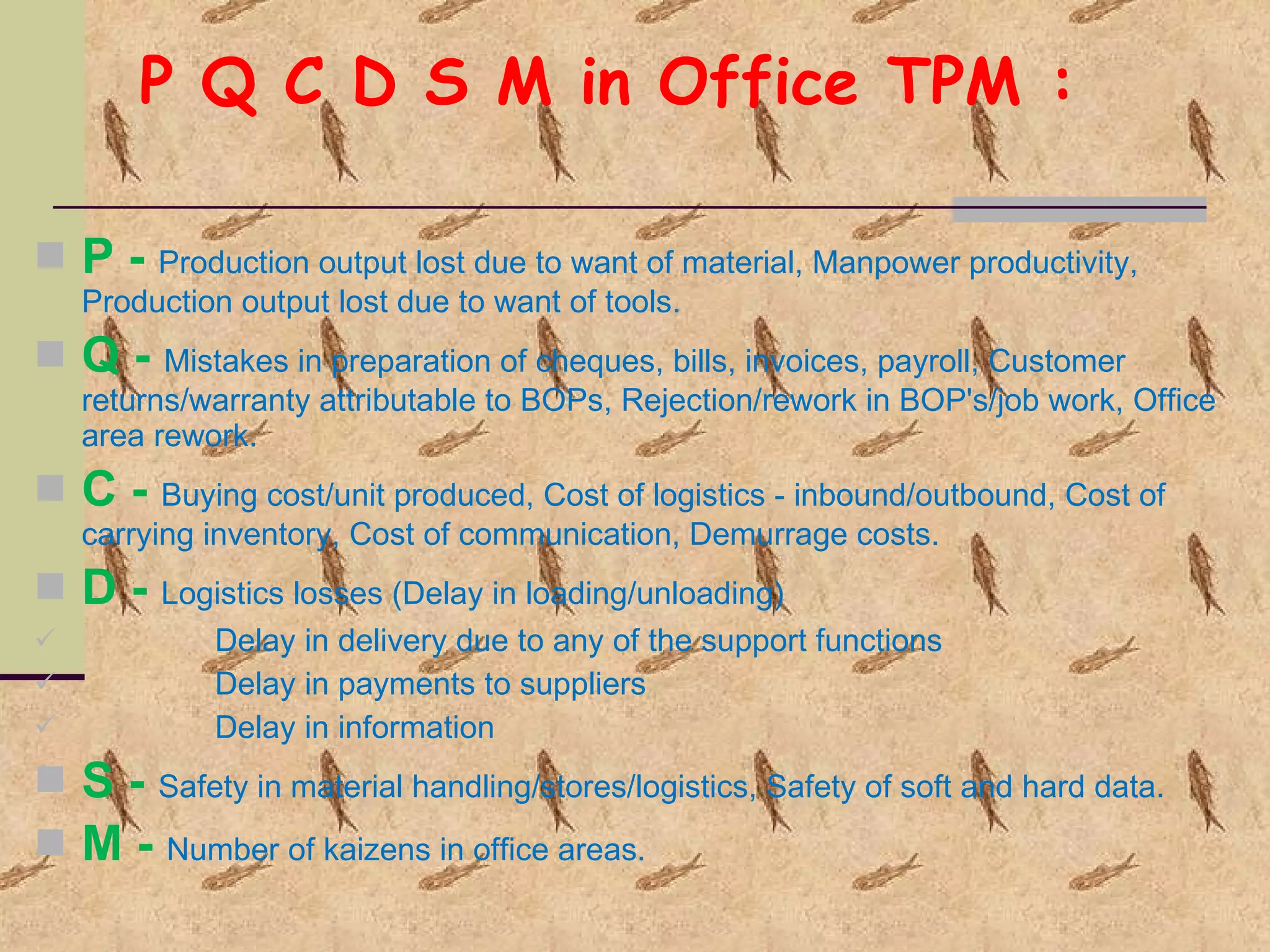

The document discusses Total Productive Maintenance (TPM), which aims to maximize equipment effectiveness by improving maintenance and involving operators. TPM covers the entire life of equipment and aims to eliminate waste and reduce costs through preventative maintenance. It differs from total quality management by focusing on equipment inputs rather than just output quality. The pillars of TPM include 5S, autonomous maintenance by operators, continuous improvement through kaizen, planned maintenance, and quality maintenance.