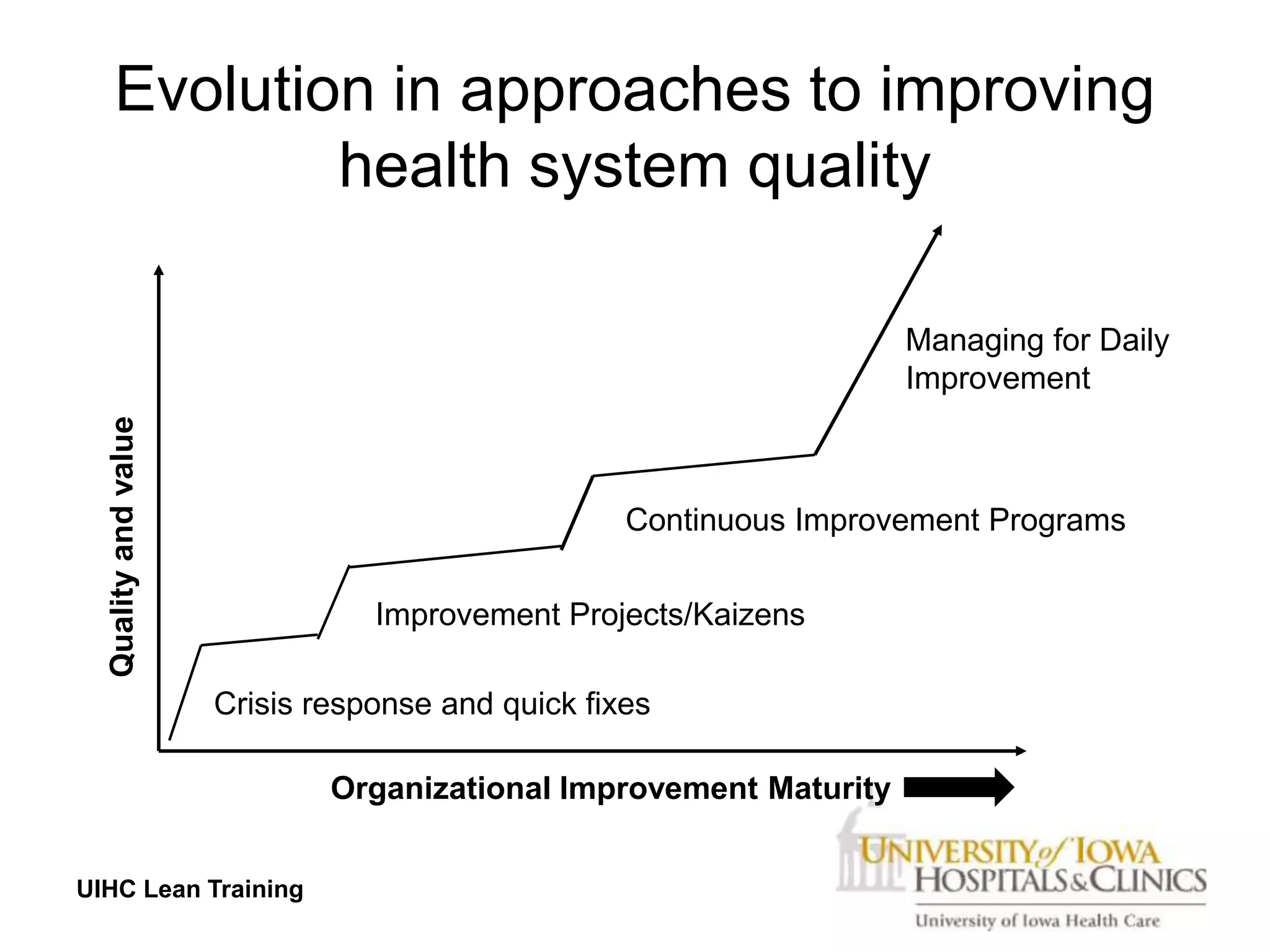

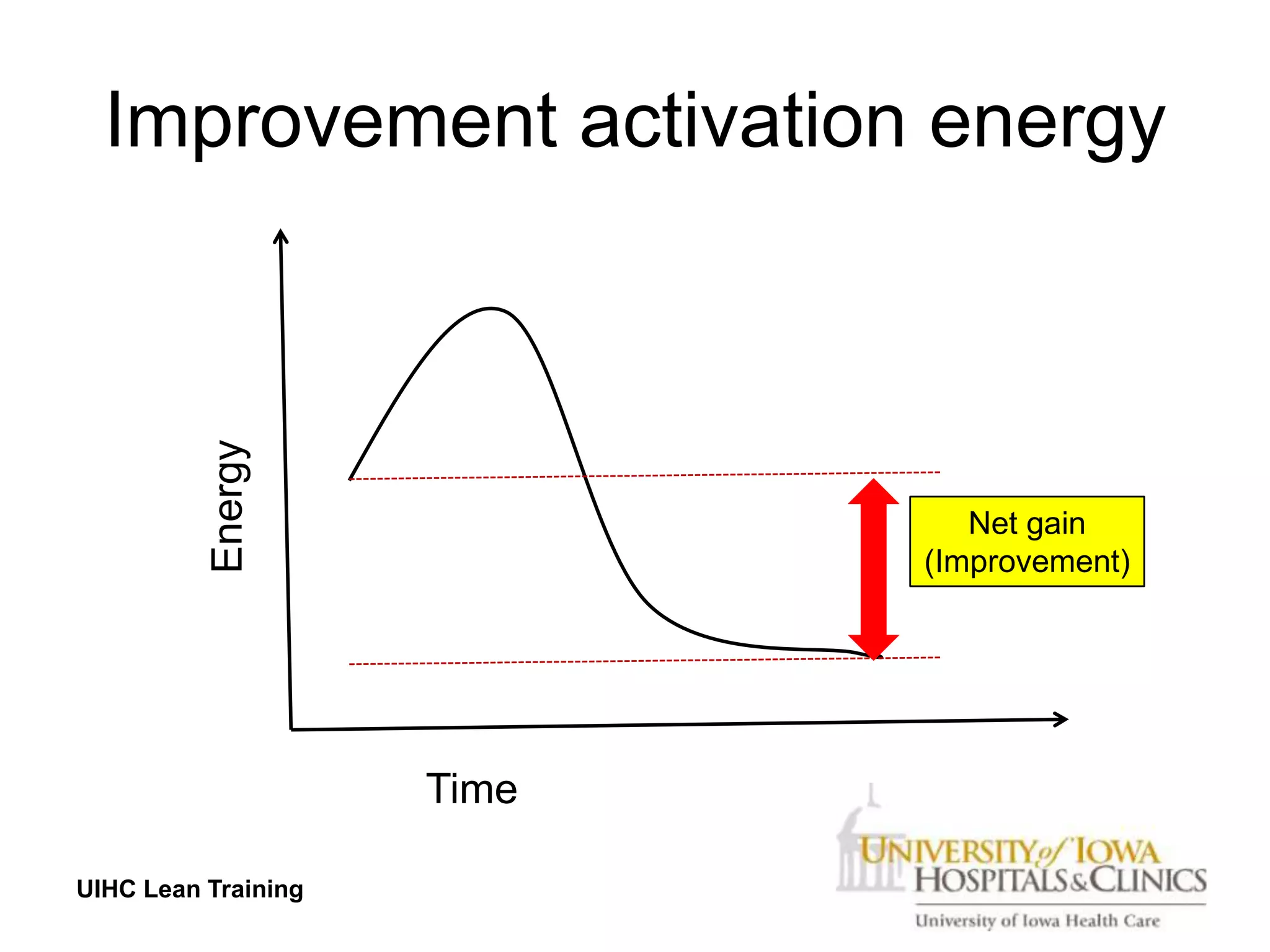

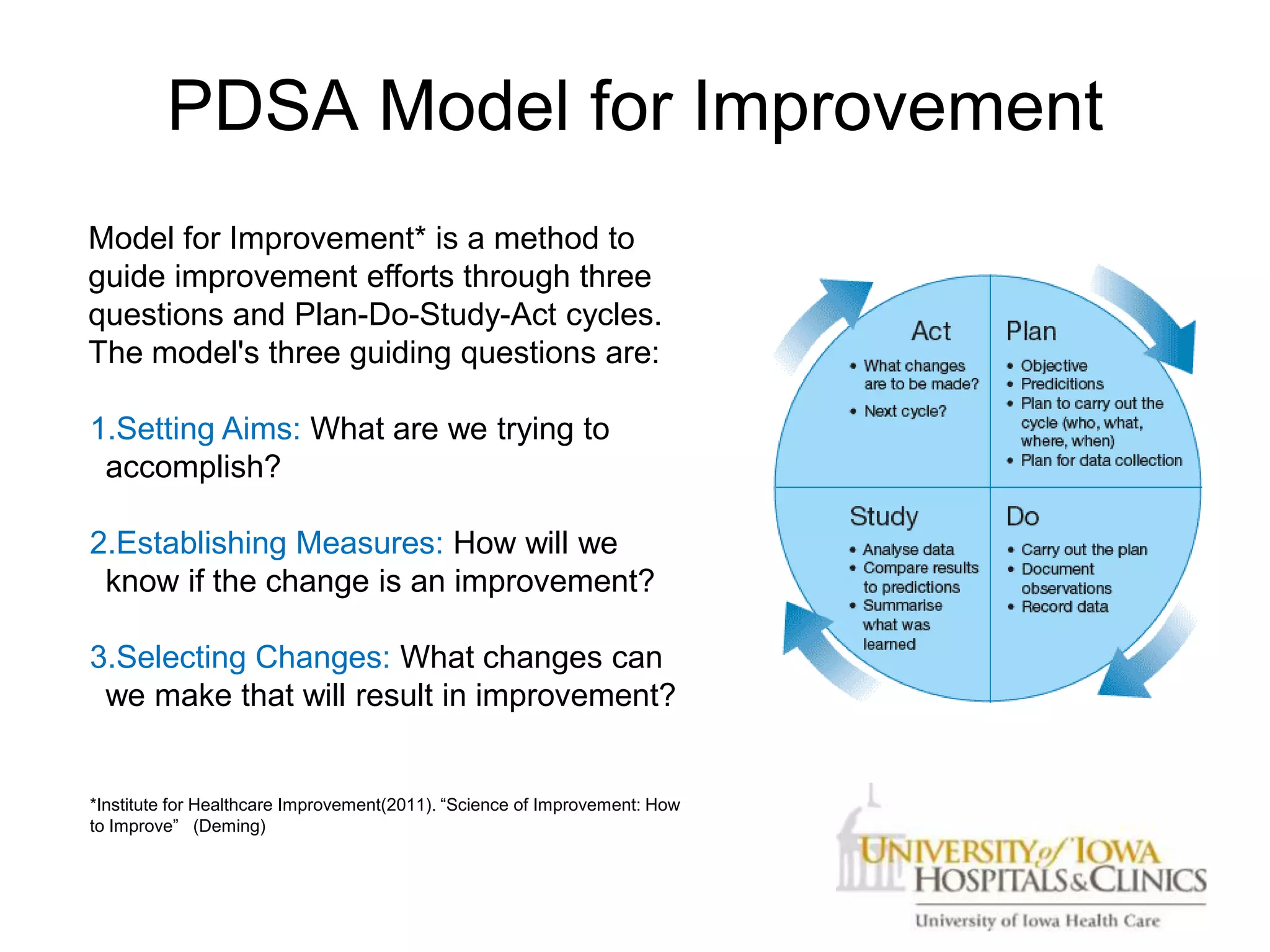

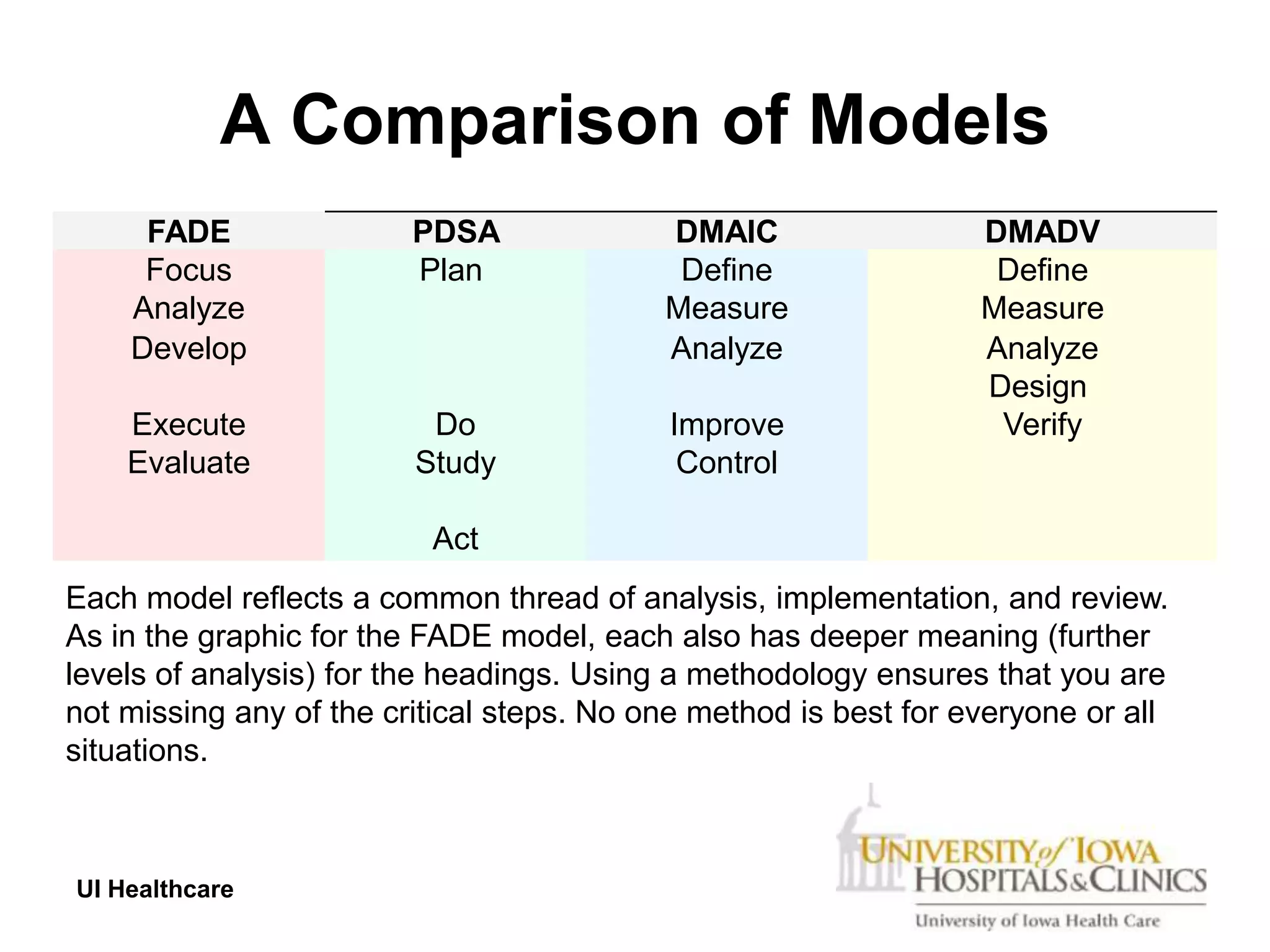

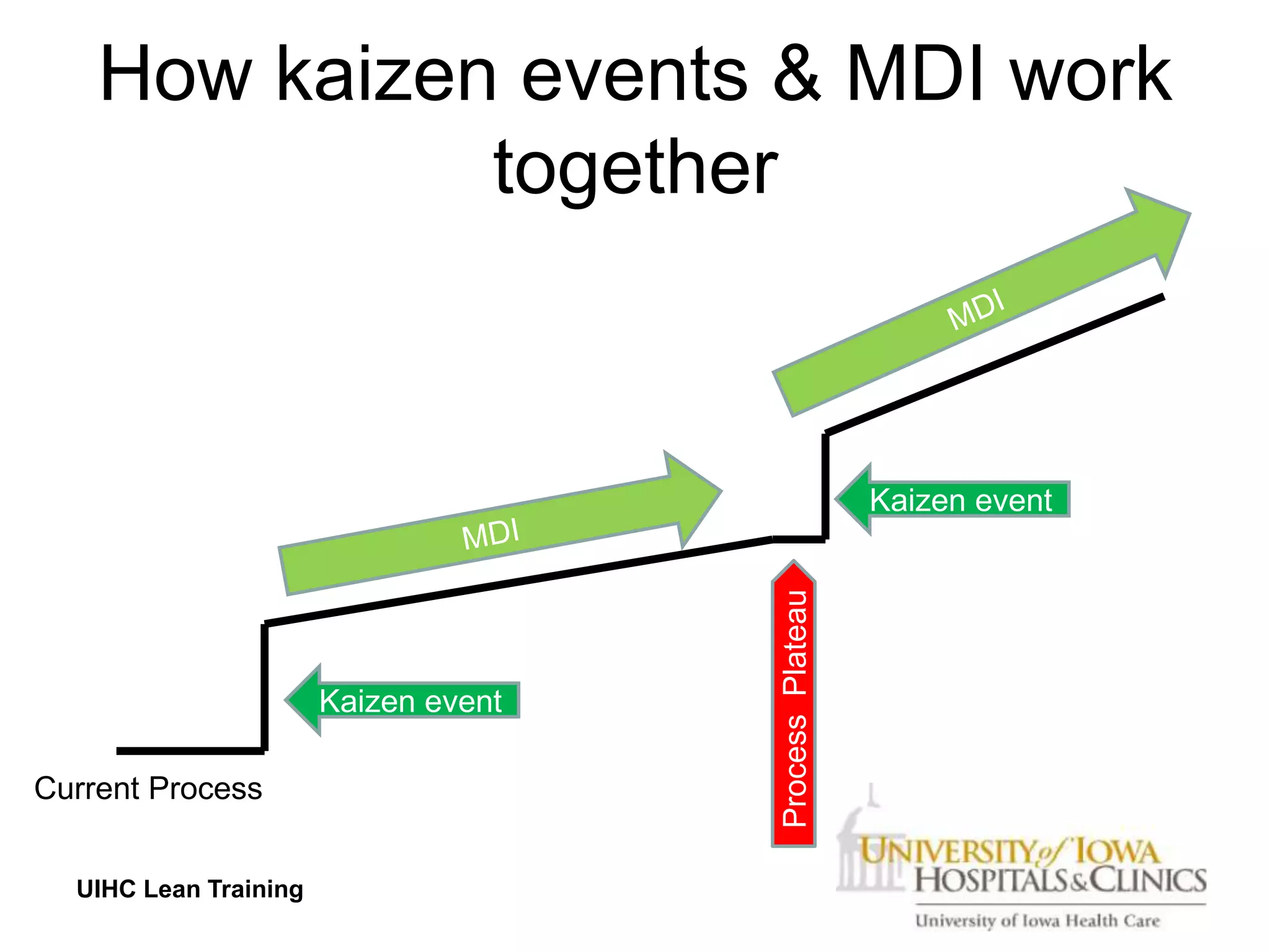

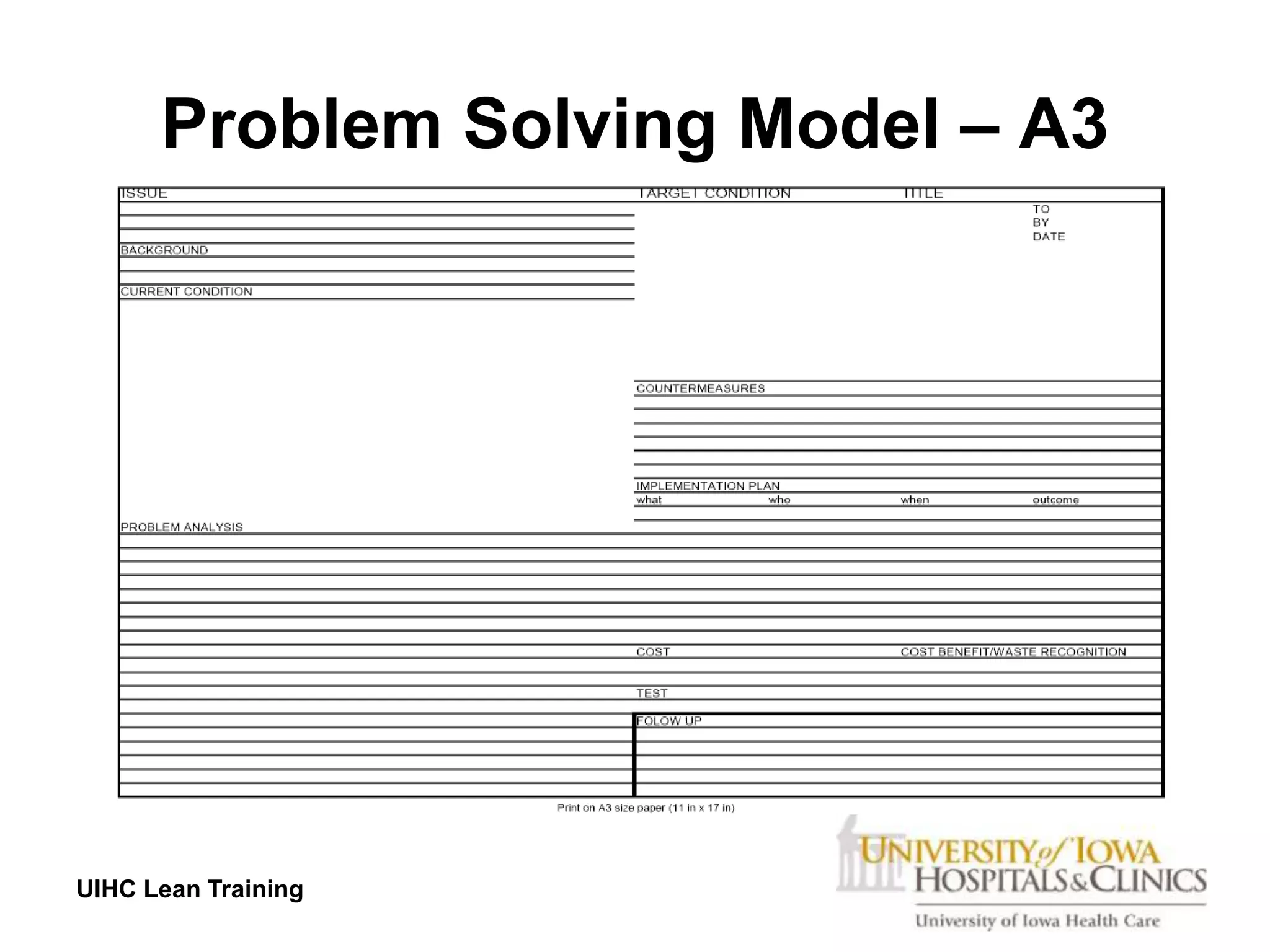

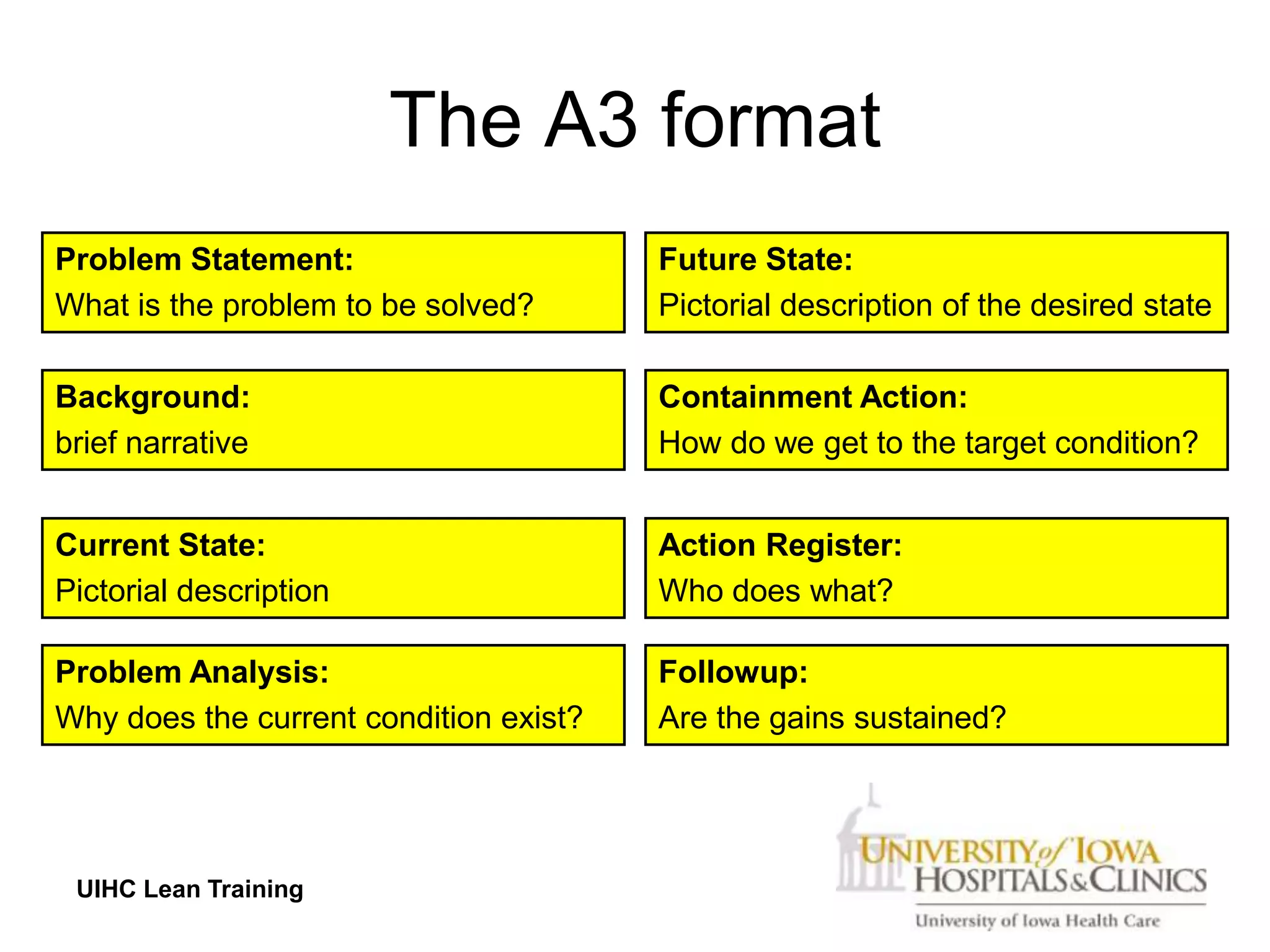

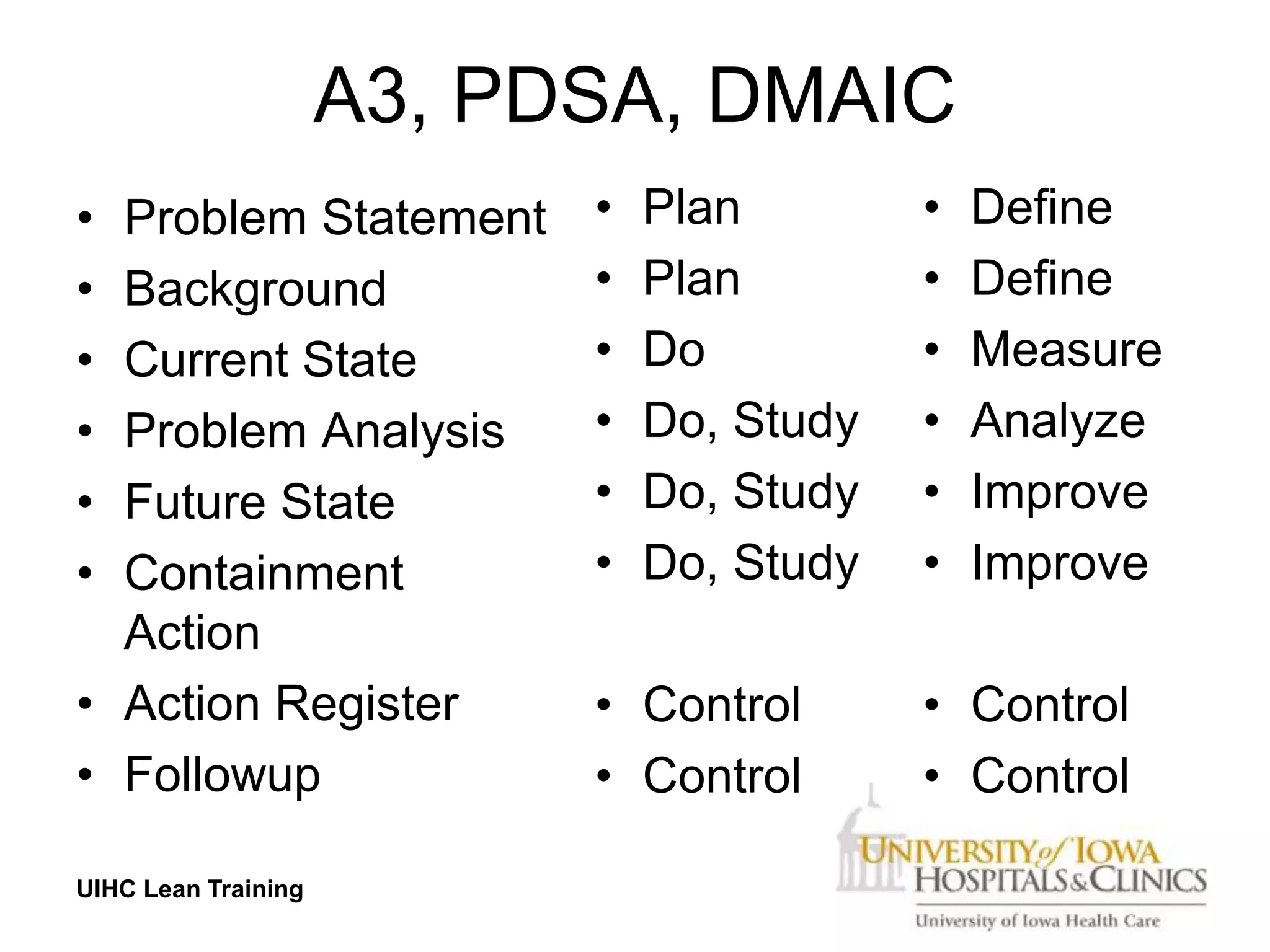

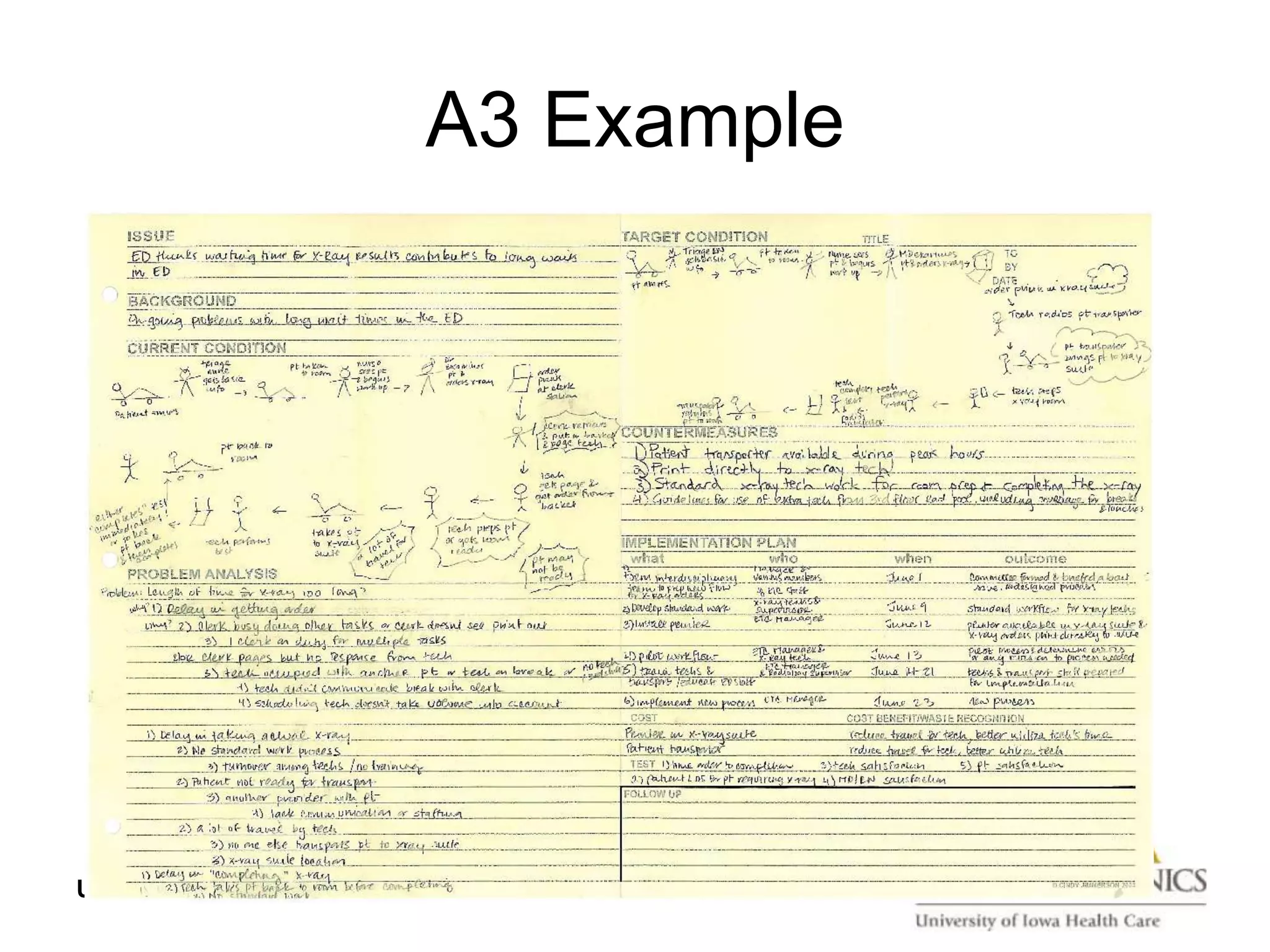

This document discusses various improvement models and approaches that can be used to enhance processes and quality, including Lean, Six Sigma, Toyota Production System, Theory of Constraints, and PDSA cycles. It explains that the most appropriate model depends on the goals of the improvement, the organization's maturity level, and available resources. Key aspects covered include using small tests of change to reduce risk, empowering teams, and focusing on incremental daily improvements in addition to discrete projects and events. The overall message is that multiple models can be effective and it's important to match the approach to the specific situation.