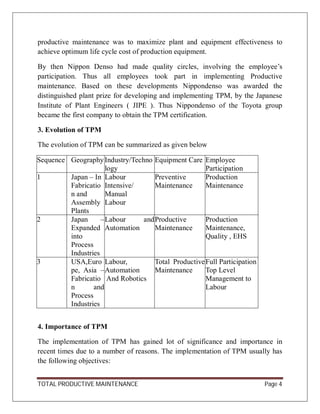

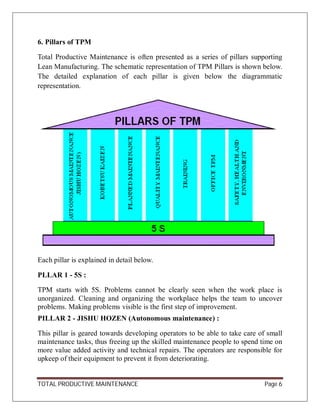

This document provides an overview of Total Productive Maintenance (TPM). It discusses the history and evolution of TPM, which originated from preventive maintenance practices in Japan. The key aspects of TPM include its 8 pillars - 5S, autonomous maintenance, kaizen, planned maintenance, quality maintenance, training, office TPM, and safety/environment. The document outlines the goals and processes for implementing each pillar. It also provides details on establishing an organizational structure for TPM and examples of companies that have successfully adopted a TPM program.