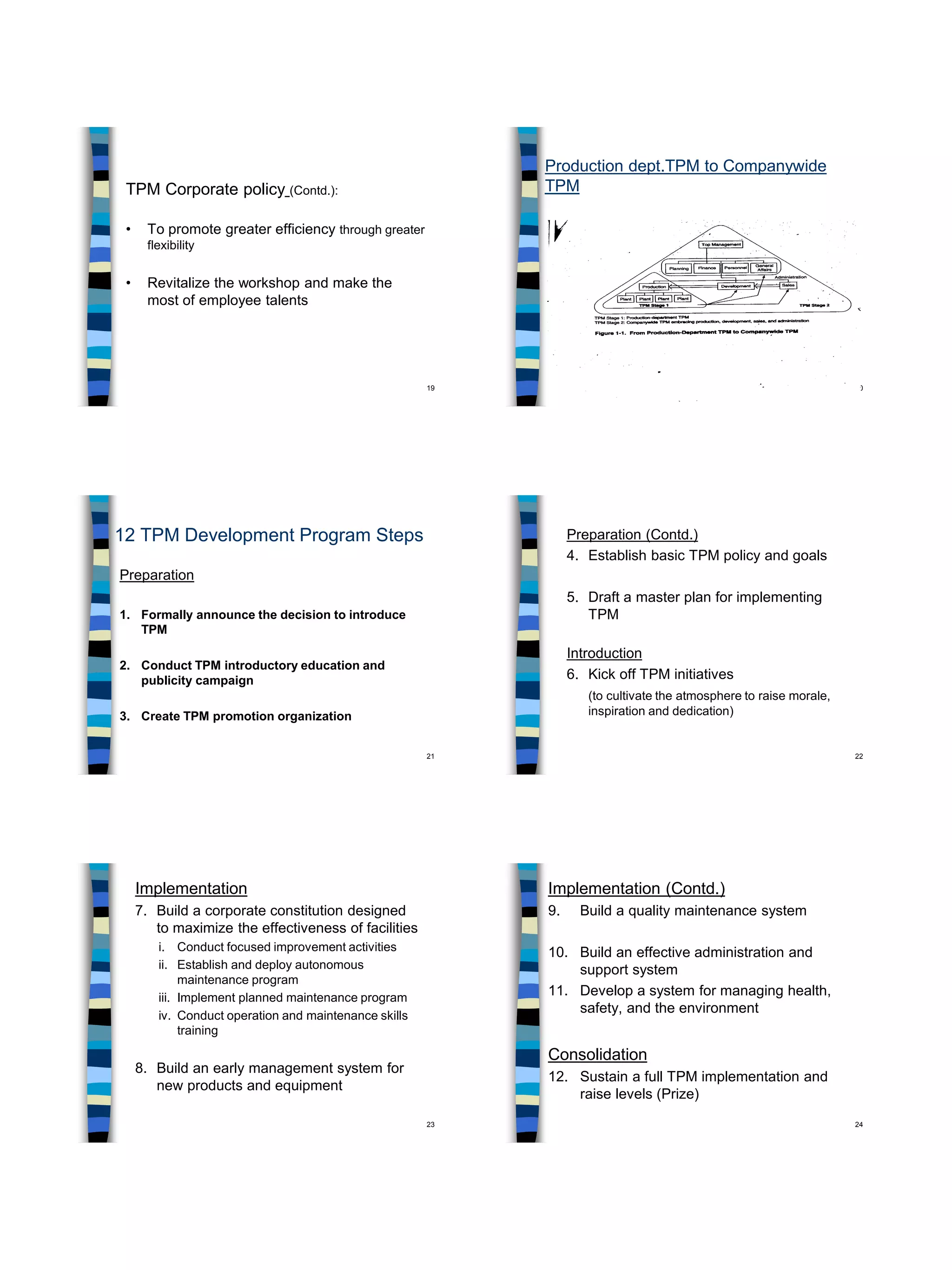

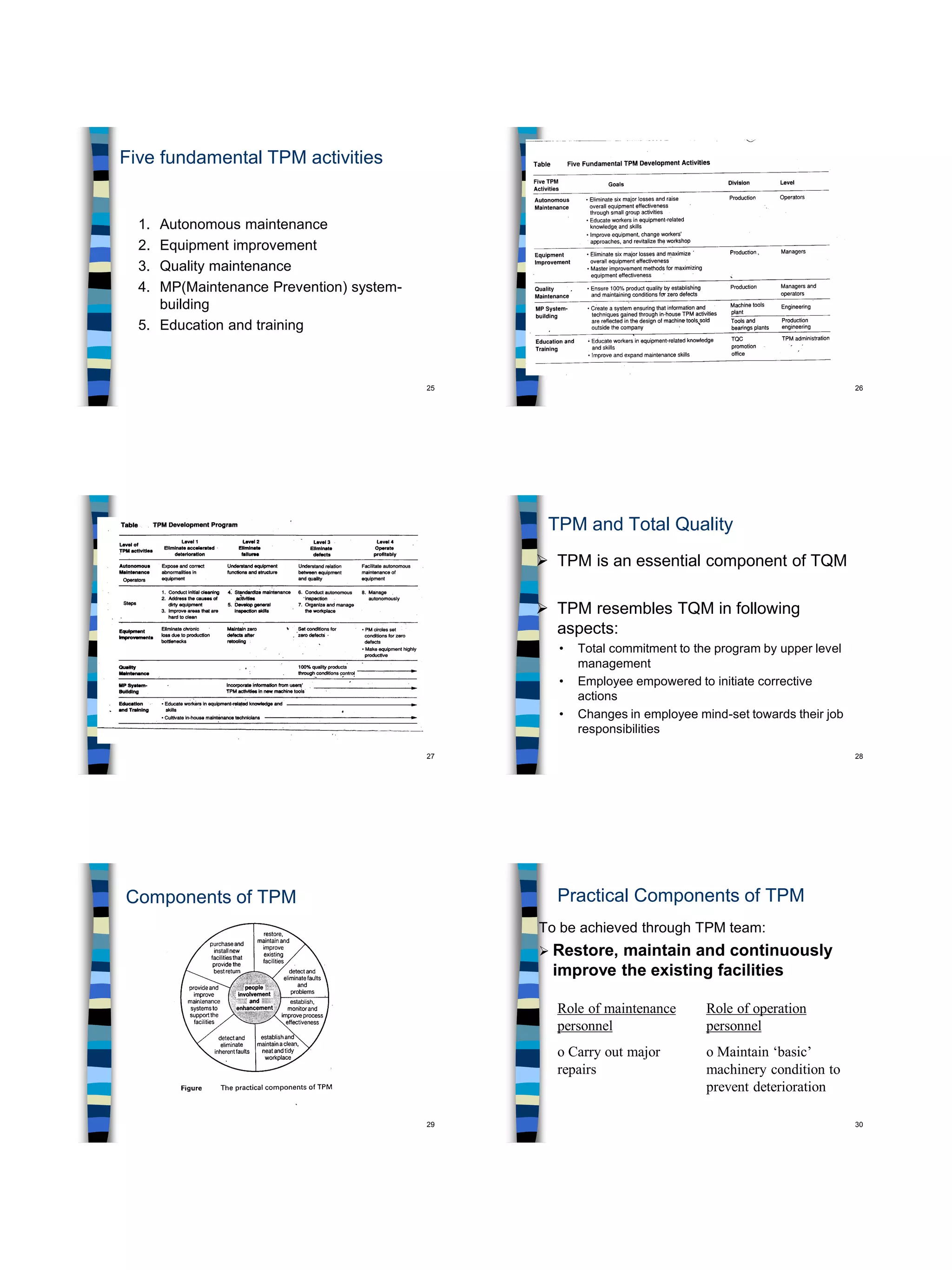

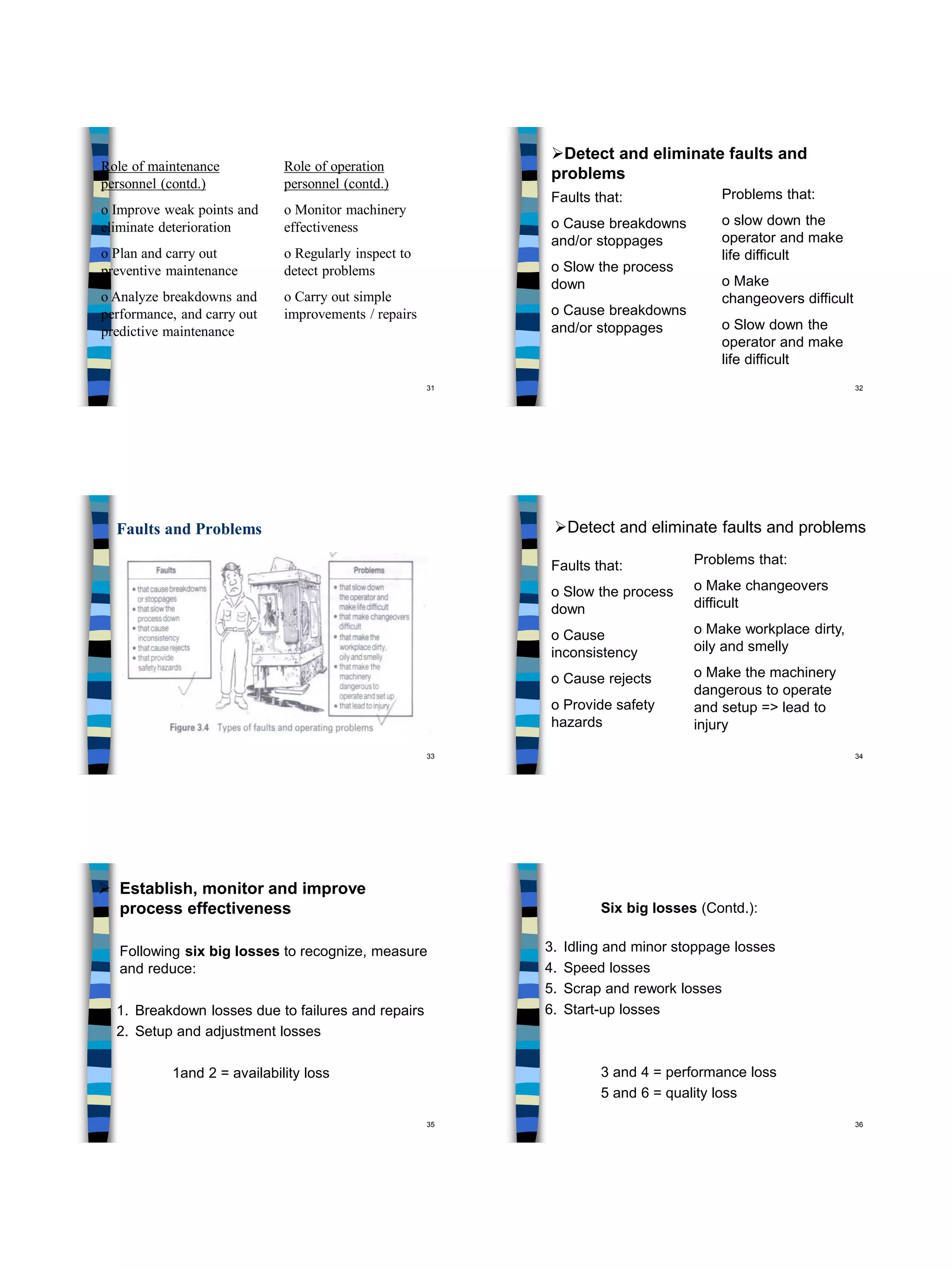

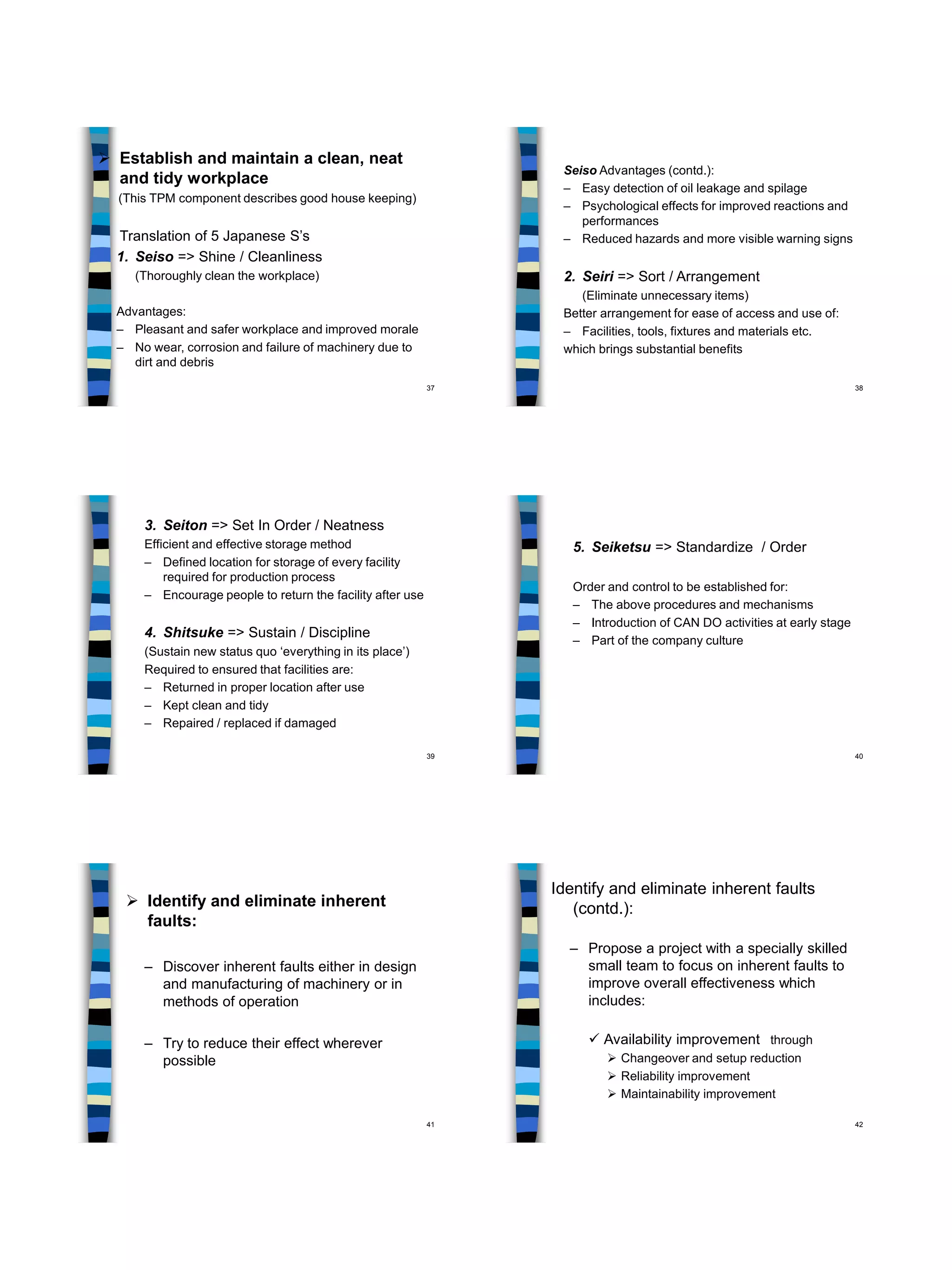

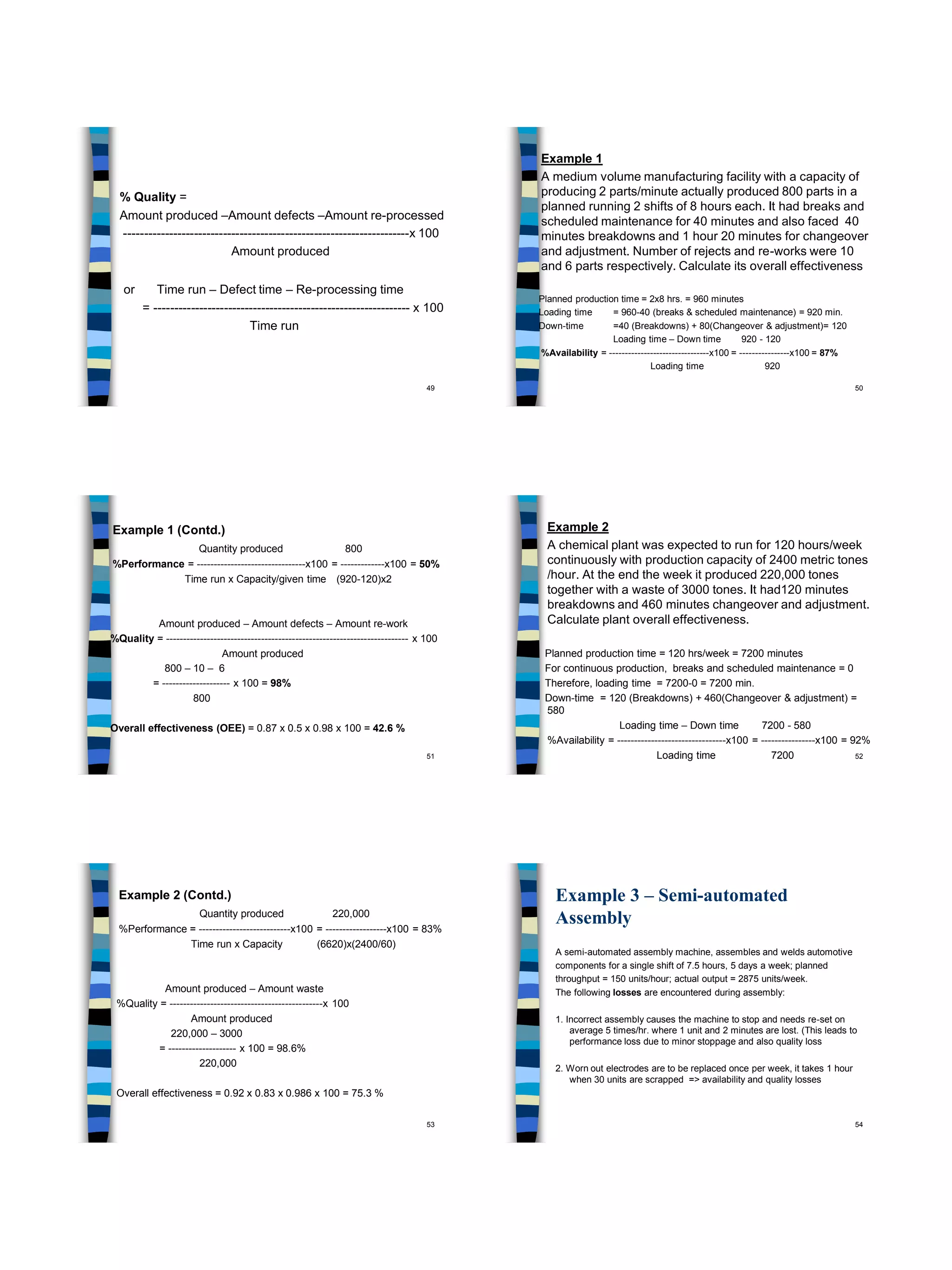

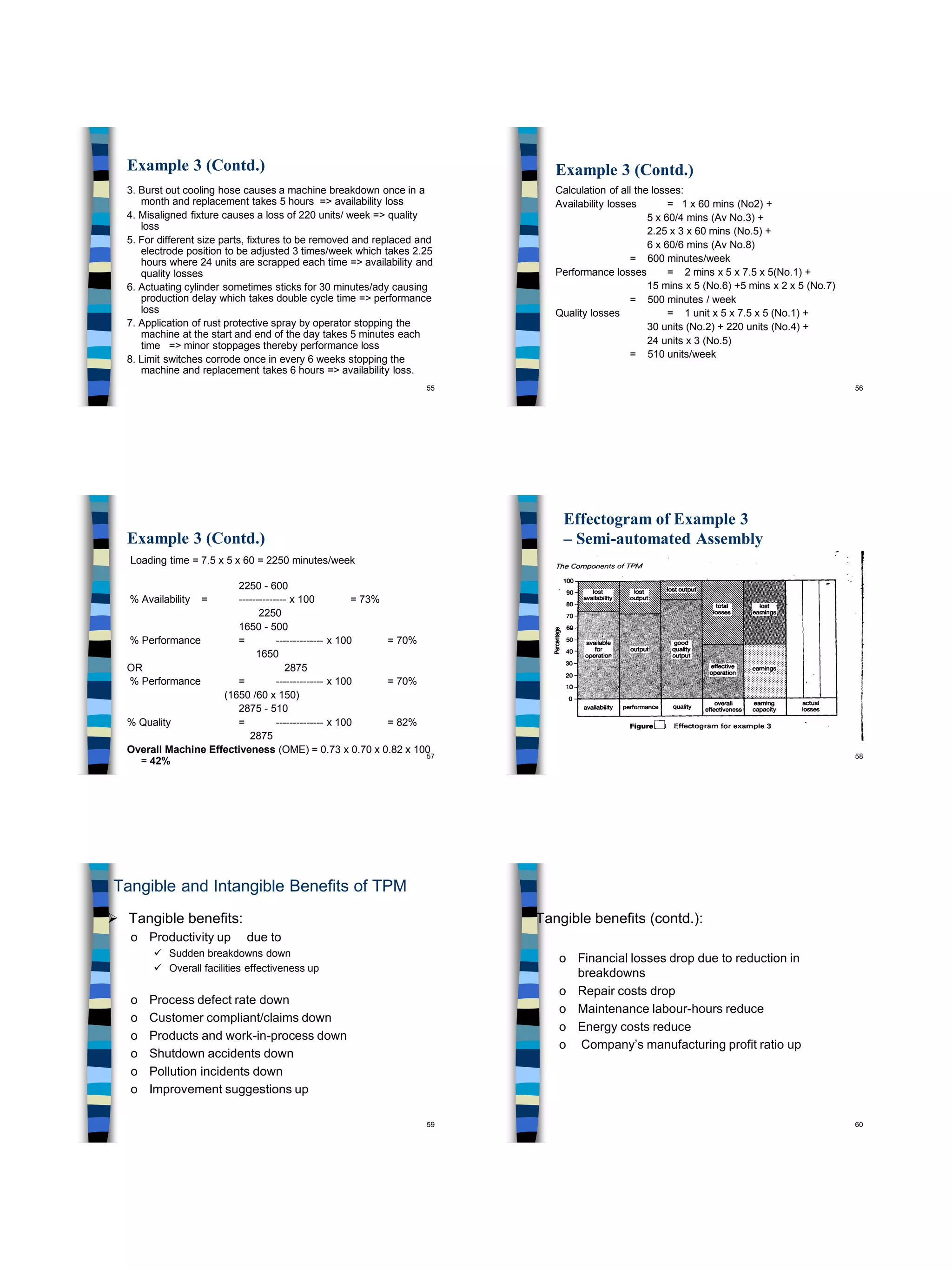

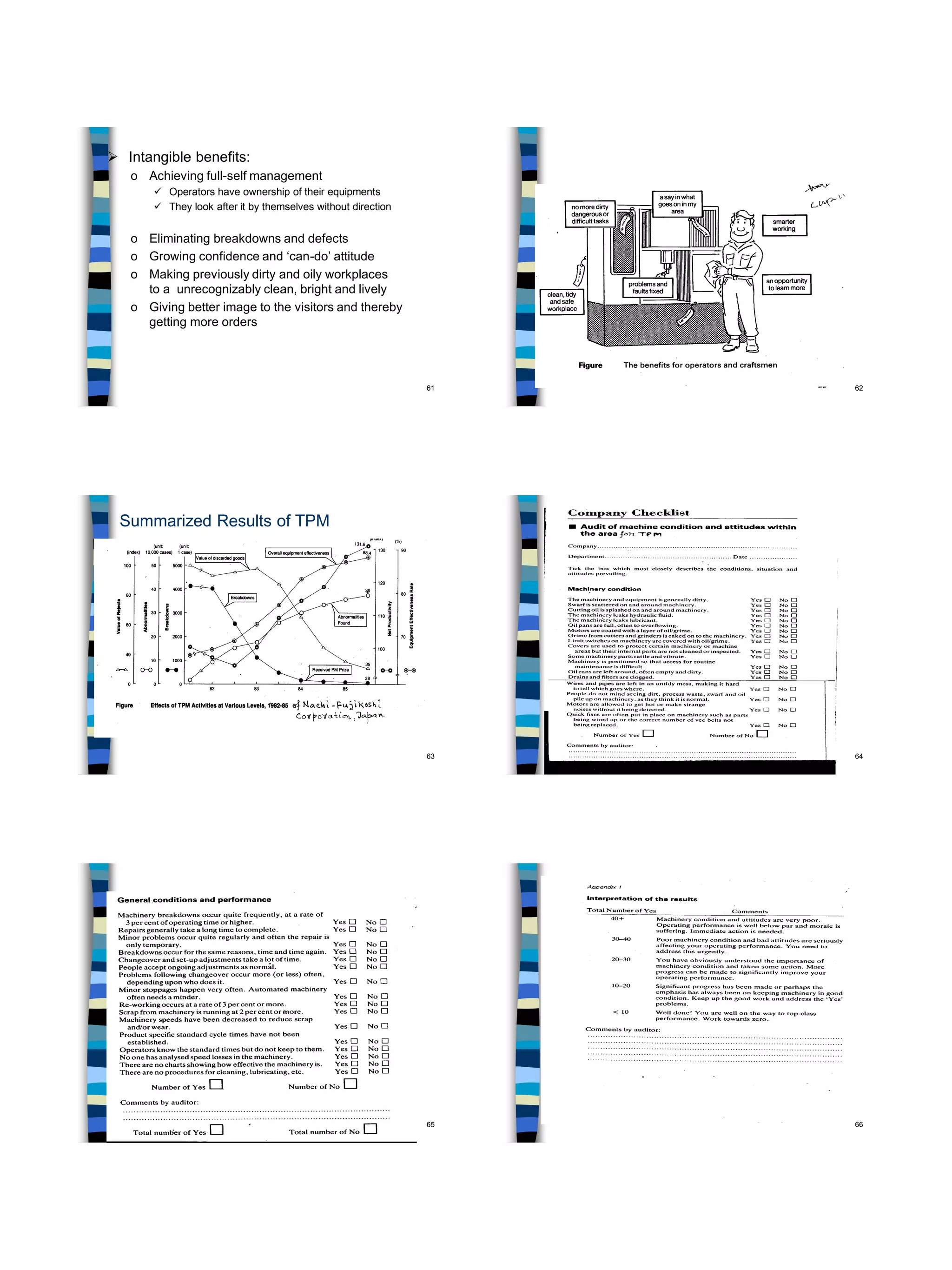

Total Productive Maintenance (TPM) is a Japanese approach for maximizing equipment effectiveness through the involvement of both maintenance and operations personnel. It aims to eliminate breakdowns and failures, accidents, and defects. The key aspects of TPM include establishing autonomous maintenance by operators, improving equipment reliability, detecting and eliminating faults and problems, and establishing clean and tidy workplaces. TPM was developed in Japan and has led to significant results like increased productivity and reduced costs when implemented successfully.