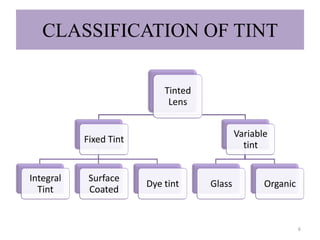

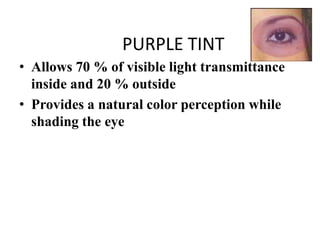

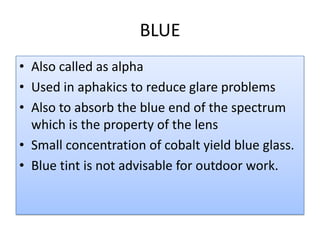

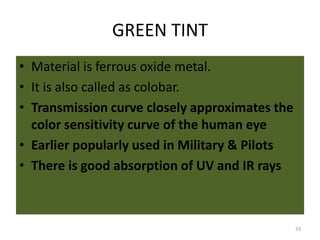

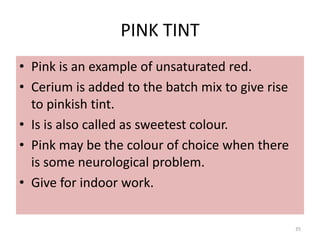

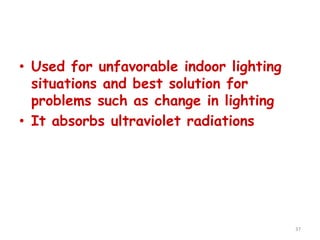

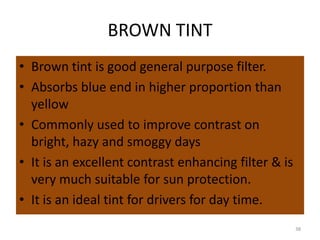

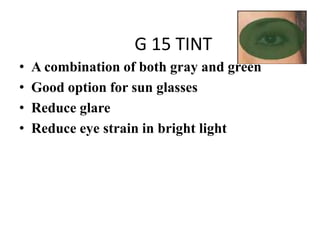

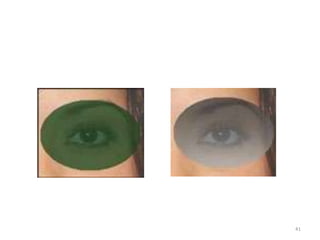

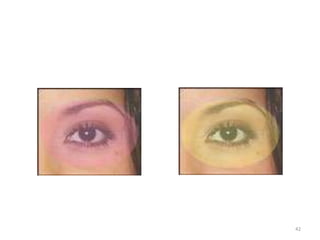

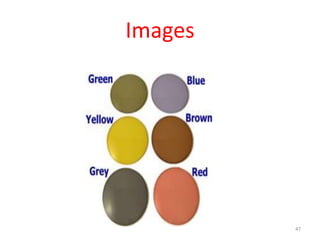

This document discusses different types of tinted lenses, including their purposes and materials. It covers integral tints produced during manufacturing by adding metals or metal oxides to glass. Surface coatings deposit metallic oxides onto glass through evaporation. Plastic lenses are dyed by immersing them in organic dyes. Various tint colors like yellow, red, purple, and brown are explained in terms of the materials used and their applications. Integral tints provide consistent tinting while surface coatings and dyes allow tinting of any prescription.