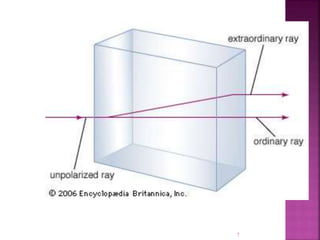

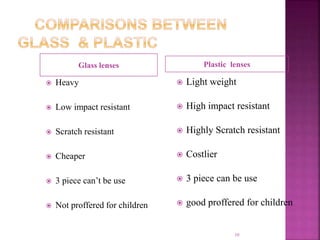

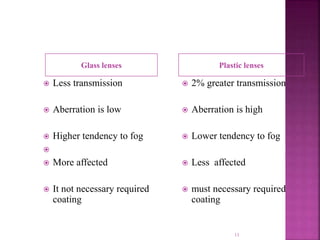

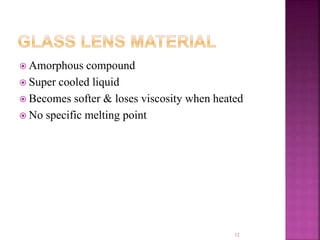

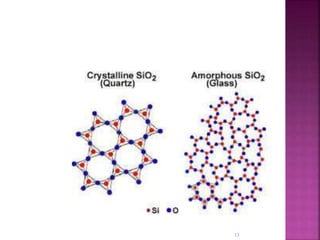

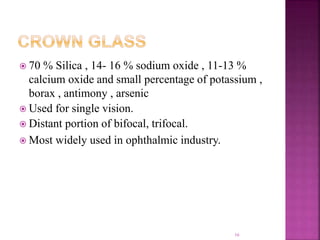

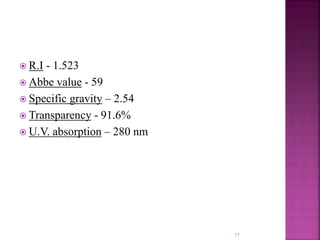

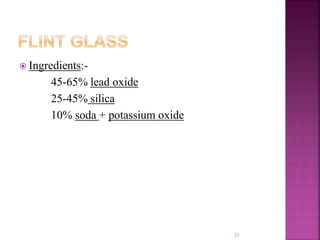

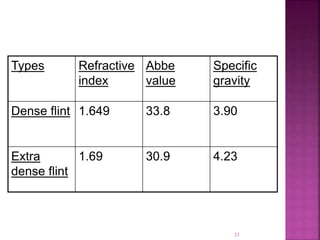

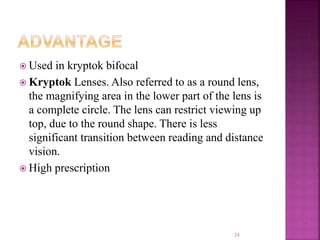

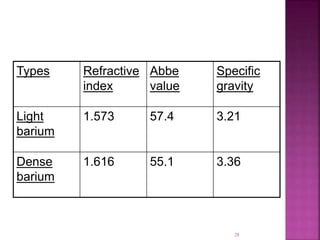

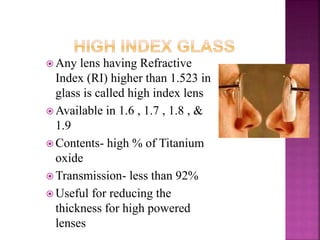

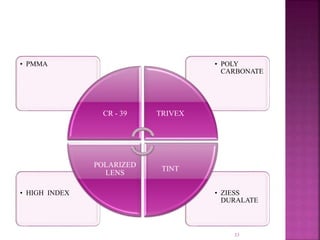

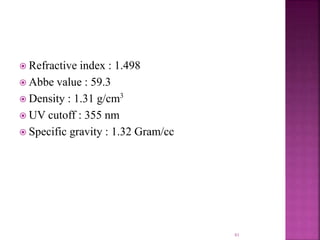

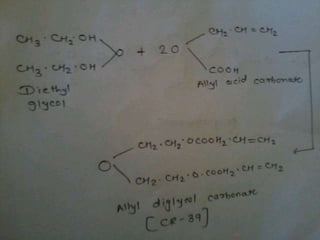

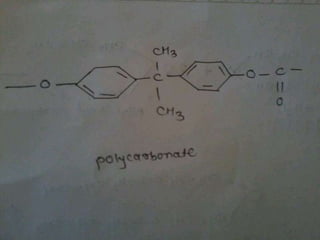

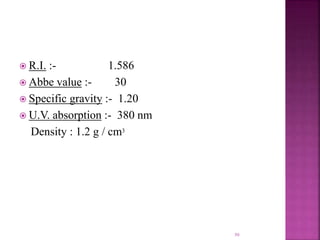

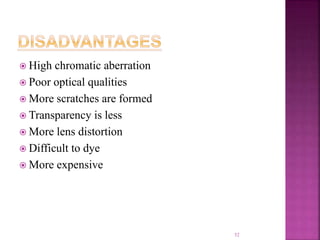

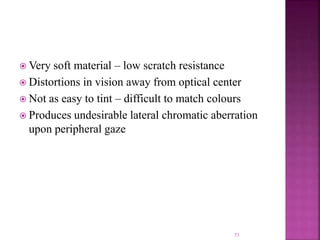

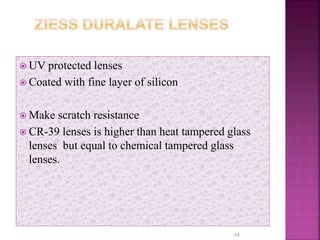

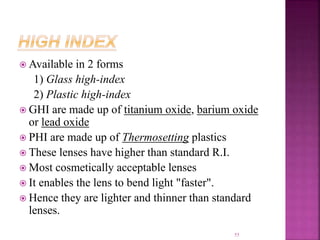

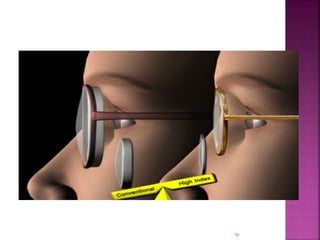

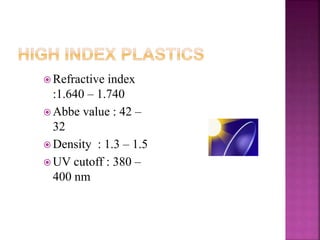

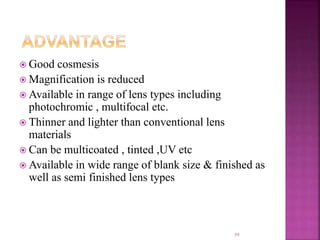

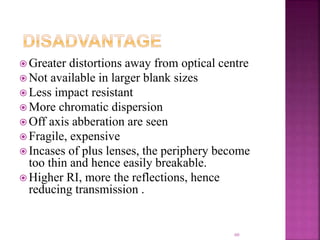

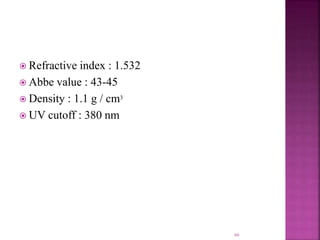

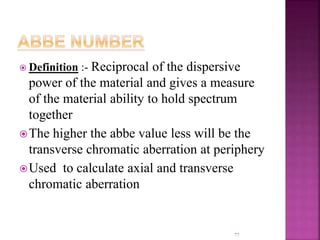

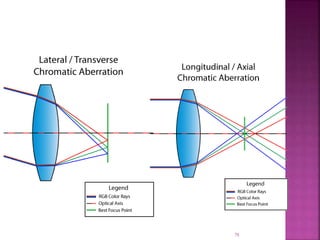

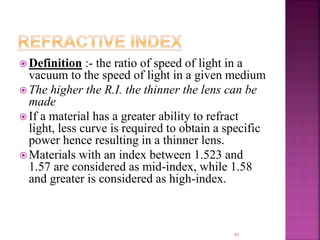

The document discusses different types of lens materials used in ophthalmology, including natural materials like quartz, glass materials like crown glass and flint glass, and plastic materials like CR-39, polycarbonate, and Trivex. It provides details on the composition, properties, advantages, and disadvantages of each material type. Key lens materials discussed include crown glass, flint glass, CR-39, polycarbonate, high index plastic and glass, and Trivex.