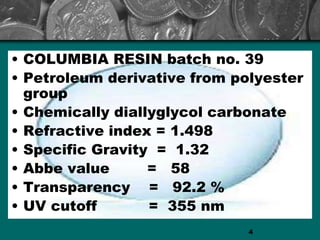

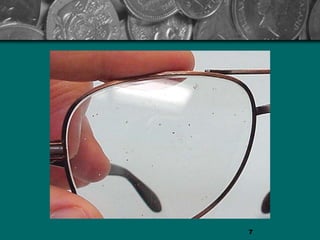

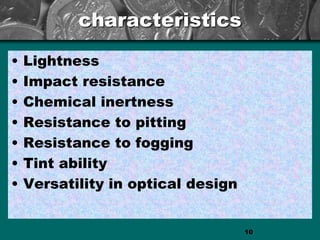

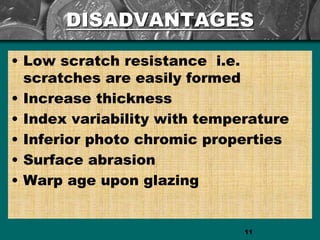

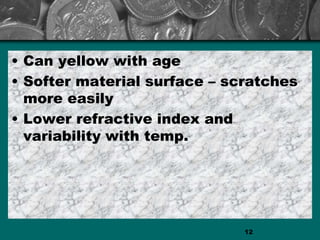

CR-39 is a plastic polymer commonly used to manufacture eyeglass lenses. It was developed in 1940 by Pittsburgh Plate Glass industries as the 39th formula of a thermosetting plastic called Columbia Resin. CR-39 lenses are lightweight, impact resistant, resistant to chemicals and temperature fluctuations, and can be tinted and coated. However, their main disadvantage is low scratch resistance, as scratches can easily form on the surface.