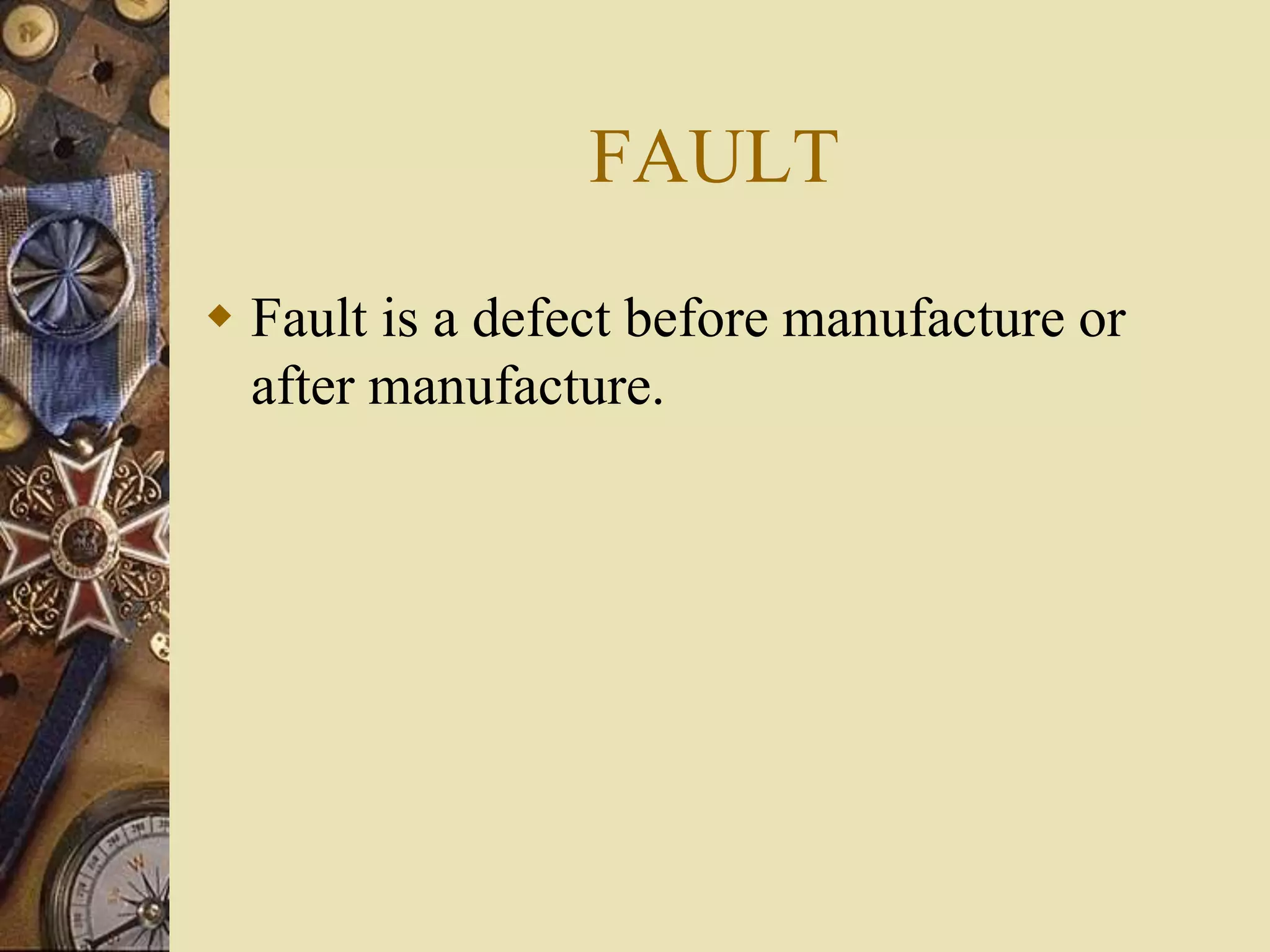

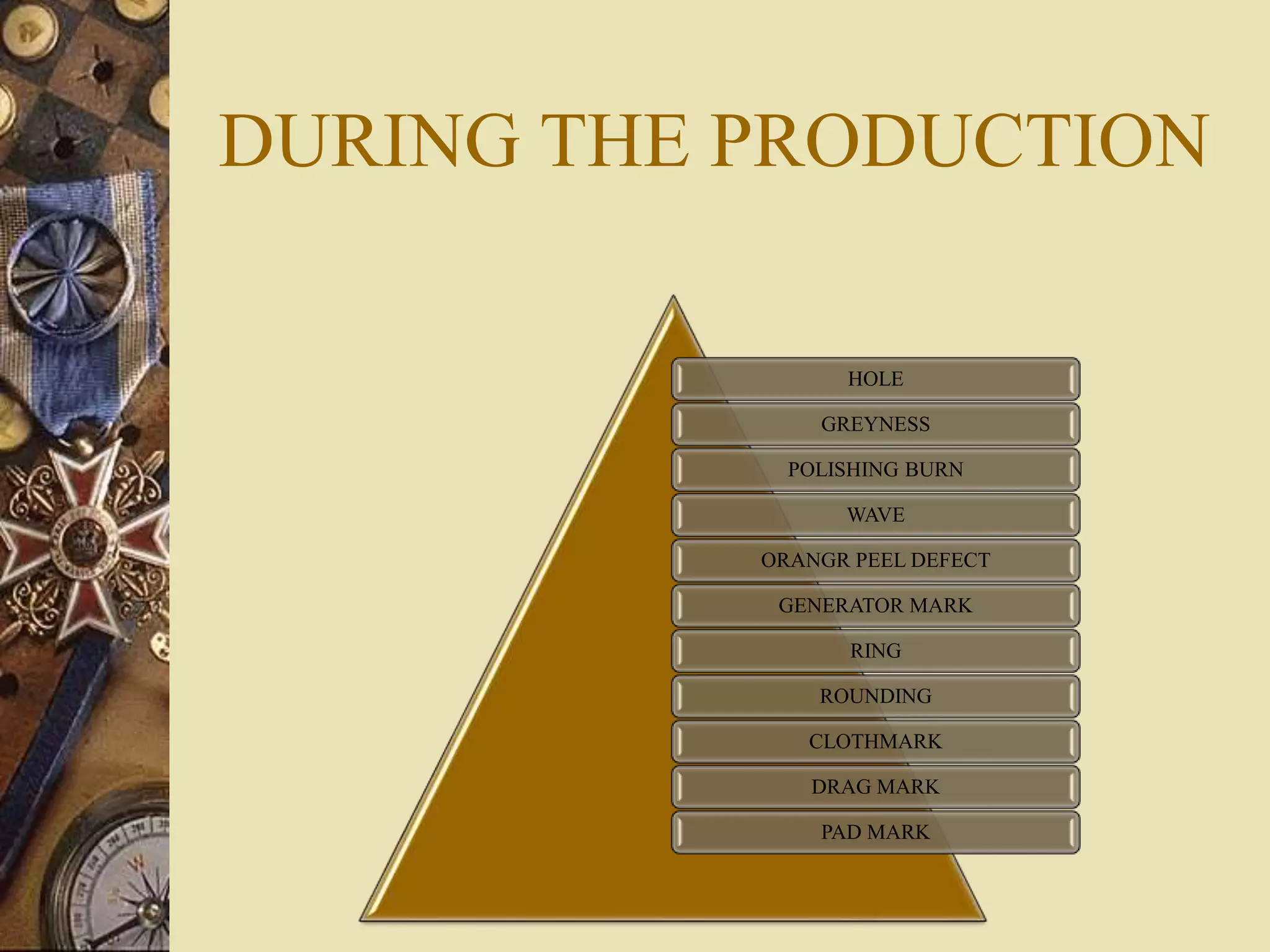

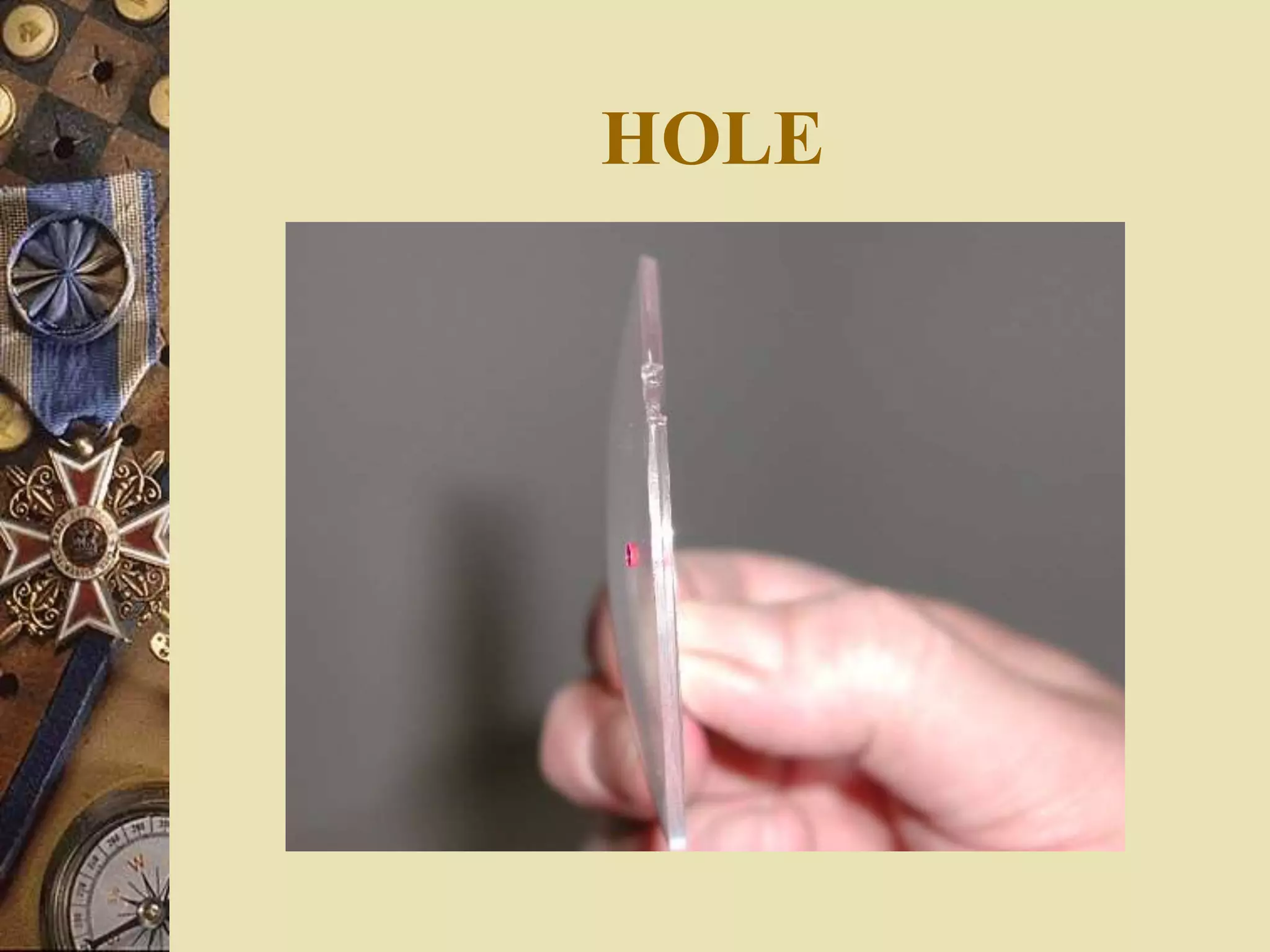

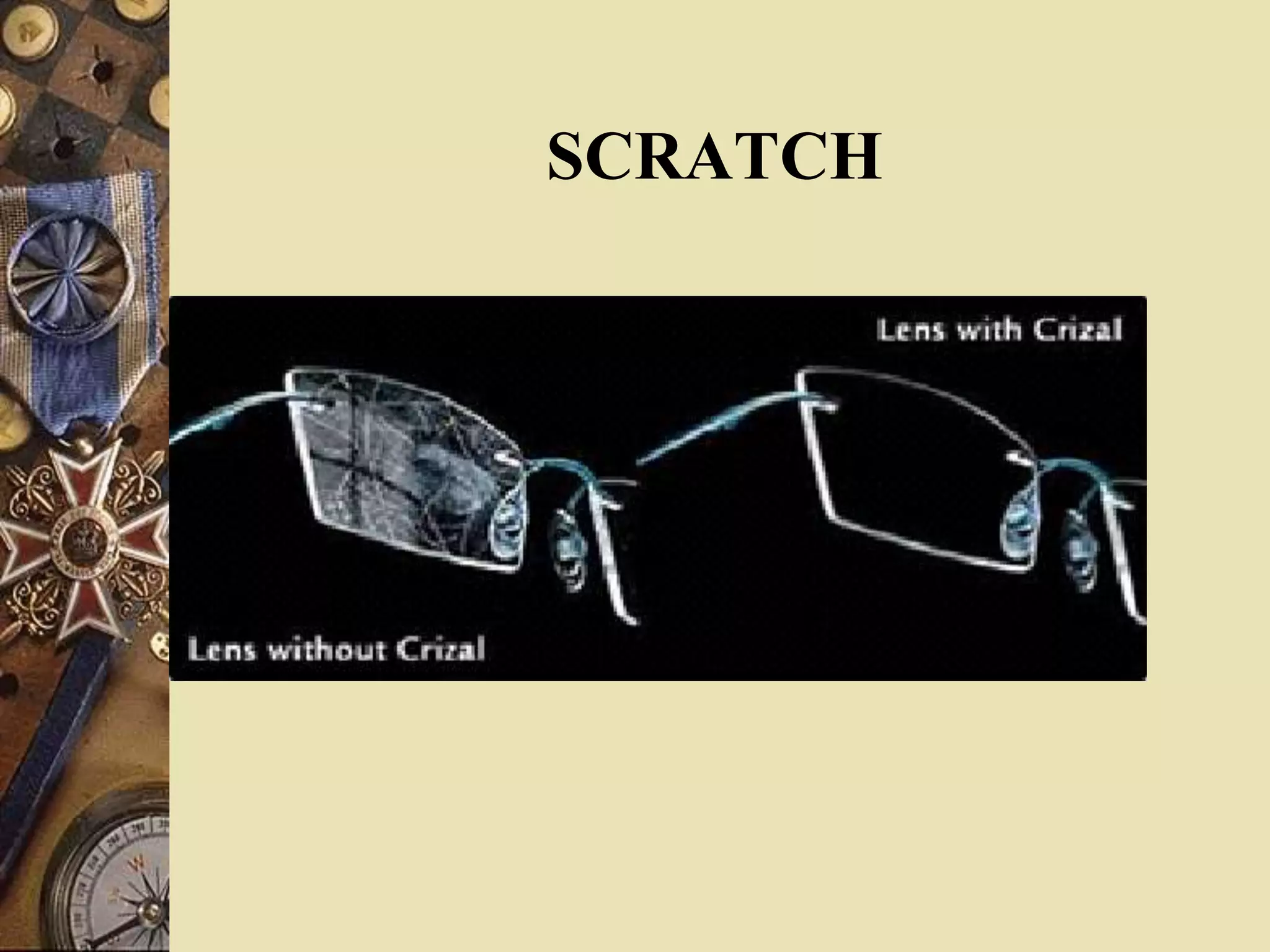

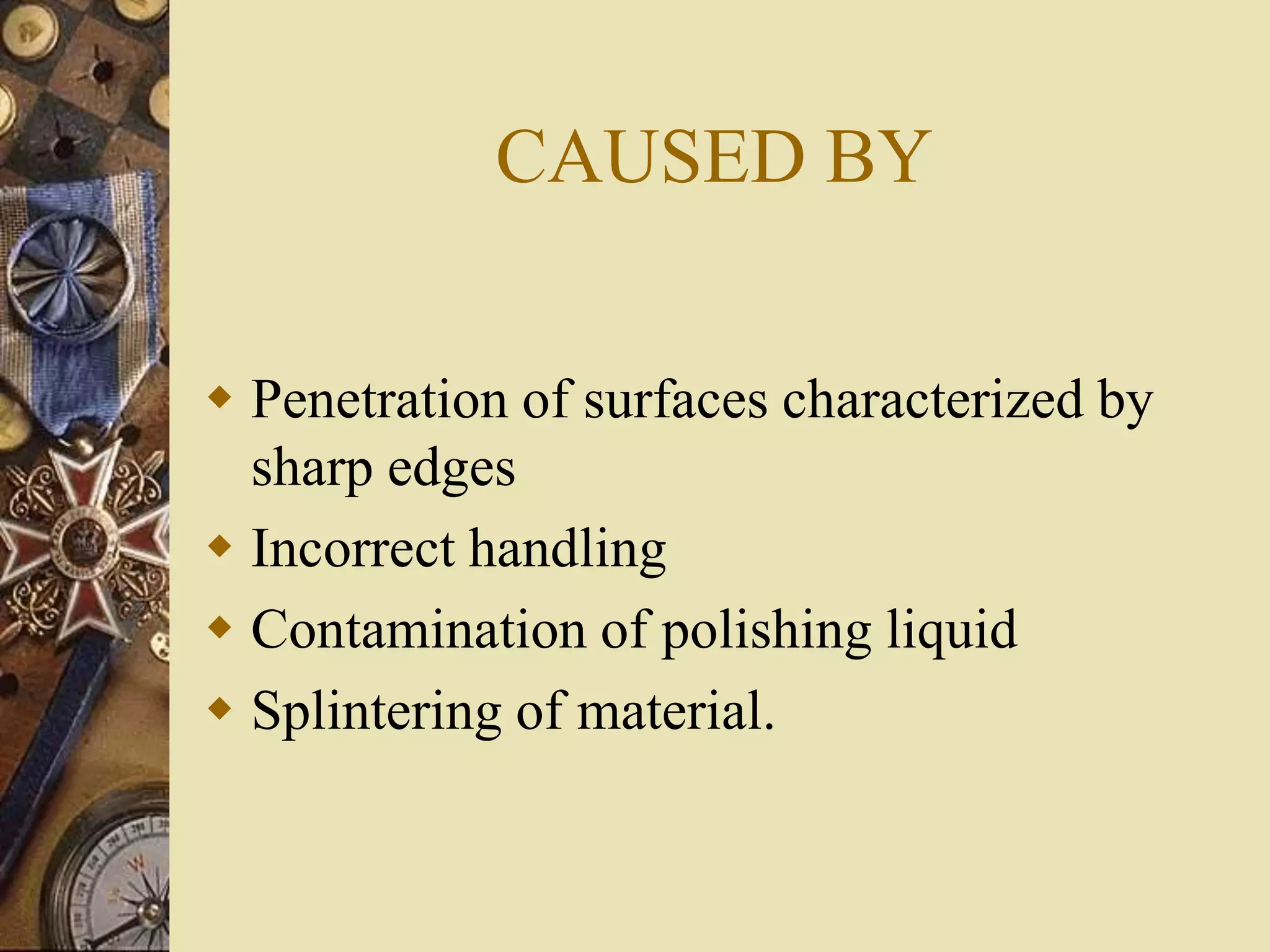

This document summarizes various types of defects that can occur in ophthalmic lenses. It categorizes defects as occurring either in the material of the lens, on the surface of the lens, or from maltreatment of the finished surface. Defects in the material include bubbles, feathers, veins, coloration and strain. Surface defects from production include holes, greyness, polishing burns, waves, rings and generator marks. Maltreatment can cause scratches, chips, bruises and other abuse marks. The document provides detailed descriptions and examples of each type of defect.

![NO TRANSMISSION

[T]

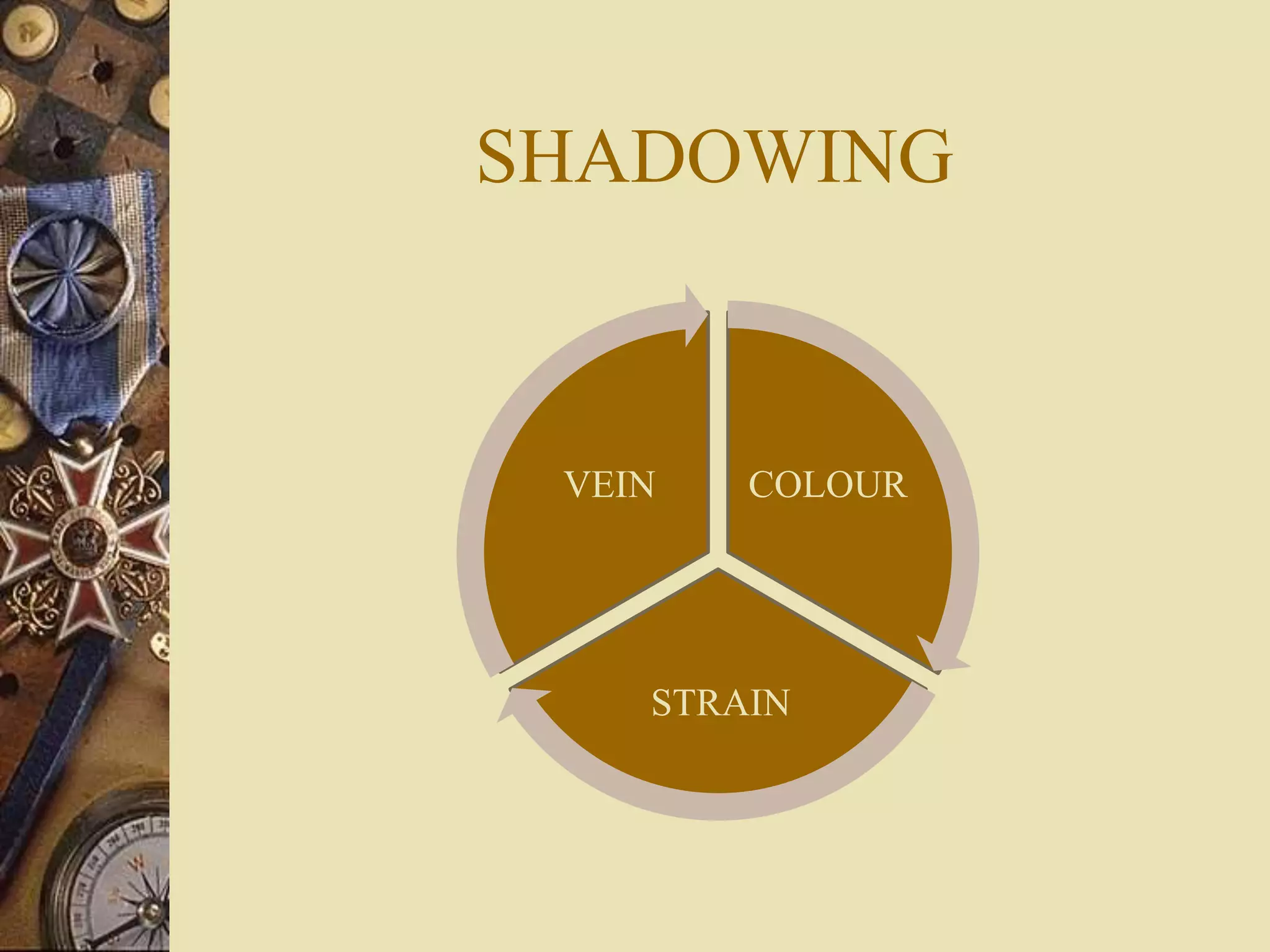

SHADOWING

[S]

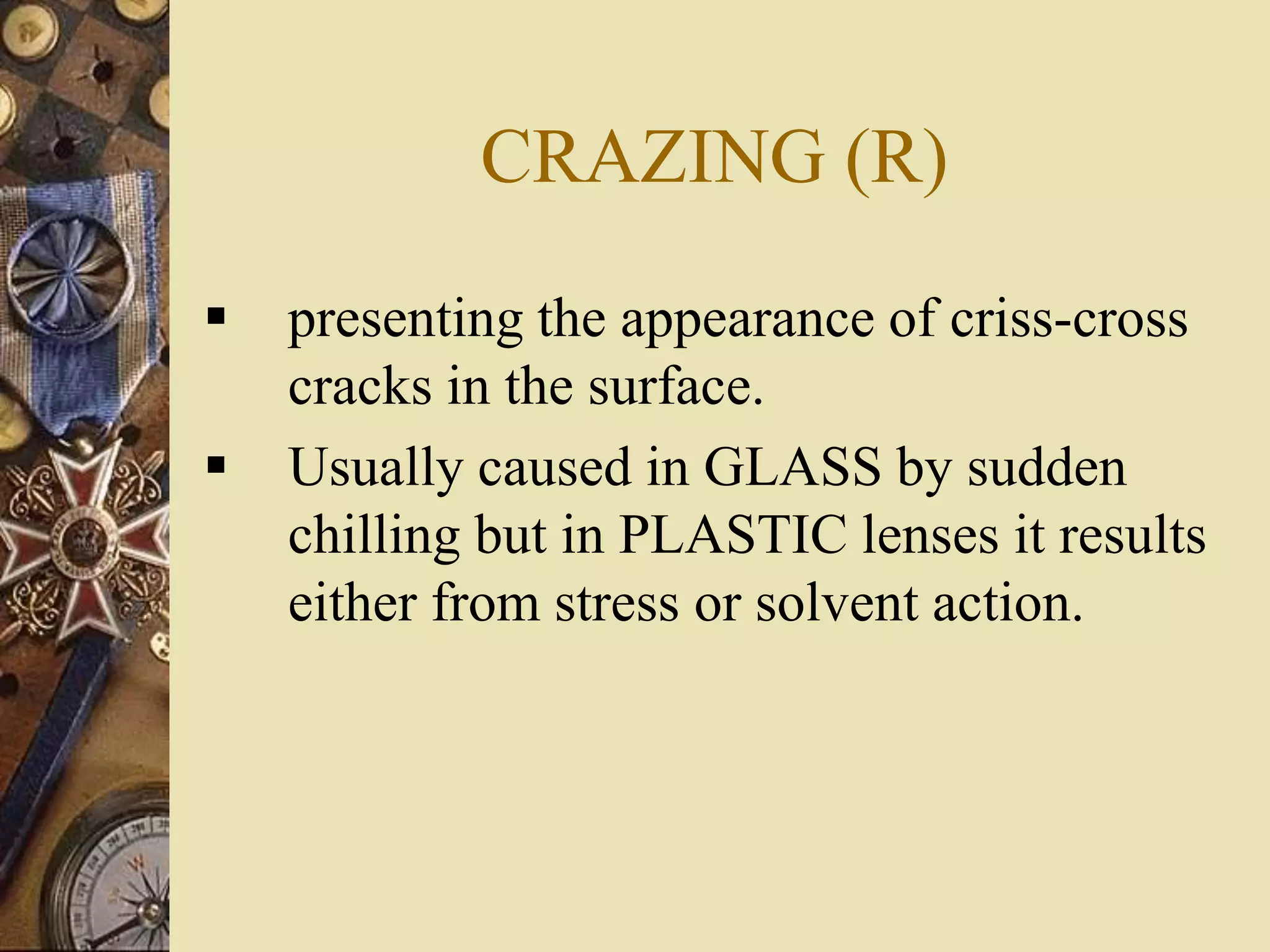

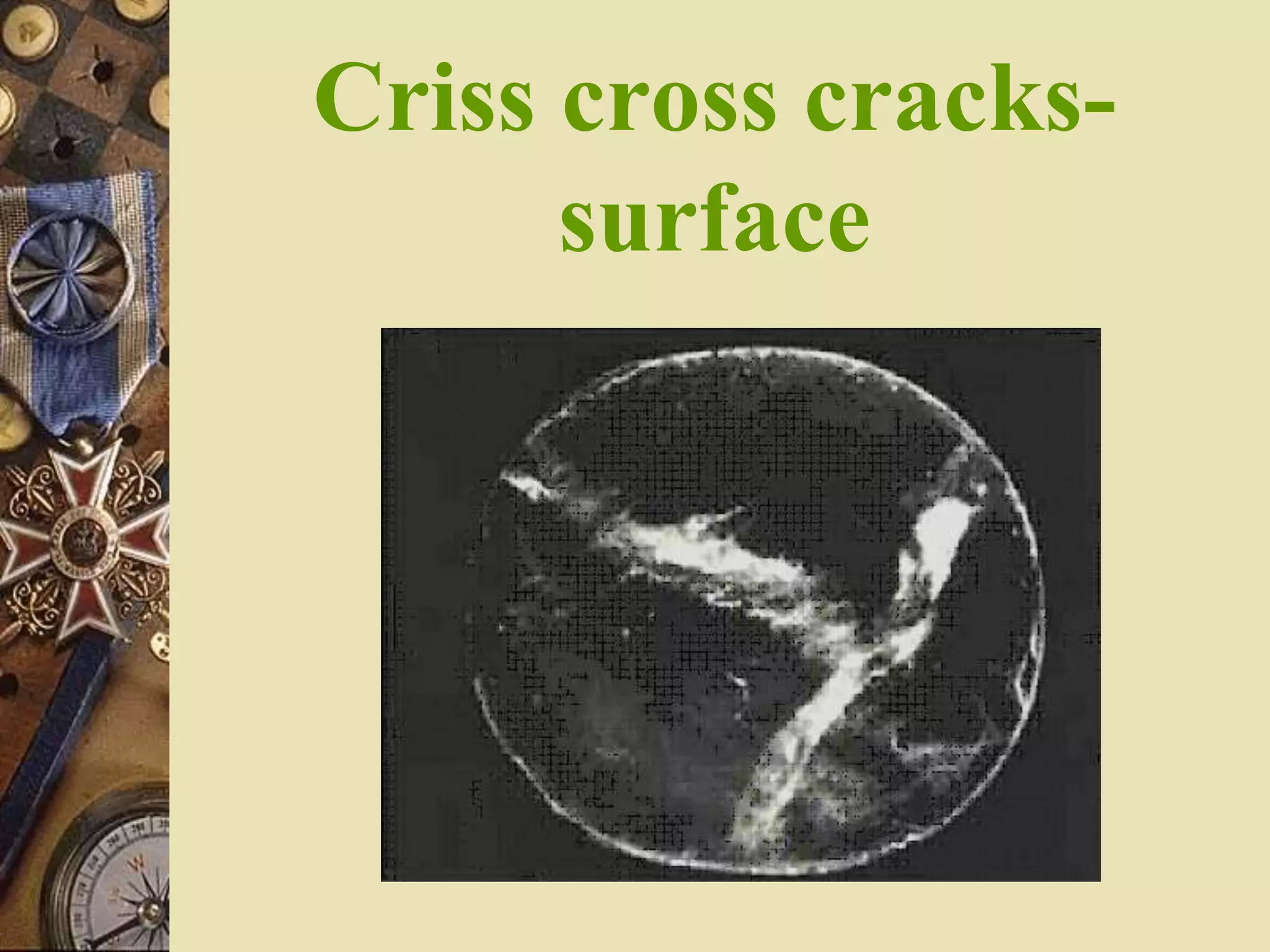

REFLECTION

[R]

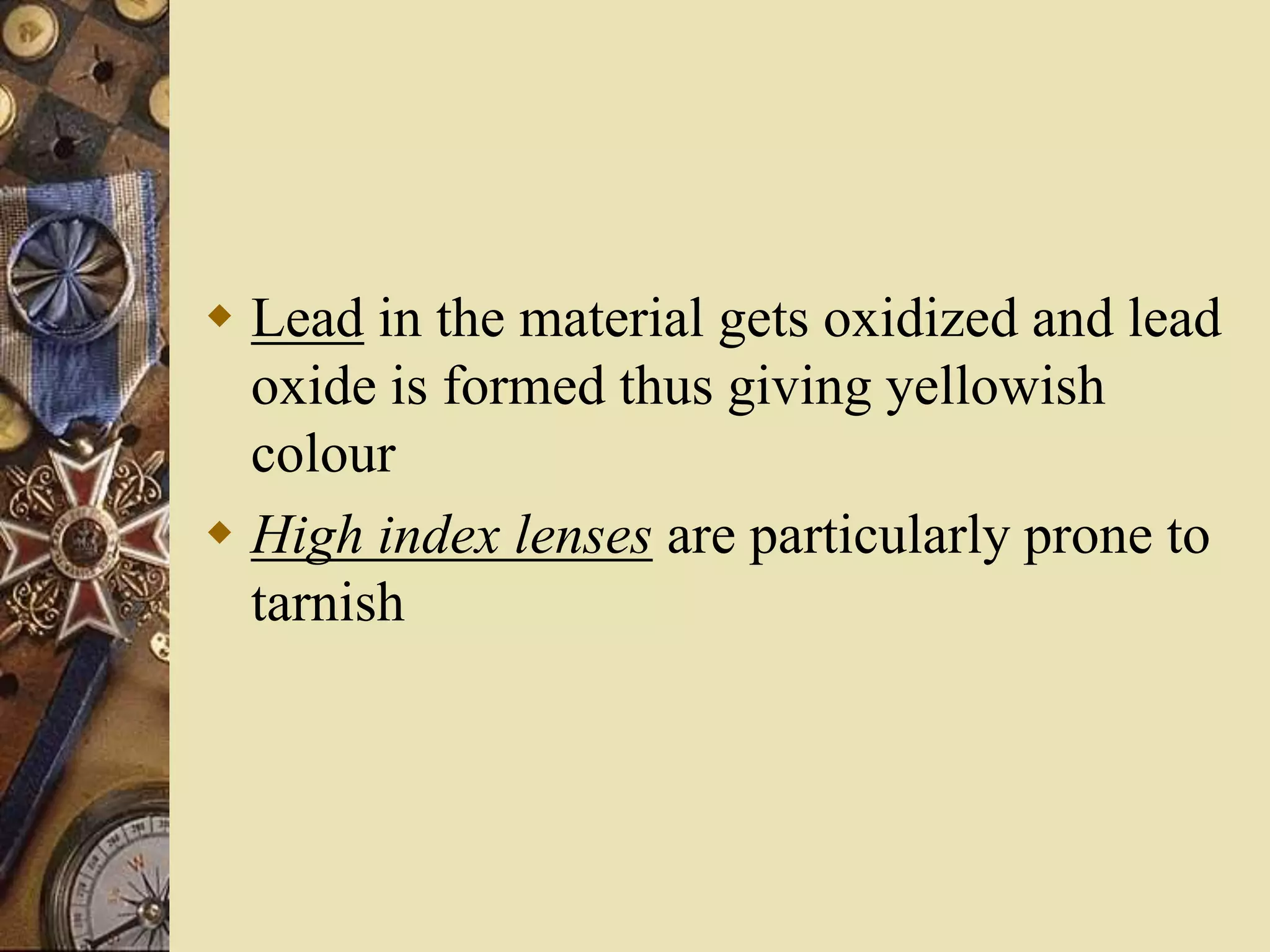

1. BAD METAL VEINS TARNISH

2. BUBBLES CORD CRAZING

3. FEATHERS STRIA HOLE

4. POLISHING

BURN

CLOTH

MARKS

GREYNESS

5. WAVES WAVES SCRATCH

6. RINGS RINGS DIG

7. DRAG

MARKS

SLEEK

8. ORANGE

PEAL

BRUISE

CHECK

9. ROUNDING CHIPS

10. ABUSE

MARKS](https://image.slidesharecdn.com/fault-140509045917-phpapp01/75/Fault-54-2048.jpg)