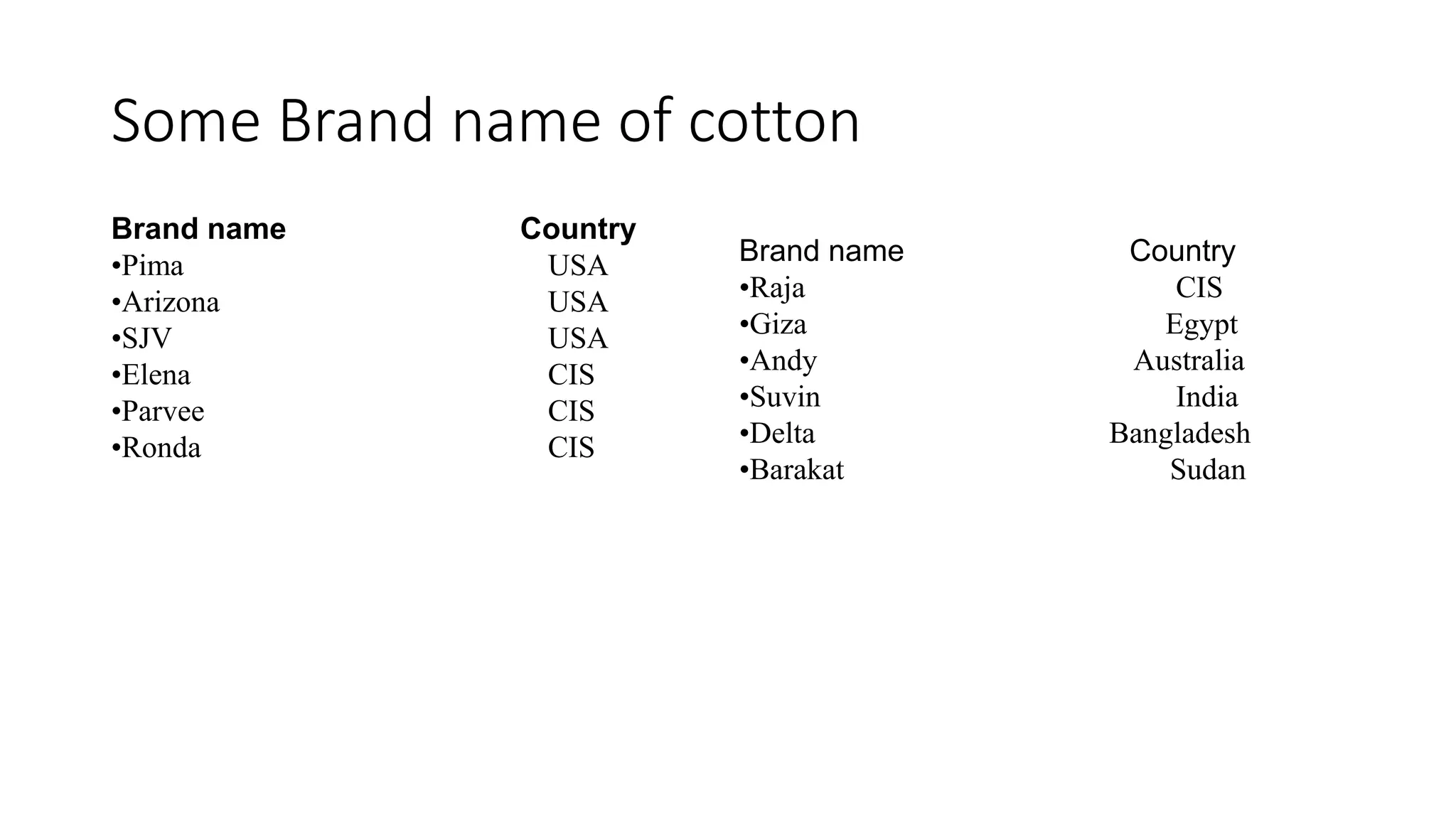

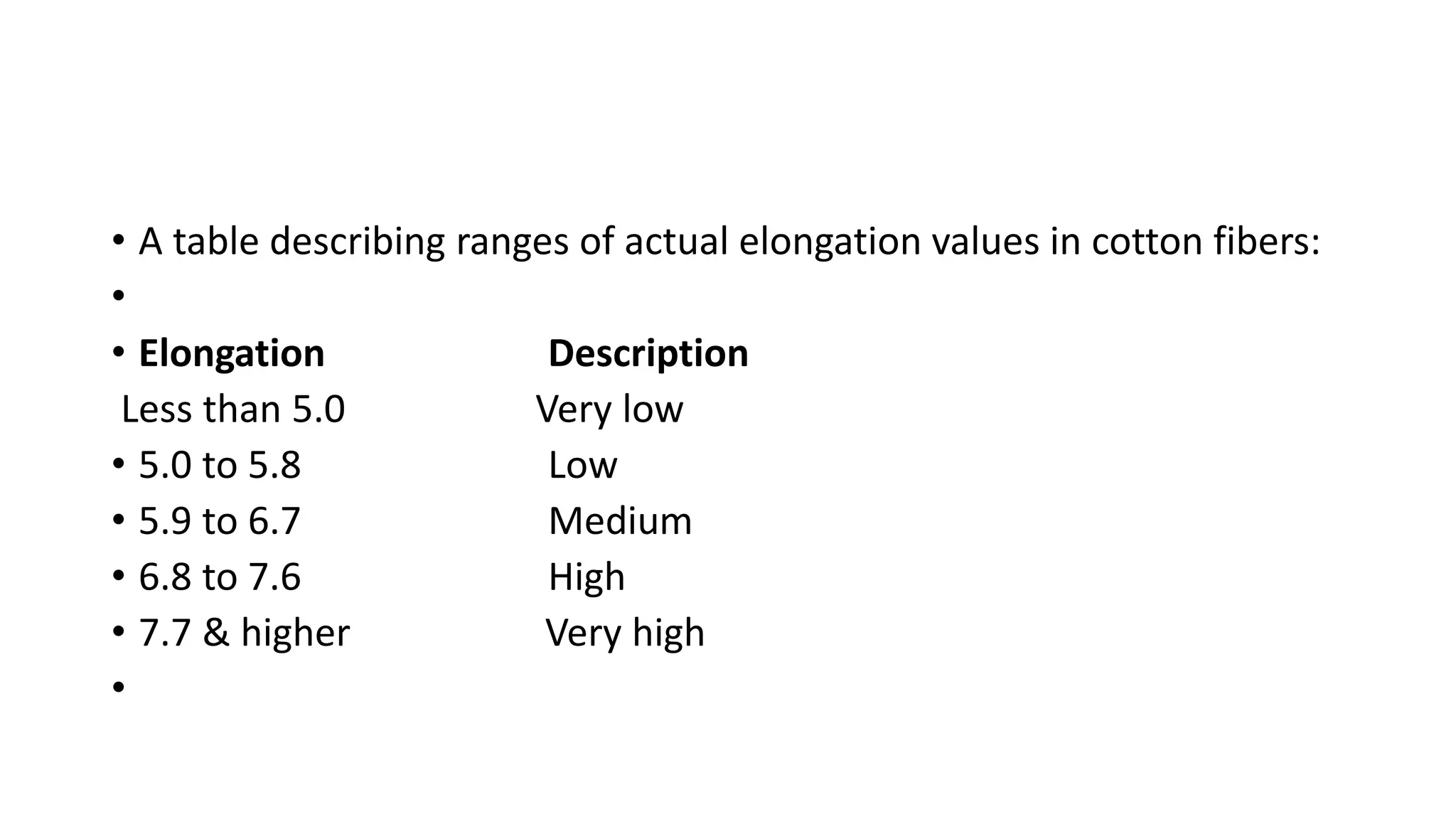

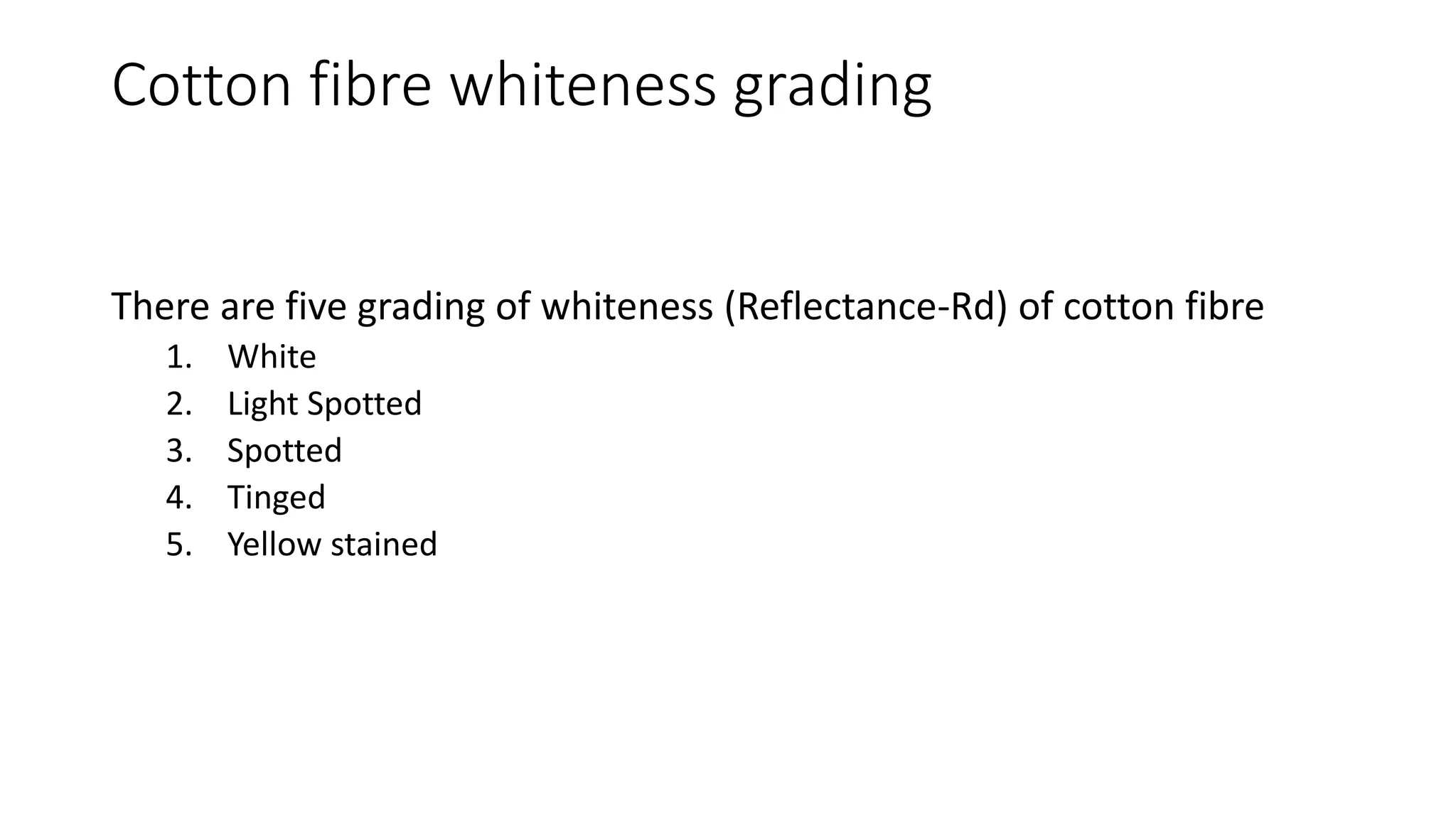

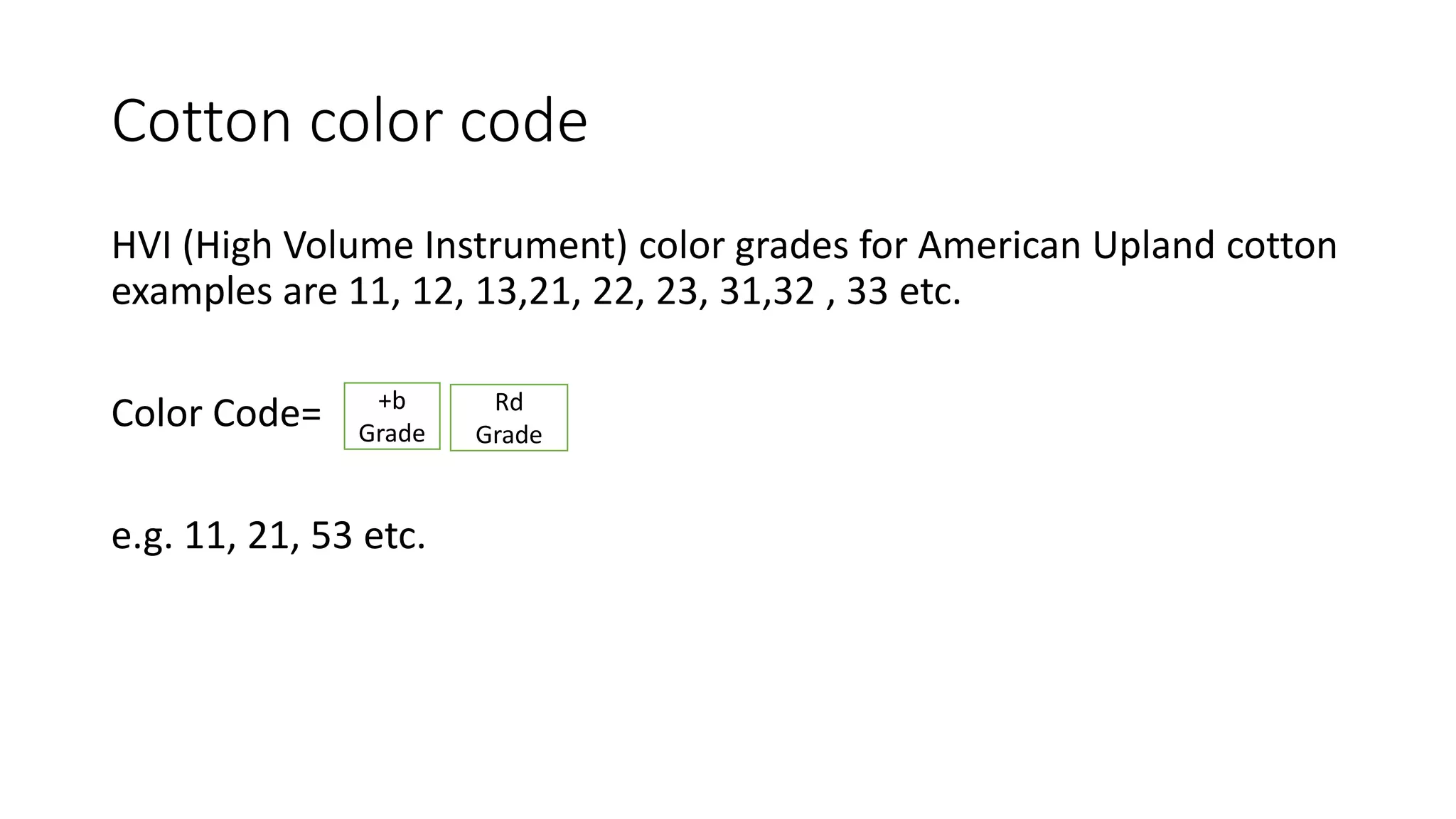

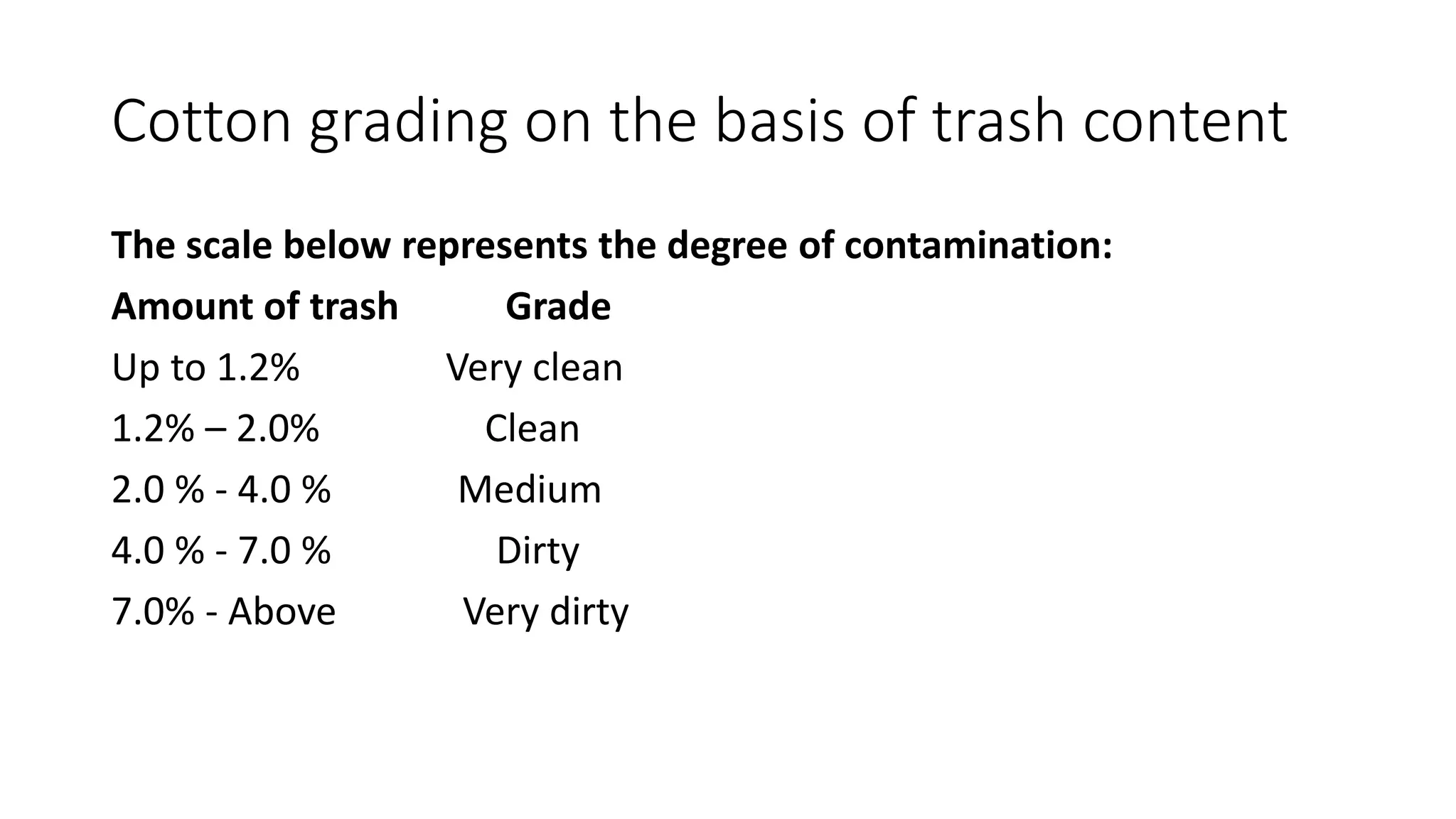

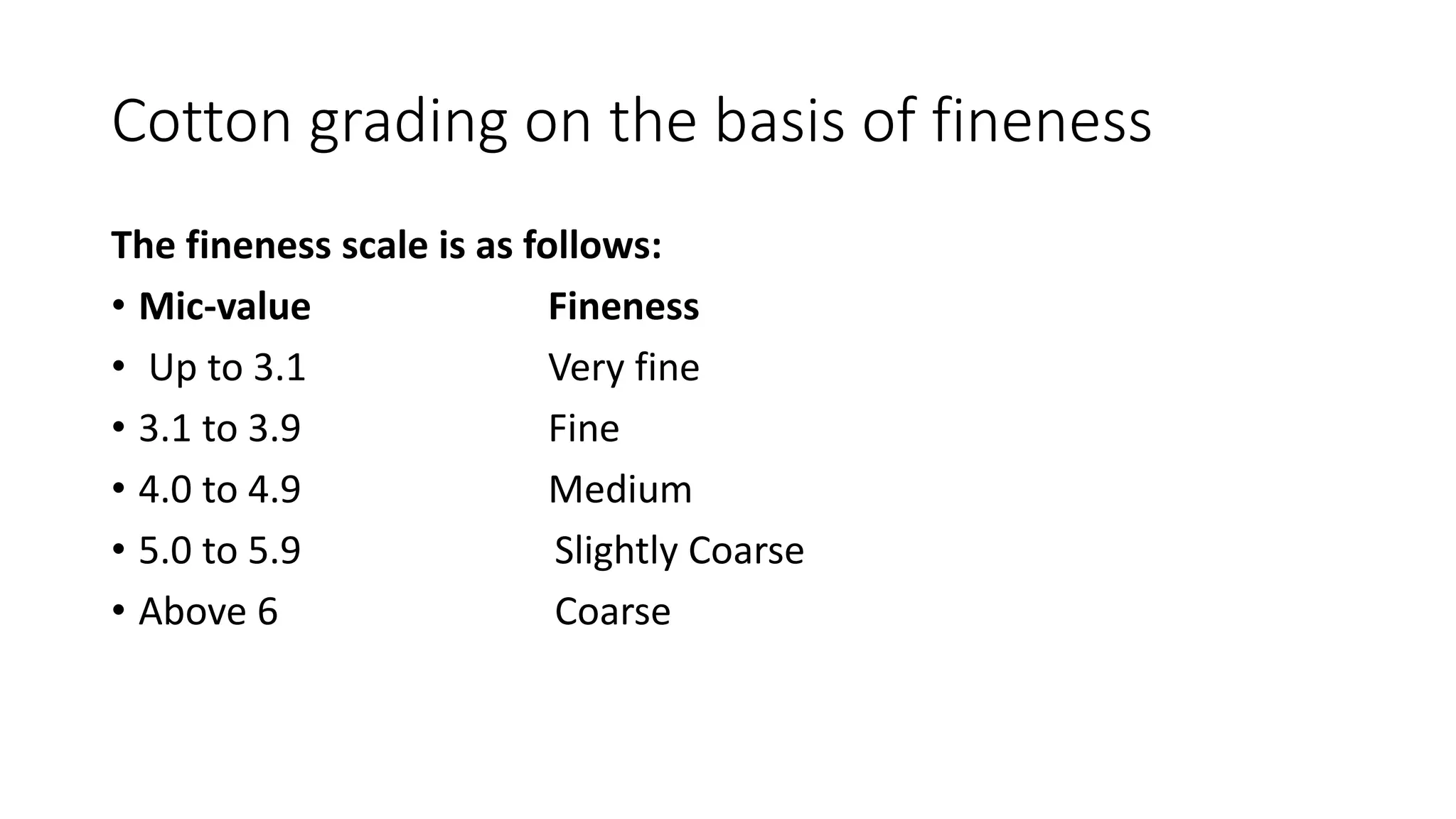

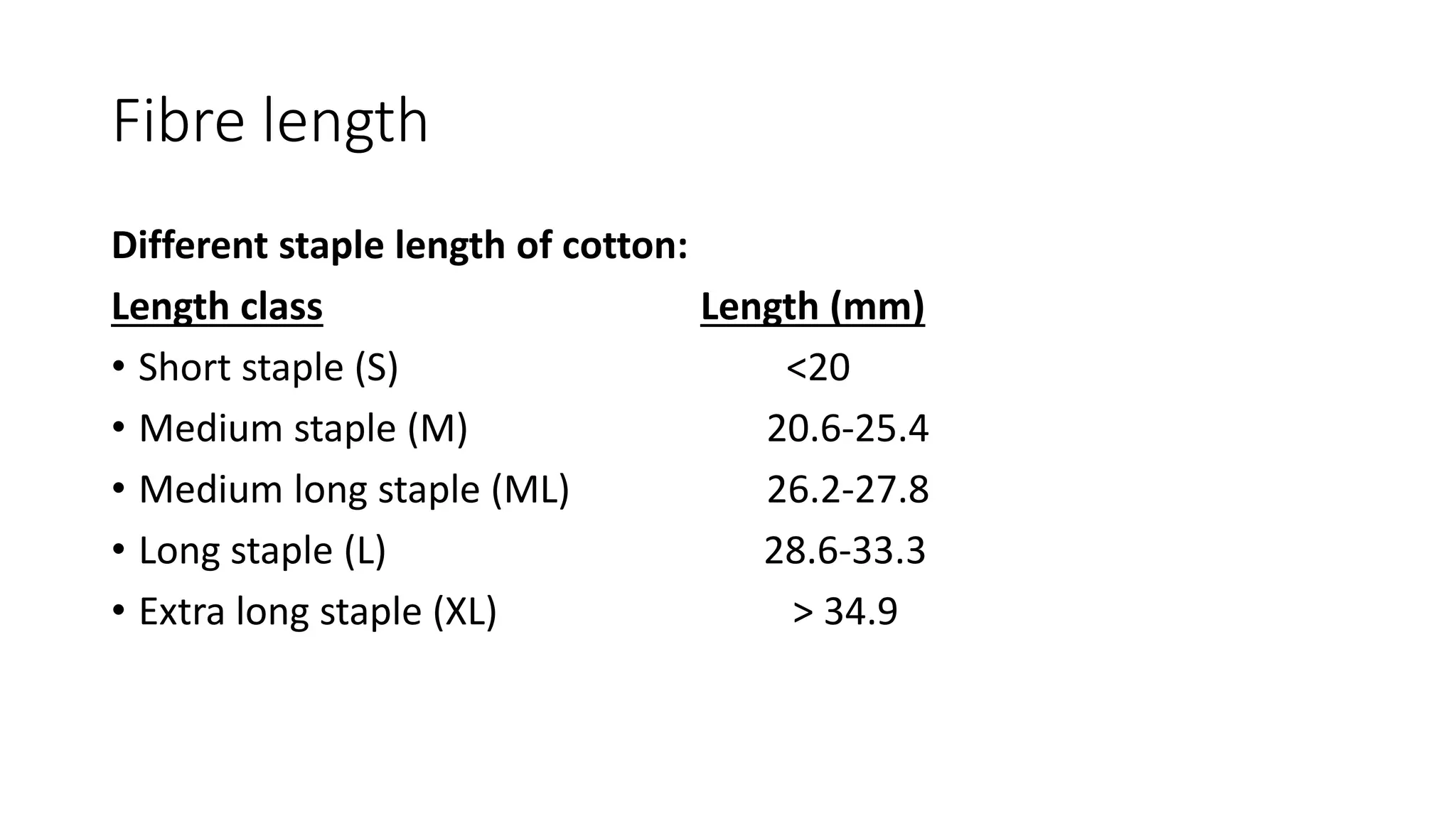

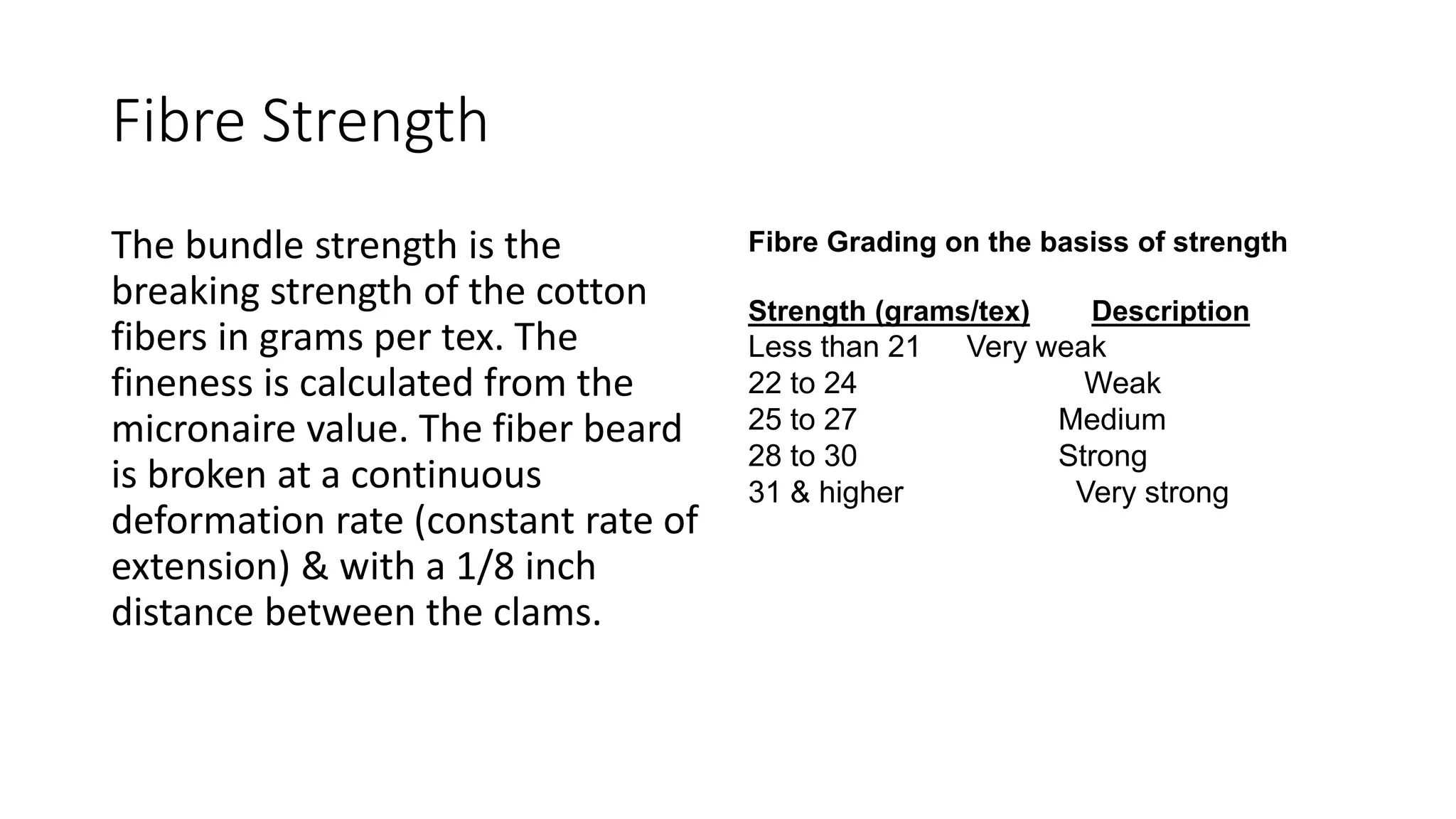

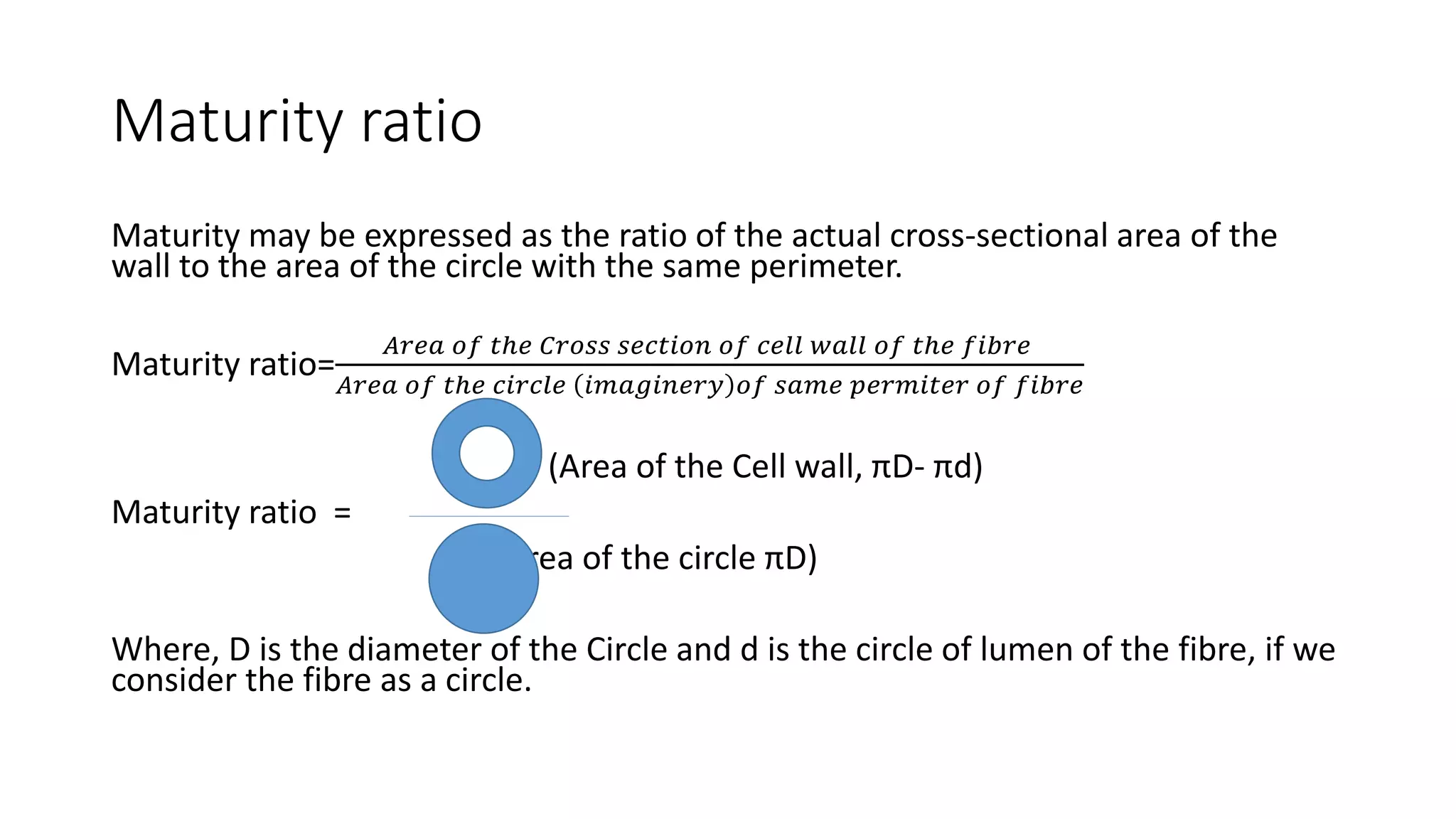

Raw cotton accounts for 50-75% of manufacturing costs and 80-90% of yarn quality. Important cotton fiber characteristics for spinning include length, strength, fineness, maturity, cleanliness, color, and elongation. Fiber properties influence spinning limit, yarn strength and evenness, fabric drape, luster, and productivity. Proper bale management and homogeneous mixing based on fiber characteristics ensures consistent yarn quality and minimizes variations.