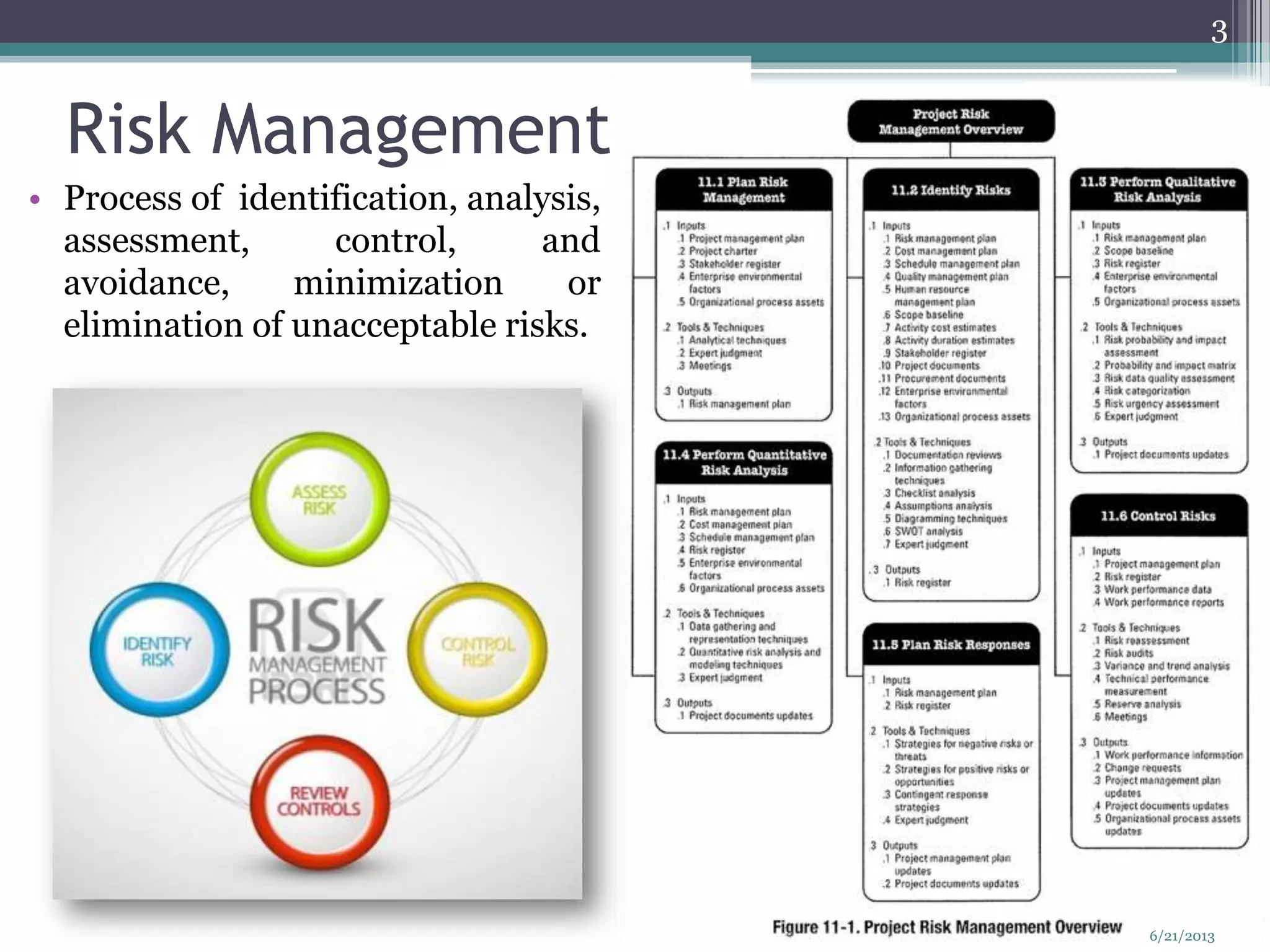

This document discusses how risk management principles from PMBOK can be applied to safety, health, and environment (SHE) programs. It provides an overview of risk management and SHE concepts. As an example, it examines health and safety risks in the catering industry and recommendations for prevention. The major risks are slips, trips, handling injuries, cuts, exposure to hot substances, and dermatitis. Proper maintenance, training, protective equipment, and cleaning are emphasized to manage these risks. The goal is to prevent workplace injuries and illnesses by identifying and eliminating hazards through a systematic risk management approach.