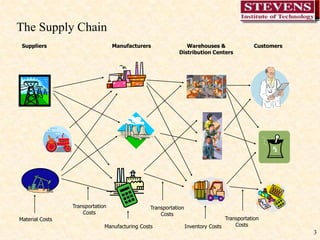

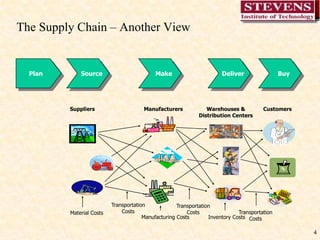

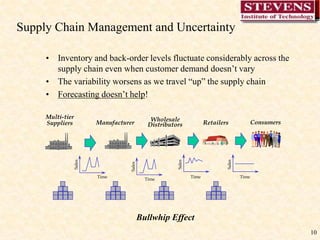

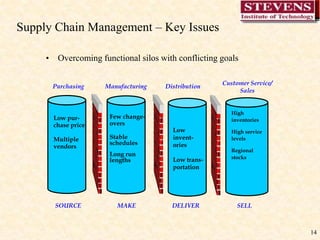

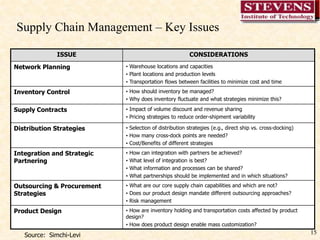

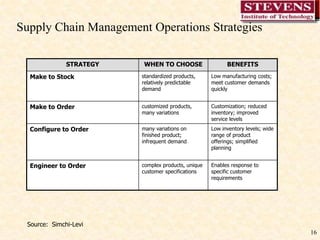

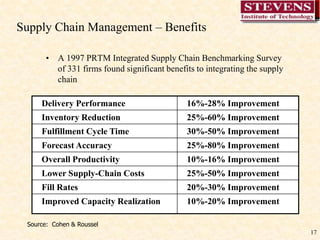

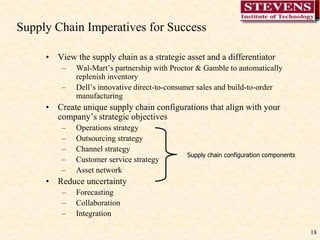

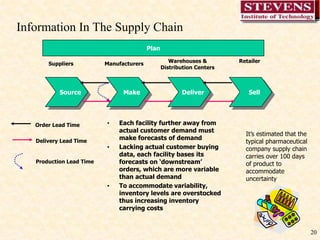

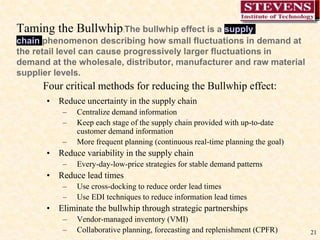

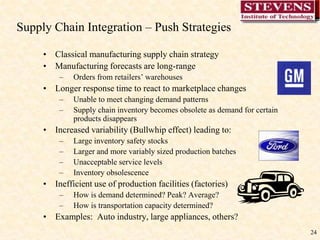

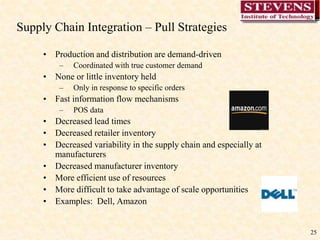

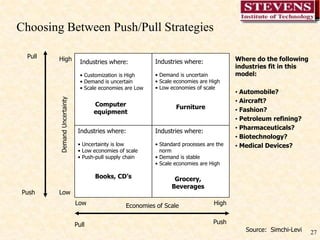

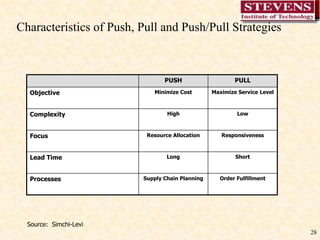

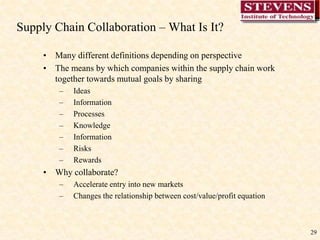

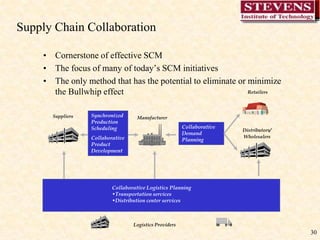

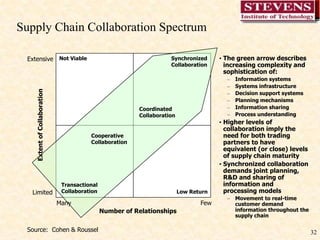

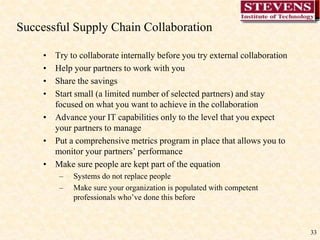

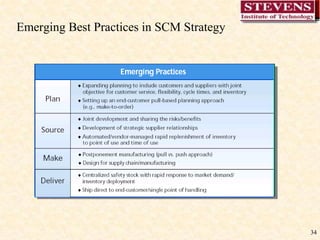

This document discusses supply chain management. It defines a supply chain as including suppliers, manufacturers, warehouses, distribution centers, and retail outlets, as well as the materials and products that flow between them. It describes how uncertainty increases as you move further up the supply chain away from customers due to lack of information. It also discusses the bullwhip effect, where small fluctuations in retail demand can cause larger fluctuations in orders as you move up the supply chain. The document emphasizes the importance of reducing uncertainty in the supply chain through improved information sharing and collaboration between partners.