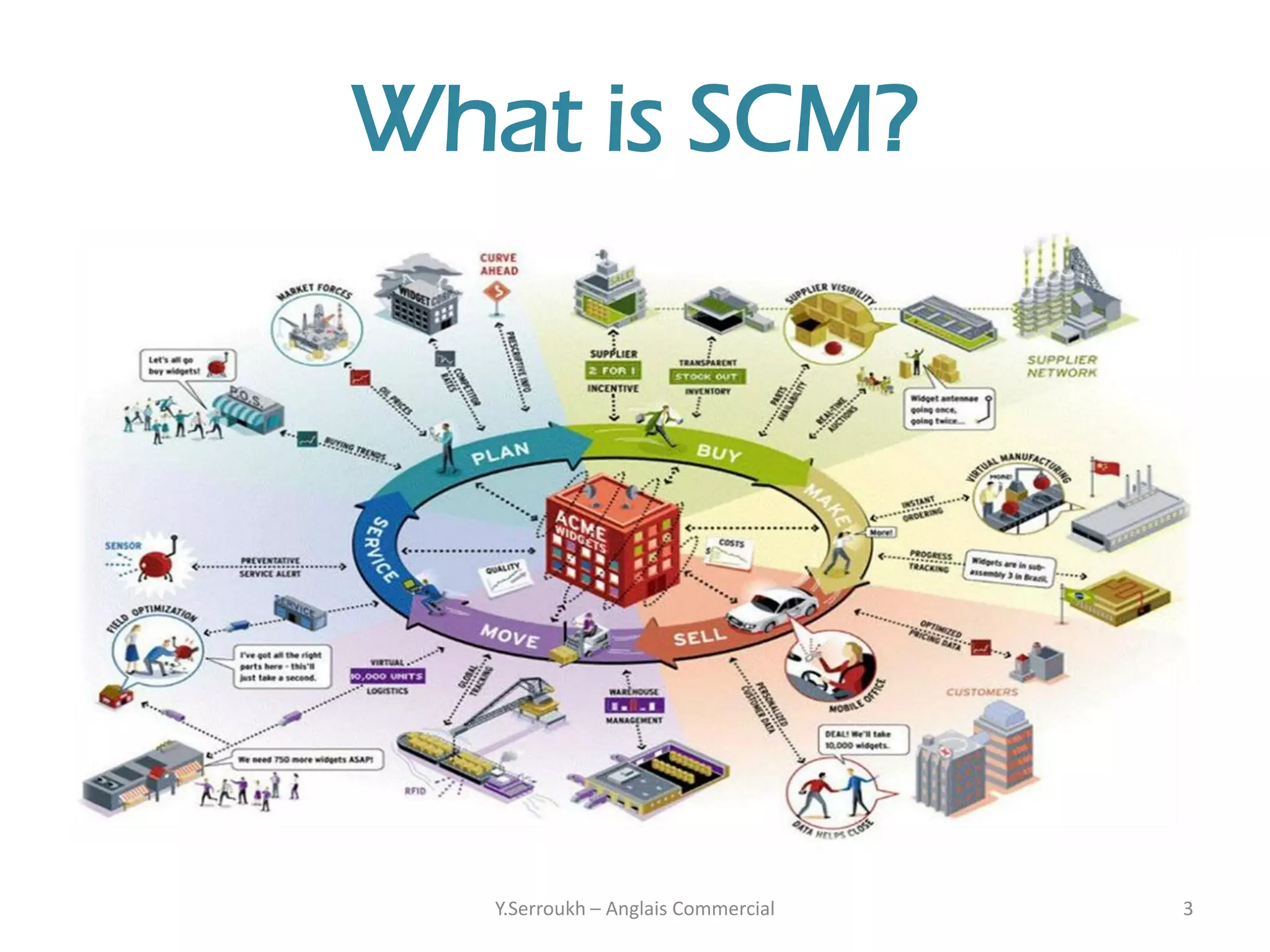

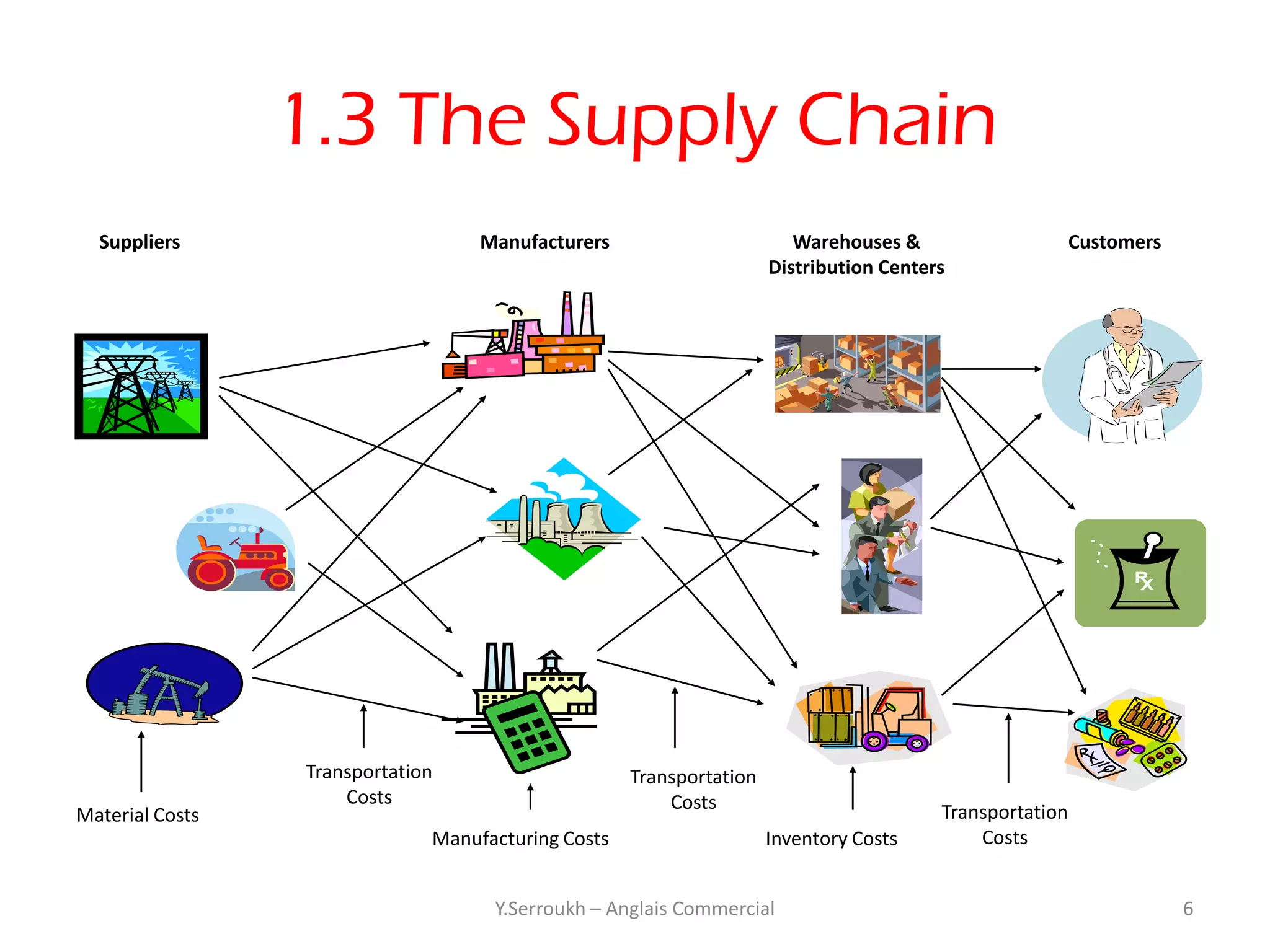

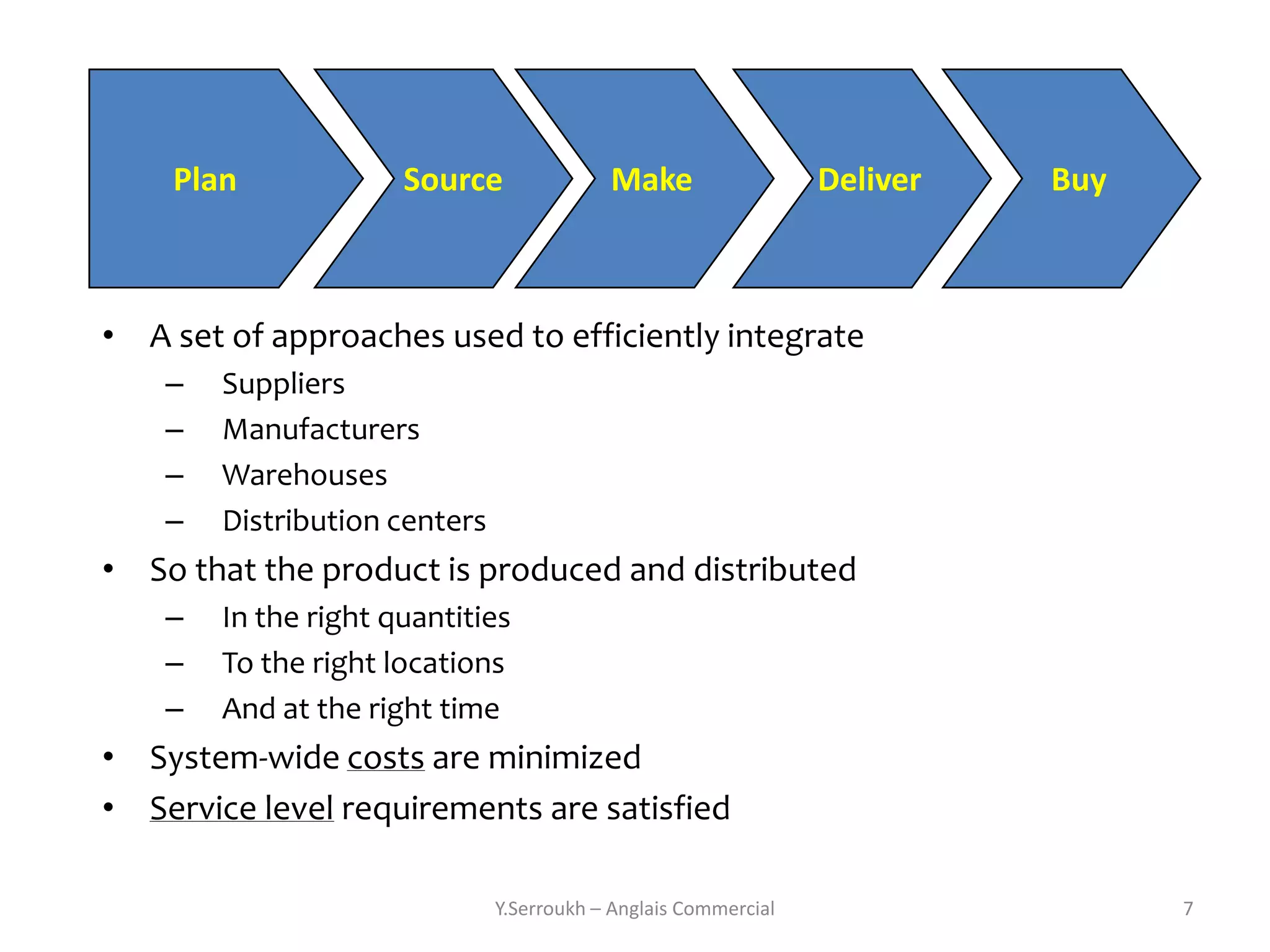

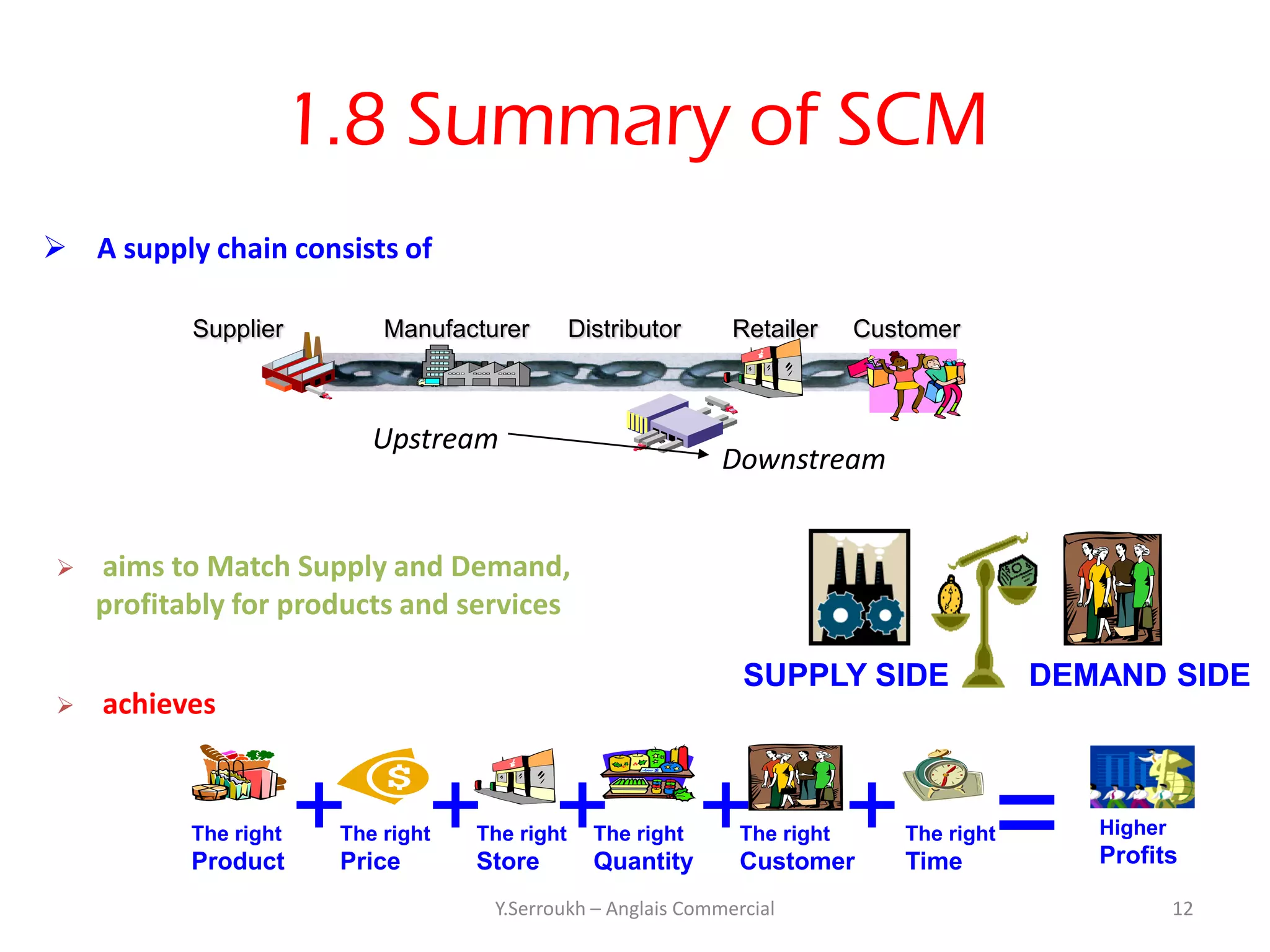

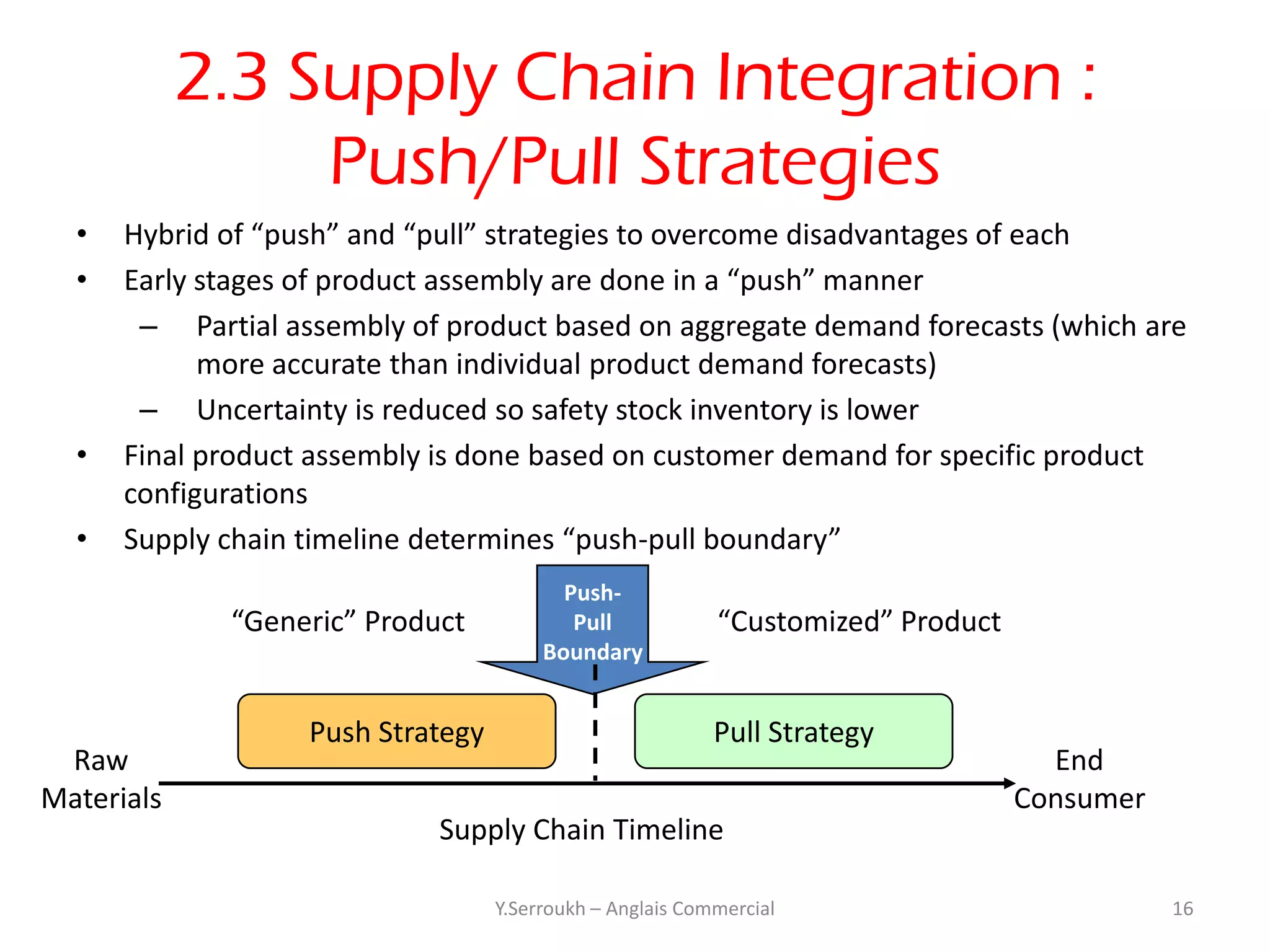

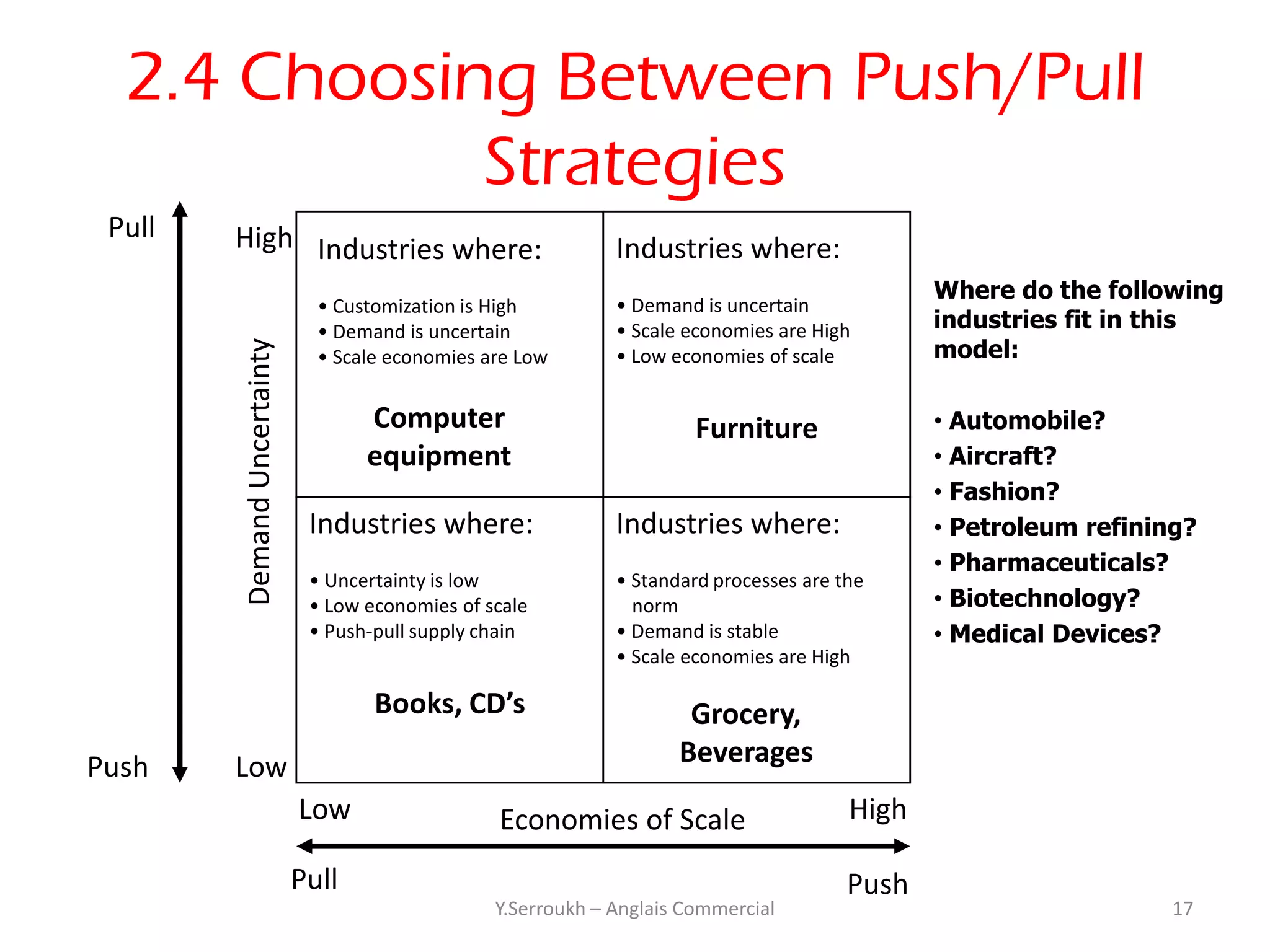

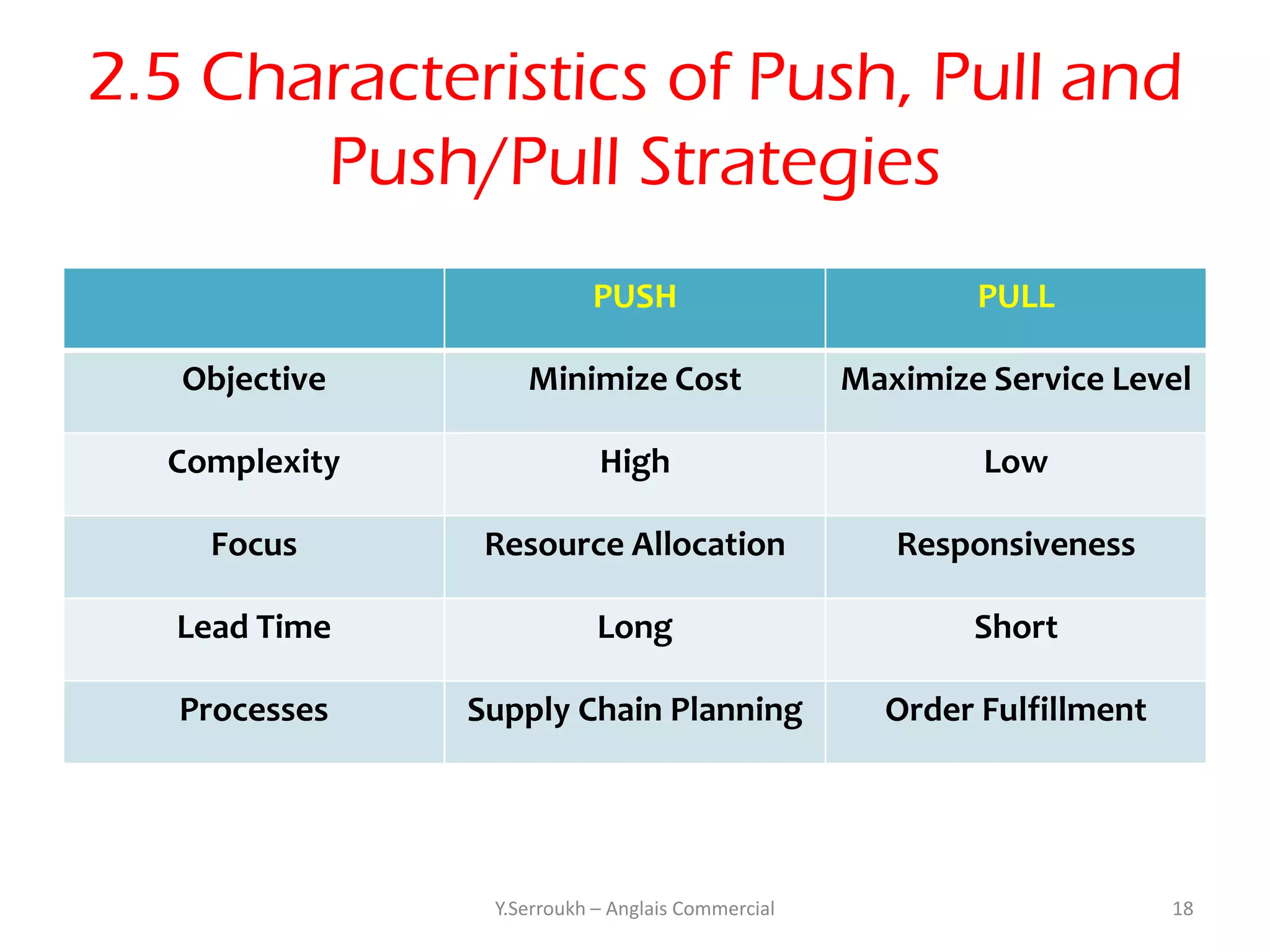

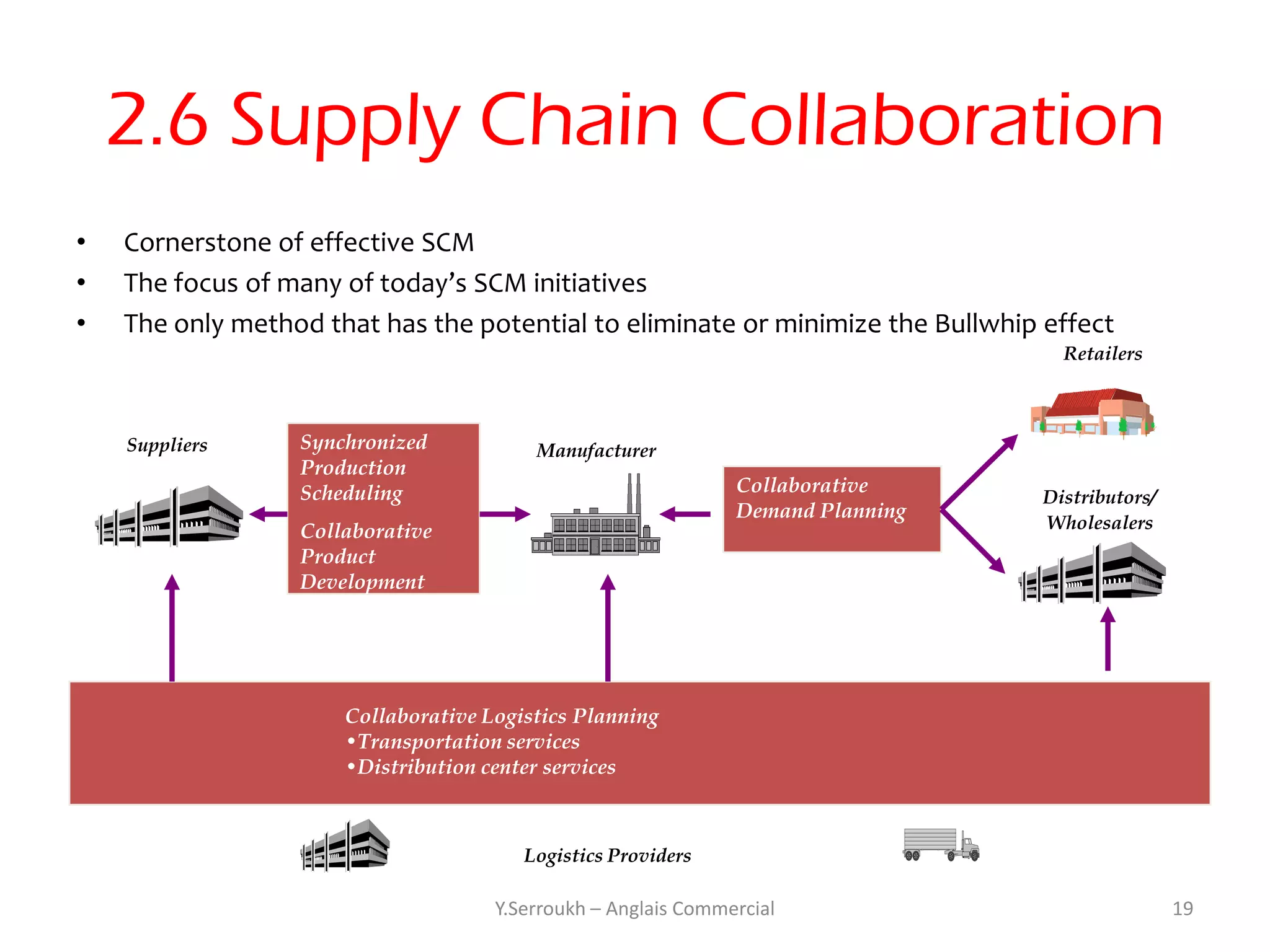

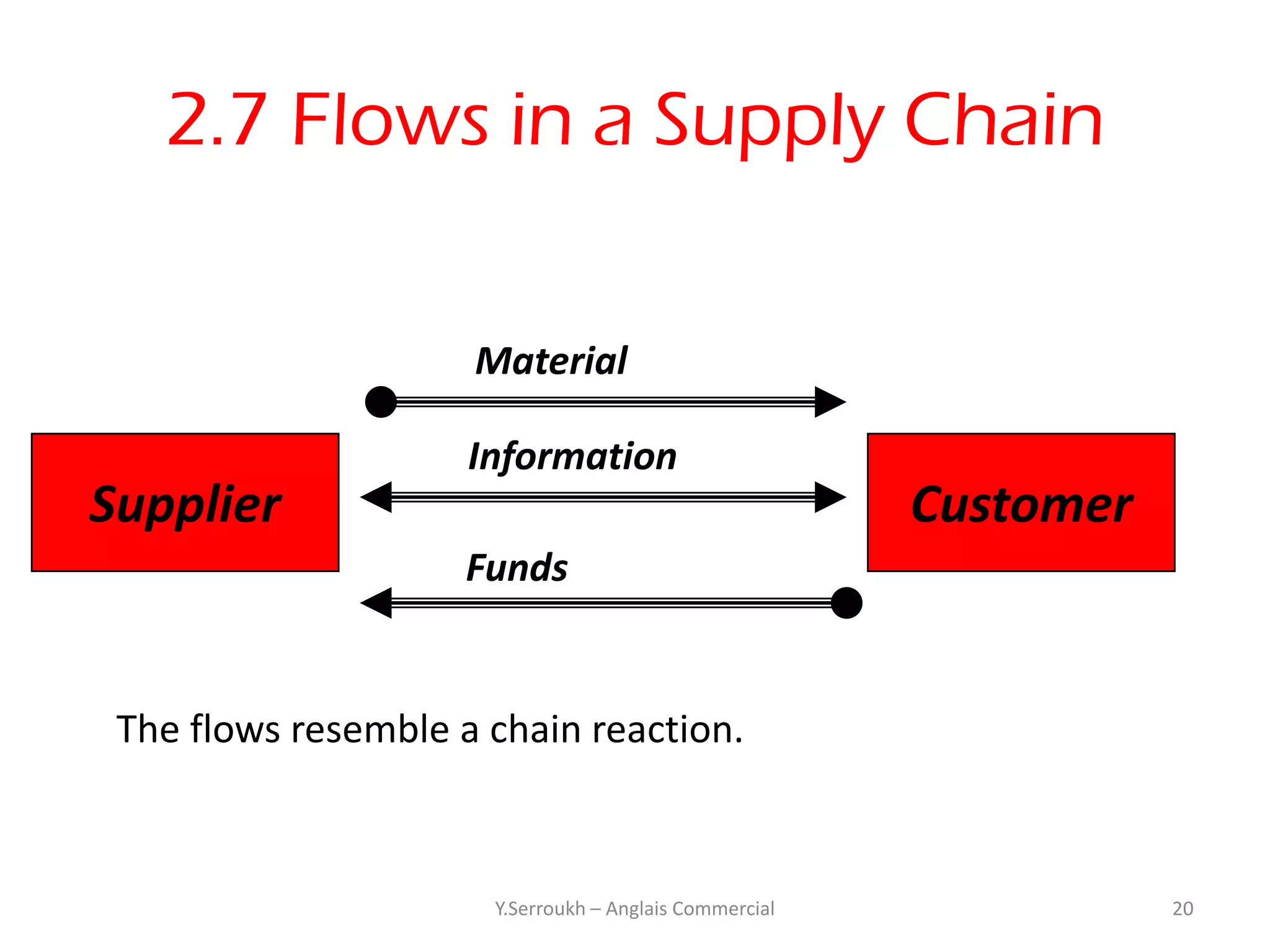

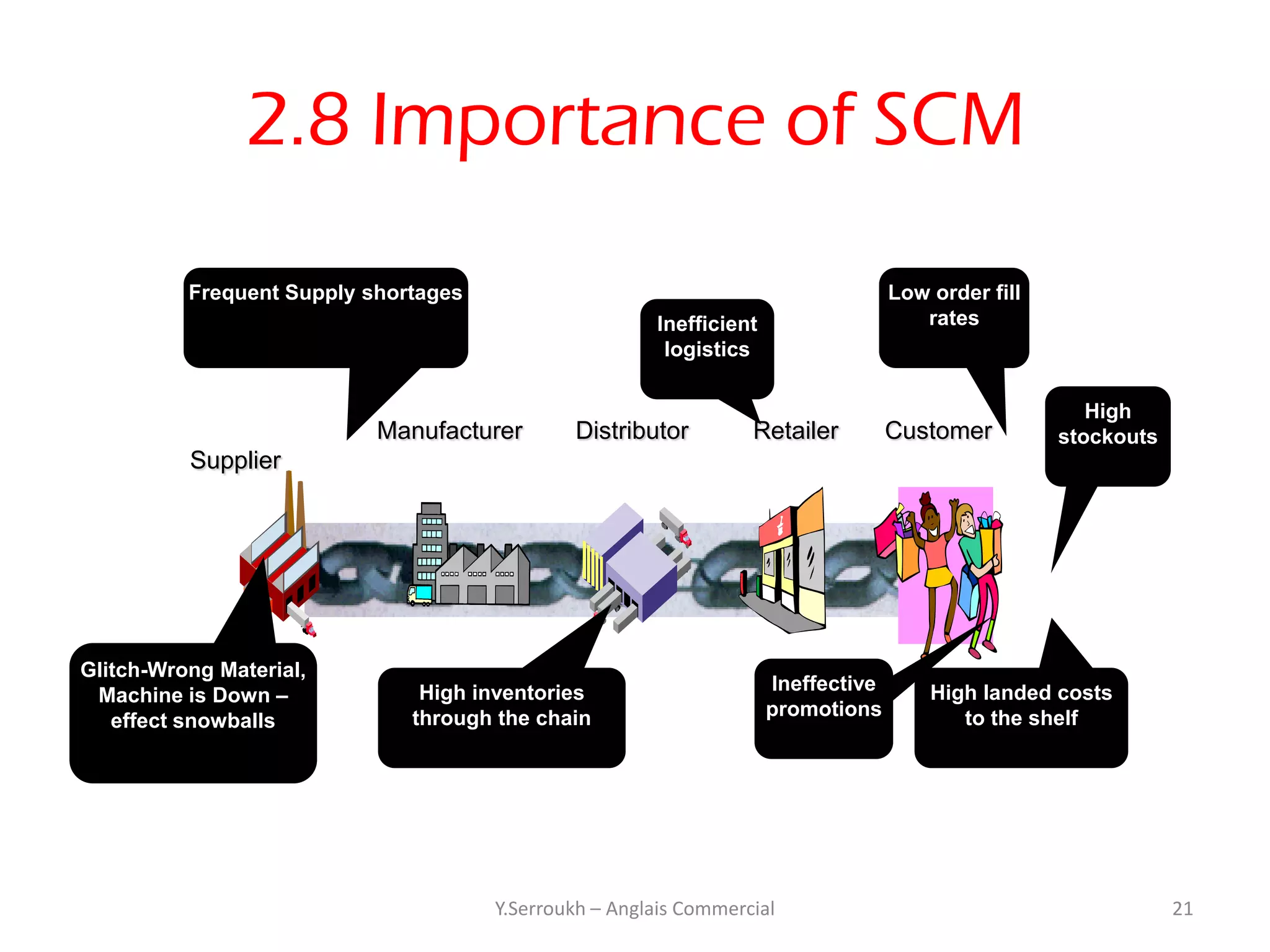

The document discusses supply chain management (SCM). It defines SCM as the management of relationships between suppliers, manufacturers, warehouses, distribution centers, and customers to deliver value to customers at a low cost. The goal of SCM is to optimize efficiency through integrating these entities. The document also describes how SCM has evolved from a "push" model driven by forecasts to a "pull" model driven by actual customer demand.