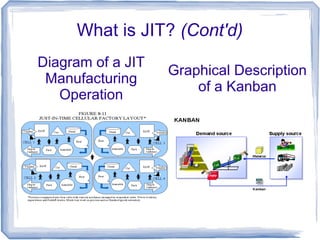

Just-In-Time (JIT) Manufacturing is a methodology aimed at reducing flow times and response times. It originated from Toyota's production system and involves supplying components as needed through kanban cards. Components do not sit idle waiting for the next process. JIT has been applied in automotive assembly, computer assembly, and meal delivery systems. While often attributed to post-WWII Japan, some argue it originated in 1890s India with the Dubbawallah meal delivery system in Mumbai. JIT helps reduce waste through techniques applied from production to customers.