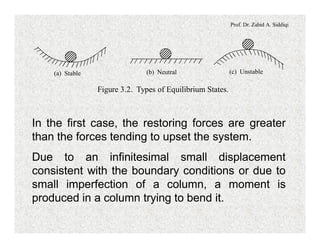

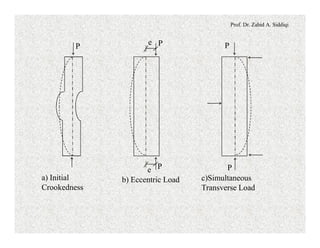

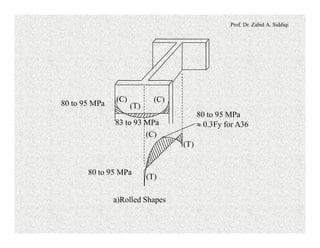

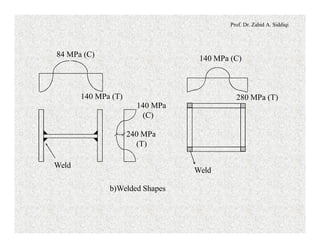

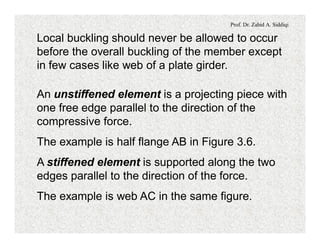

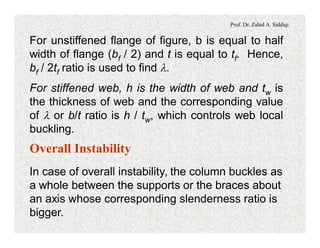

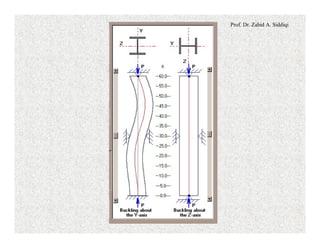

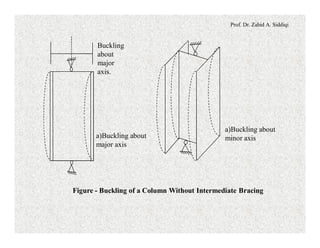

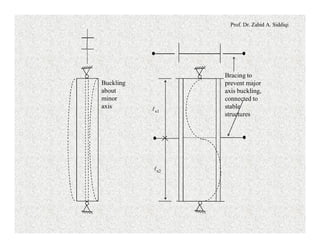

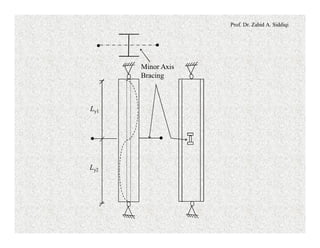

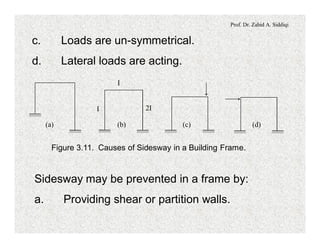

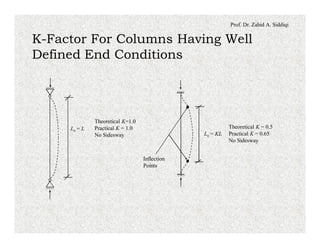

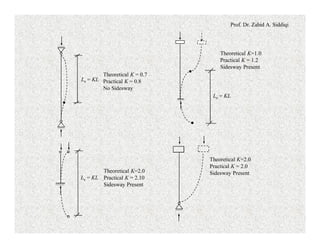

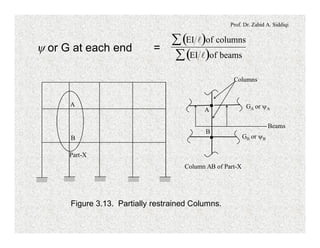

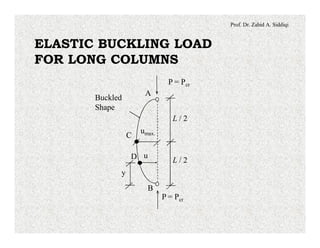

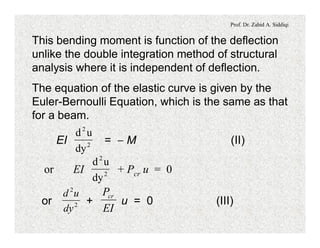

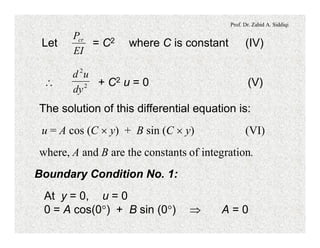

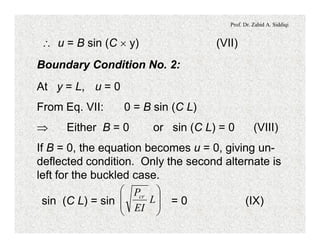

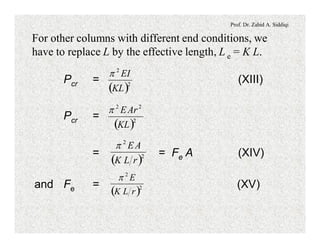

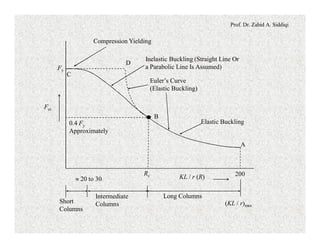

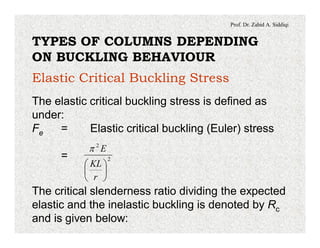

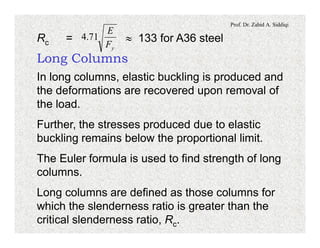

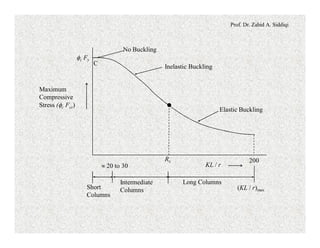

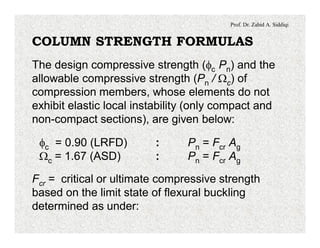

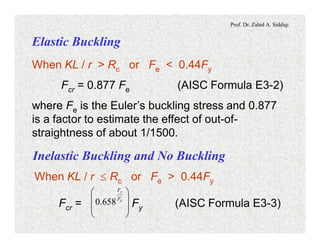

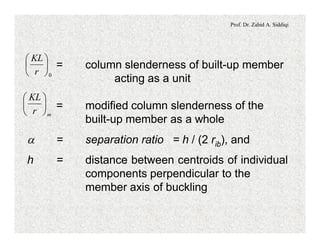

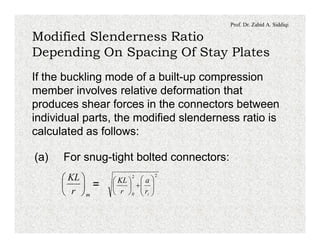

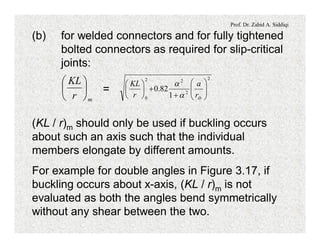

This document discusses compression members and buckling of steel columns. It defines compression members as members subjected to compressive stresses that tend to shorten or squeeze the member. Examples given include struts, columns, truss chords, and beams. It notes that compression members are more prone to buckling than tension members. Buckling occurs when the critical buckling load is reached due to factors like member length, cross-section, end conditions, and imperfections. The effective length factor K is introduced to account for end conditions and sidesway in calculating the critical slenderness ratio.