This document discusses tension members in structural engineering. It defines tension members as linear members that experience axial forces that elongate or stretch the member. Examples given include ropes, ties in trusses, suspenders in bridges. The document discusses the types of cross-sections used for tension members like angles, channels, rods. It also discusses the calculation of net effective sectional area and provides examples. Other topics covered include types of failures in tension members, design strength calculations, limiting slenderness ratios, tension splices, and lug angles.

![AACE Engineering College : Ankushapur, Ghatkesar, Telangana 501301 (EAMCET Code: ACEG)

16 Design of Steel Structures

For Micro Notes by the

Student

Previous TSPSC & APPSC Questions

01. Net effective area in tension in case of single angle connected by one leg

only is given by: a + kb. The value of k is

(a) 1/ [1+(b/3a)] (b) 1/[1+(a/3b)]

(c) 1/[1+(0.2 b/a] (d) 1/[1+(0.1 b/a)]

02. The maximum permissible slenderness ratio for tension member is

(a) 400 (b) 350 (c) 300 (d) 250

03. The net effective area in case of a single- angle member having the net

connected leg area of 50 mm2

and gross area of unconnected leg as 100

mm2

is

(a) 75 mm2

(b) 130 mm2

(c) 150 mm2

(d) 110 mm2

04. The effective area of 100 ×100 × 6 connected to a gusset plate through one

leg with 20 mm diameter rivets is

(a) 1044.0 mm2

(b) 936.7 mm2

(c) 885.3 mm2

(d) 116.0 mm2

05. Two tension members having different sizes are connected using

(a) Gusset plate (b) Filler plates

(c) Shear legs (d) All of the above

06. The Lug angle is a member which ___ (TSPSC AEE Manager 2015)

(a) is connected to the main tension member to increase its stiffness

(b) is connected to the main tension member for erection purpose.

(c) is connected to the main tension member to increase its strength

locally.

(d) is connected to the main tension member to transfer the tensile force

economically to the joint.

07. Which one is not a possible mode of failure in case of tension members?

(APGENCO Trainee AE-2017)

(a) Yielding of gross section (b) Rupture at the net section

(c) Instability of the element (d) Block shear

KEY for Previous Questions

01. (a) 02. (a) 03. (d) 04. (c) 05. (b)

06. (d) 07. (a)](https://image.slidesharecdn.com/iii-design-of-steel-structures-unit-2-210523063202/85/Iii-design-of-steel-structures-unit-2-16-320.jpg)

![AACE Engineering College : Ankushapur, Ghatkesar, Telangana 501301 (EAMCET Code: ACEG)

36 Design of Steel Structures

For Micro Notes by the

Student

(LSD Principle)

V = 2.5% of axial column load (WSM Principle)

• The lacing should be designed to resist additional shear due to

bending if the compression member carries bending

• For single lacing, the force (Design compression or Design tensile)

in each lacing bar,

;

sin

F

N

V

θ

=

sin

F

V

2 θ

= [for double lacing, (N=2)]

sin

F

V

4 θ

= [for double lacing, (N = 4)]

• The effective slenderness ratio of laced builtup column should be

increased by 5% (IS800:2007 specification only)

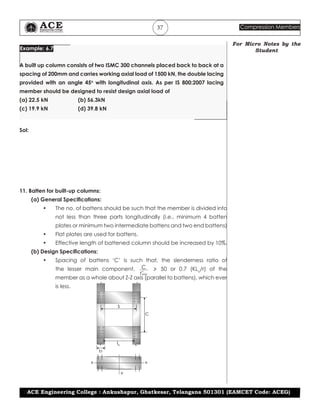

Example: 6.6

A built up column consists of two ISMC 450 channels placed back to back

carries factored load of 2500 kN, the single lacing provided with an angle 45o

with longitudinal axis should be designed to transverse shear as per IS800:2007

of

(a) 15.0 kN (b) 22.5kN

(c) 62.5kN (d) 44.1 kN

.Sol:](https://image.slidesharecdn.com/iii-design-of-steel-structures-unit-2-210523063202/85/Iii-design-of-steel-structures-unit-2-36-320.jpg)

![AACE Engineering College : Ankushapur, Ghatkesar, Telangana 501301 (EAMCET Code: ACEG)

38 Design of Steel Structures

For Micro Notes by the

Student

Where,

rc

min

= minimum radius of gyration of component.

S = transverse distance between centroids of bolt group or rivet group

C = Spacing of battens

lb

= transverse distance between centroids of inner end bolt group or rivet

group

• Battens should be designed to carry bending moment and shear

forces arising from a transverse shear of

V = 2.5% of design axial column load

(LSD Principle)

V = 2.5% of axial column load (WSM Principle)

Longitudinal shear on batten, V1

= VC/NS

Moment on batten, M=VC/2N

Where,

N = No. of parallel plates of battens

= 2 in the above figures.

• Thickness of batten, tb 50

b

,

$

lb

= length of batten plate

• Effective depth of batten

d > 3a/4 for intermediate batten

d > a for end batten

d > 2b for any batten

• Over all depth of batten (D)

D = Effective depth of batten (d) + 2x

edge distance

Working Stress Method Concepts

12. Axial compressive strength (Pc

) of a member:

Pc

= Ae

× σac

Where

Ae

= Effective sectional area of a member,

σac

= Axial allowable compressive stress

IS800:1894 uses Merchant Rankine formula to calculate σac

:

.

.

f f

f f

f

0 6

0 6

/

ac

y

n

cc

n n

y cc

y

1

# #

#

σ =

+

7 A

Where,

fy

= Yield stress of steel

fcc

= Elastic critical stress in compression

= π2

E / [KL/r]2

E = Young’s modulus of steel](https://image.slidesharecdn.com/iii-design-of-steel-structures-unit-2-210523063202/85/Iii-design-of-steel-structures-unit-2-38-320.jpg)

![AACE Engineering College : Ankushapur, Ghatkesar, Telangana 501301 (EAMCET Code: ACEG)

39 Compression Members

For Micro Notes by the

Student

KL/r = Slenderness ratio

Minimum radius of gyration of member

Effective length of member

r

KL

min

=

n = a material factor (n = 1.4 for steel)

Minimum radius of gyration about minor axis

/ /

r I A Minimummoment of inertia Area

min

= =

] g

13. Effective length (KL) and allowable axial compressive stress For angle struts,

the specifications as per IS800:1984 are as follows:

End Condition

Effective

length (KL)

Allowable

axial

compressive

stress (σac

)

(a) For discontinuous members

For single rivet

or bolt

1.0 L 0.8σac

For double

rivet Double

bolt & weld

0.85L σac

(b) For Continuous members

For single or

double angle

0.70L

to

0.85L

σac

14. Cased Columns:

• It is necessary to encase the members of steel framed building in

concrete to meet architectural appearance and also increase fire

resistance and check corrosion of steel members

• For designing of cased column, the entire load is assumed to be taken

steel section only and encasement is taken increasing the stiffness of

the column

Specifications of encased columns:

• The member is of symmetrical I-shape or a single I beam, or channels

back to back with or without flange plates.

• The overall dimensions of the steel section do not exceed 750 mm x

450 mm, the large dimension being parallel to web.

• The load carrying capacity of encased column should not exceed 2

times the load permitted on an uncased column.

• The minimum width of solid casing is bo

+ 100 mm, where bo

is the width

of steel flange of column in mm.

• The radius of gyration for encased column (about YY-axis) is given by](https://image.slidesharecdn.com/iii-design-of-steel-structures-unit-2-210523063202/85/Iii-design-of-steel-structures-unit-2-39-320.jpg)