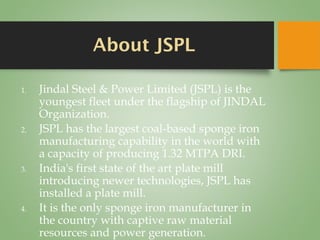

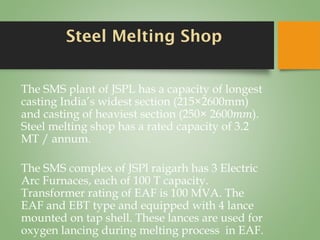

The document provides information about the steel melting shop (SMS) at Jindal Steel and Power Limited (JSPL) Raigarh plant. The key points are:

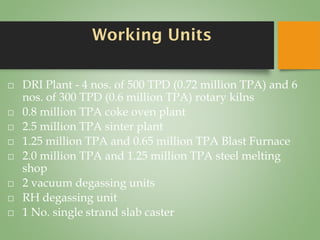

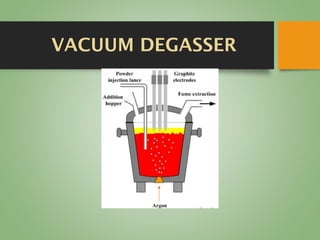

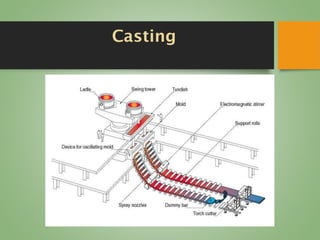

1. The SMS has a capacity of 3.2 million tonnes per year and includes 3 electric arc furnaces, a ladle refining furnace, and vacuum degassing units.

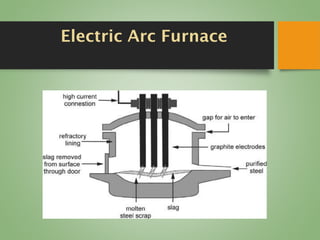

2. The melting process involves charging raw materials into the electric arc furnaces and applying electrical energy to melt them. Secondary refining then occurs in the ladle refining furnace and vacuum degassing units.

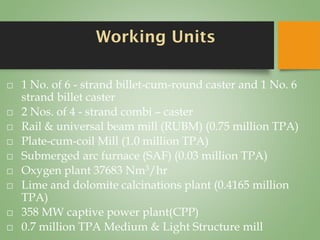

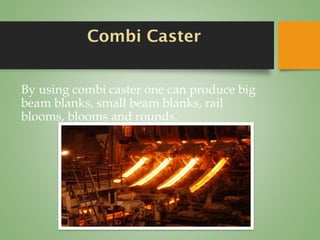

3. Final products are continuously cast into blooms, billets, rounds and other sections using various casters like the