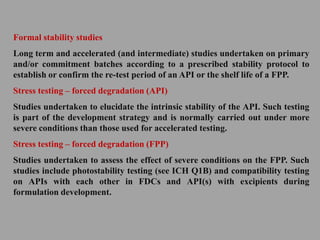

The document discusses stability testing of pharmaceutical products. It defines the purpose of stability testing as providing evidence of how a product's quality varies over time under the influence of factors like temperature, humidity and light. There are two main types of stability studies: stability studies and accelerated stability studies. Stability studies involve testing products under various storage conditions like long term, intermediate and accelerated conditions over minimum time periods to establish a product's shelf life.