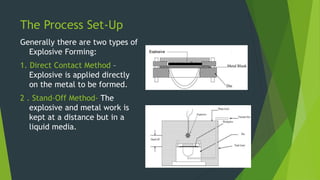

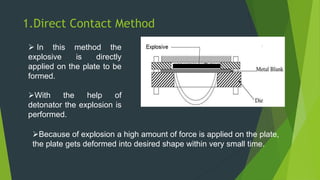

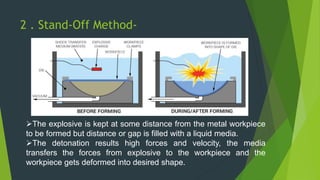

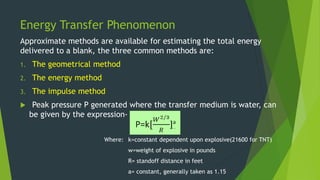

This document summarizes explosive forming, a manufacturing technique that uses controlled explosions to deform metal parts. It describes how explosives are either detonated directly on the metal or underwater with the metal placed nearby. The process can form parts from a few inches to 15 feet. Different types of explosives are used, with high explosives like dynamite and TNT producing high pressures over short times to form the metal. The document outlines the direct contact and stand-off methods, energy transfer phenomena, advantages of lower costs and more versatile shapes compared to conventional forming, and disadvantages of special expertise and safety concerns.