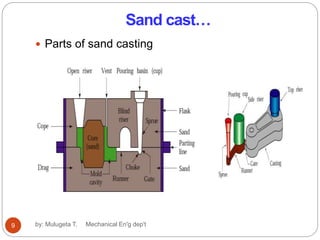

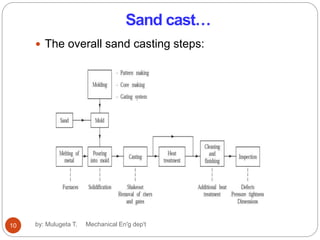

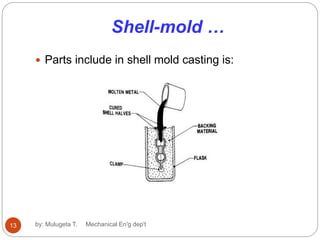

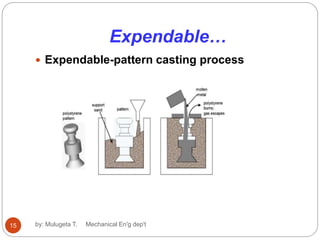

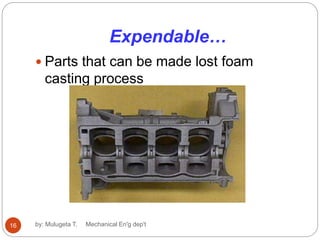

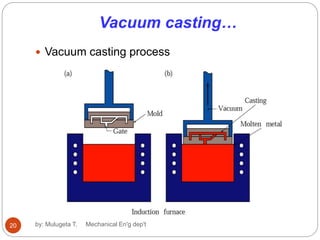

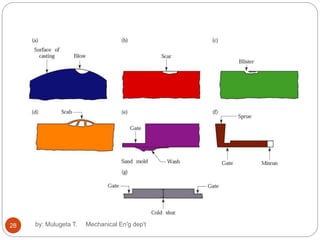

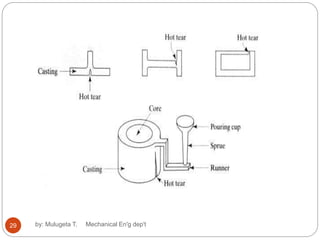

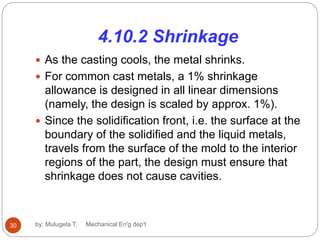

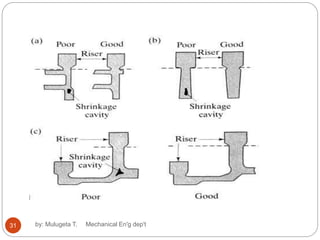

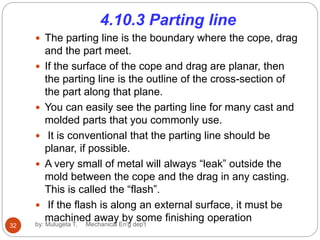

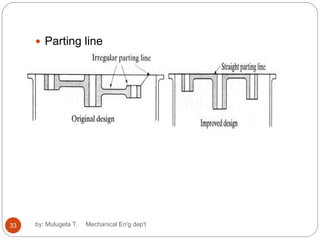

This document provides an overview of various casting processes and considerations for casting design and quality. It describes common casting methods like sand casting, shell mold casting, expendable pattern casting, investment casting, vacuum casting, die casting, and centrifugal casting. Key factors that affect casting quality are discussed, such as allowing for metal shrinkage during solidification, avoiding thin sections and corners prone to defects, and designing the parting line to be planar for easier mold separation. Overall, the document outlines fundamental concepts for casting processes and guidelines for optimizing casting design.