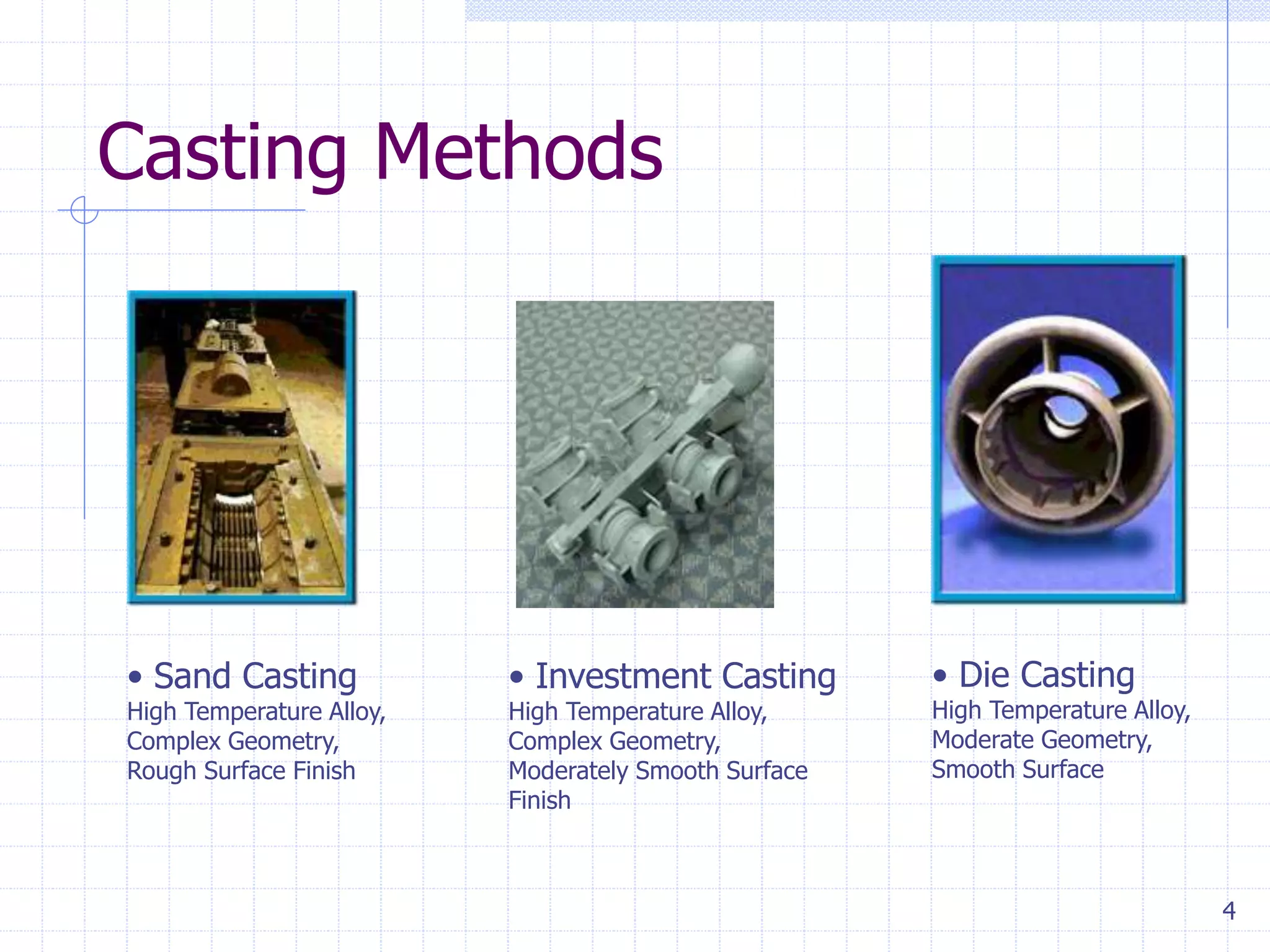

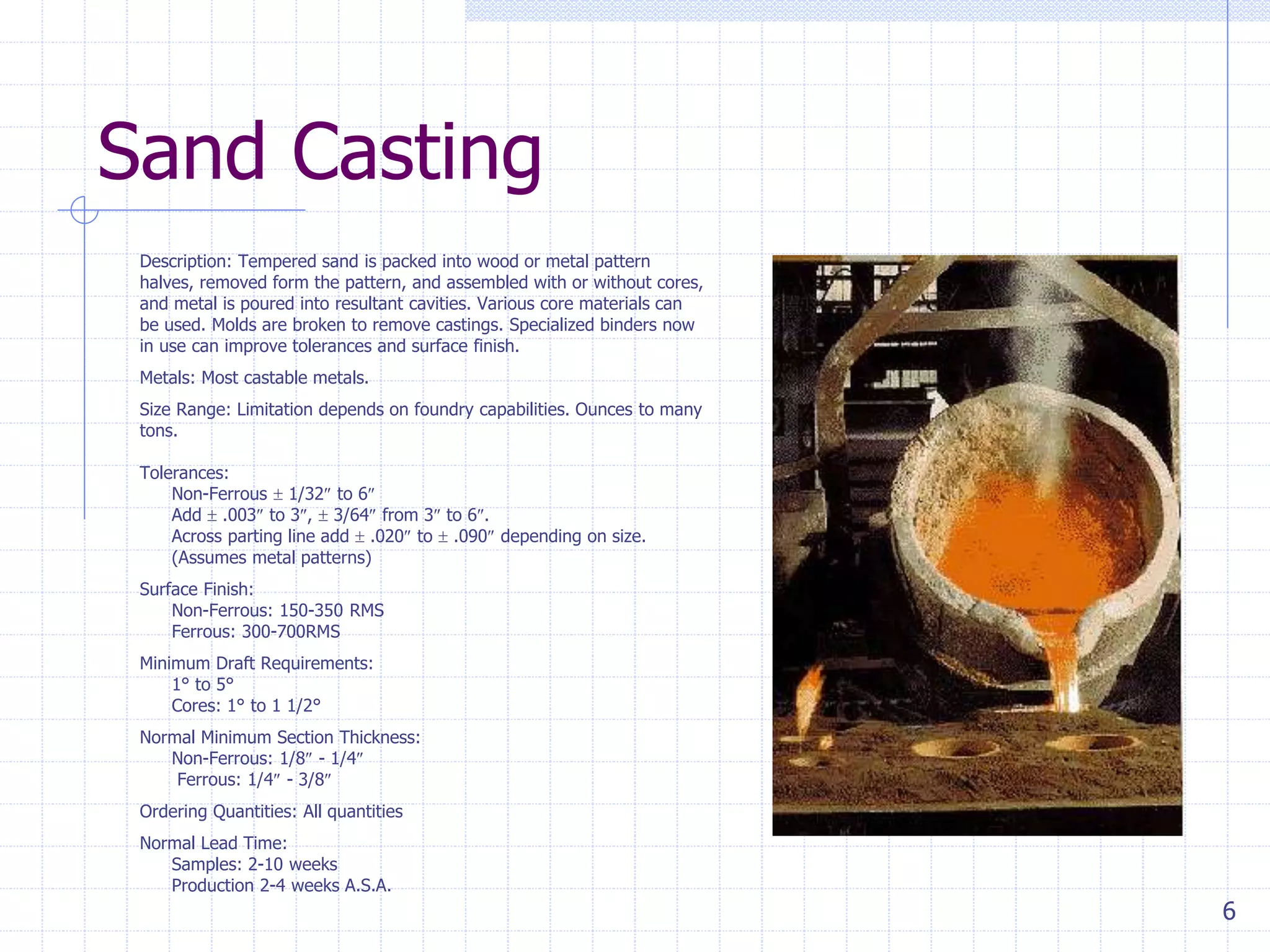

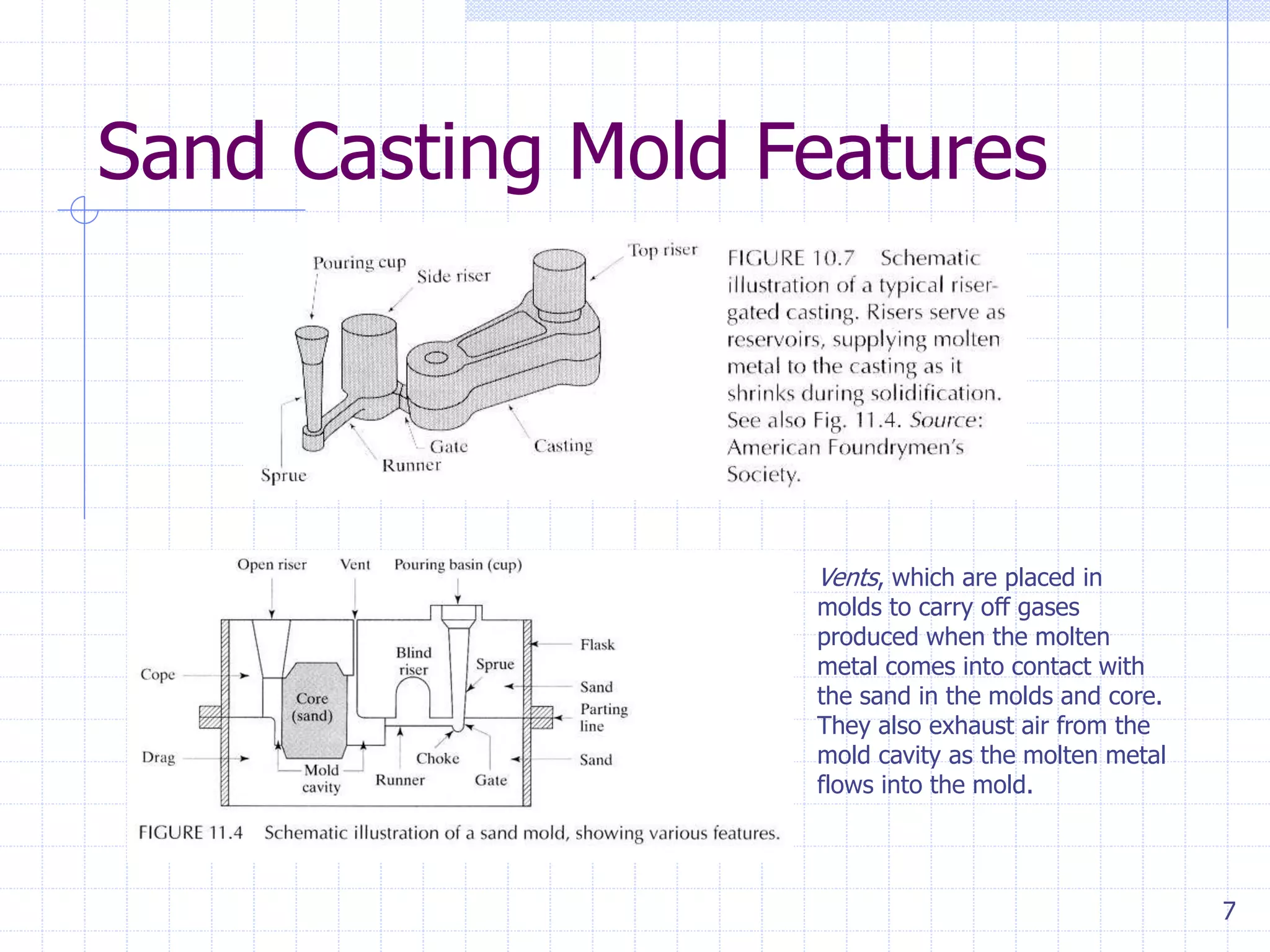

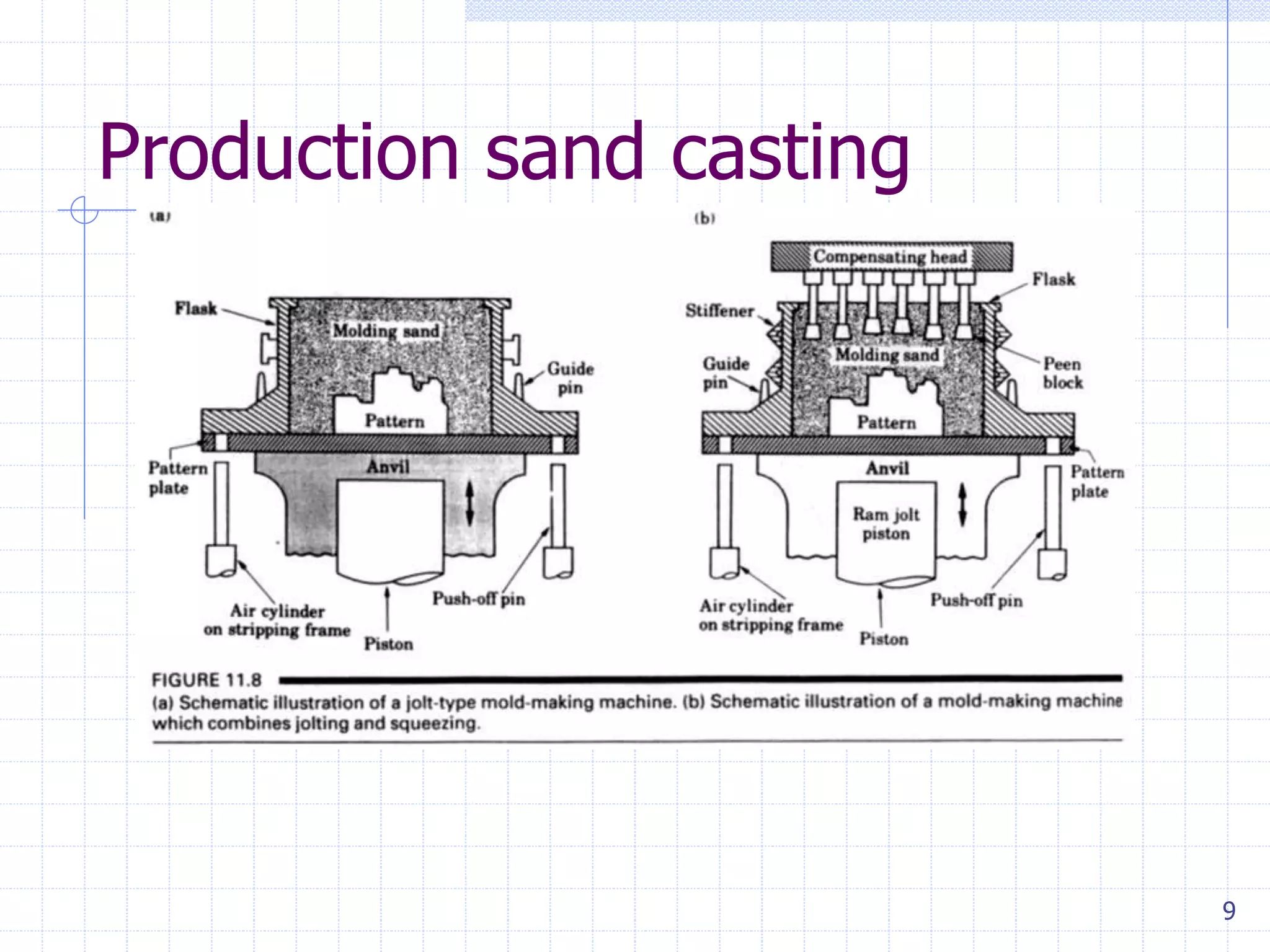

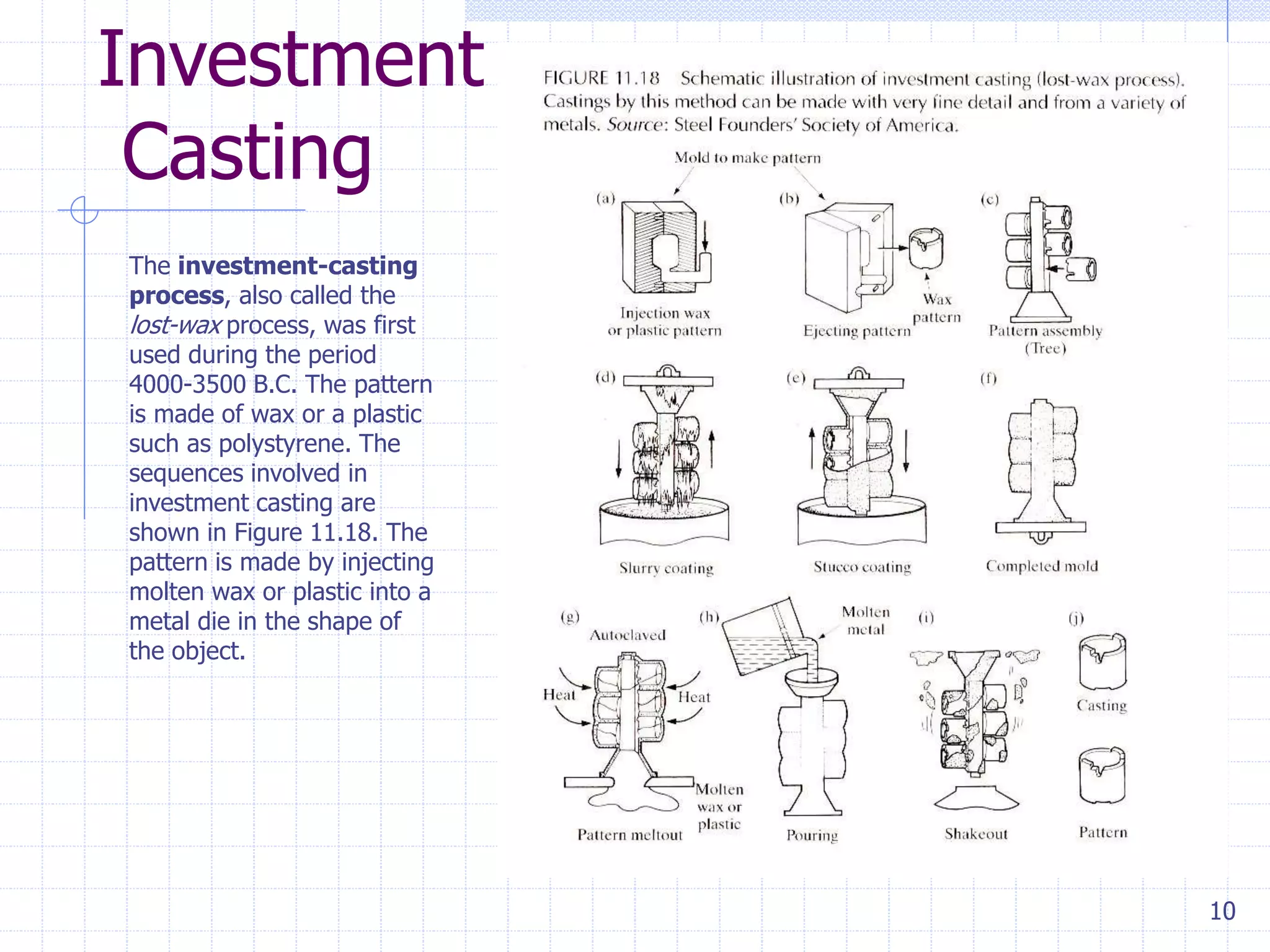

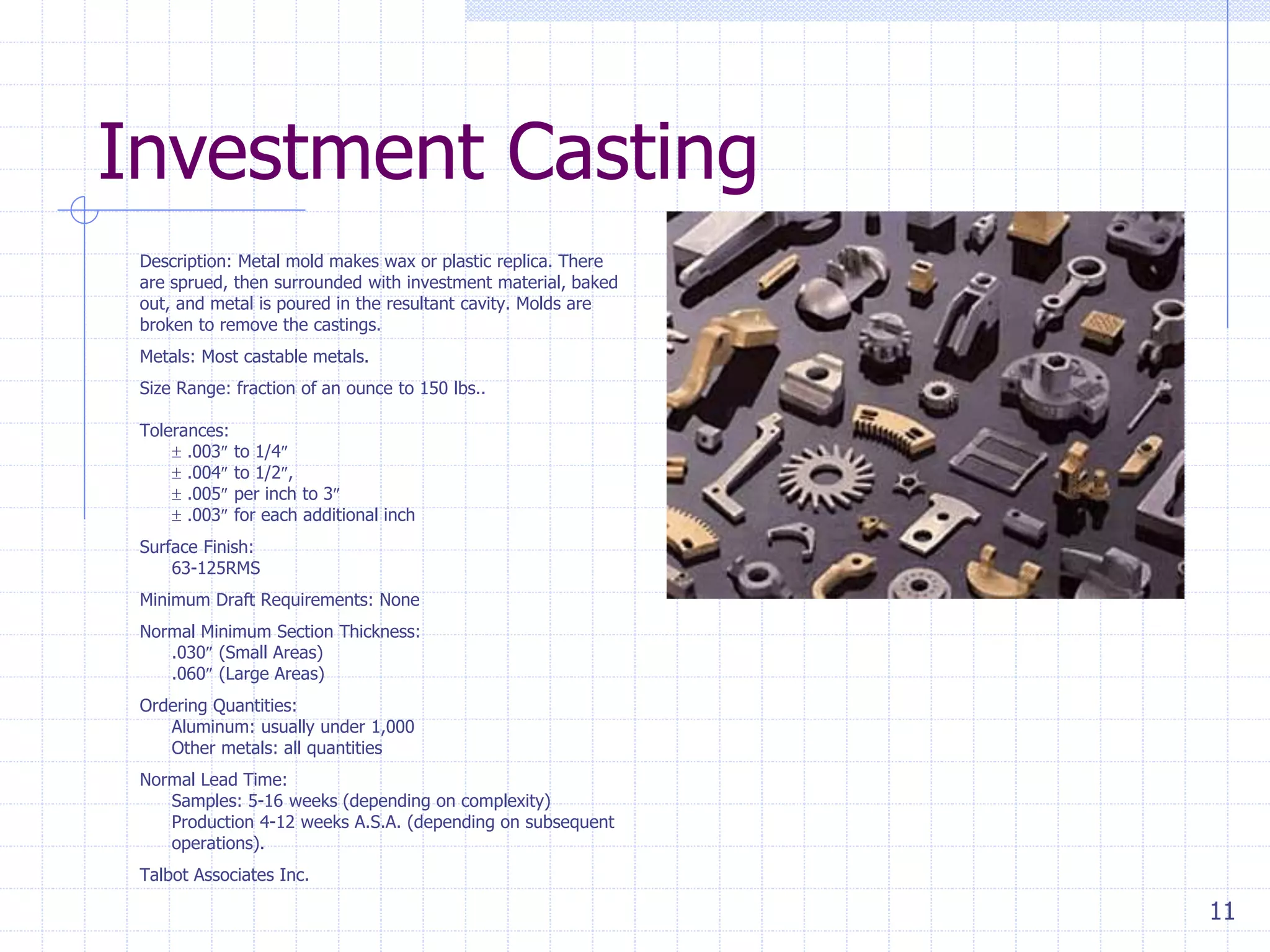

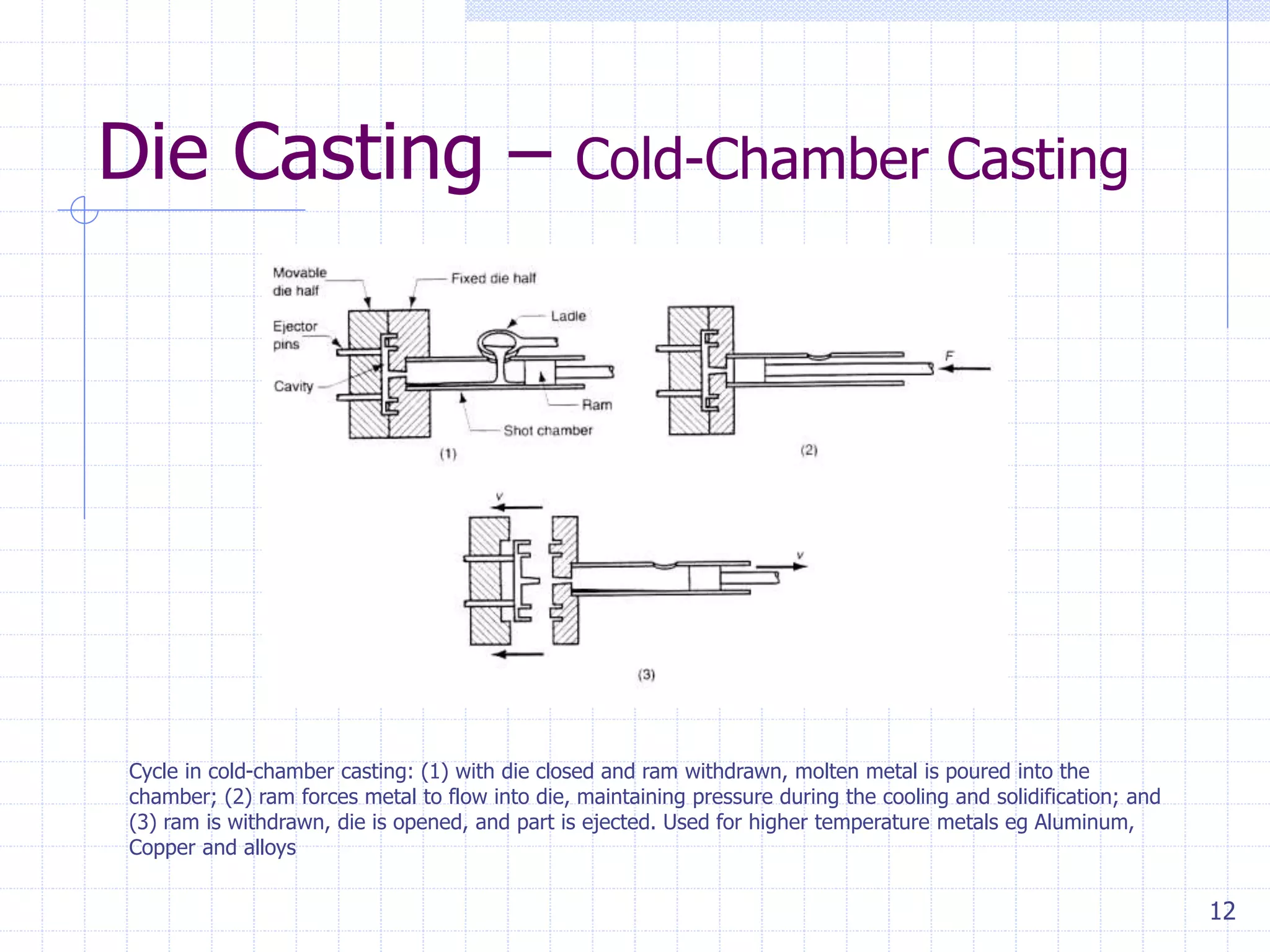

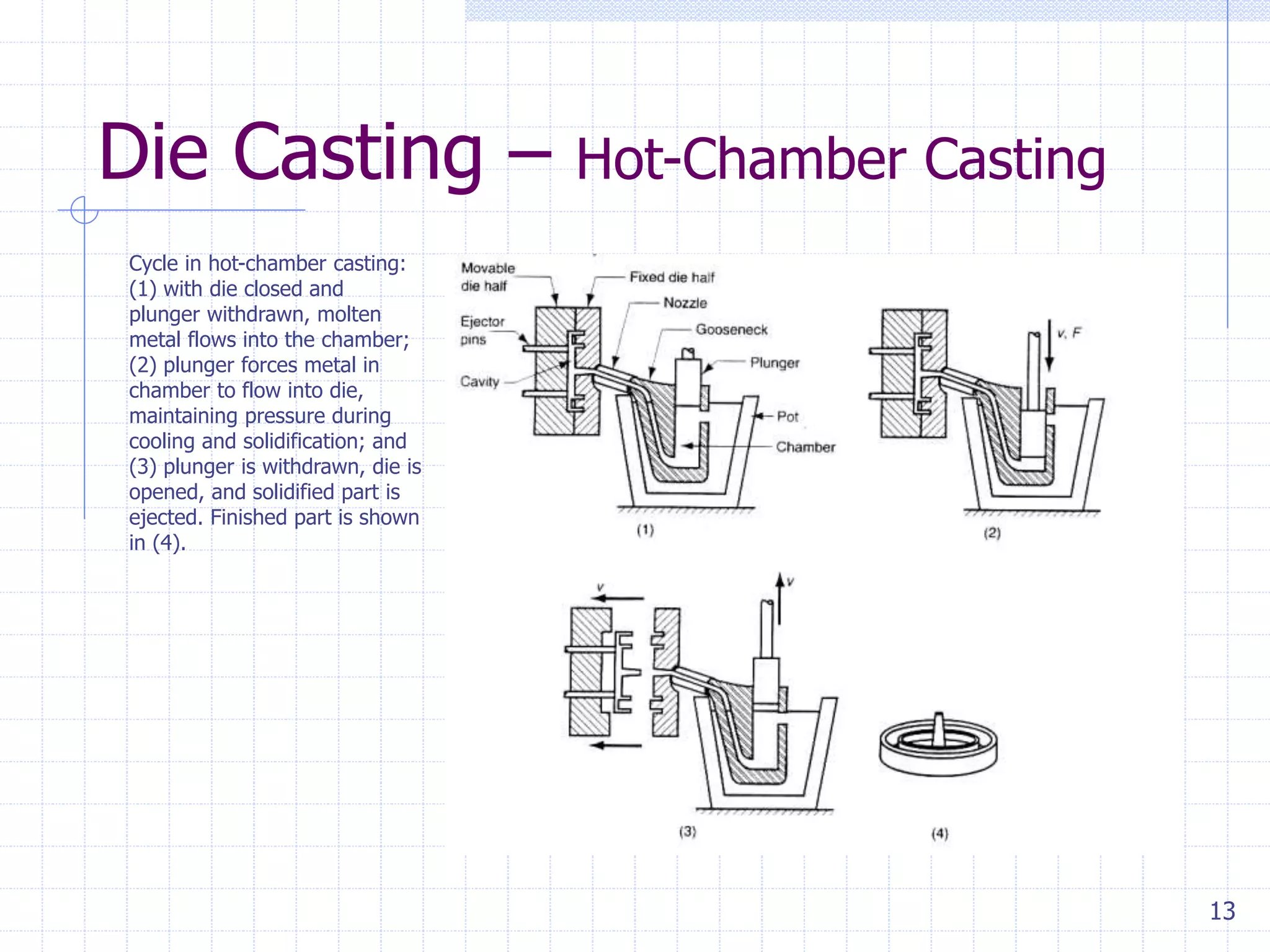

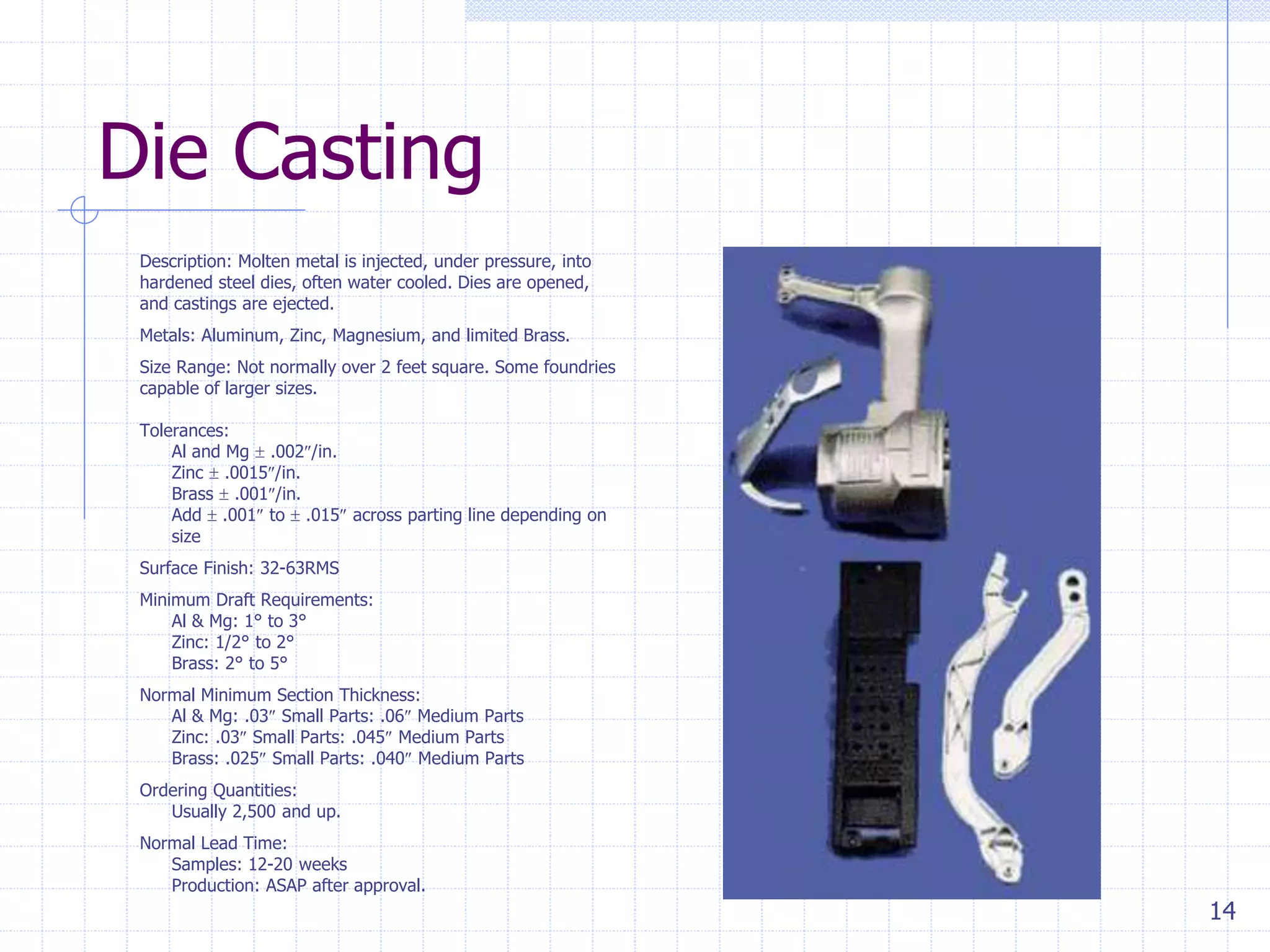

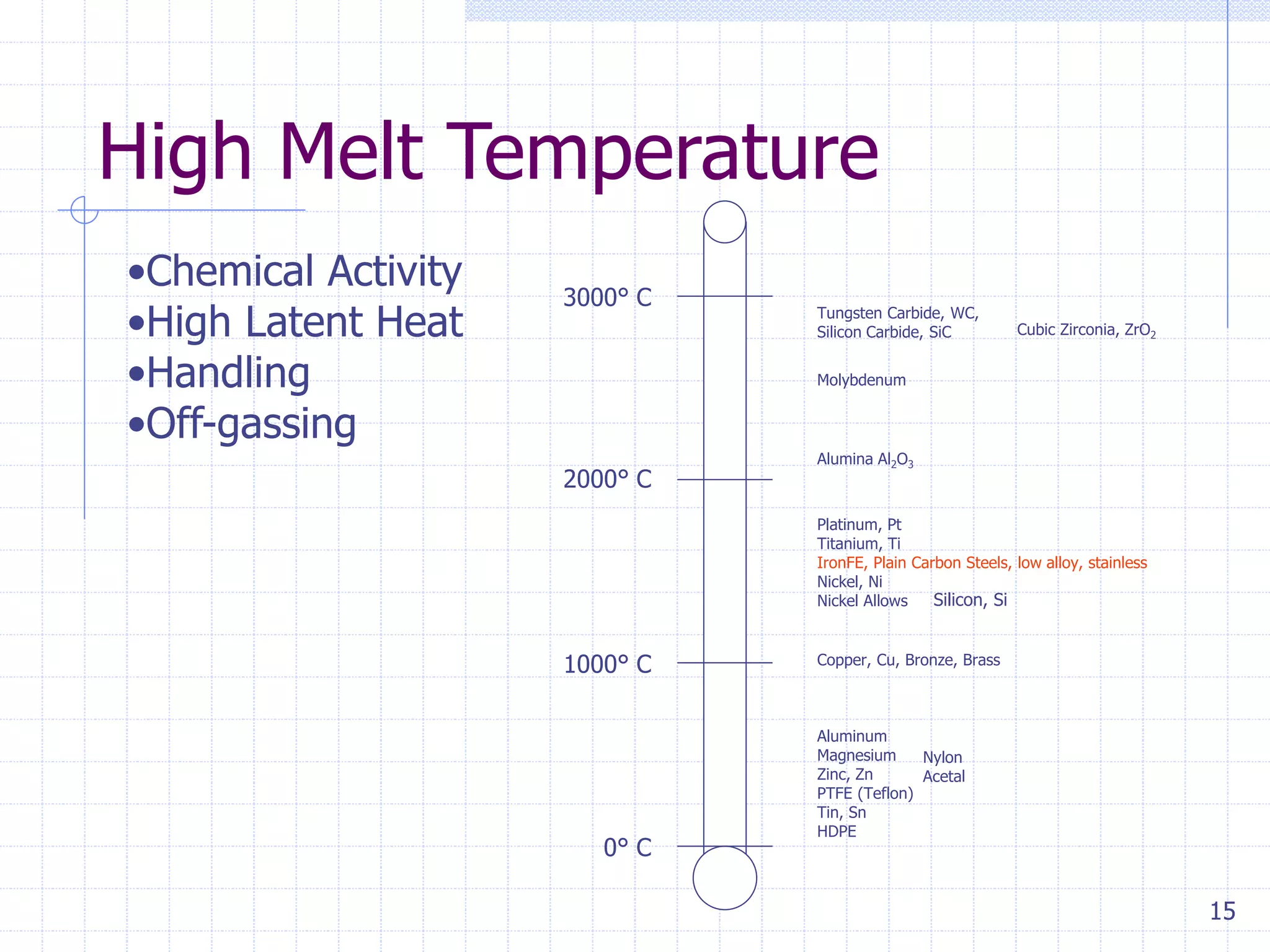

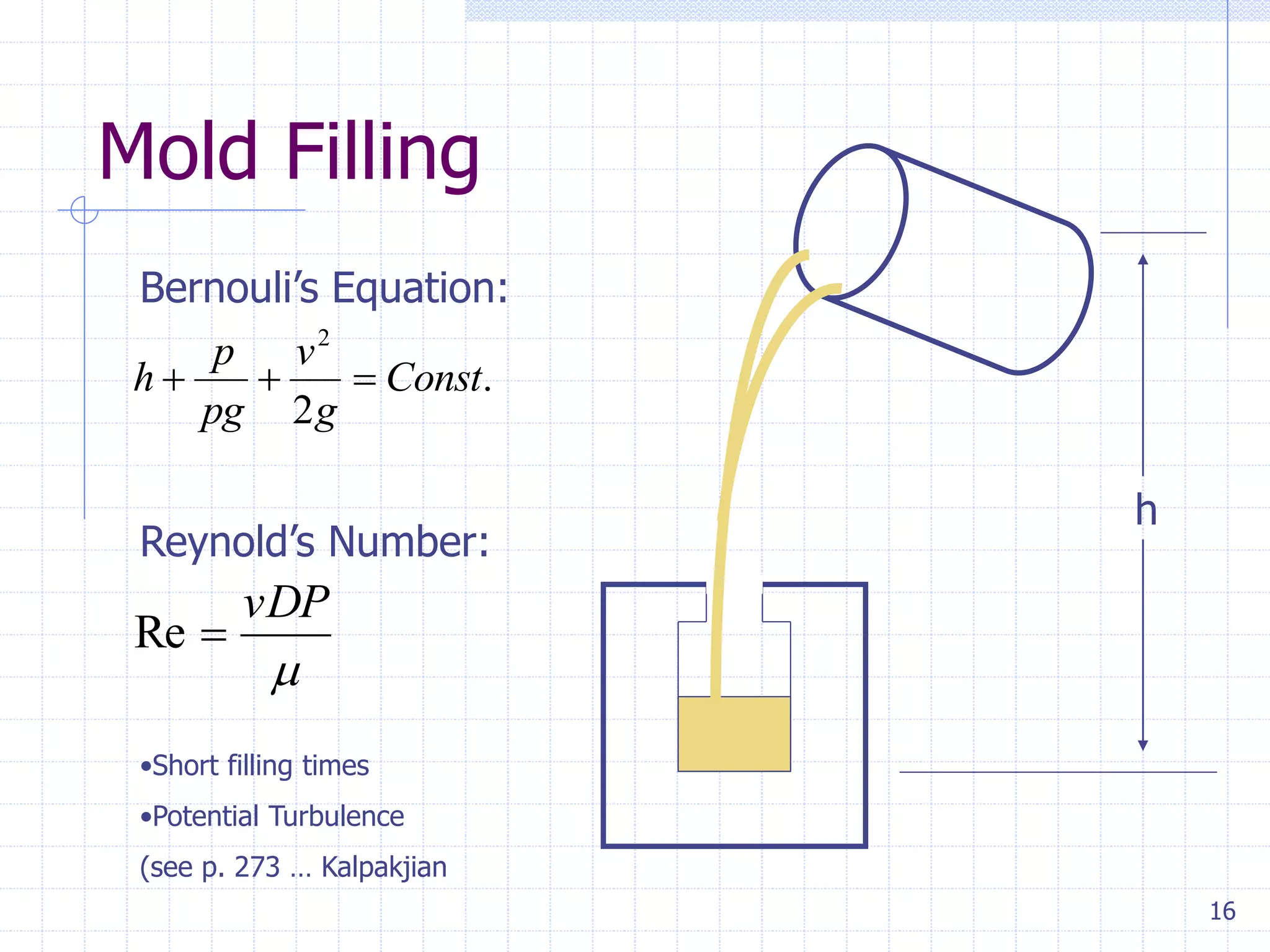

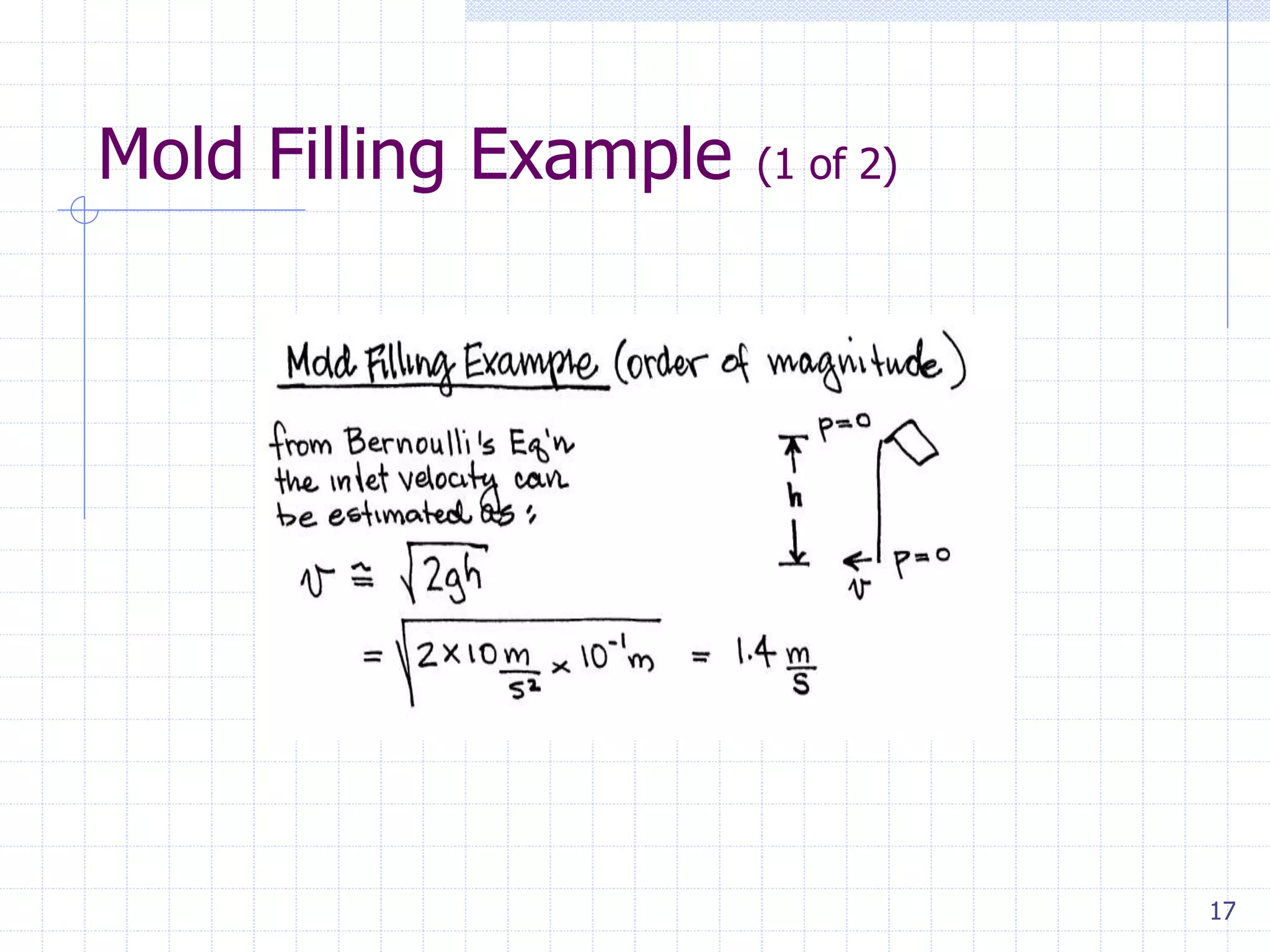

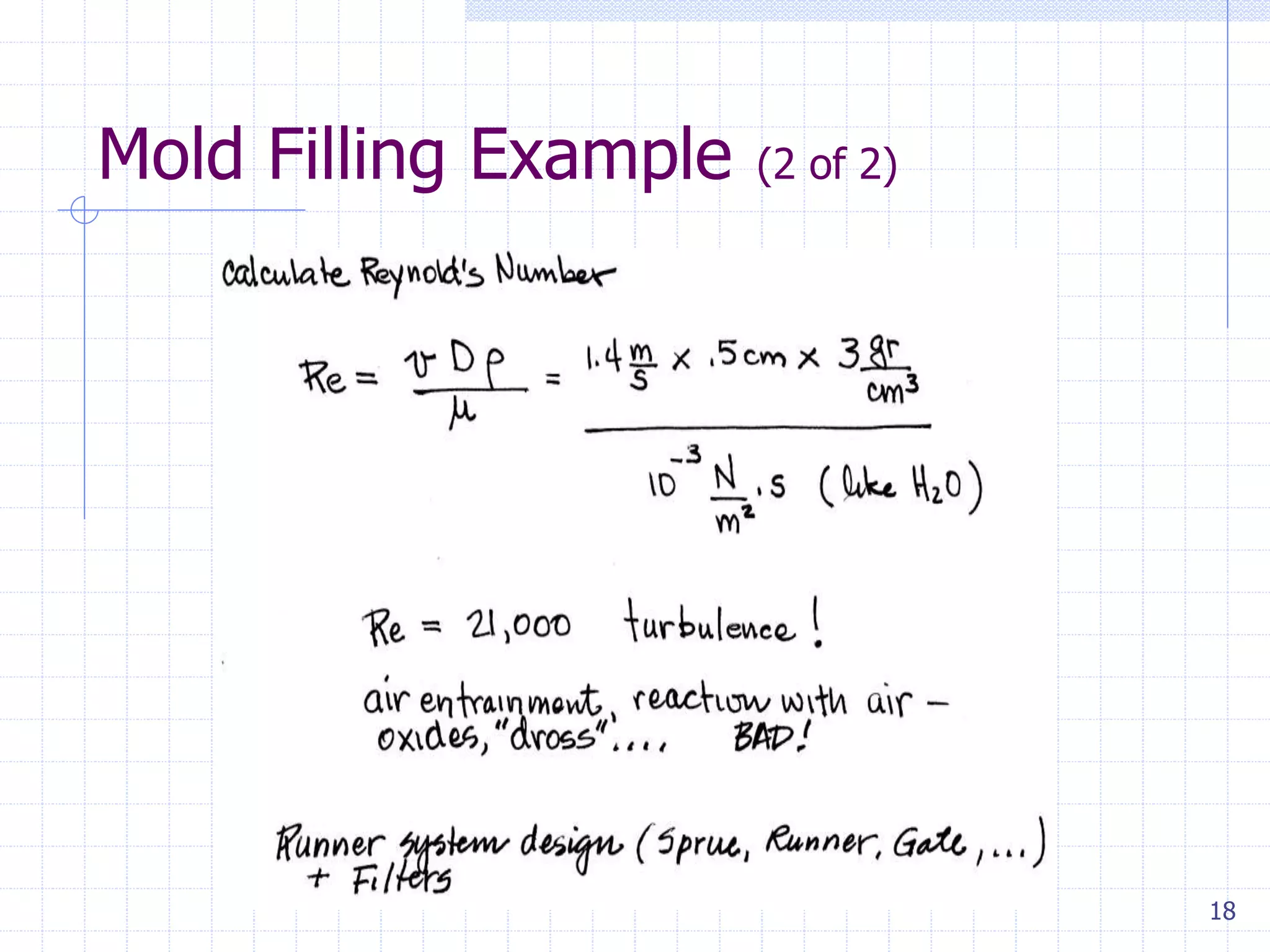

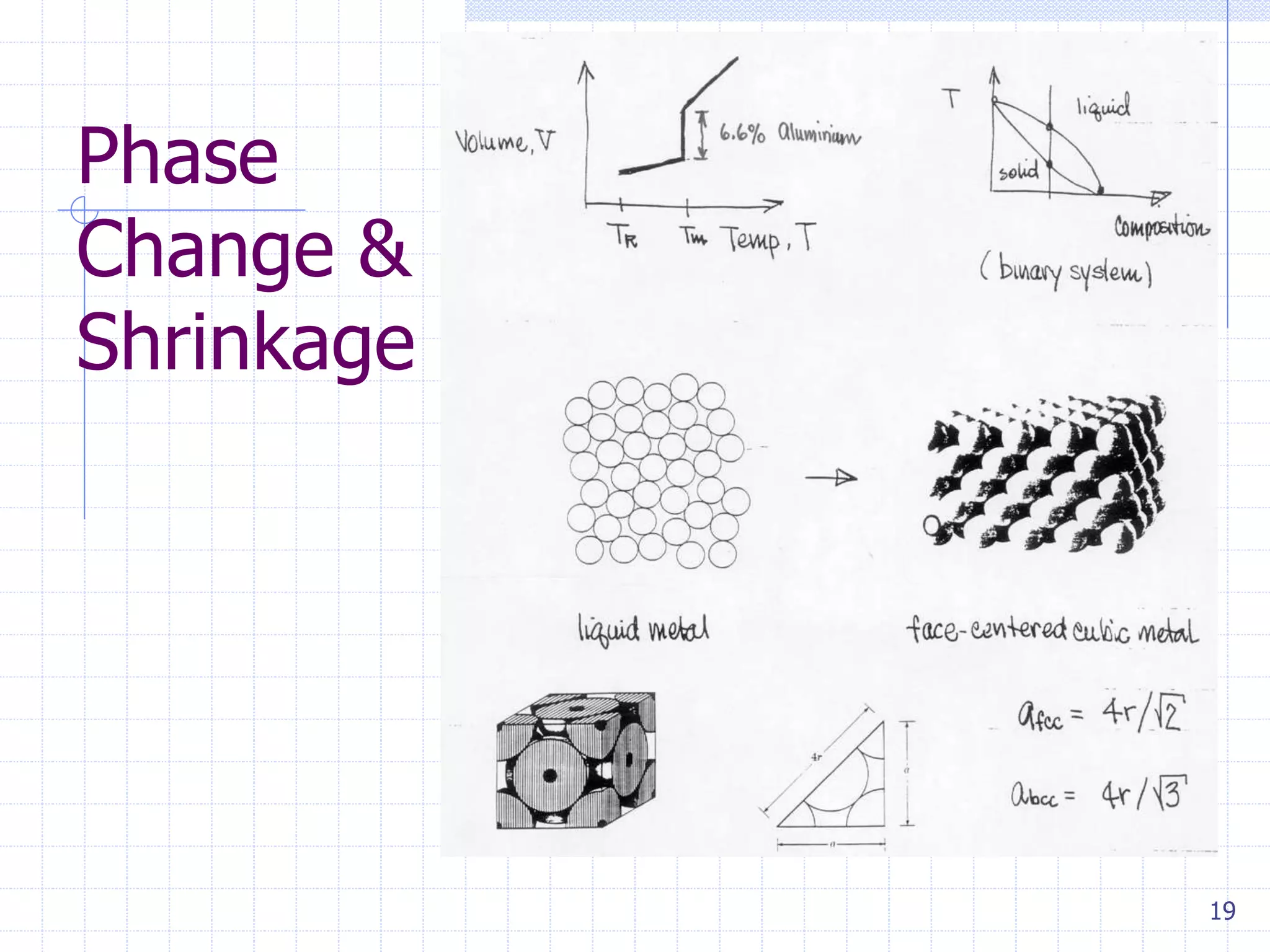

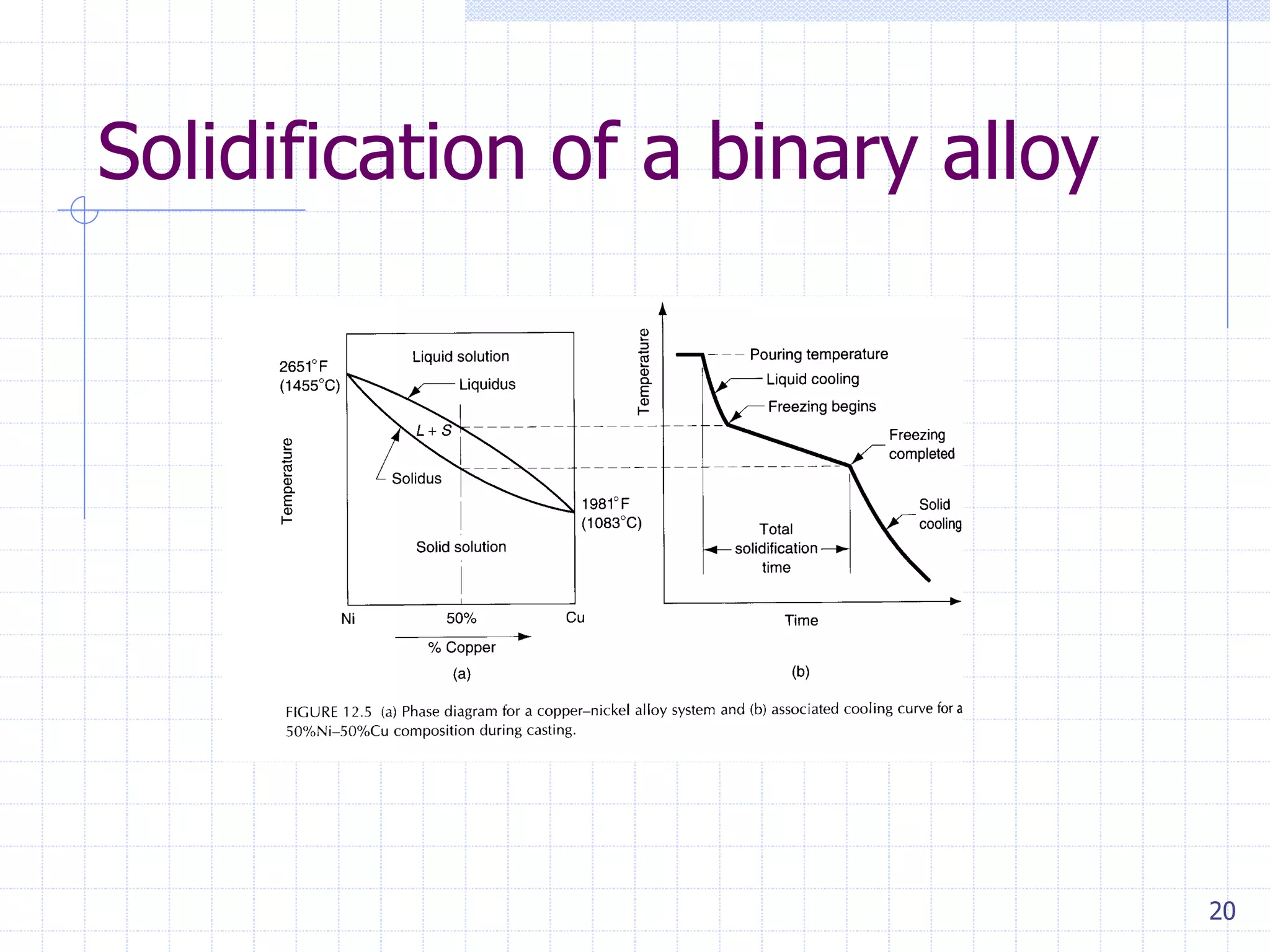

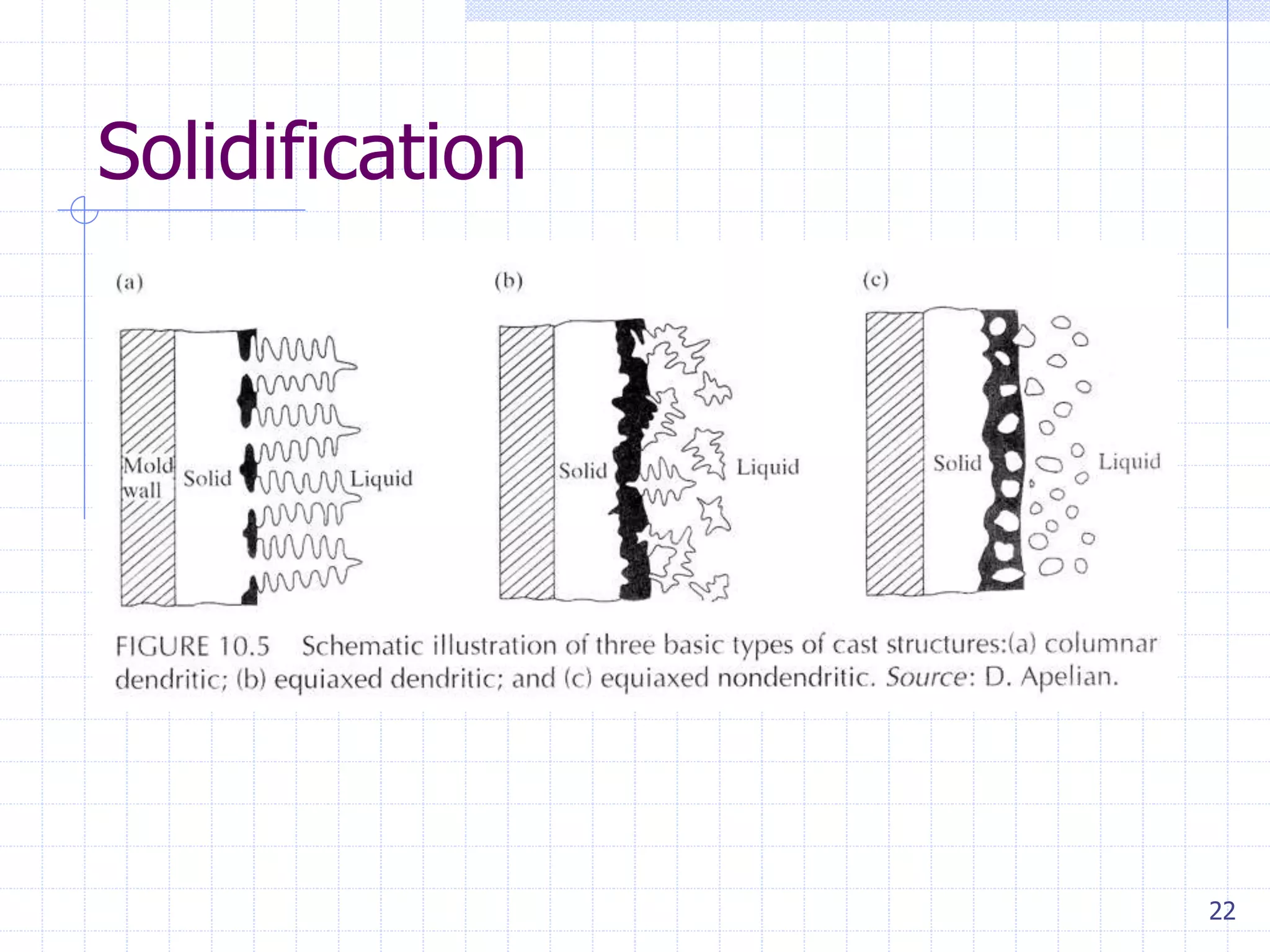

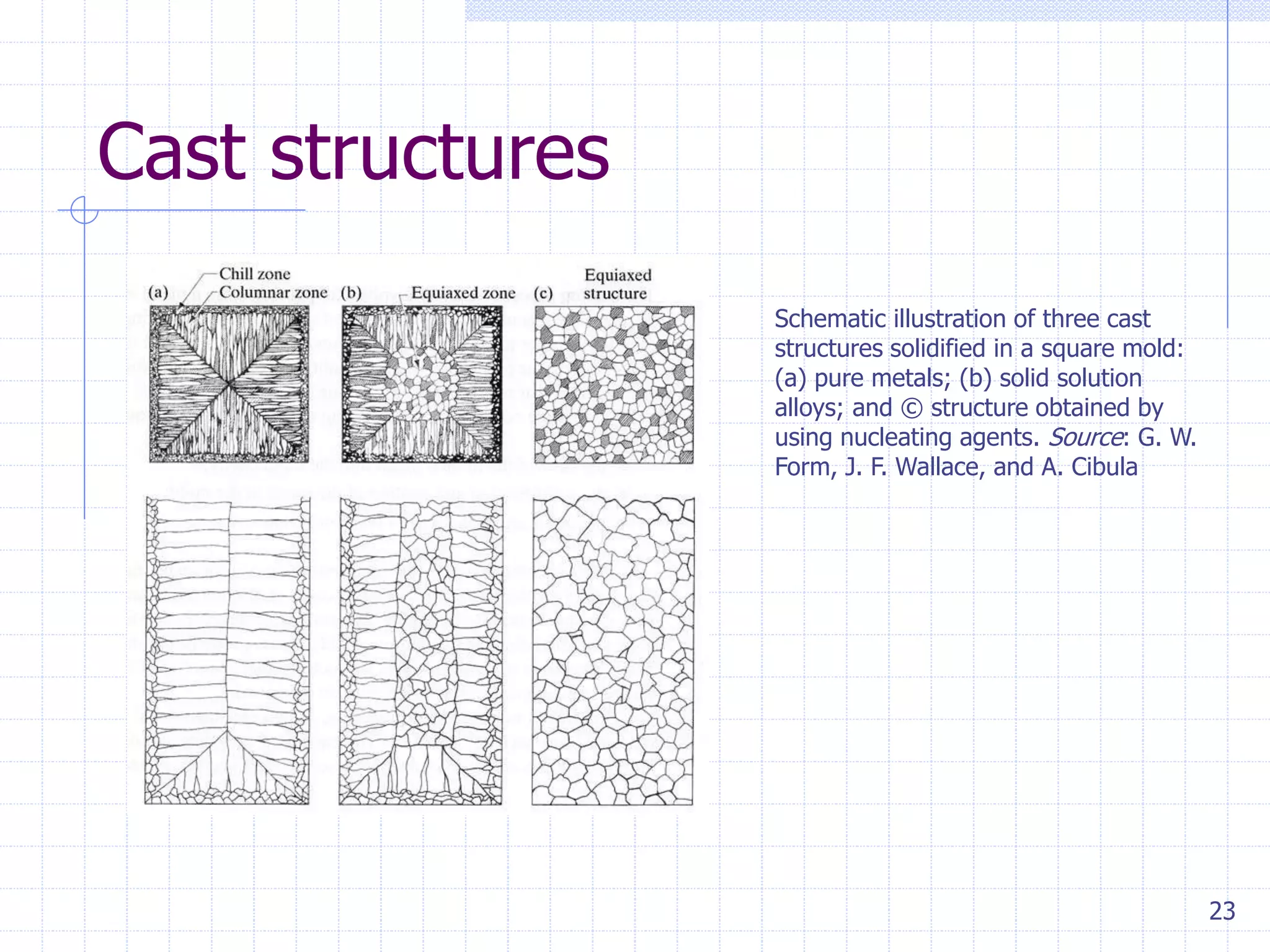

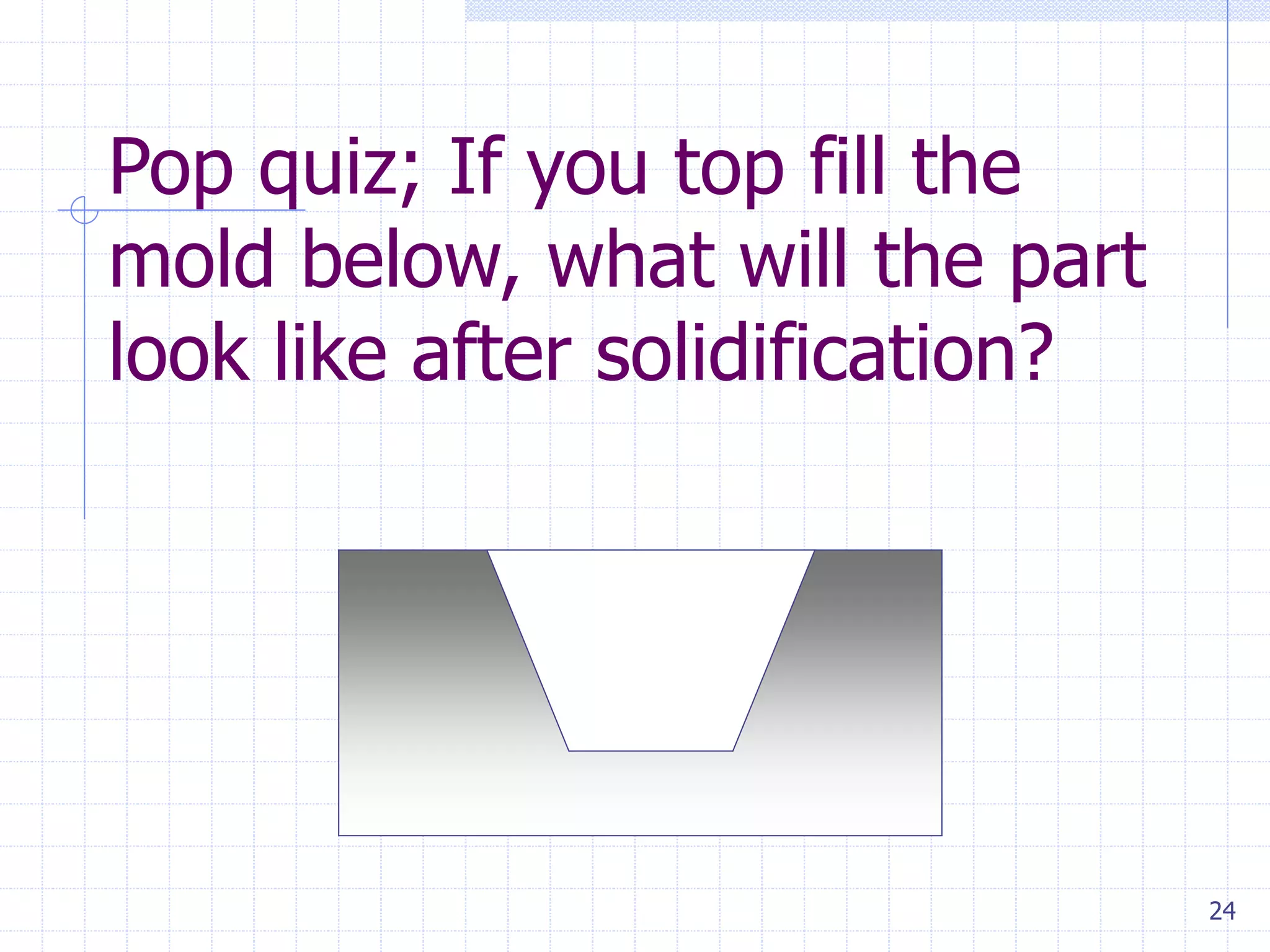

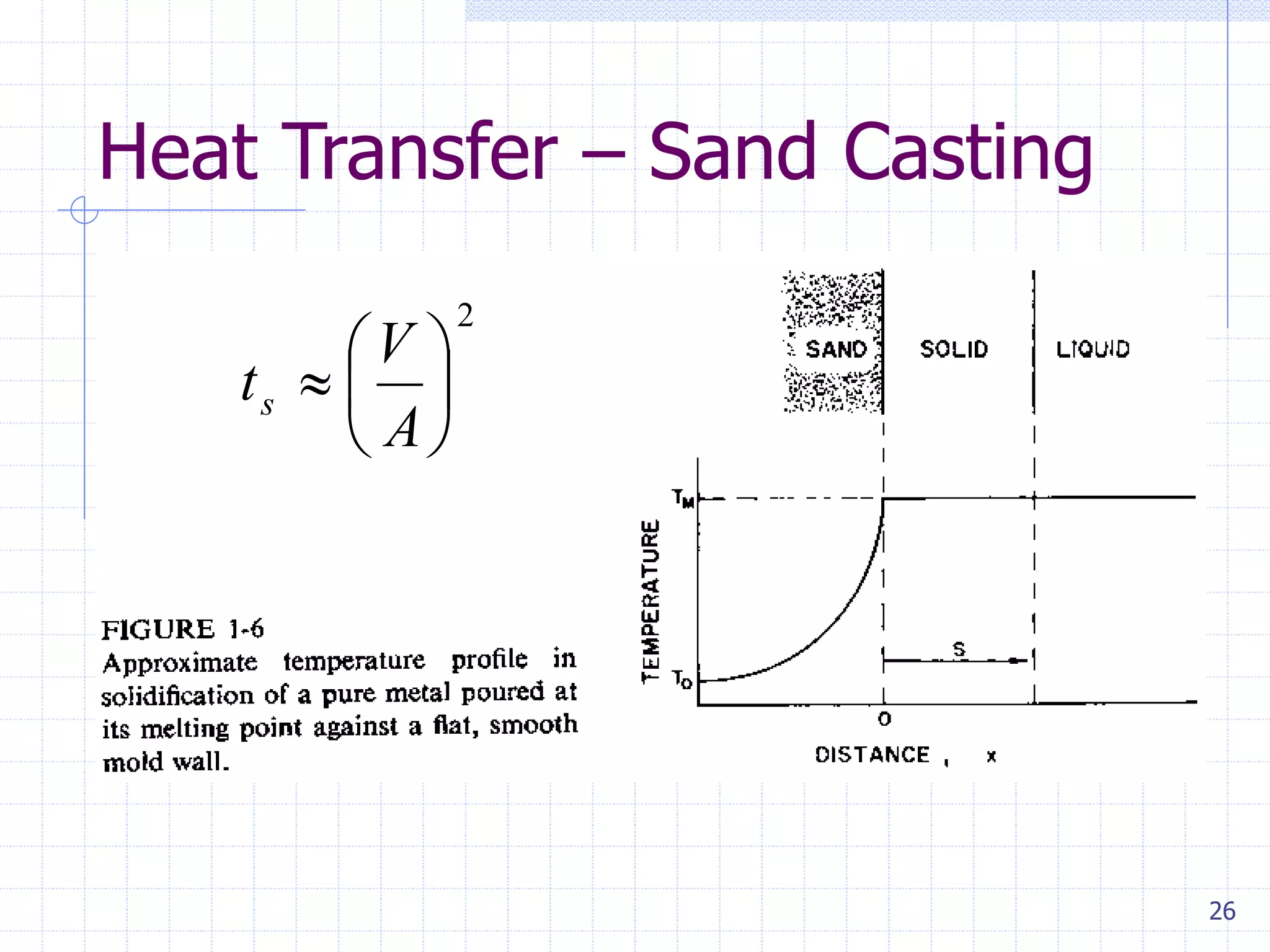

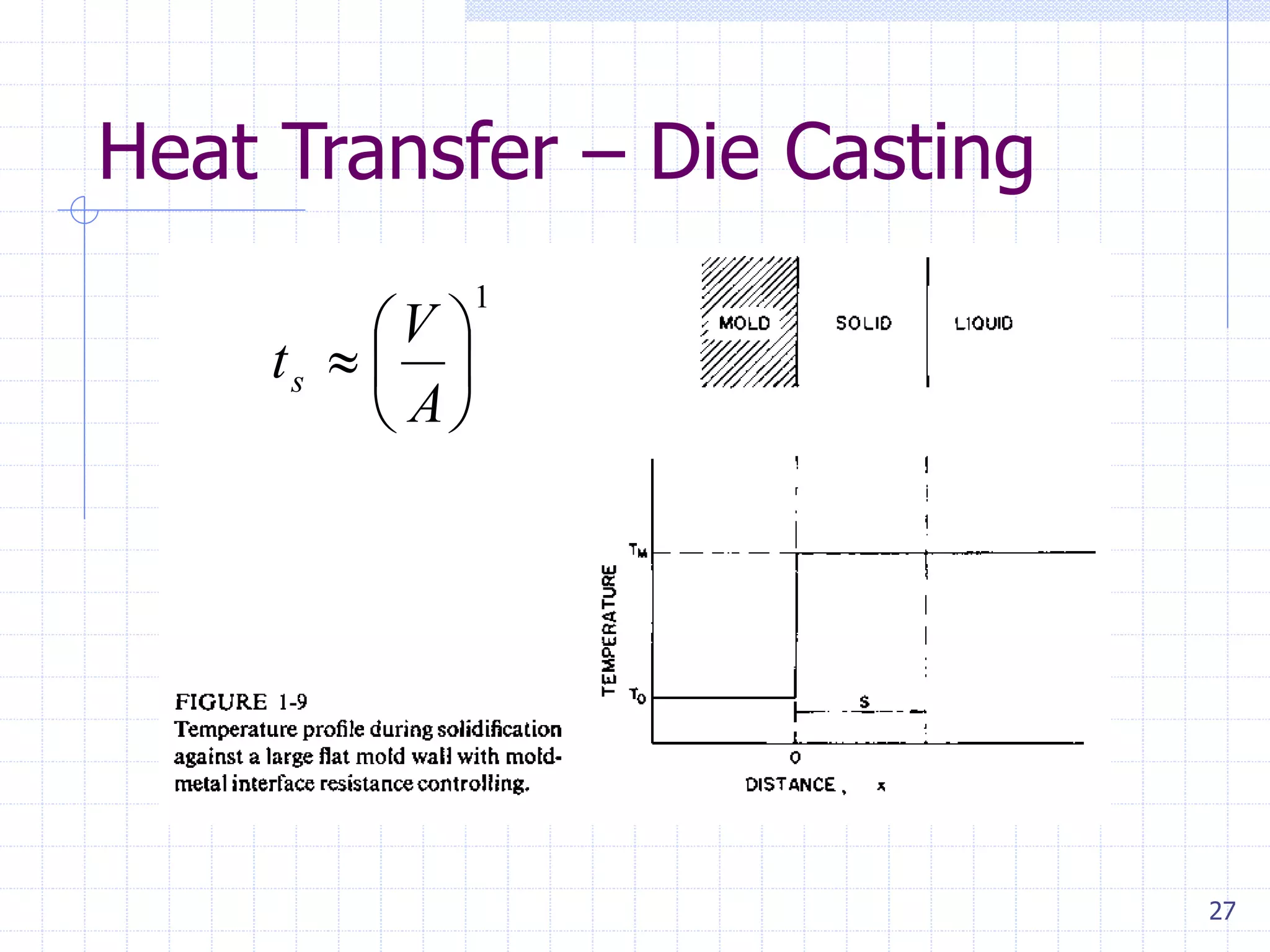

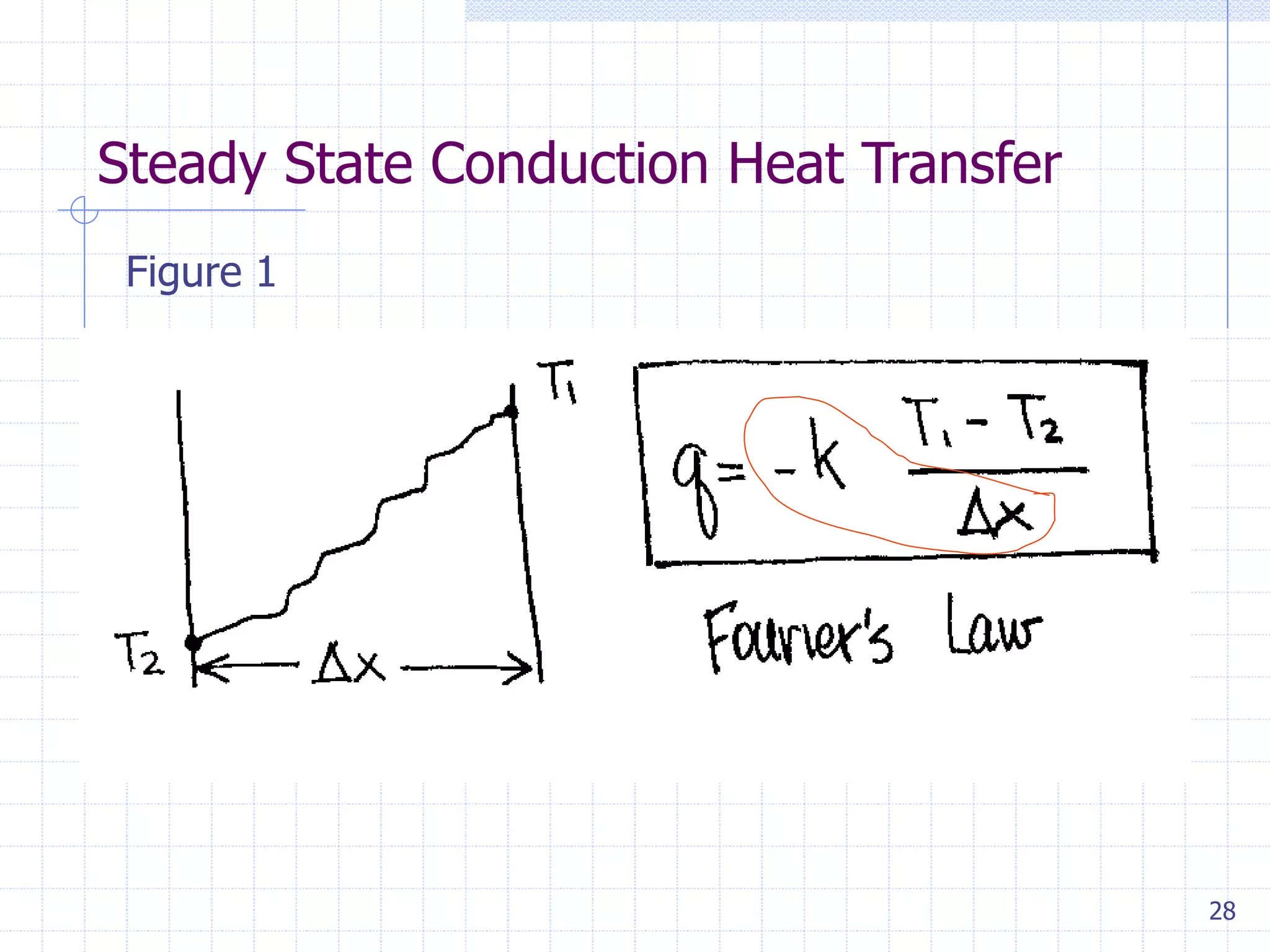

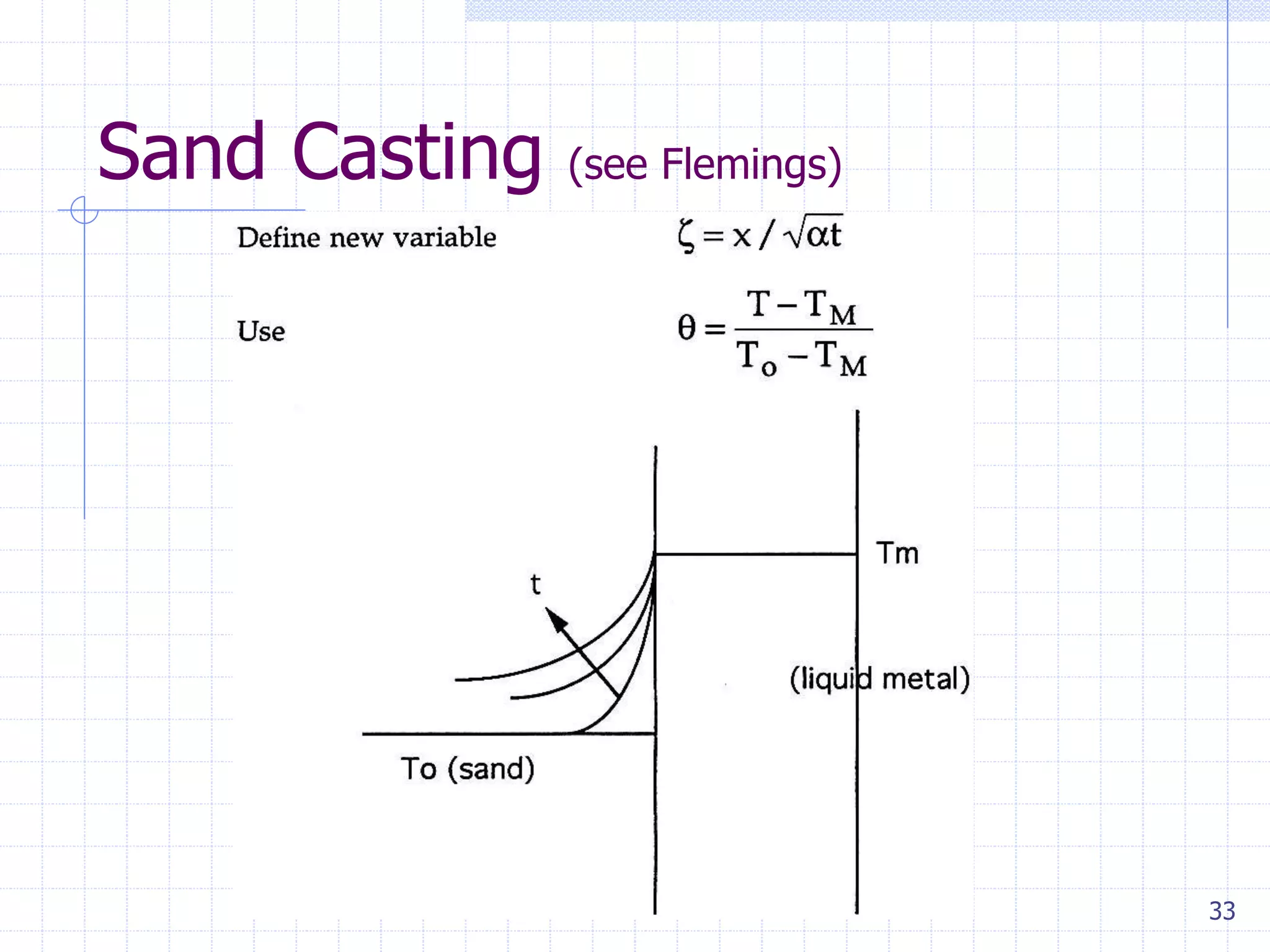

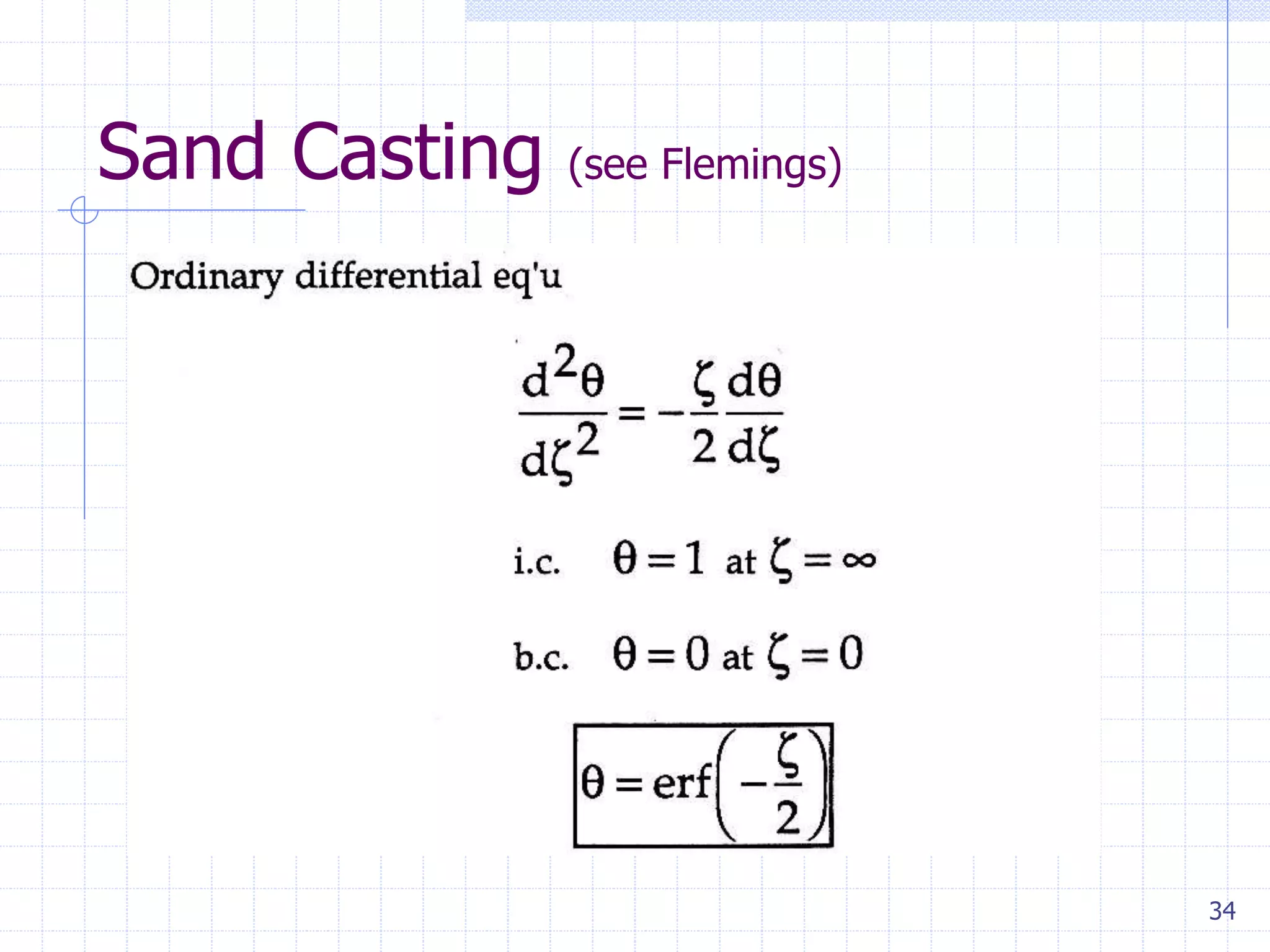

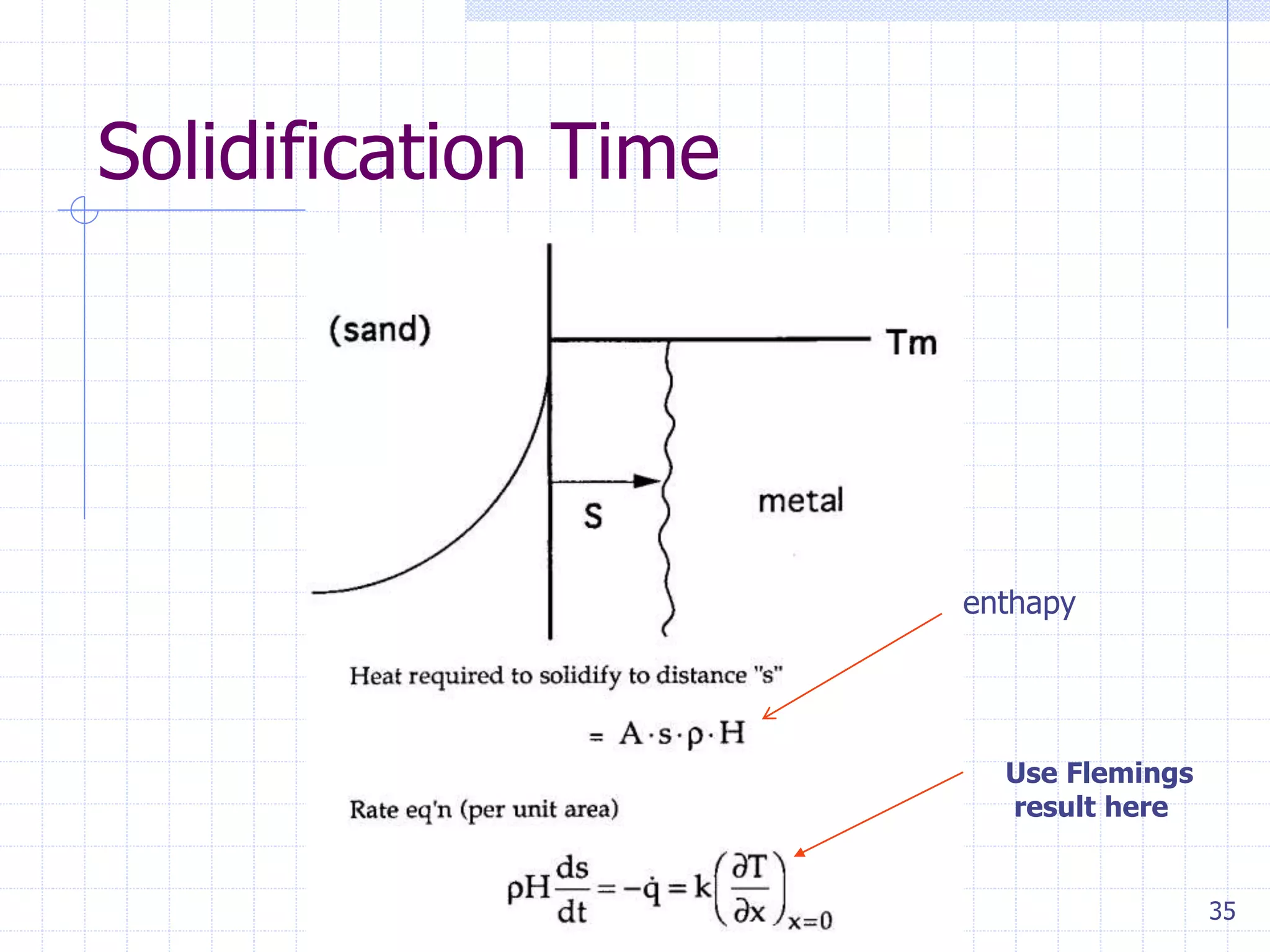

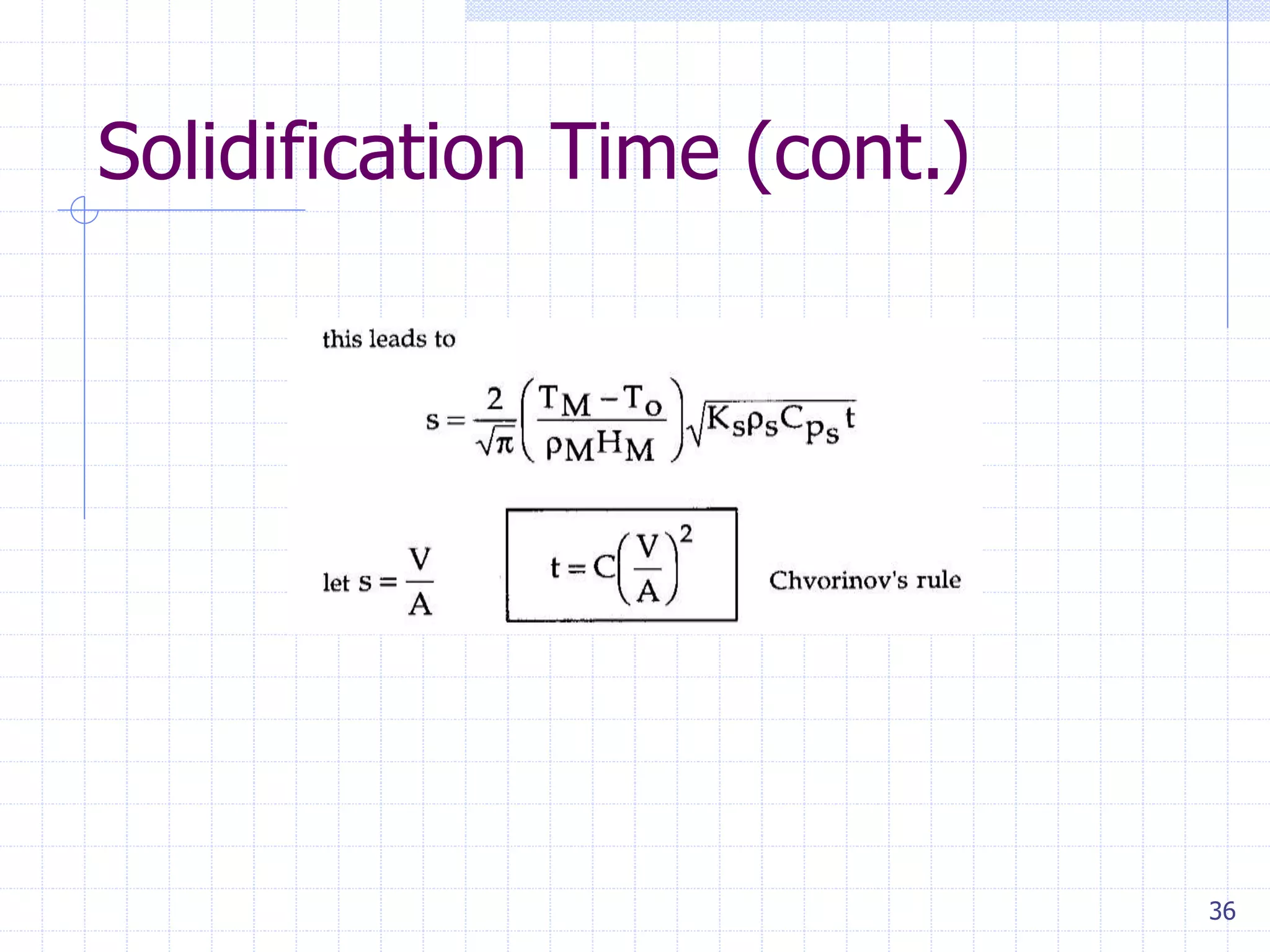

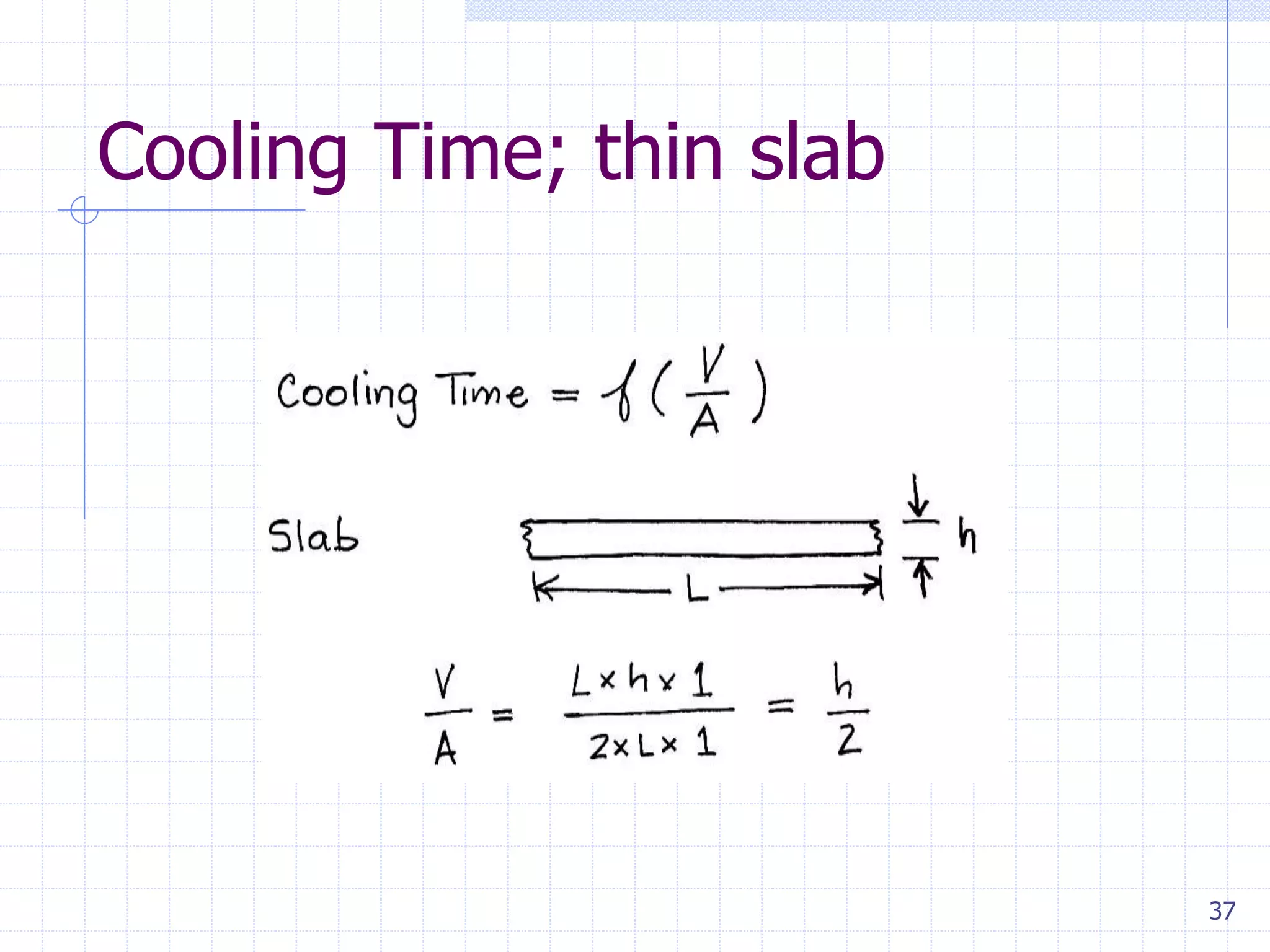

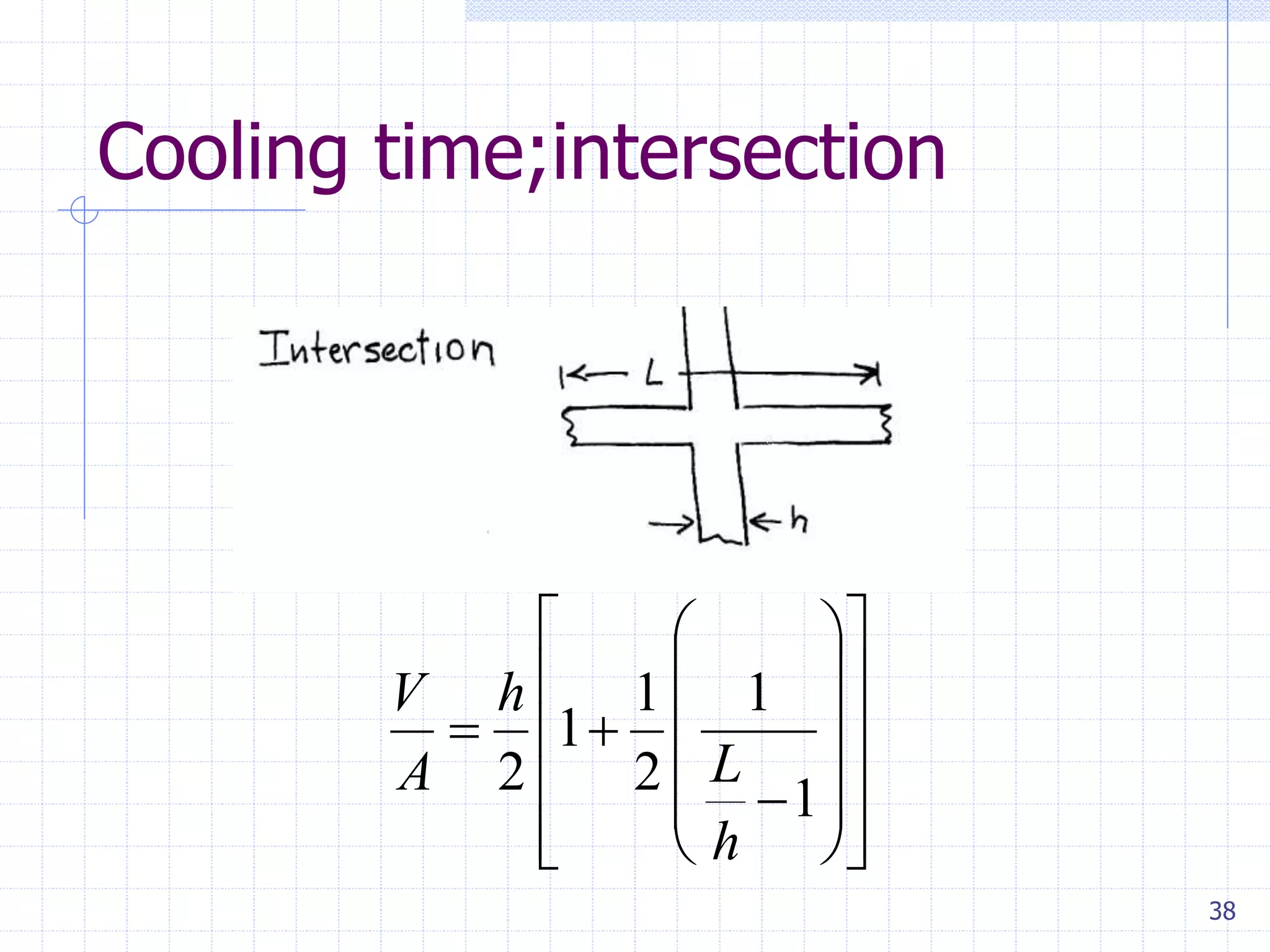

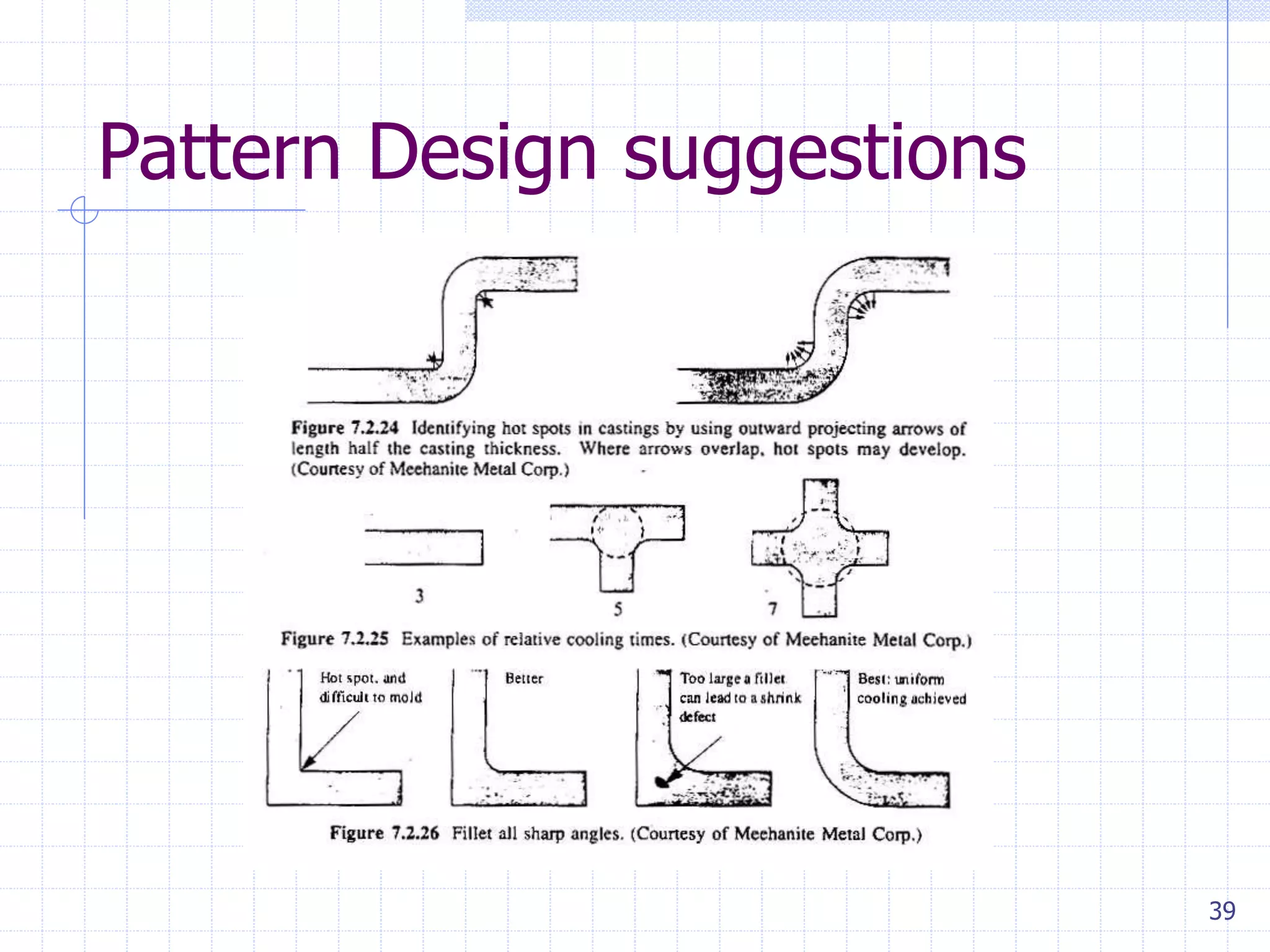

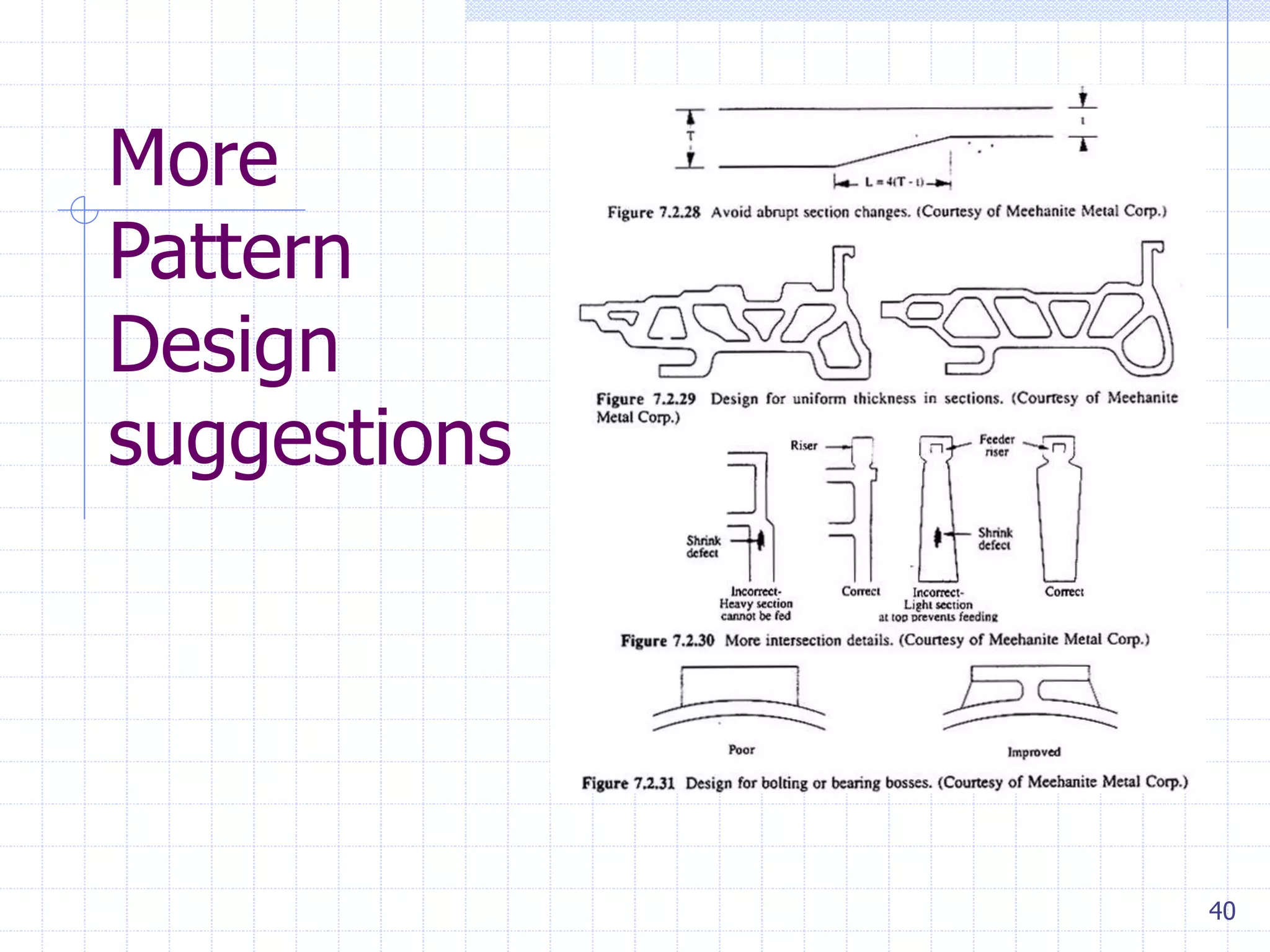

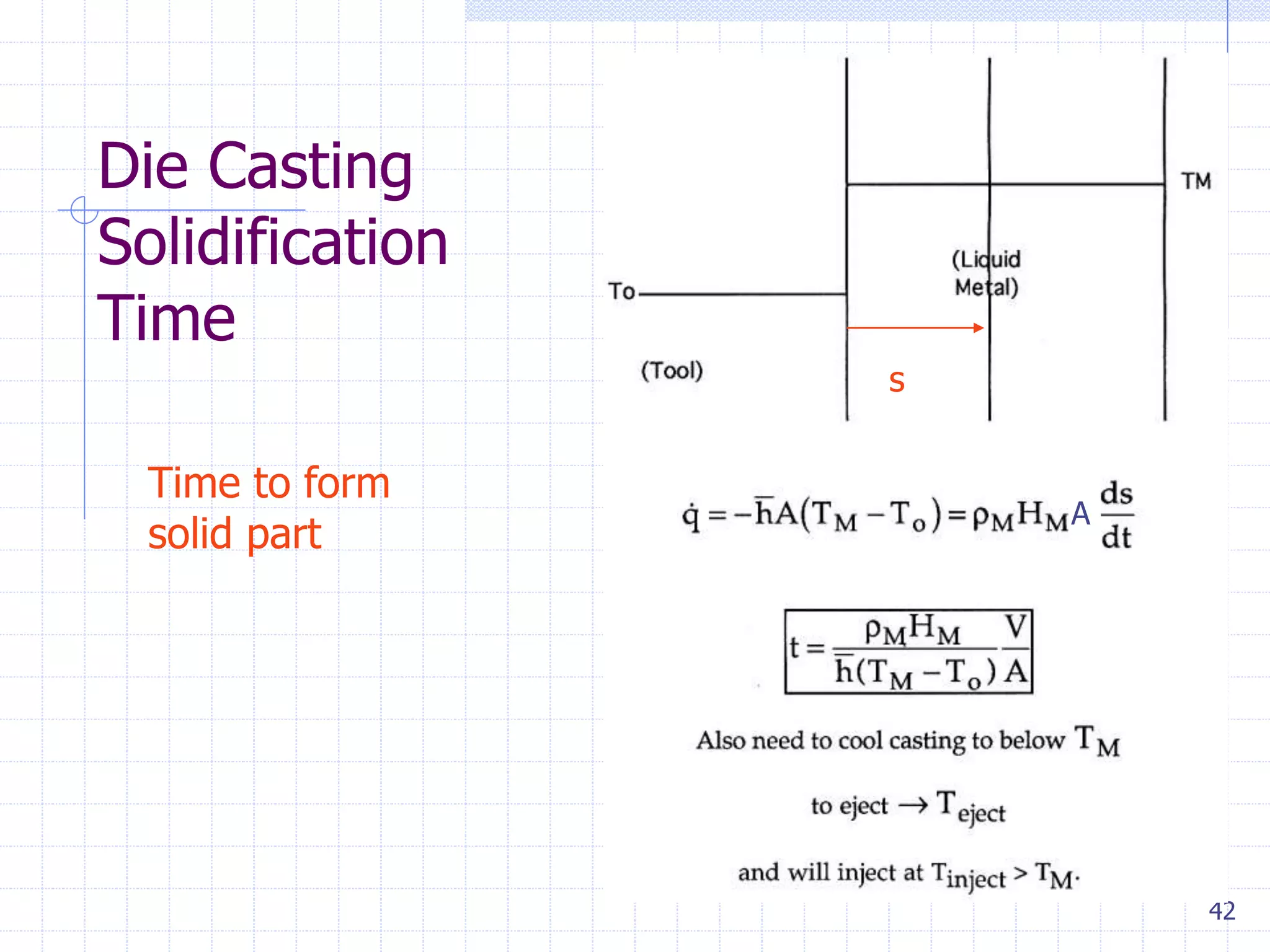

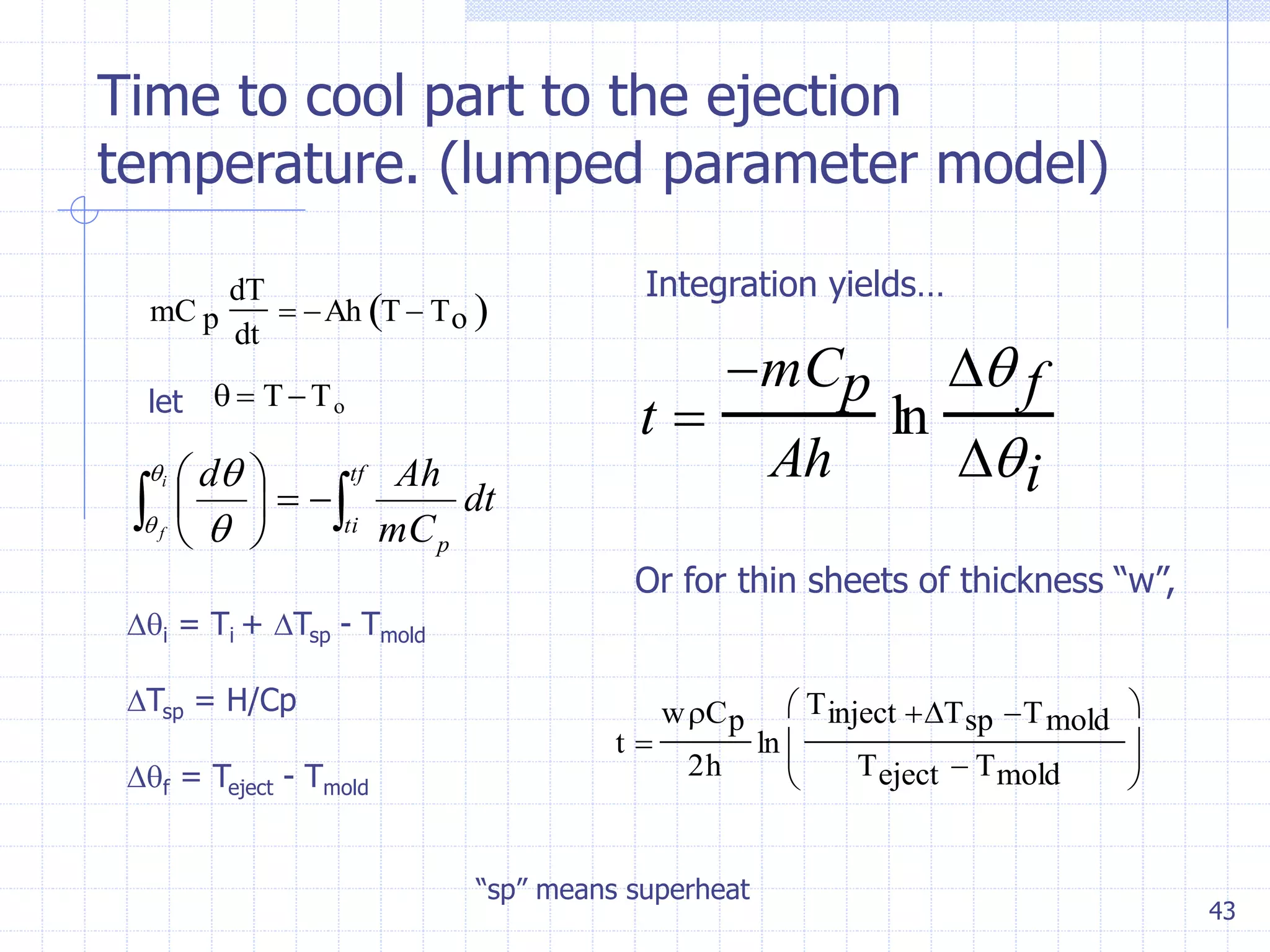

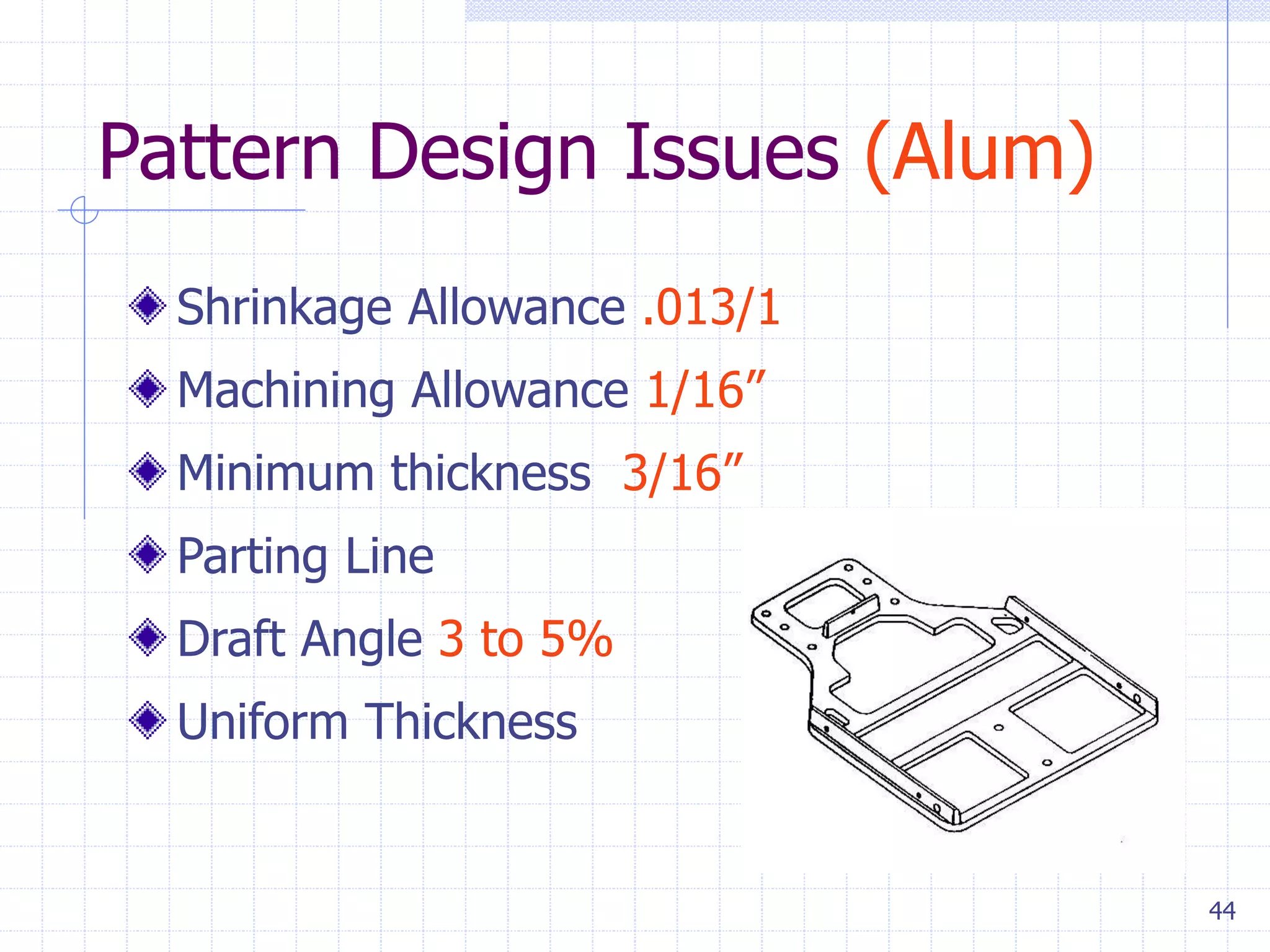

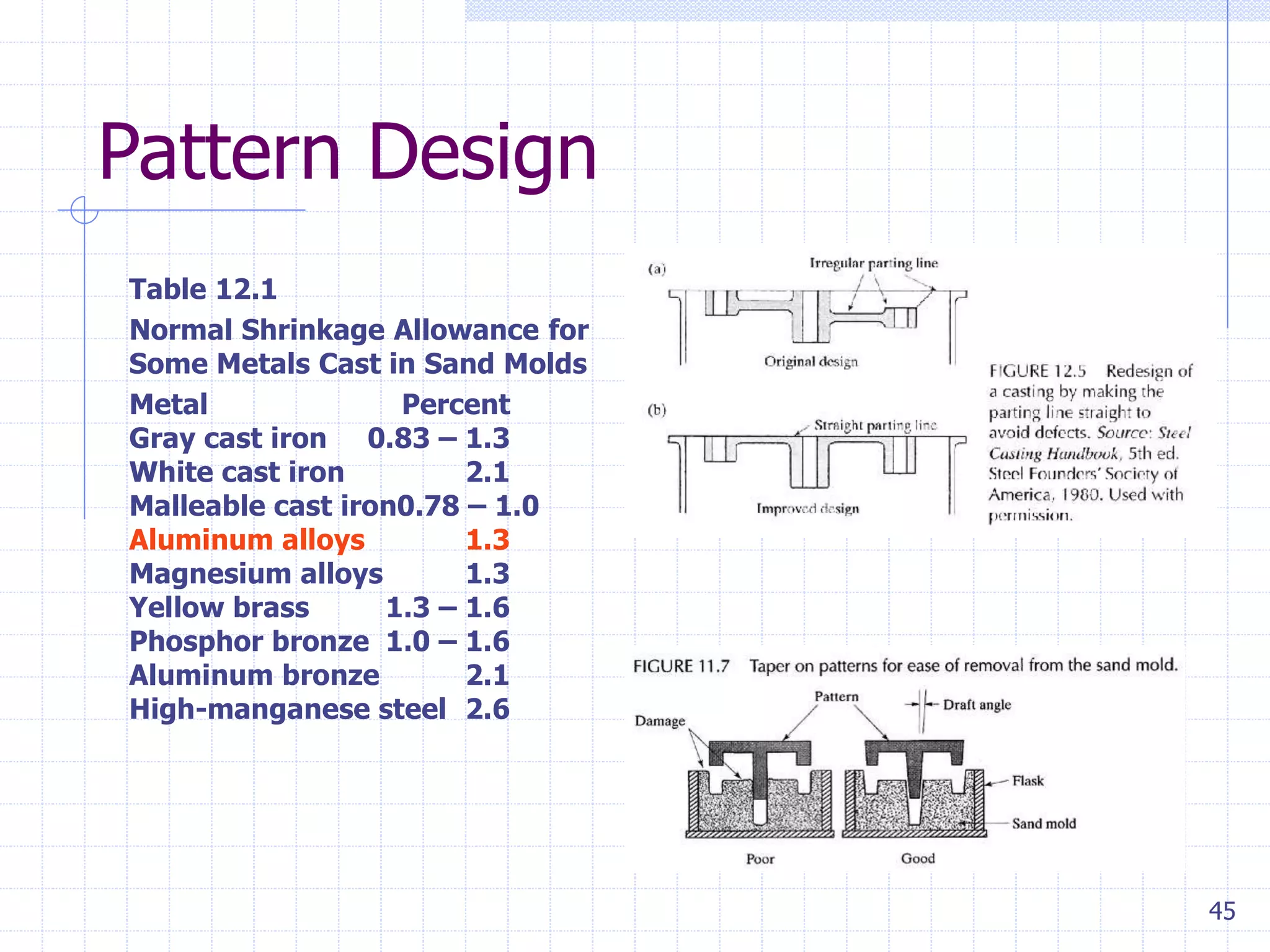

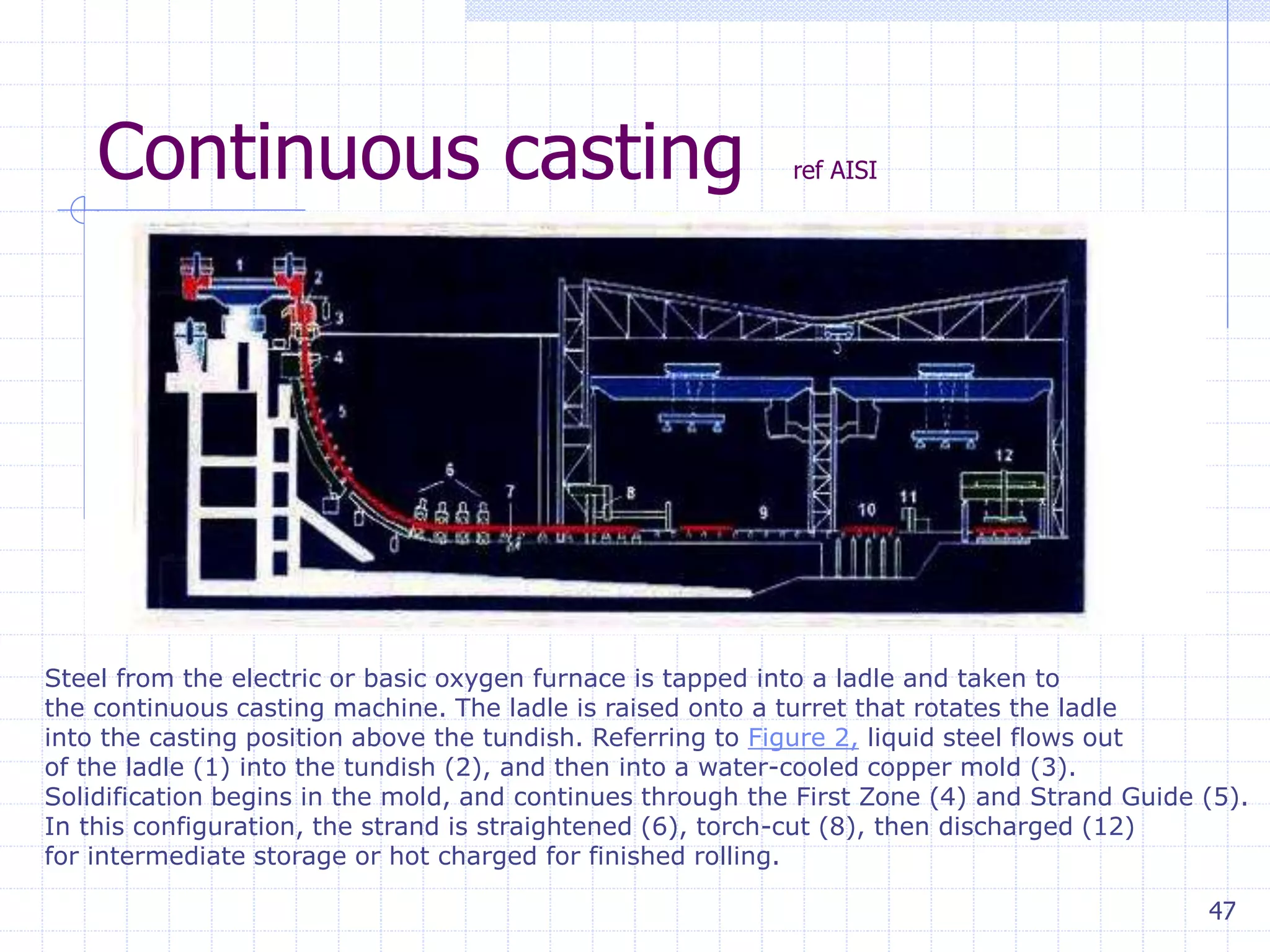

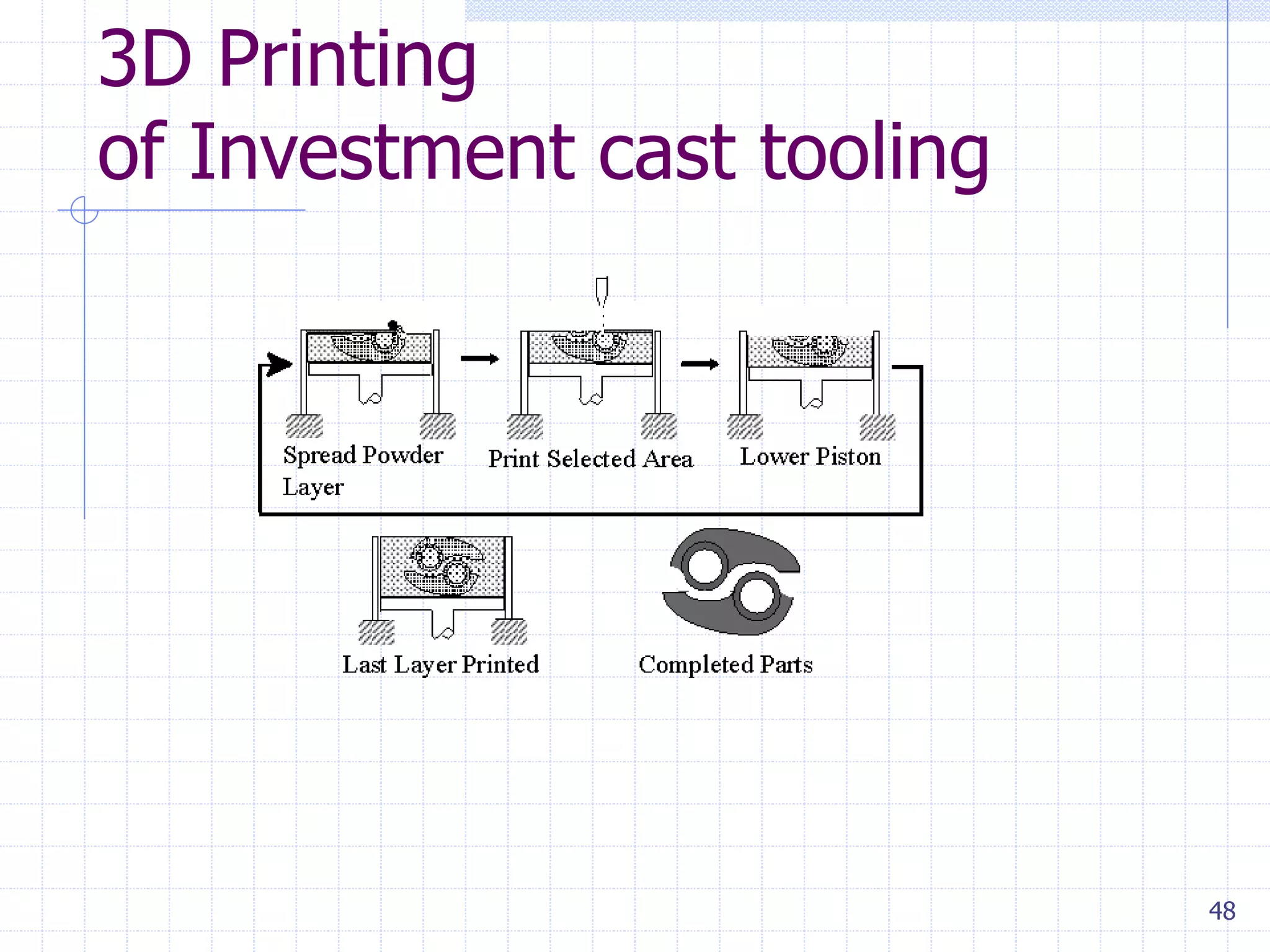

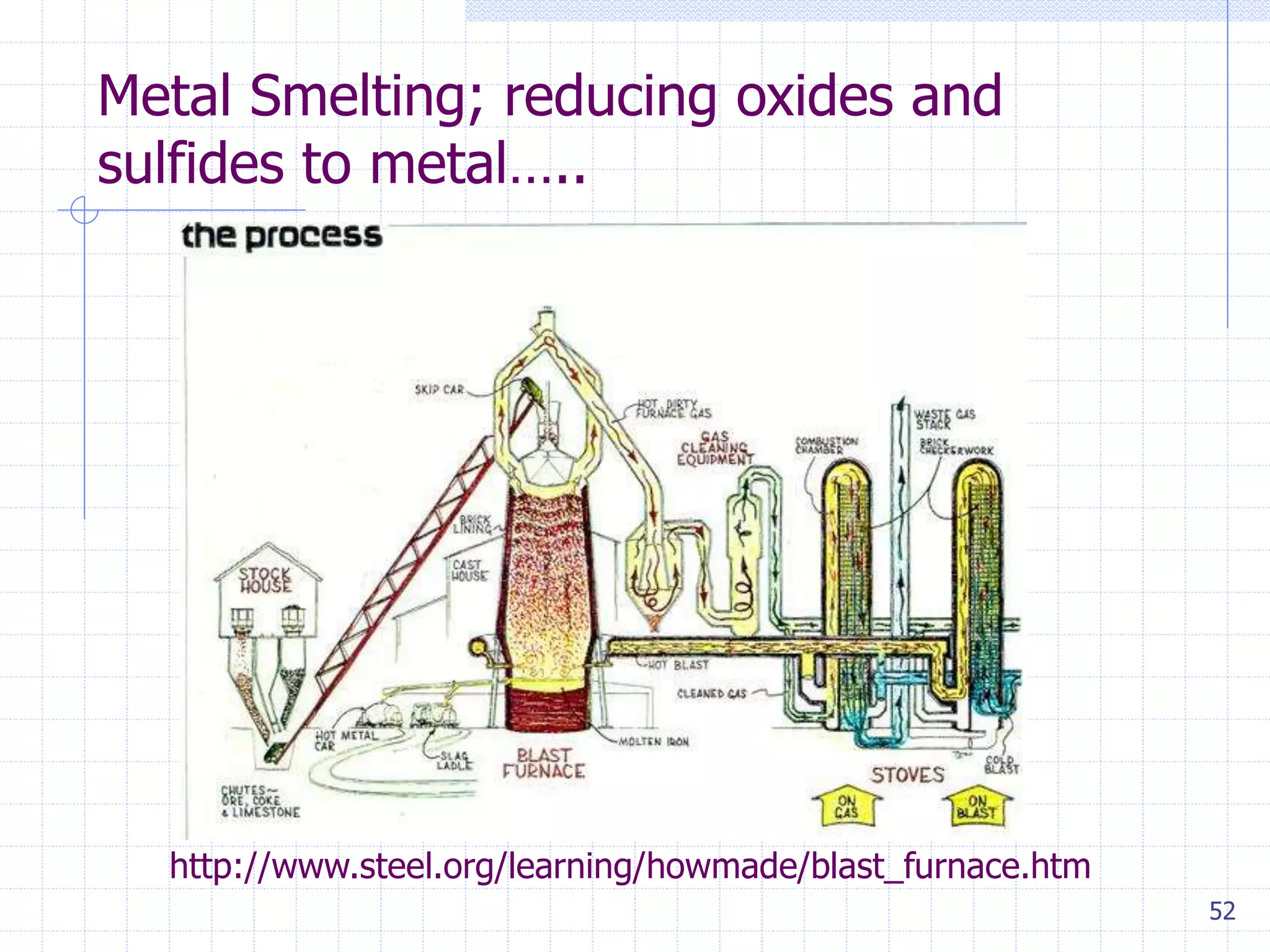

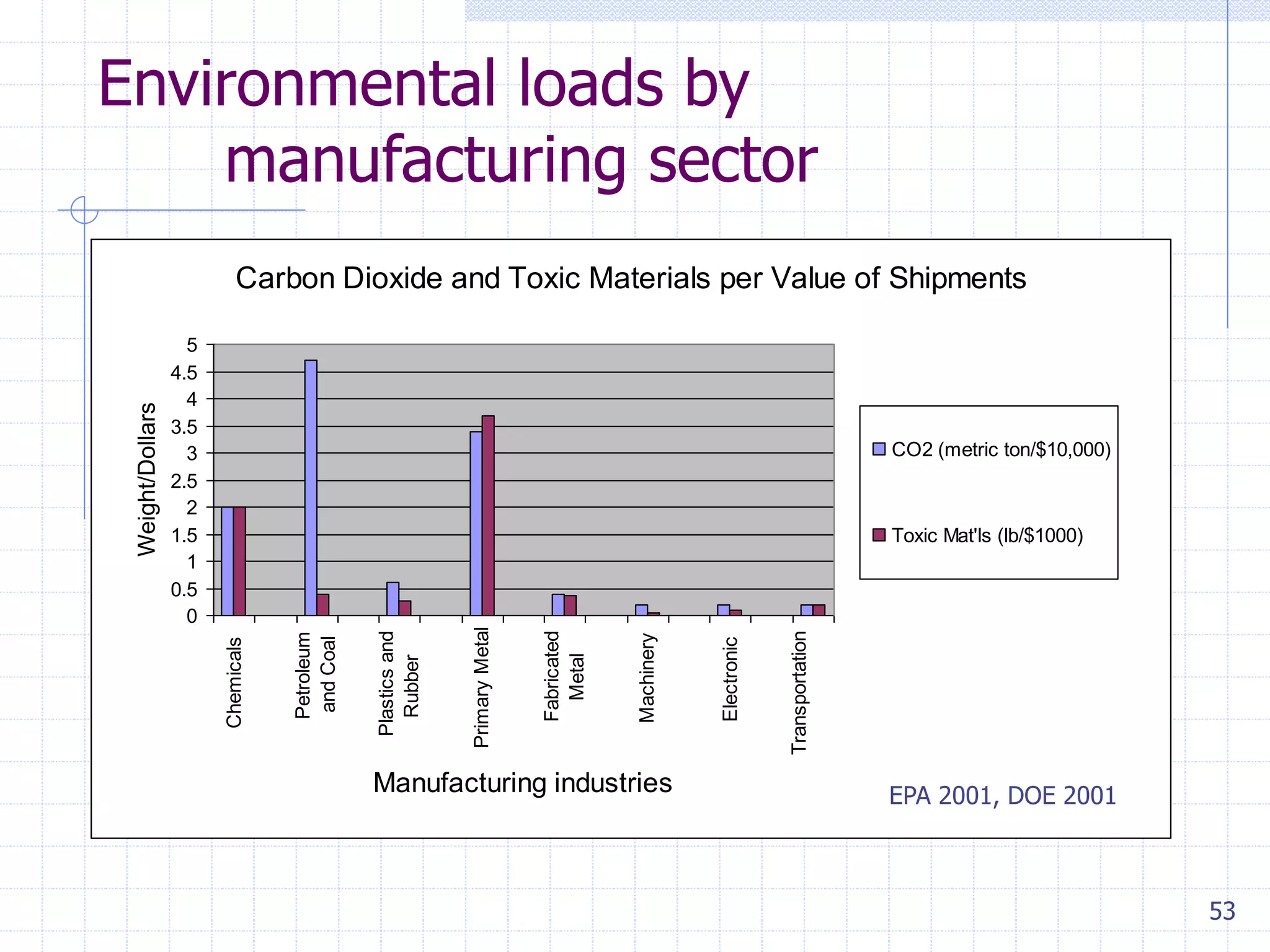

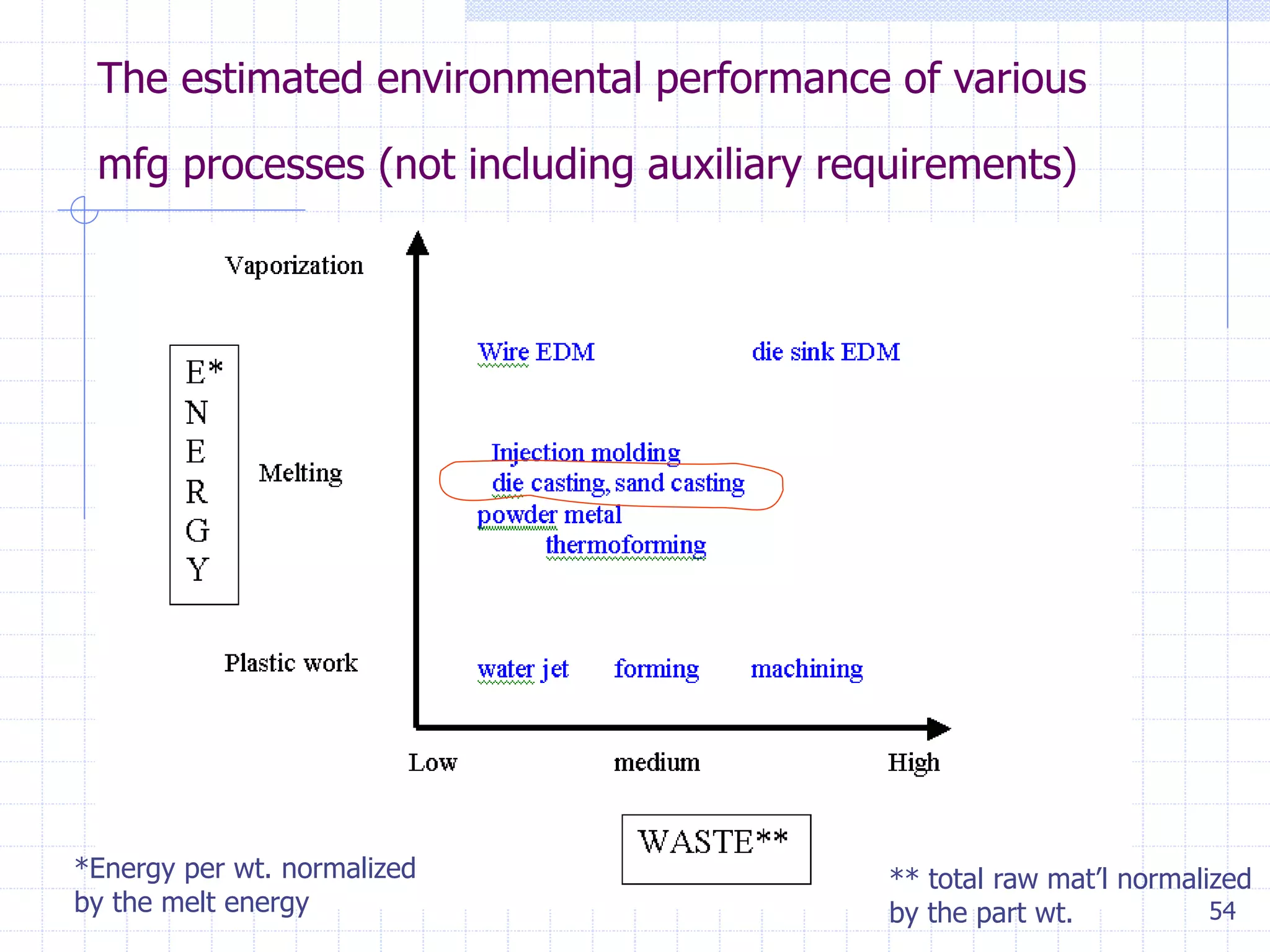

Sand casting, investment casting, and die casting were discussed as the main casting methods. Key topics included mold filling and solidification, phase change and shrinkage during solidification, heat transfer considerations, and pattern design guidelines. Variations such as continuous casting and 3D printing of tooling were also mentioned. Environmental issues associated with casting operations like energy usage, emissions, and waste disposal were reviewed.