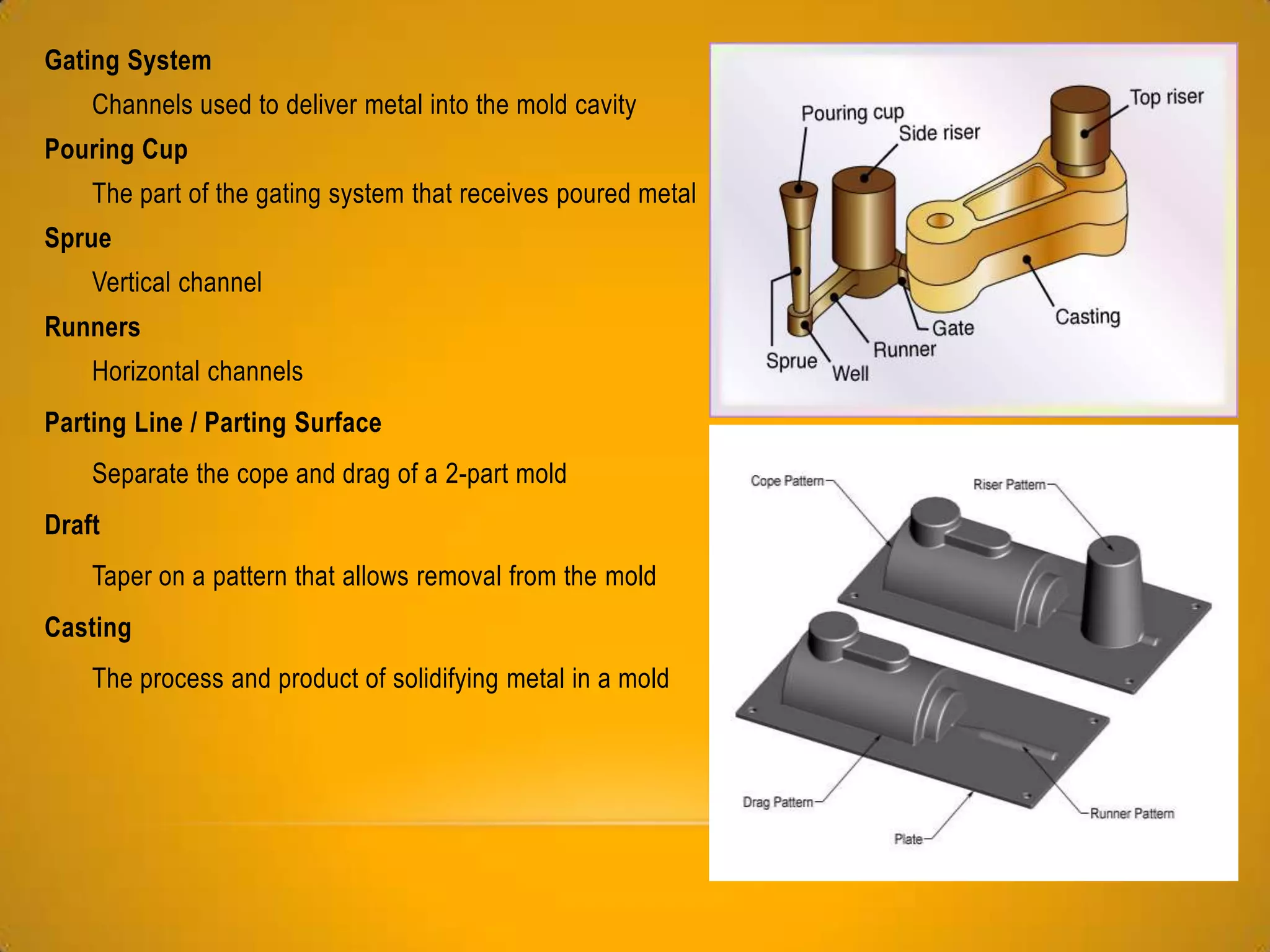

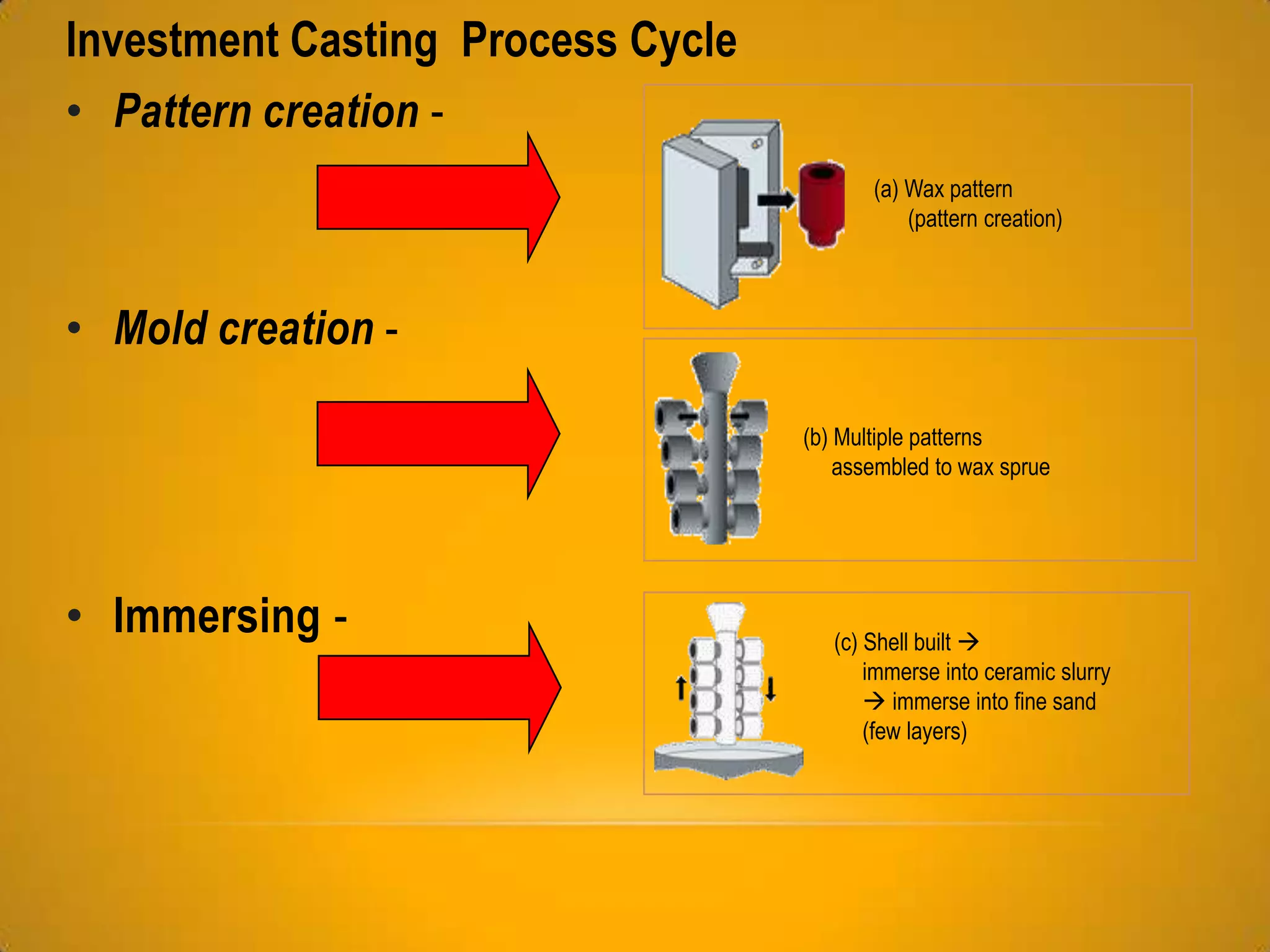

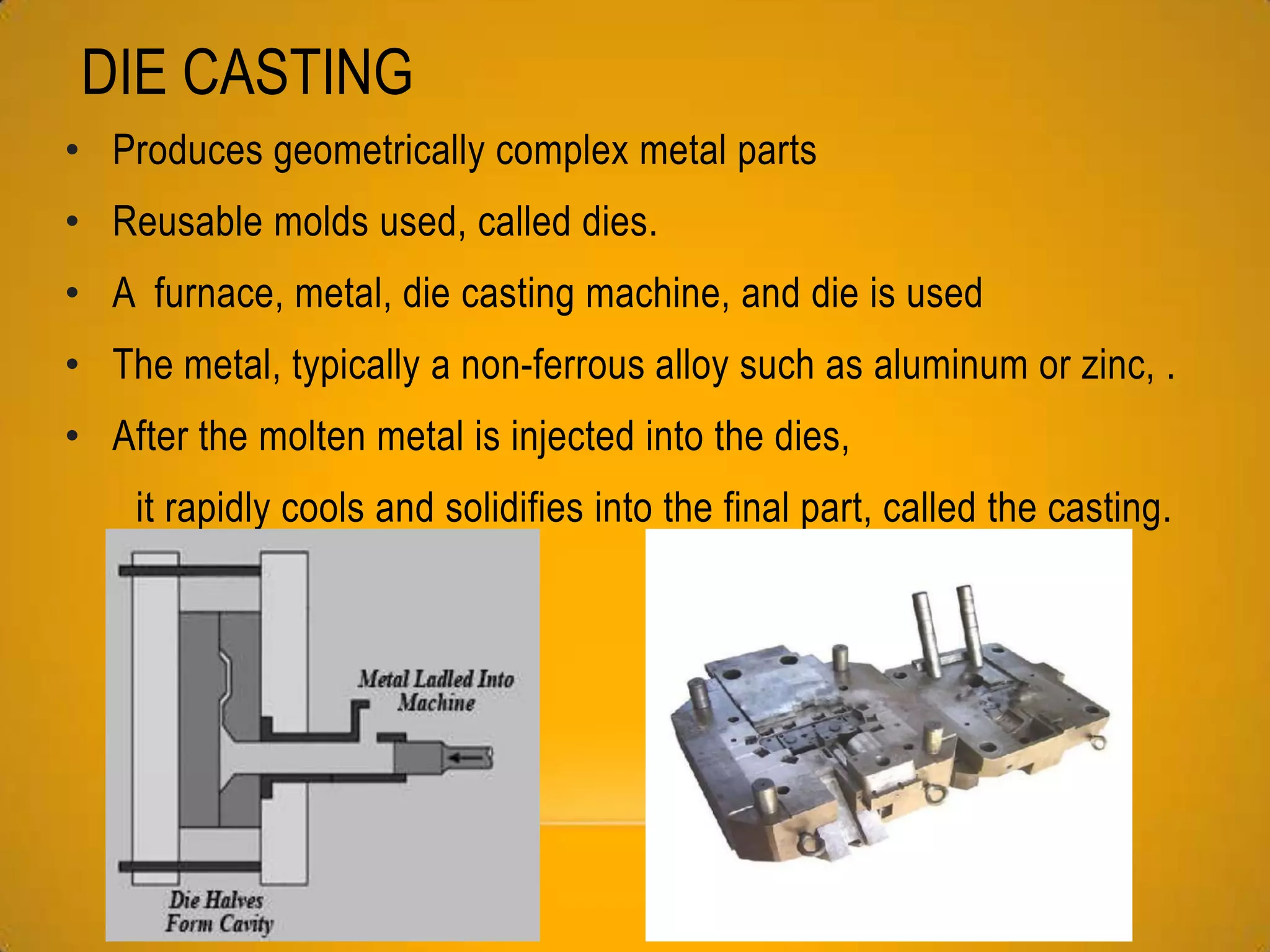

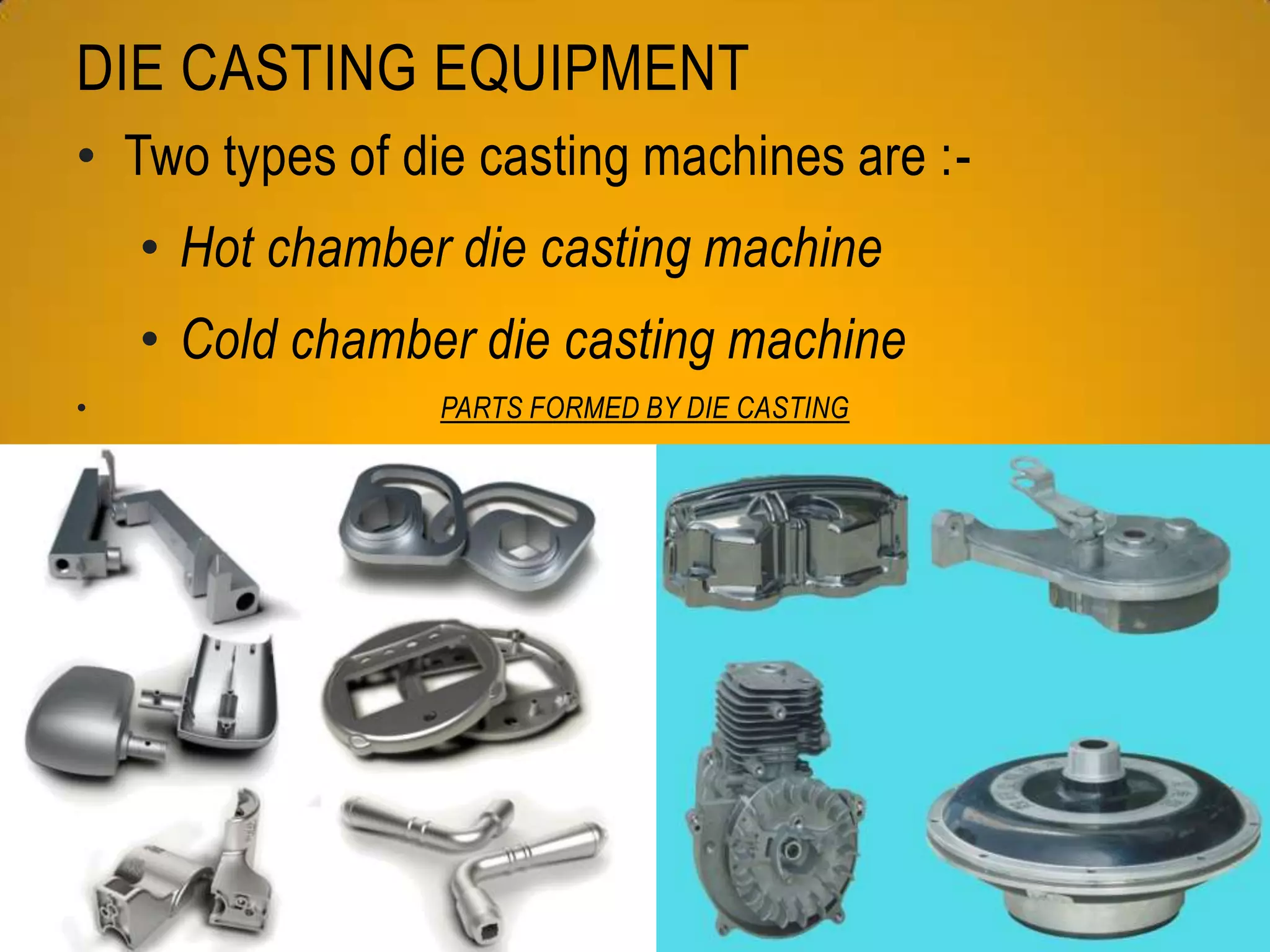

Casting is a process where molten metal is poured into a mold and allowed to solidify. There are several casting methods, including sand casting where a mold is made of sand and discarded after use, investment casting where a wax pattern is used to make a ceramic mold, and die casting where molds called dies are used to produce parts by injecting molten metal under high pressure. Each method has advantages like complexity of parts possible but also disadvantages like costs or surface finish.