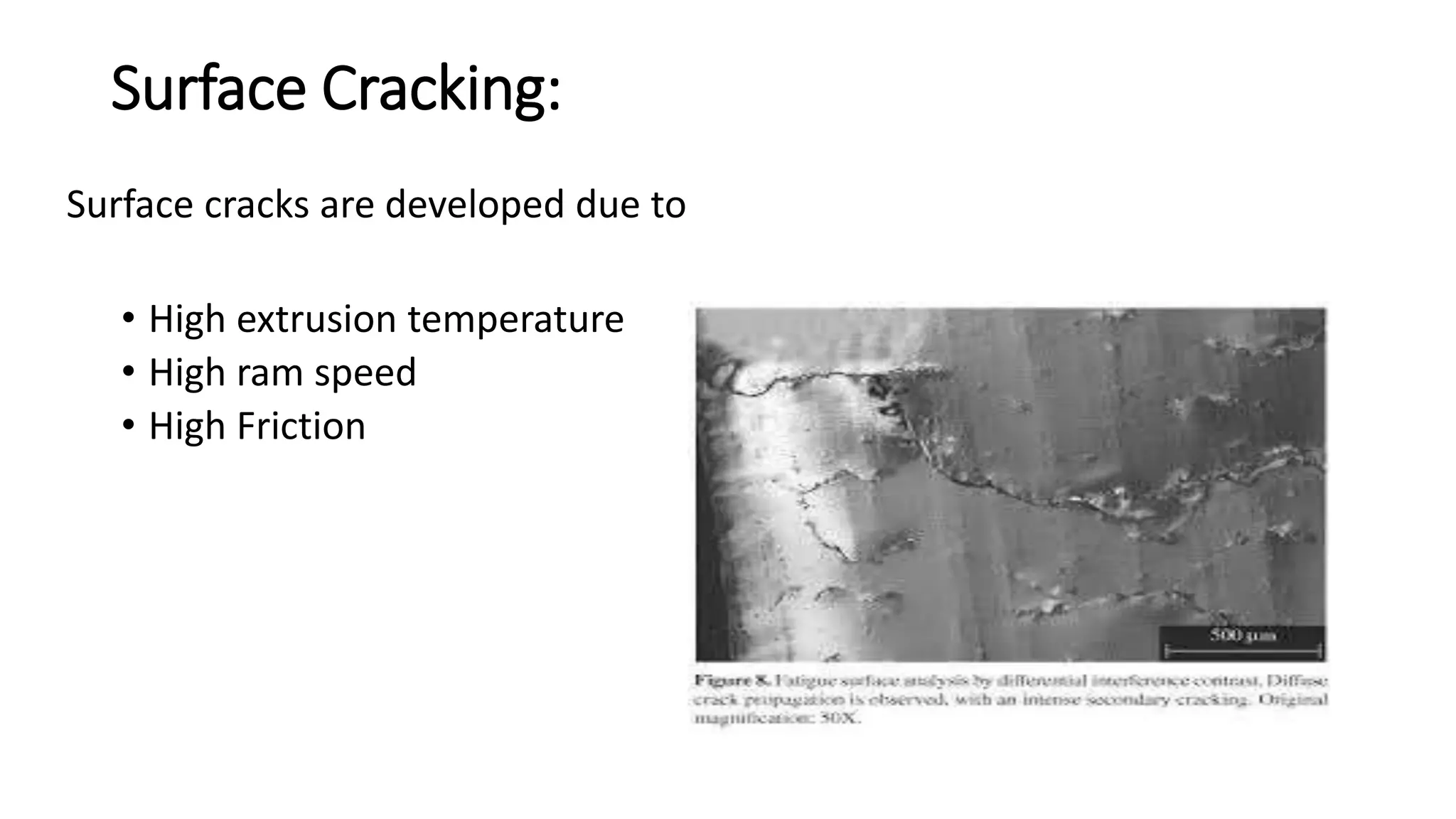

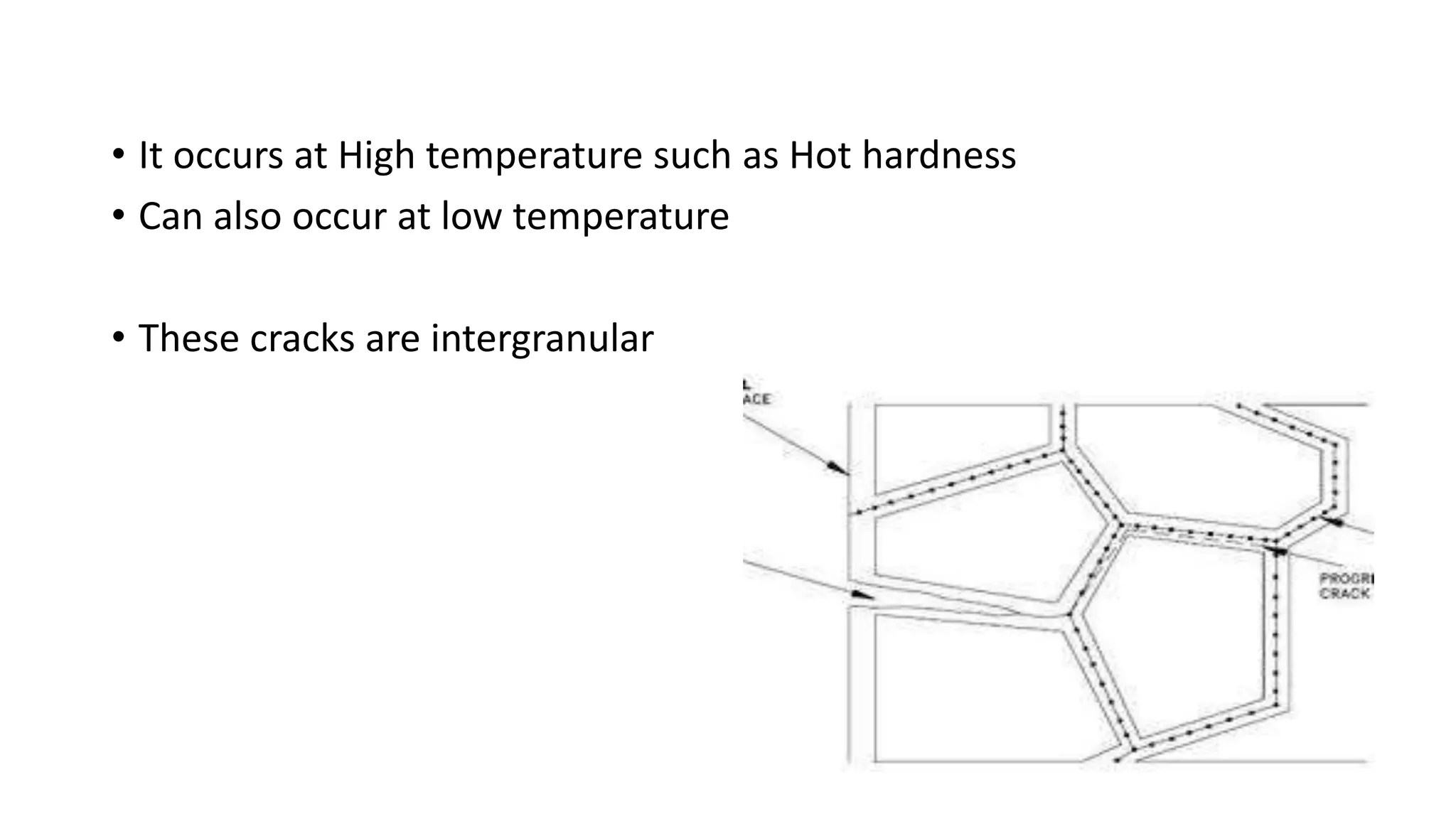

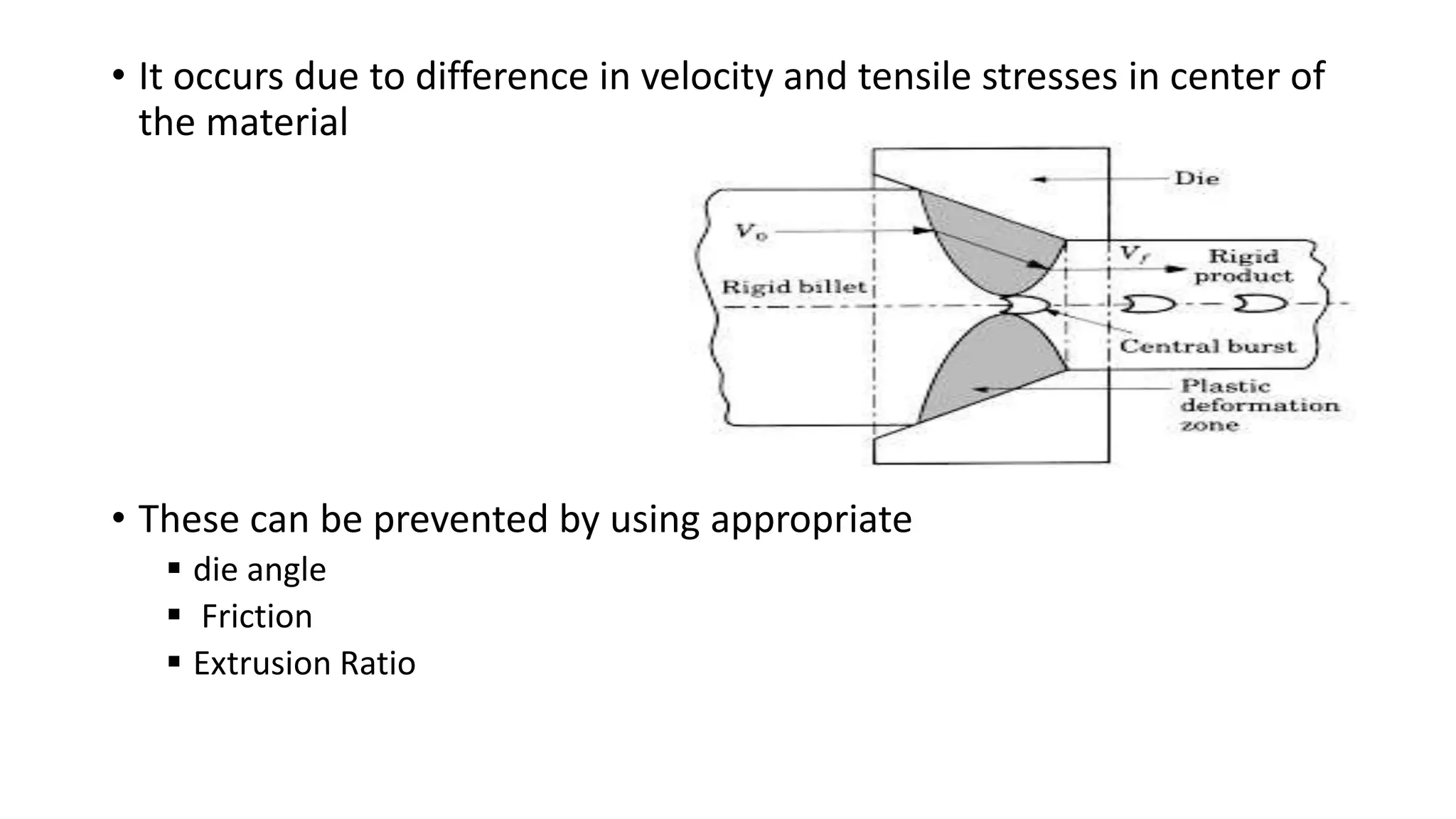

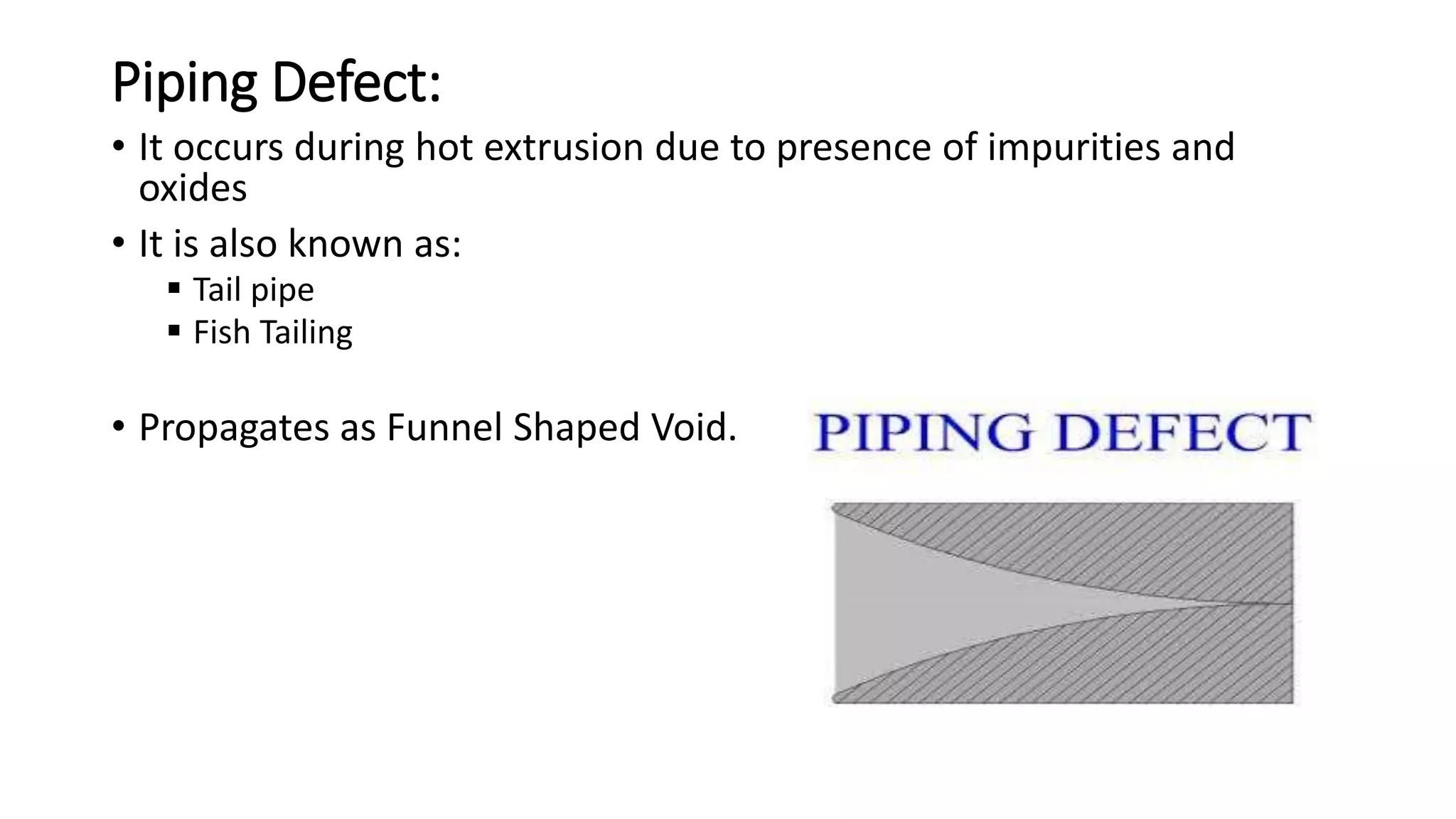

The presentation discusses extrusion defects, highlighting that these irregularities arise from non-uniform flow and stress distribution, influenced by wall friction and temperature. Key types of defects include surface cracking, internal cracking, and piping defects, each caused by specific conditions during the extrusion process. Preventive measures include modifying the flow pattern, controlling temperature and friction, and machining the billet surface prior to extrusion.