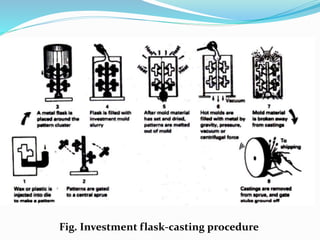

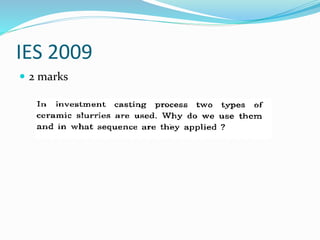

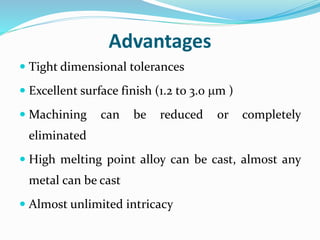

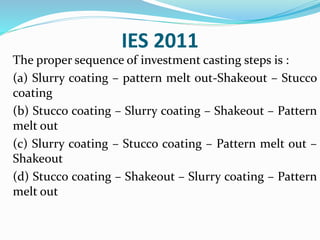

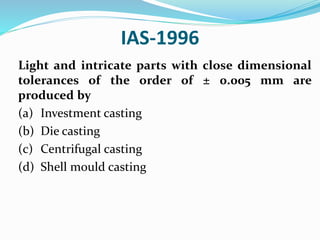

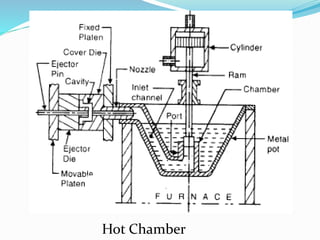

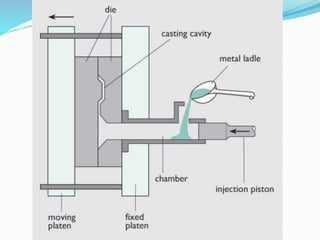

Shell moulding involves coating a heated metal pattern with a thermosetting resin and sand mixture to form a shell around it. When the shell is removed, it can be used like a mold cavity. The moulding sand is a mixture of quartz sand and bakelite, coated using cold or hot coating methods. Shell moulding allows for complex parts with good tolerances and surface finish. Investment casting uses wax or plastic patterns coated with refractory material and then melted out before pouring metal. It produces parts with tight tolerances and surface finishes of 1.2–3 μm. Die casting injects molten metal into metal dies under high pressure. It results in very smooth surfaces, accuracy, and mechanical properties,