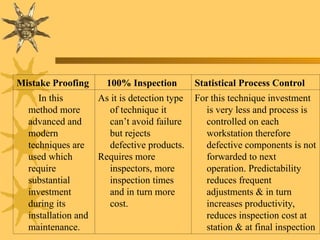

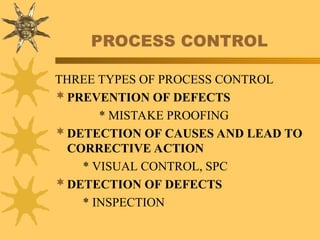

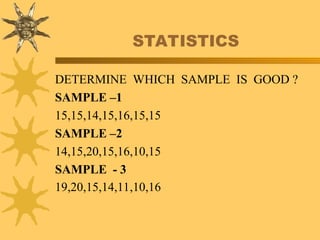

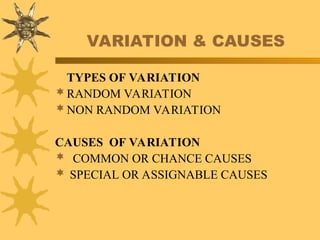

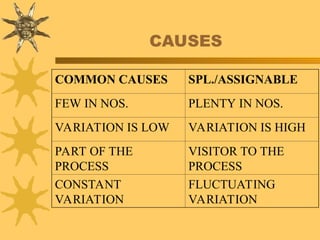

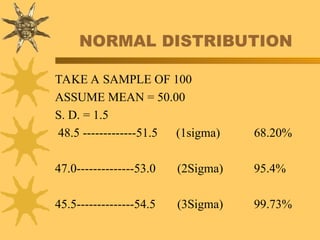

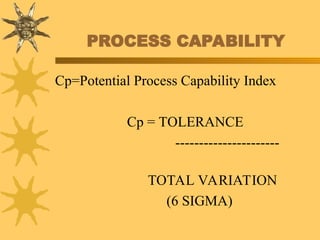

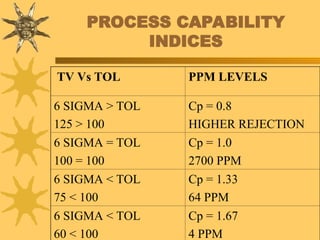

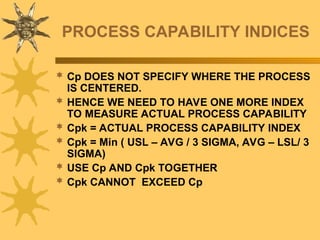

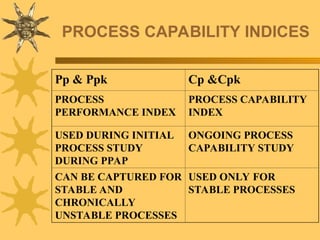

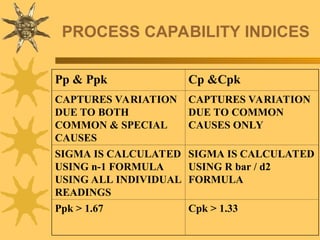

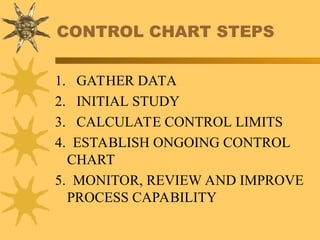

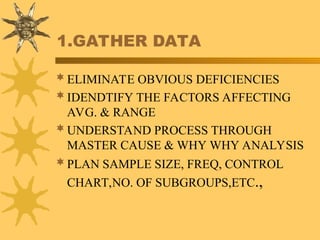

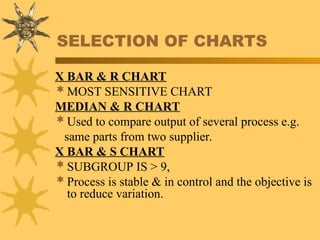

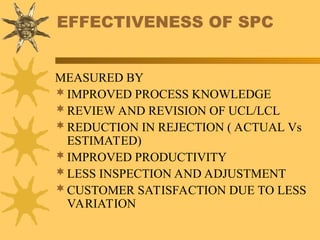

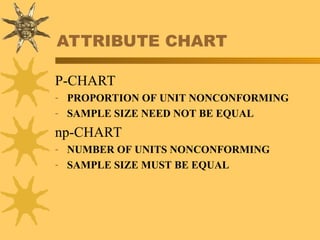

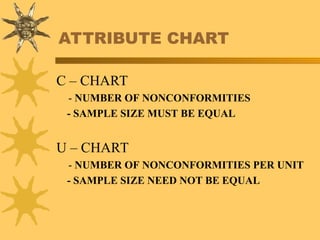

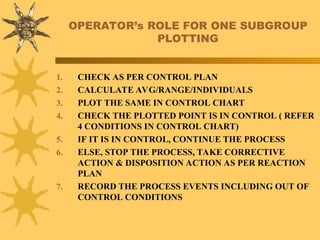

The document outlines a training program on Statistical Process Control (SPC), covering topics such as process control, variation, causes of variation, statistical control tools, and control chart methodologies. It emphasizes the significance of predicting process stability and managing variation through statistical techniques to enhance productivity and reduce inspection costs. Furthermore, it describes various control charts and process capability indices, including CP and CPK, and the importance of monitoring and improving process capability in manufacturing.