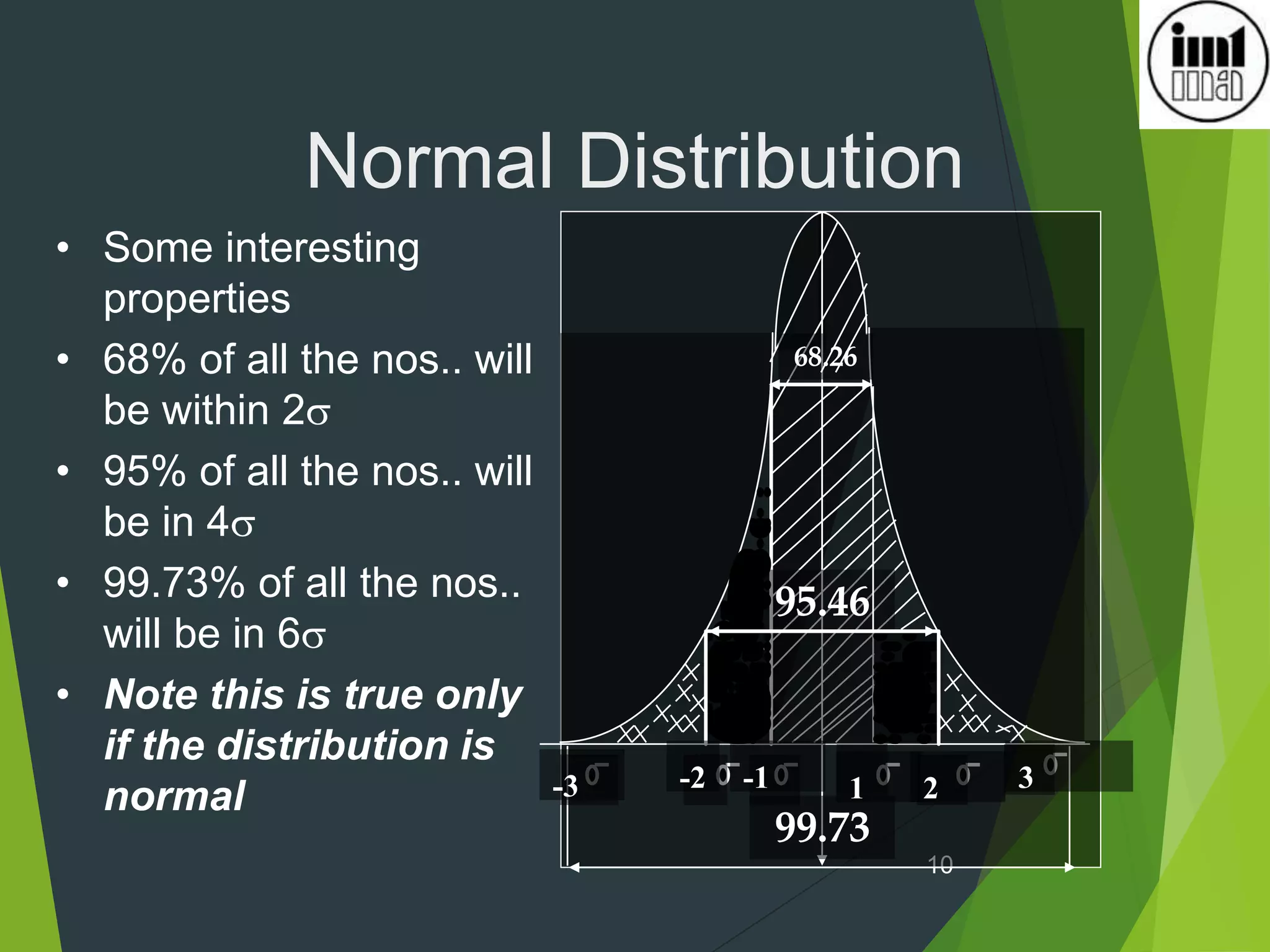

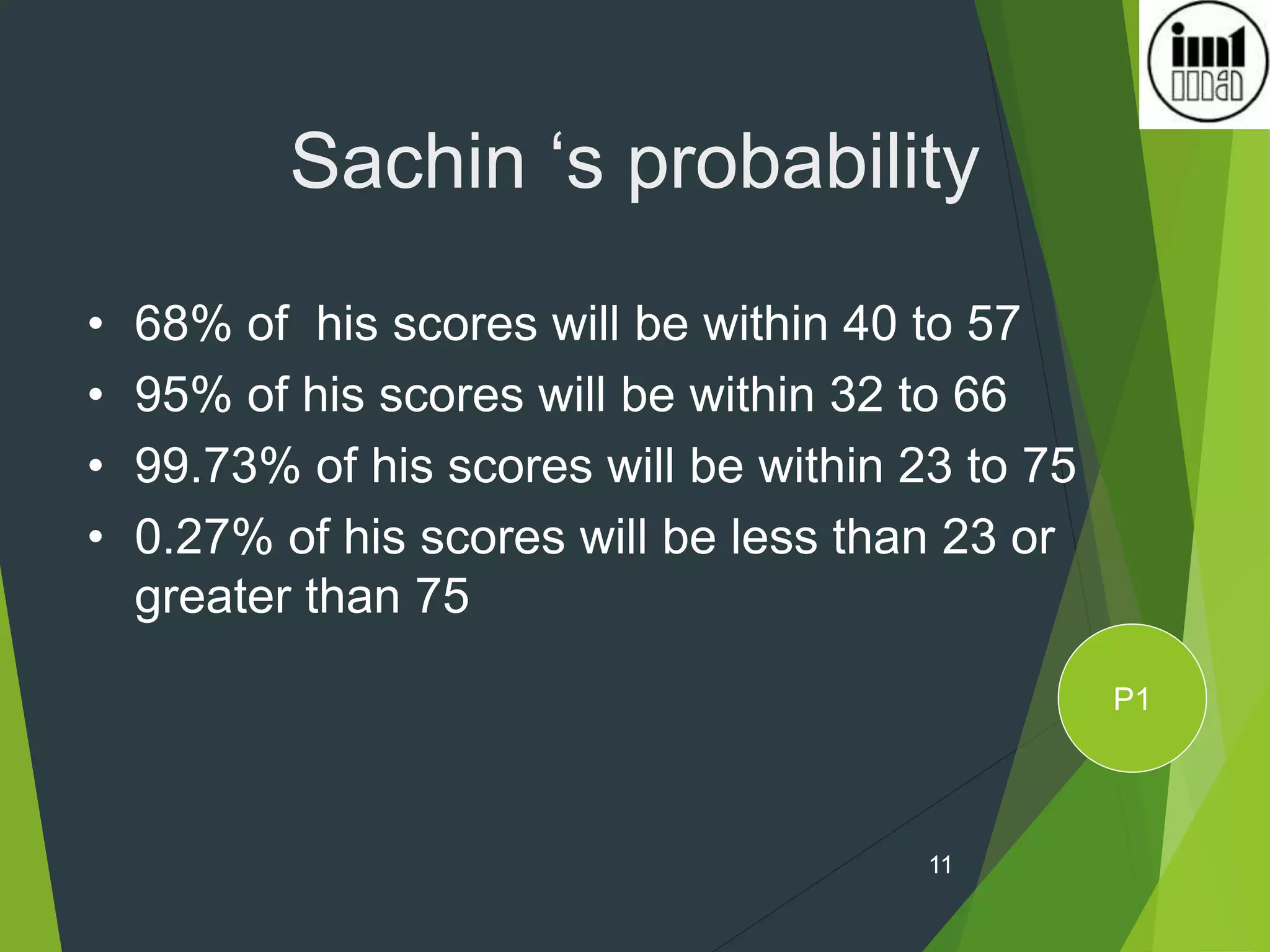

The document discusses fundamentals of process capability including:

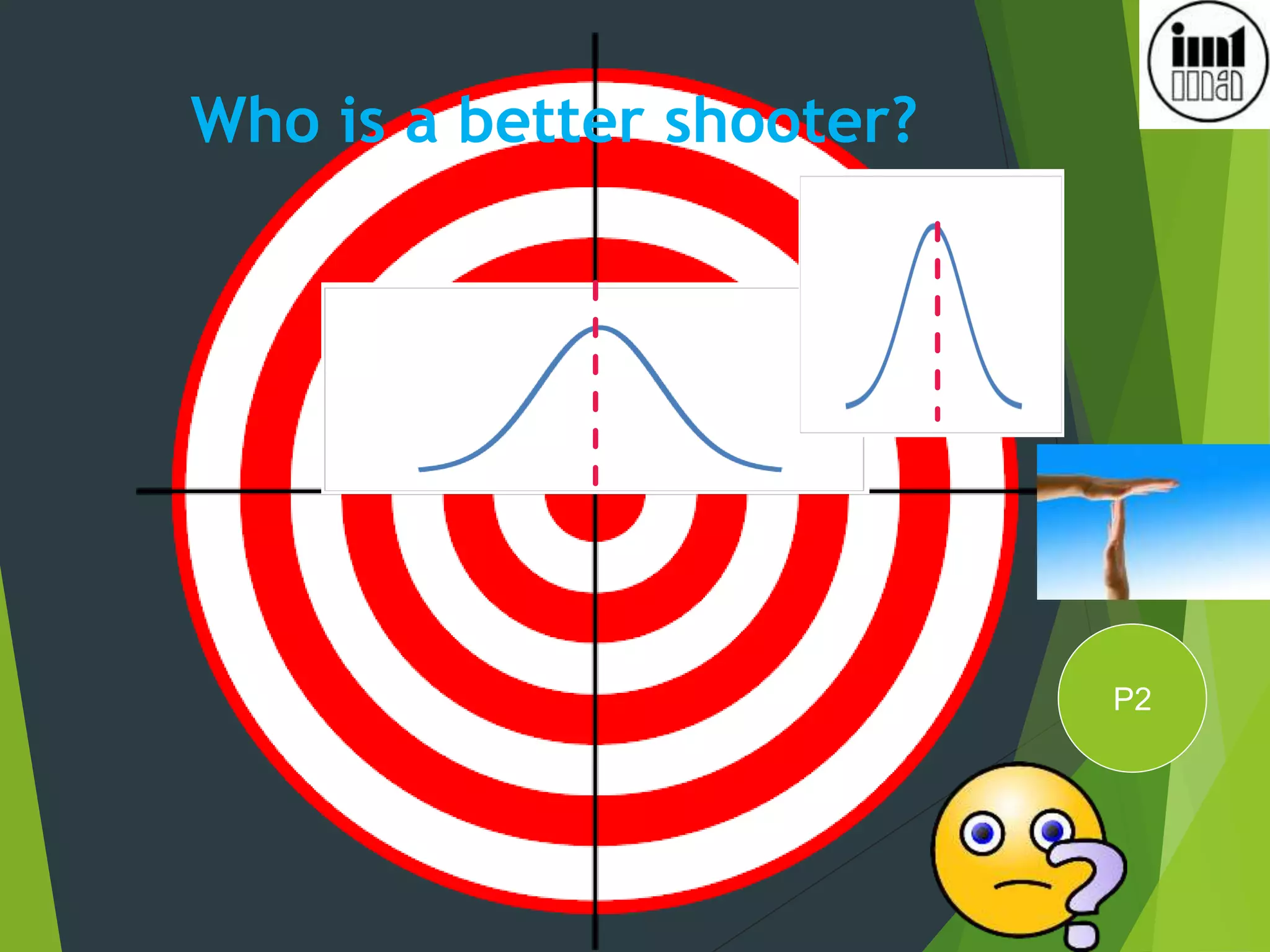

1) Achieving process control is key to reducing variation and non-conforming parts to achieve quality and cost targets.

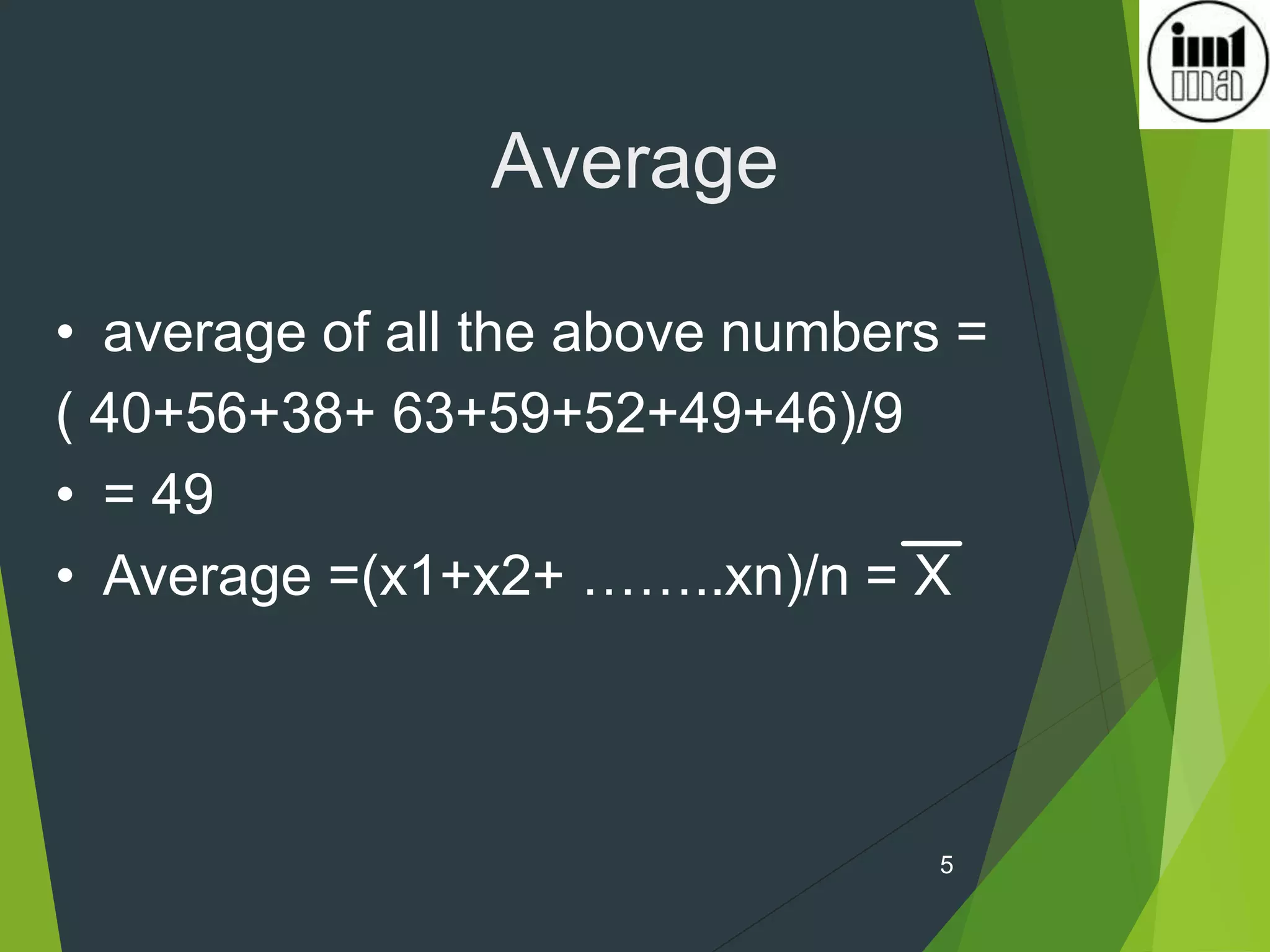

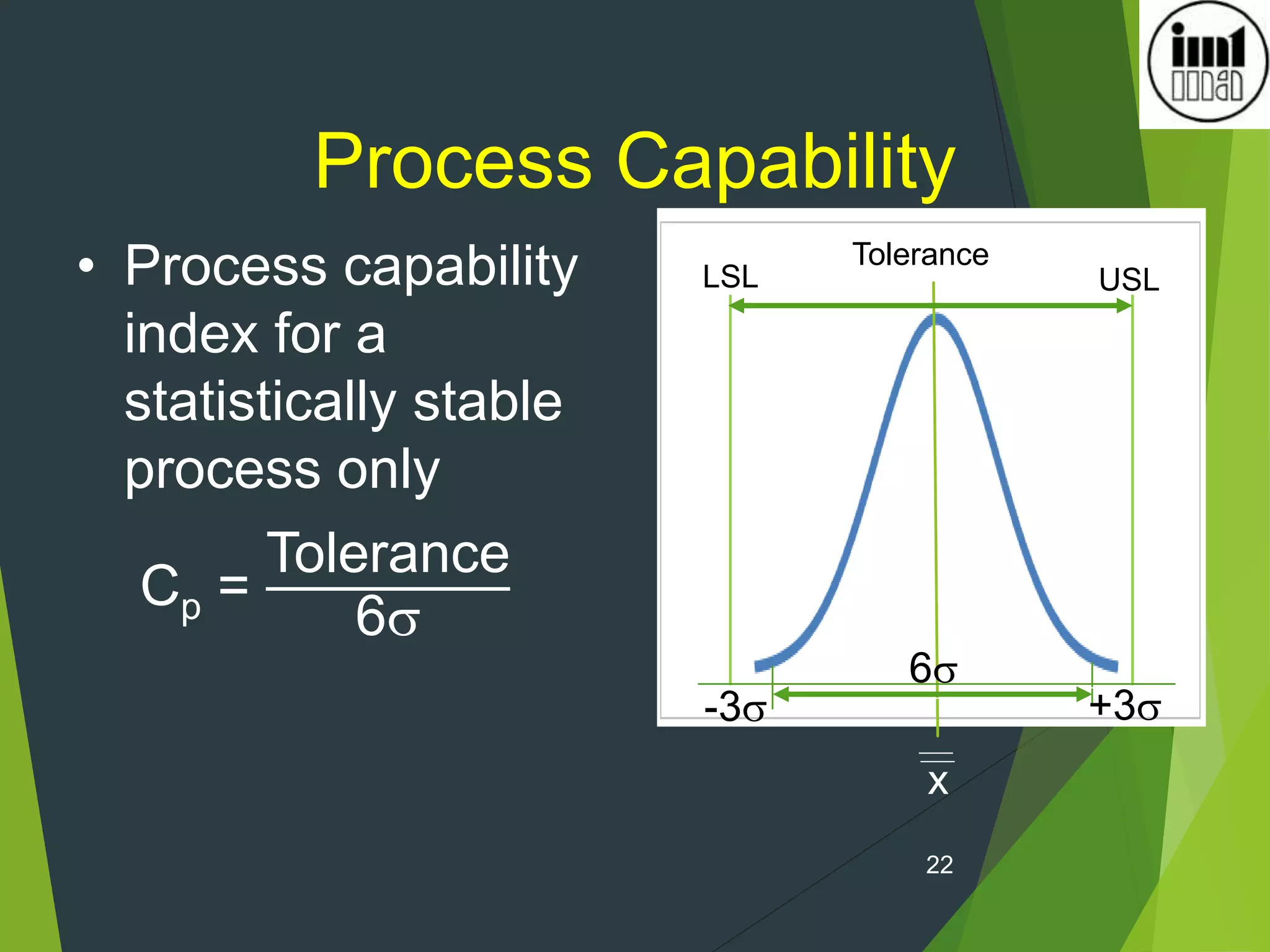

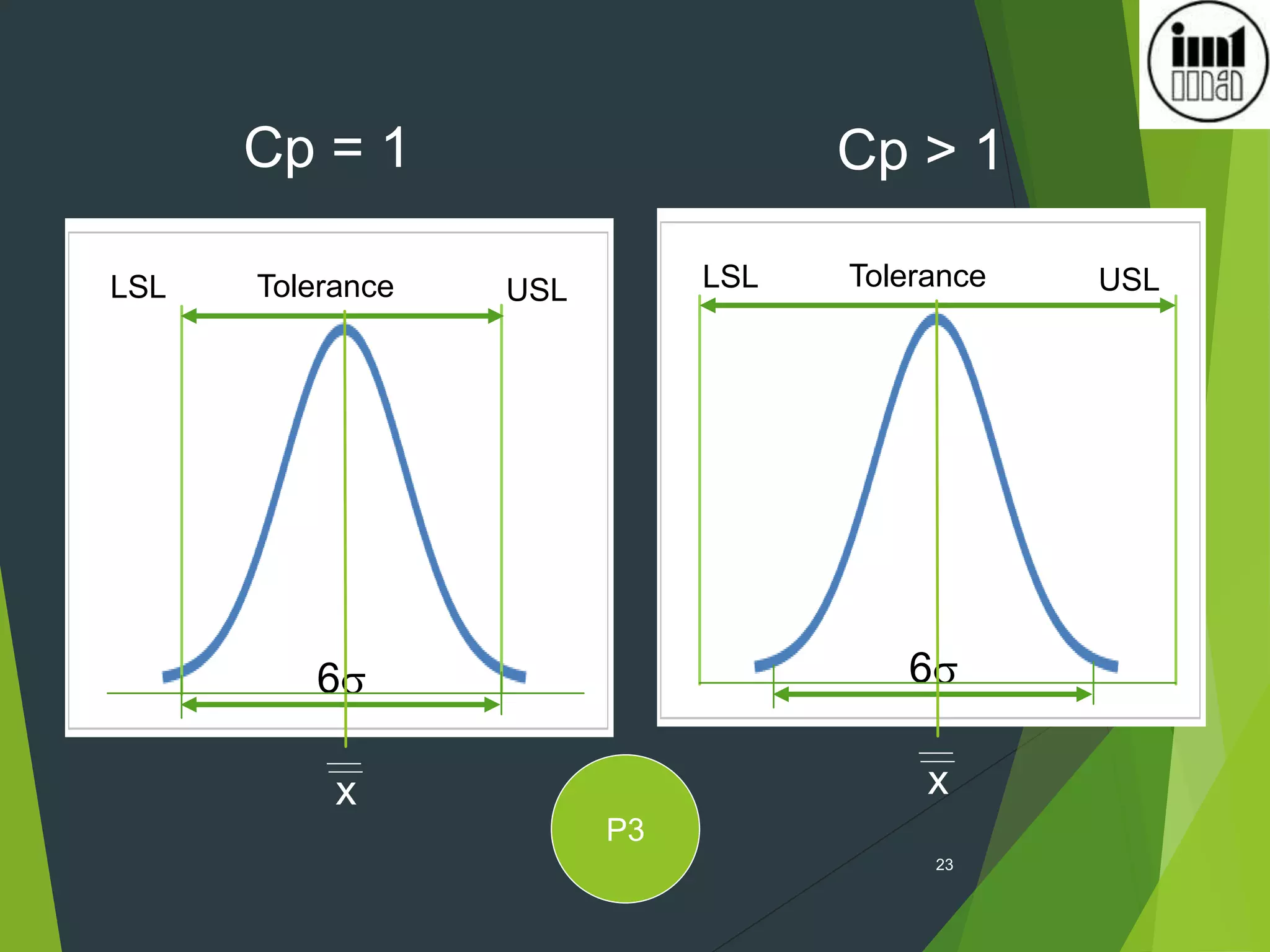

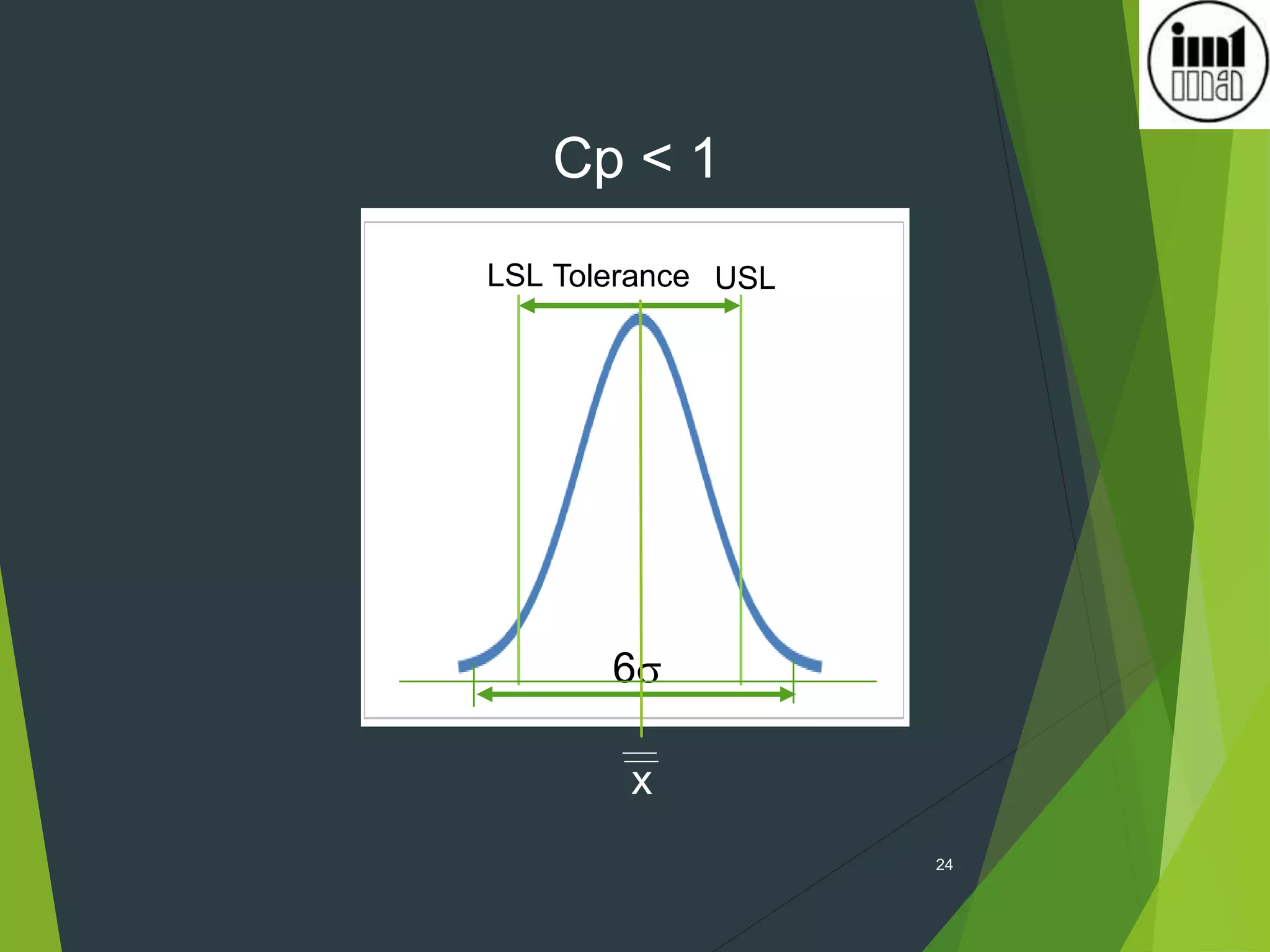

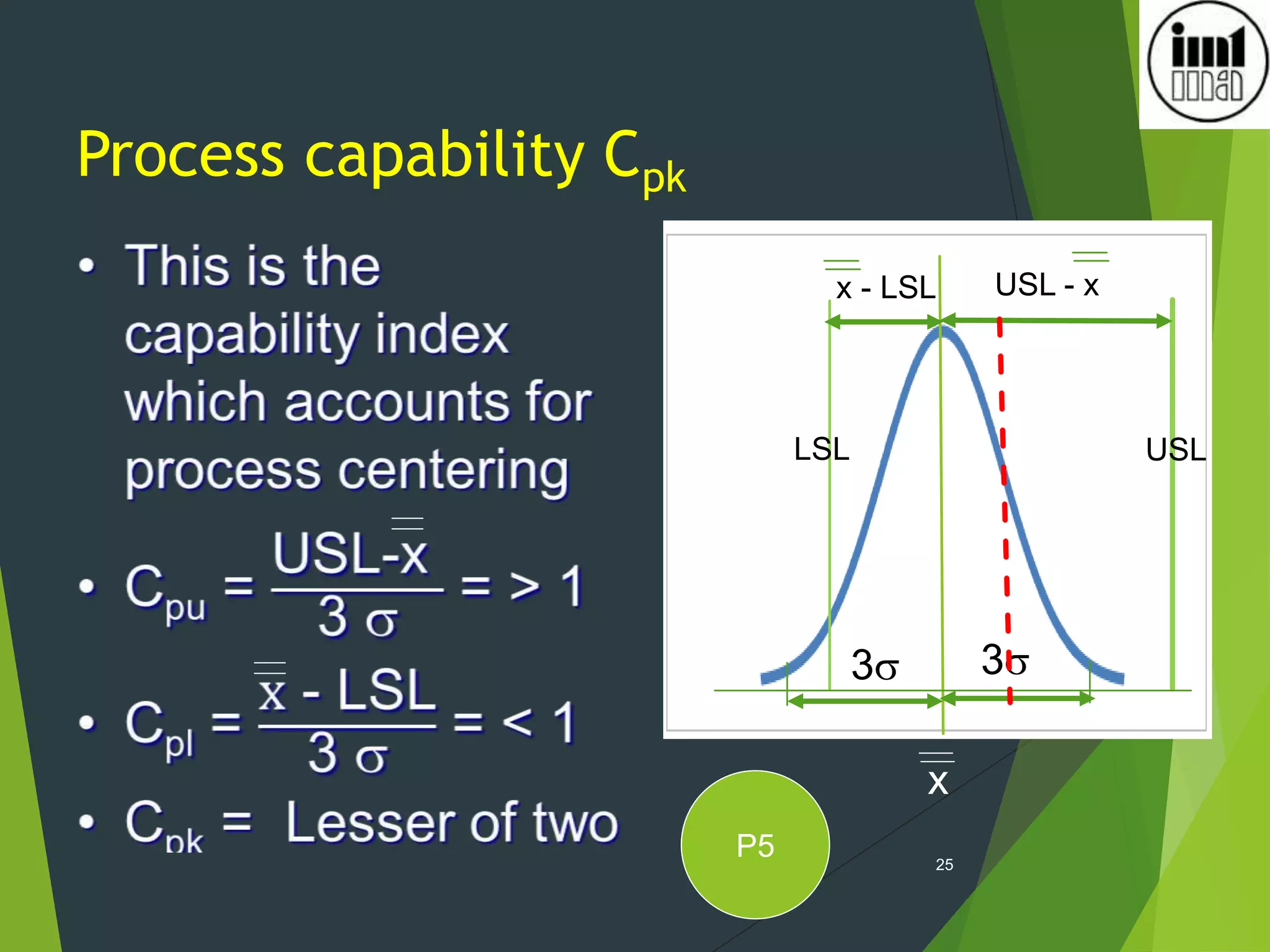

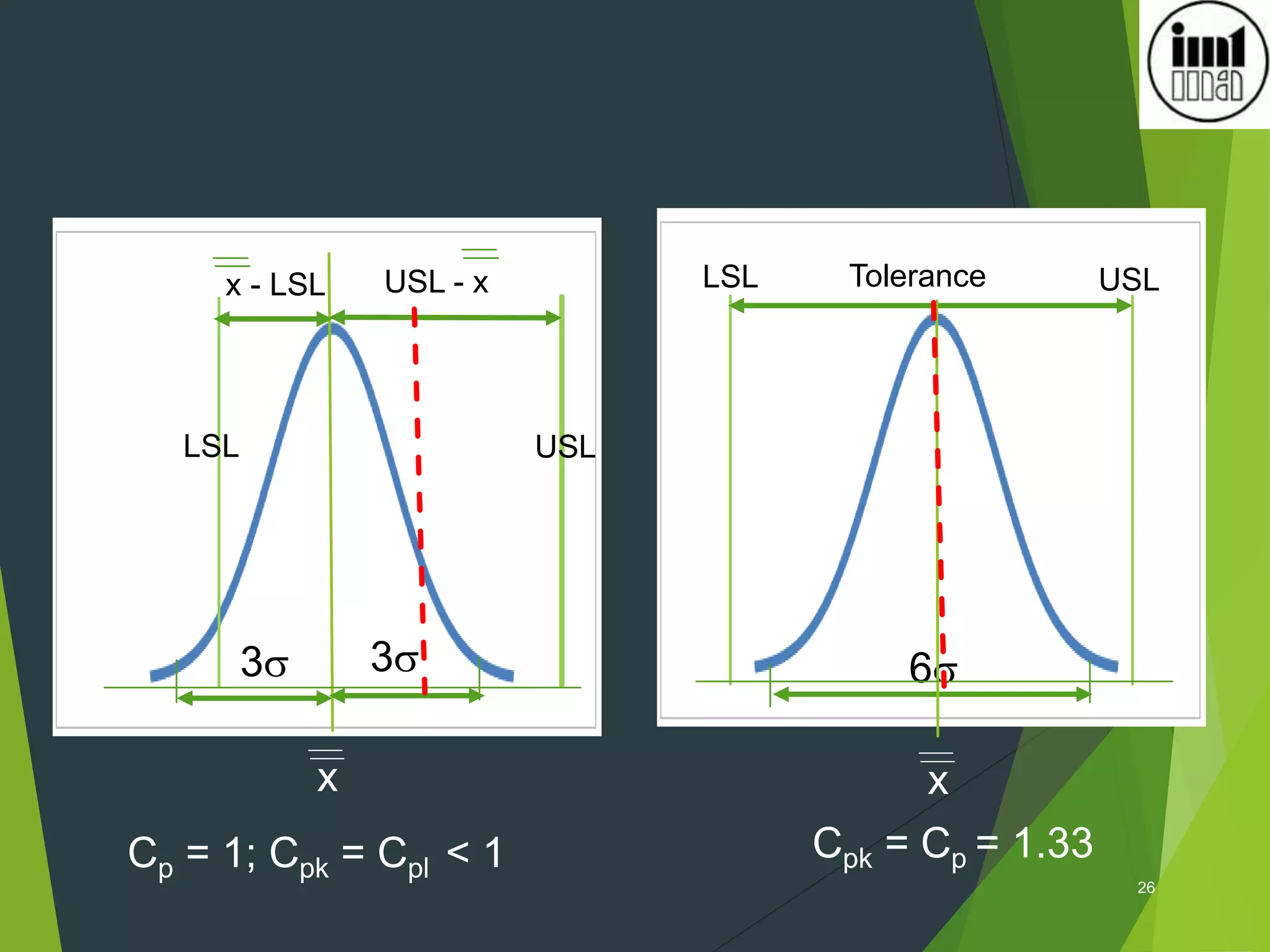

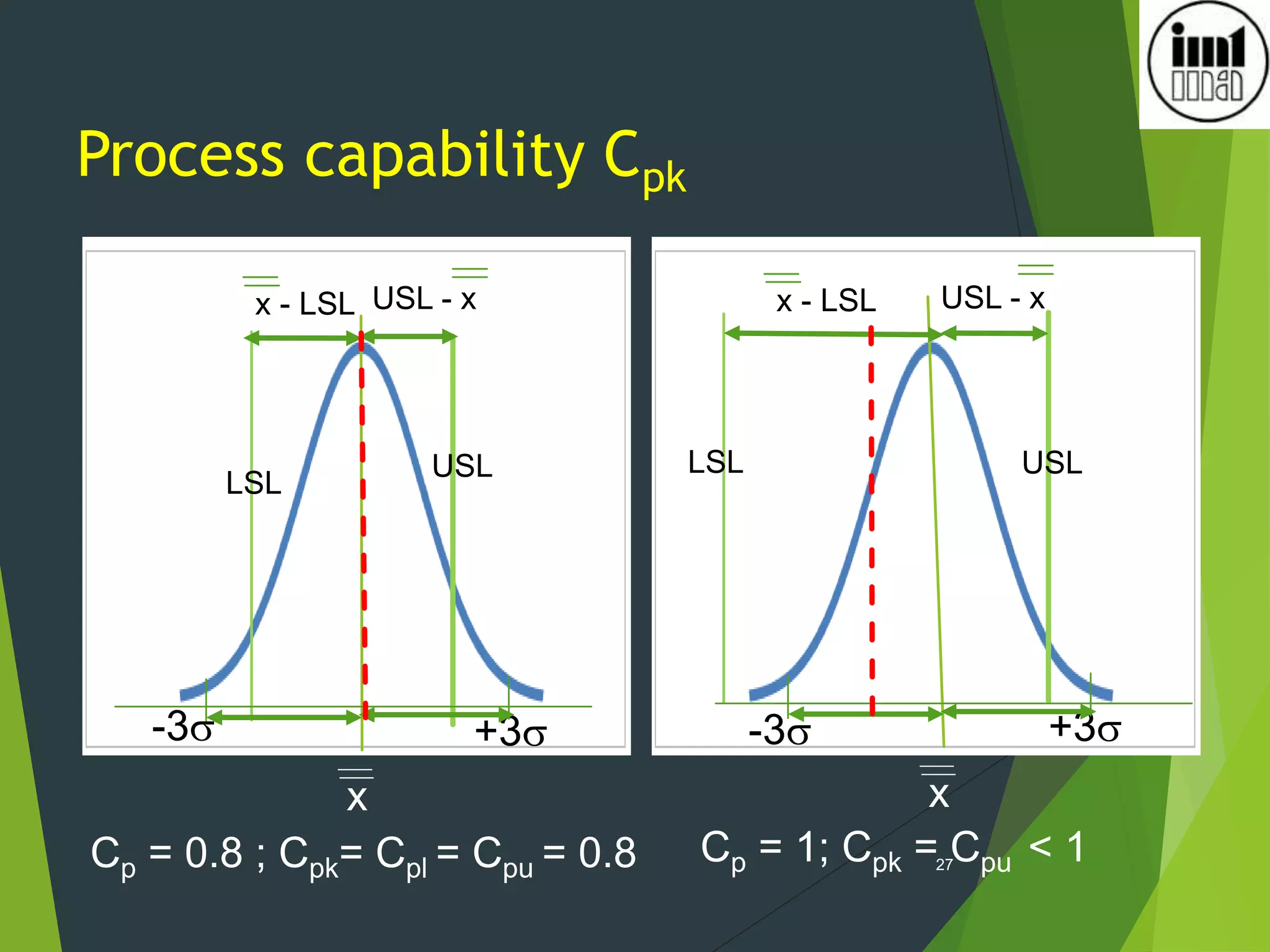

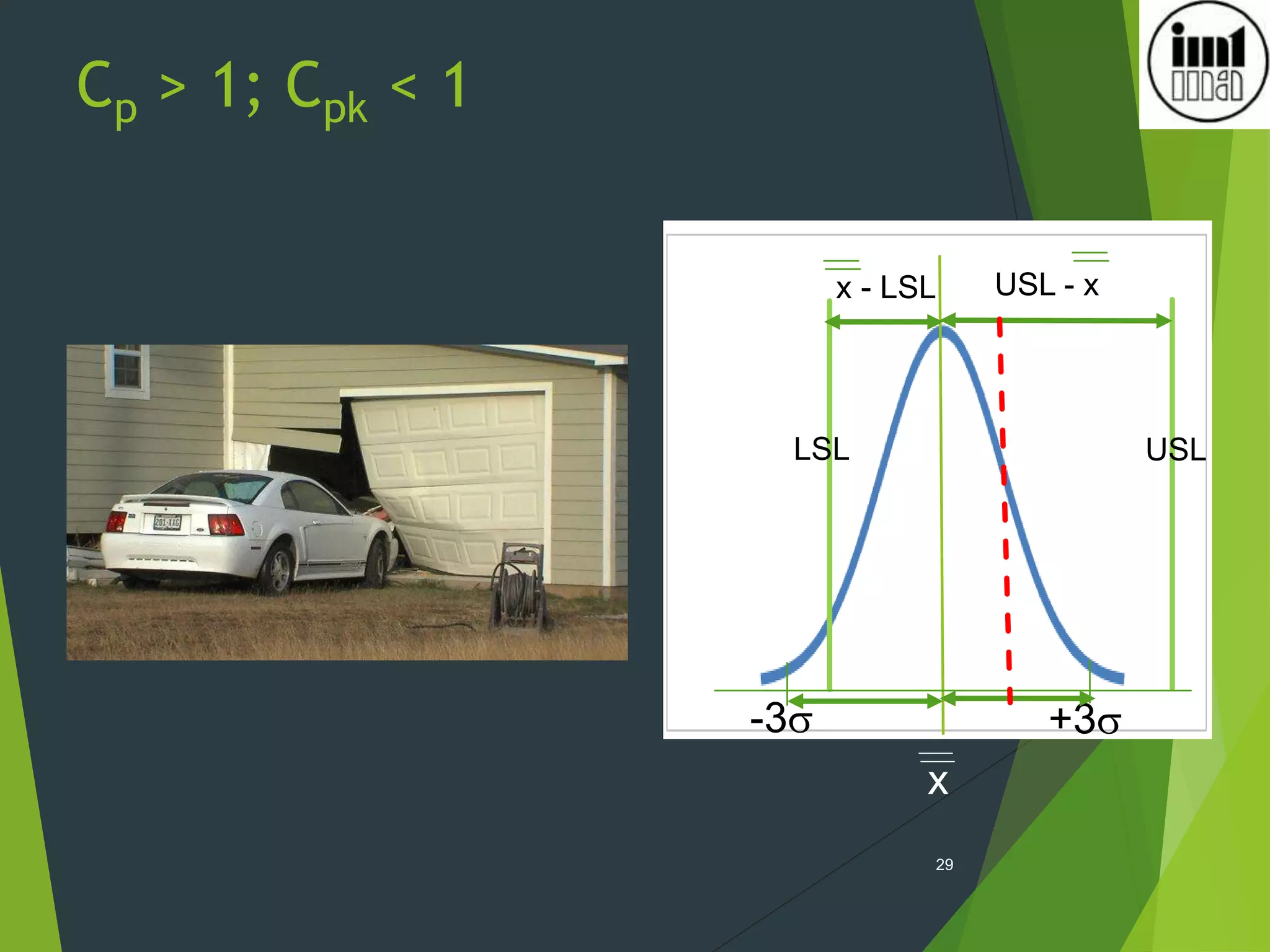

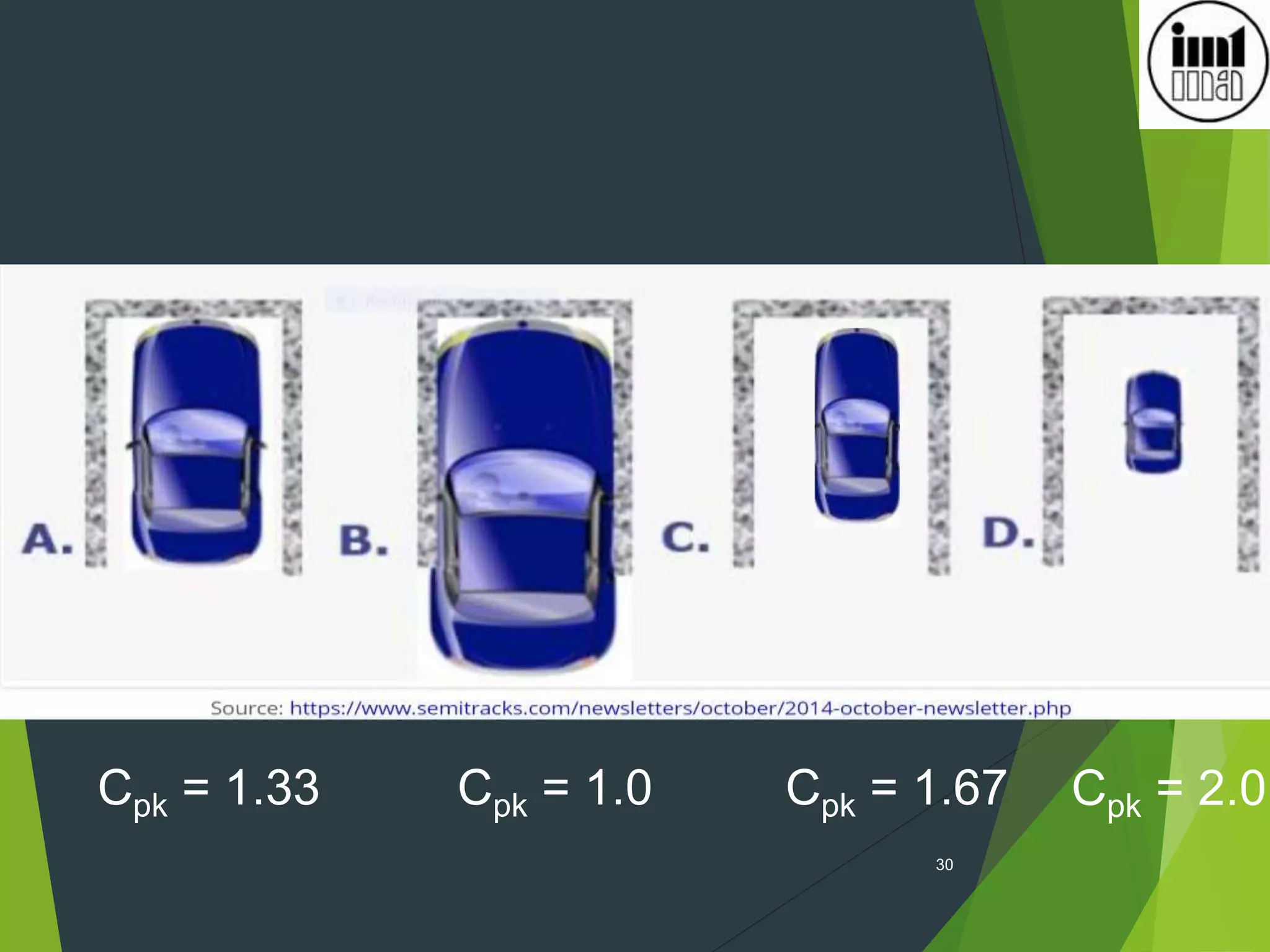

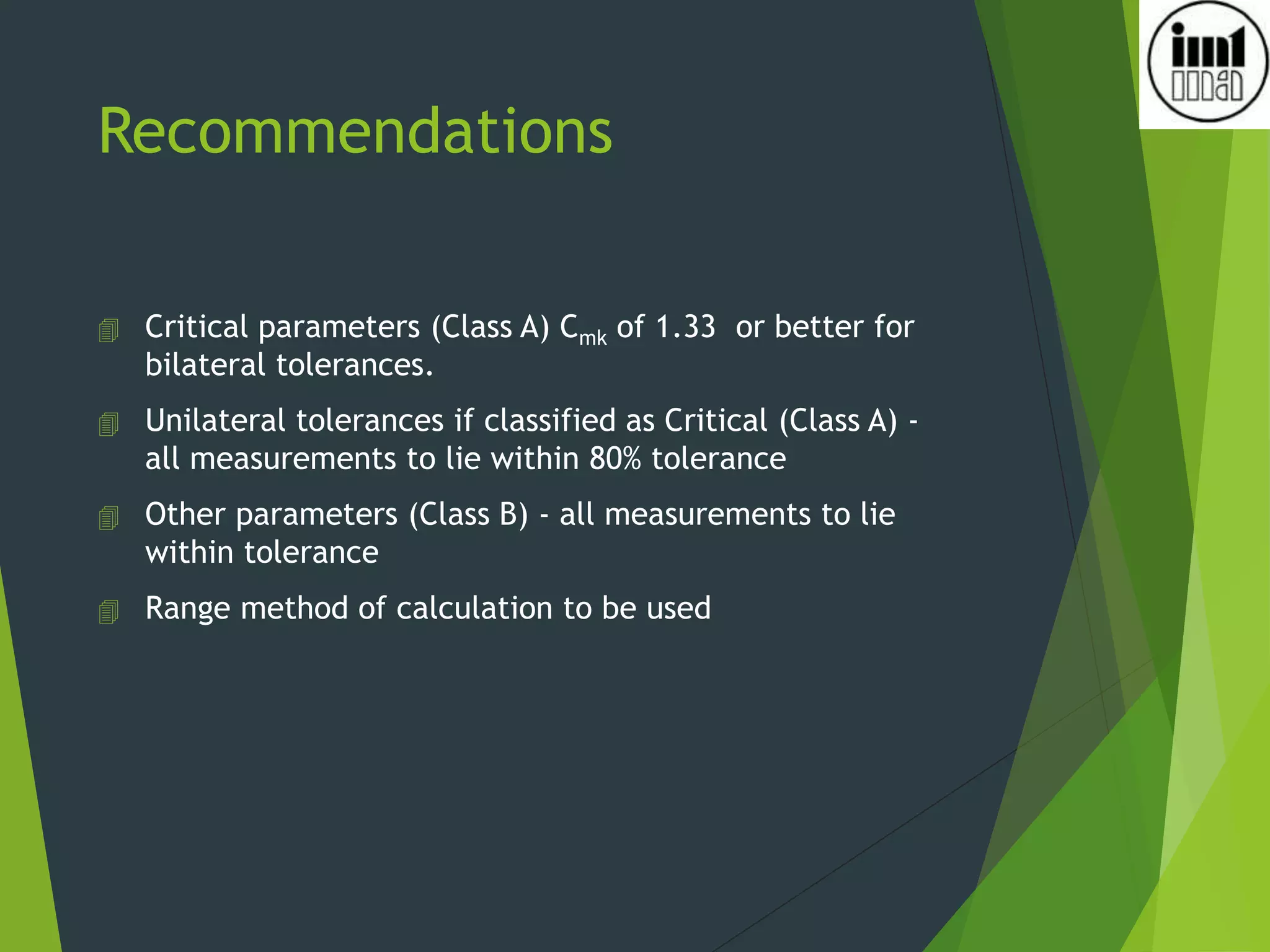

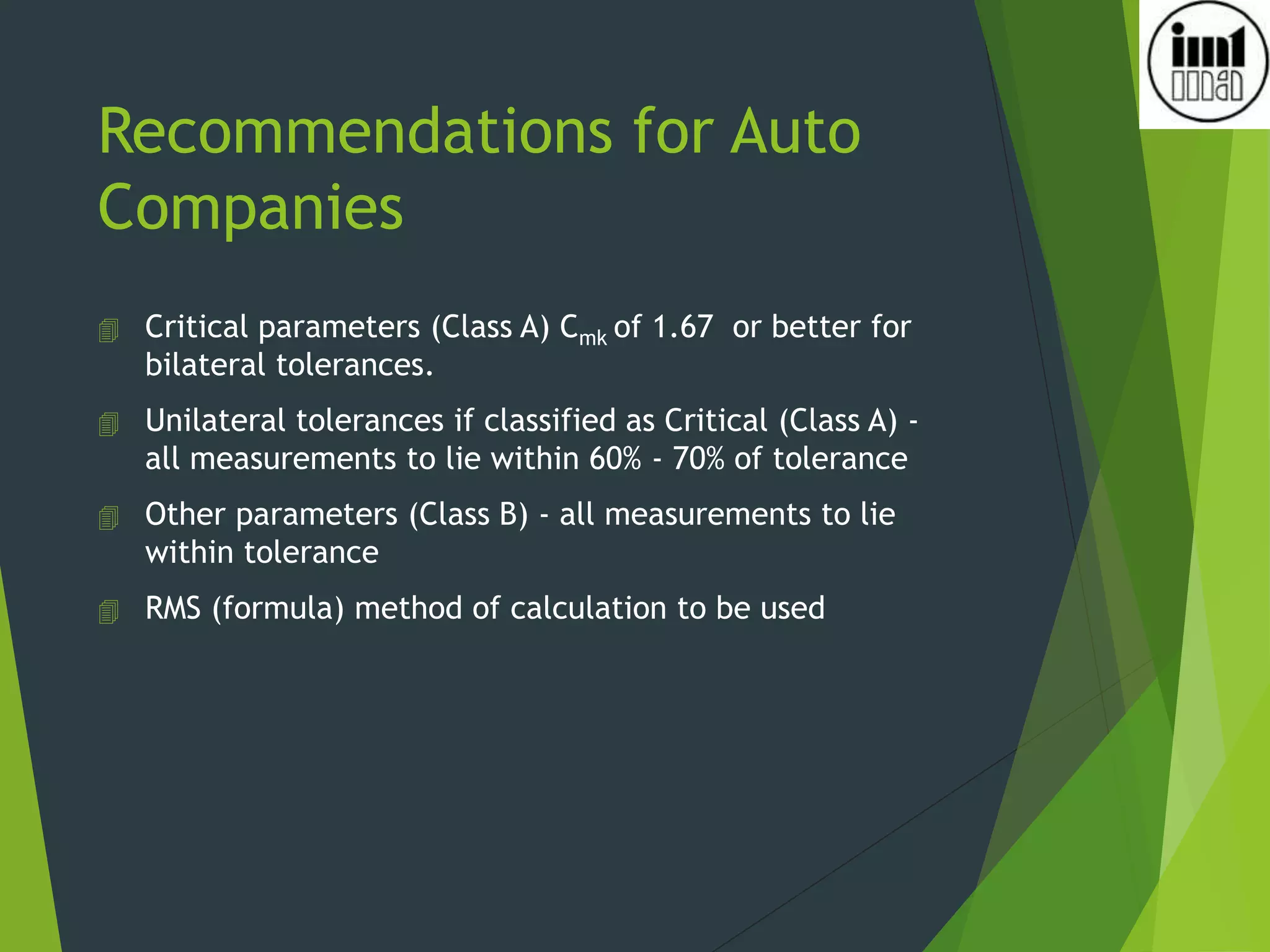

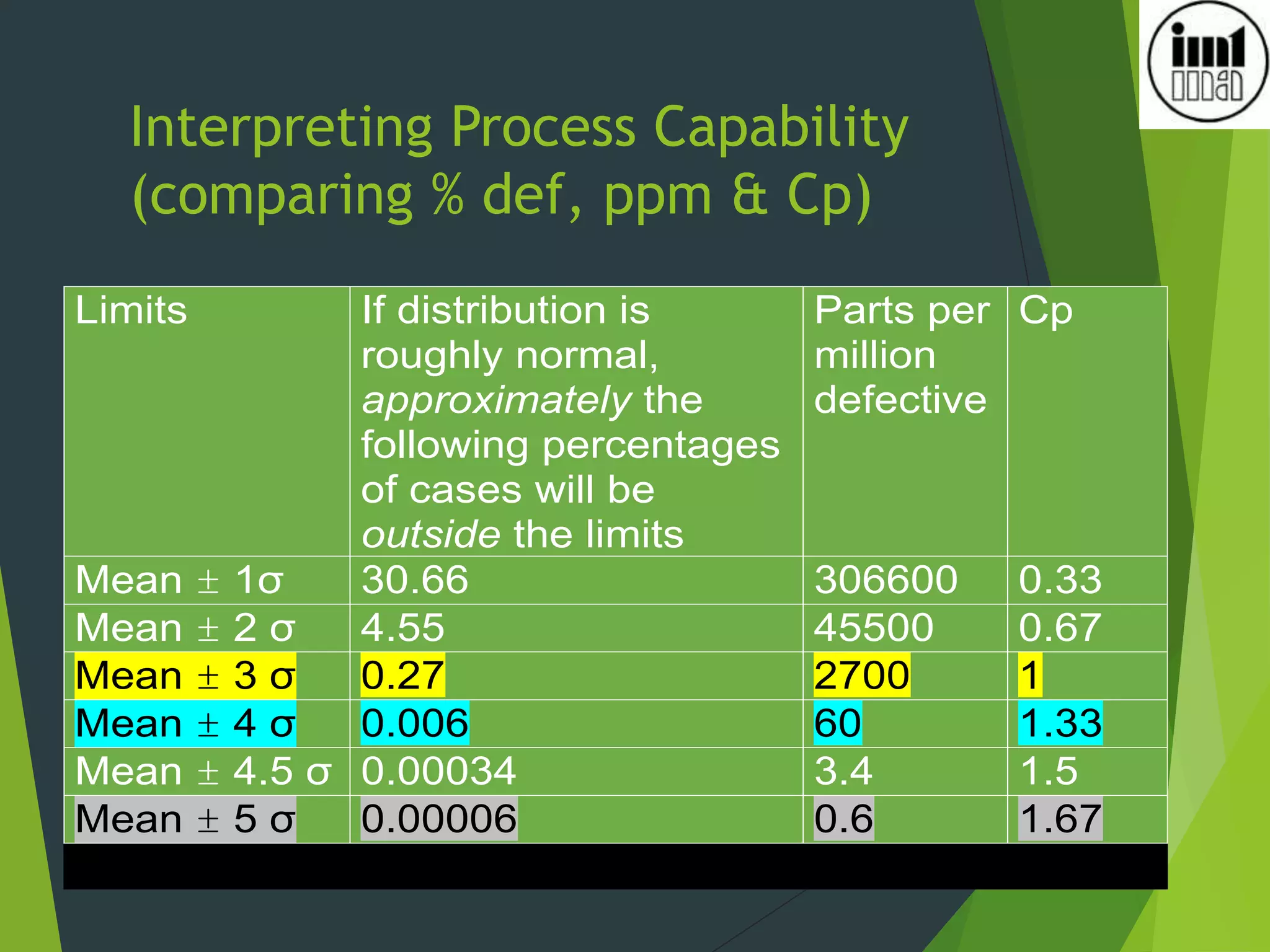

2) Process capability indices like Cp, Cpk measure how well a process performs versus specifications and a value of 1.33 or higher indicates a stable and capable process.

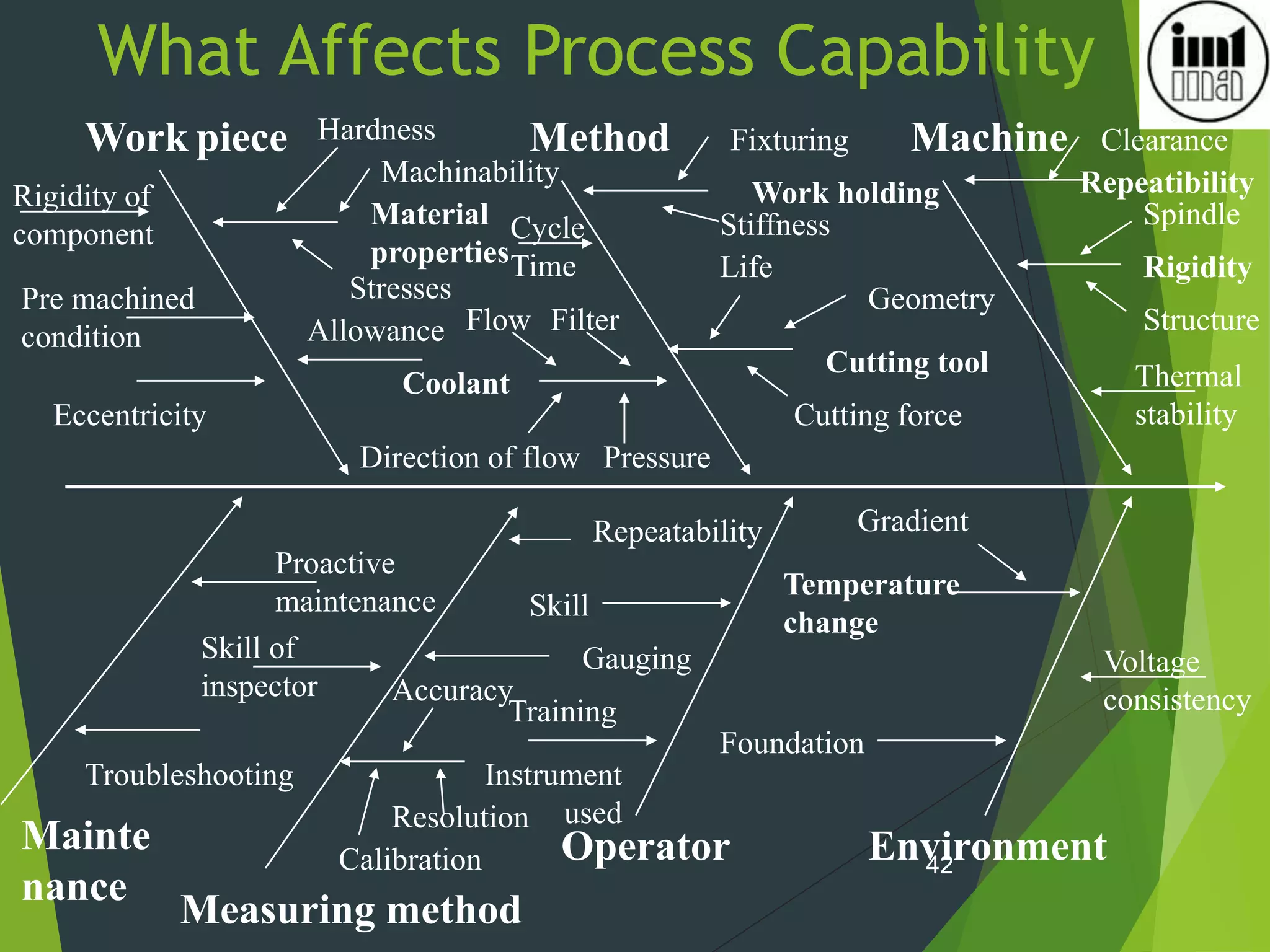

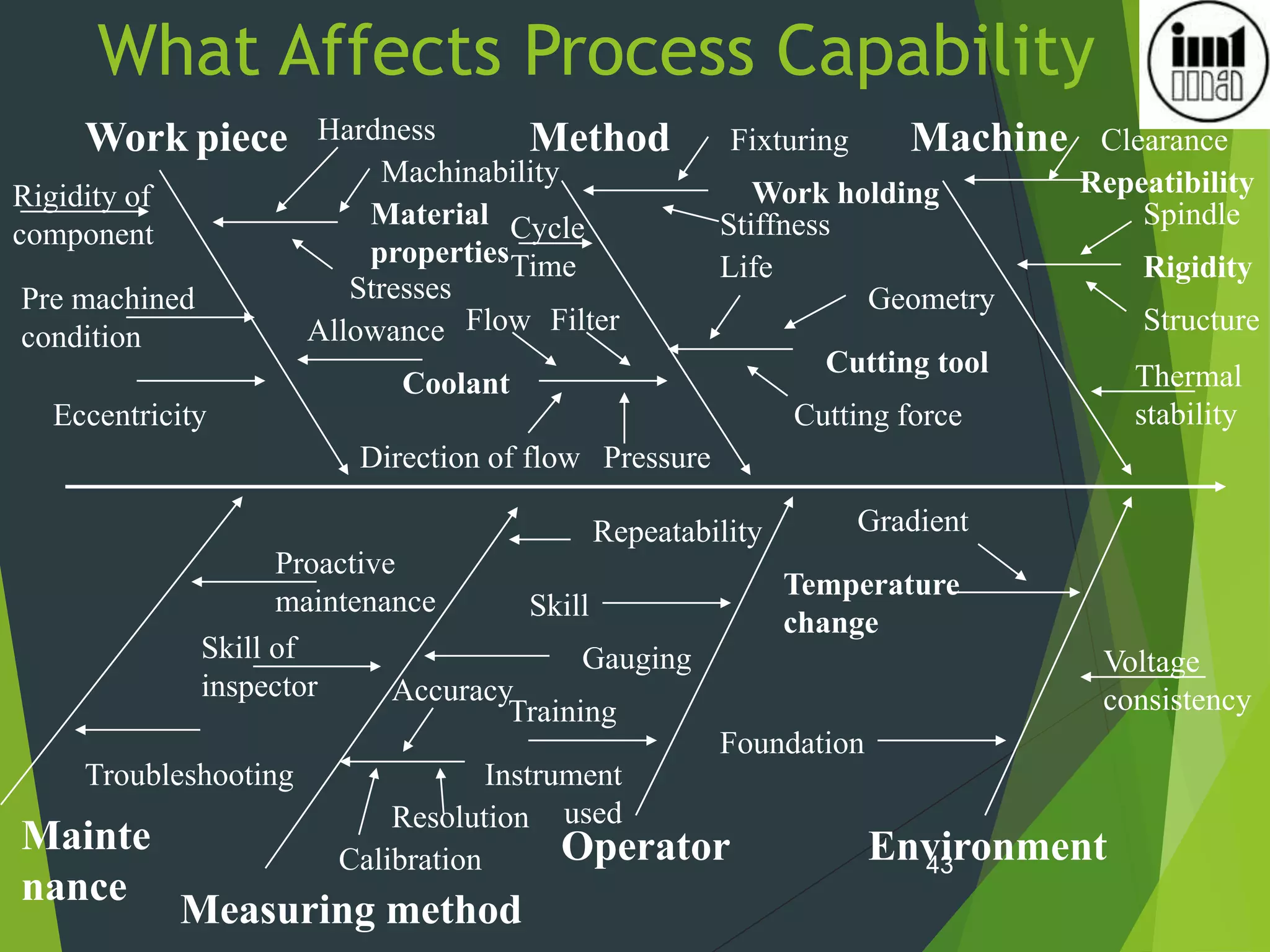

3) Many factors can impact a process's capability including the machine, environment, operator, material and more; conducting process capability studies helps evaluate a process and identify sources of variation.

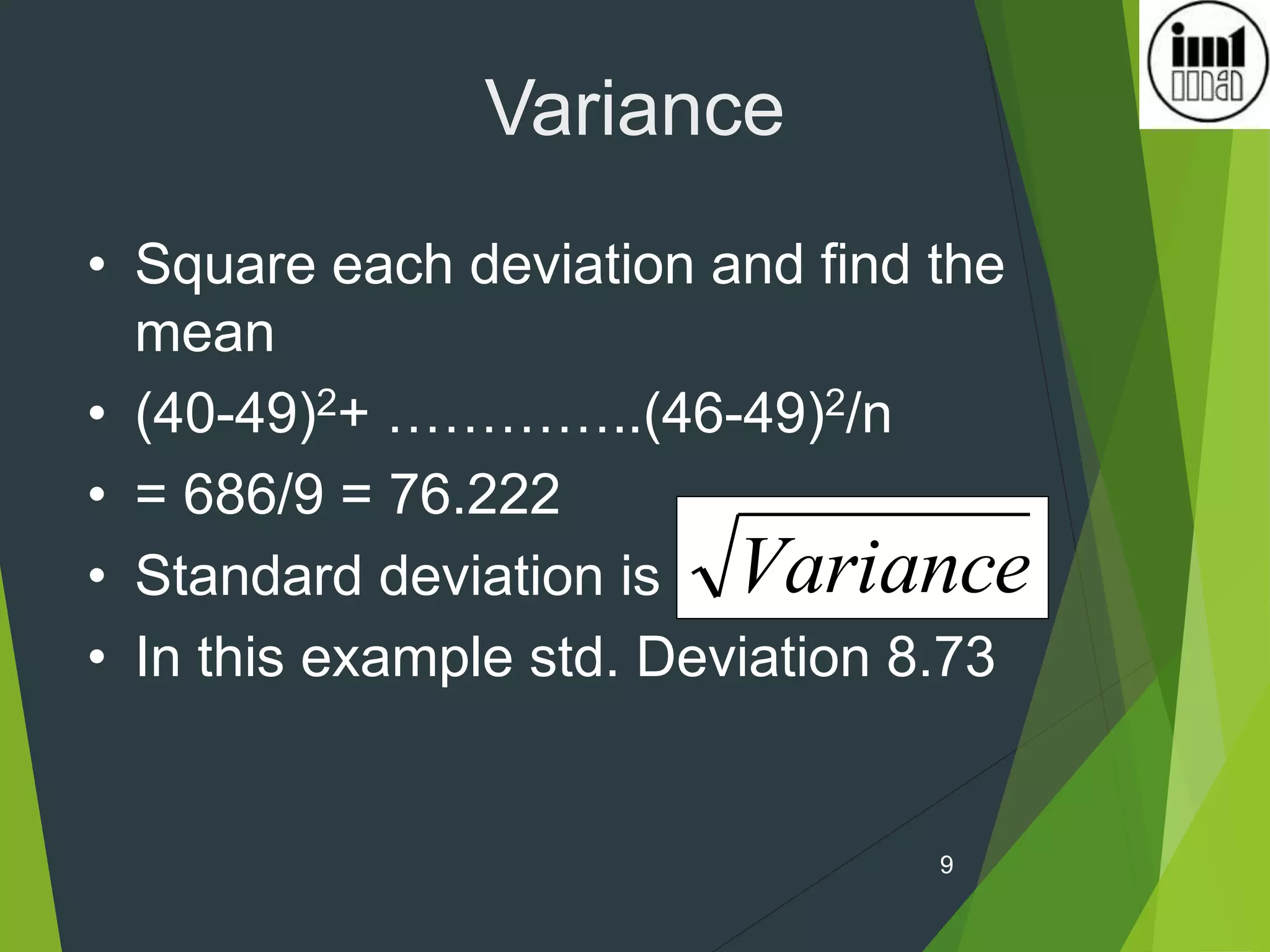

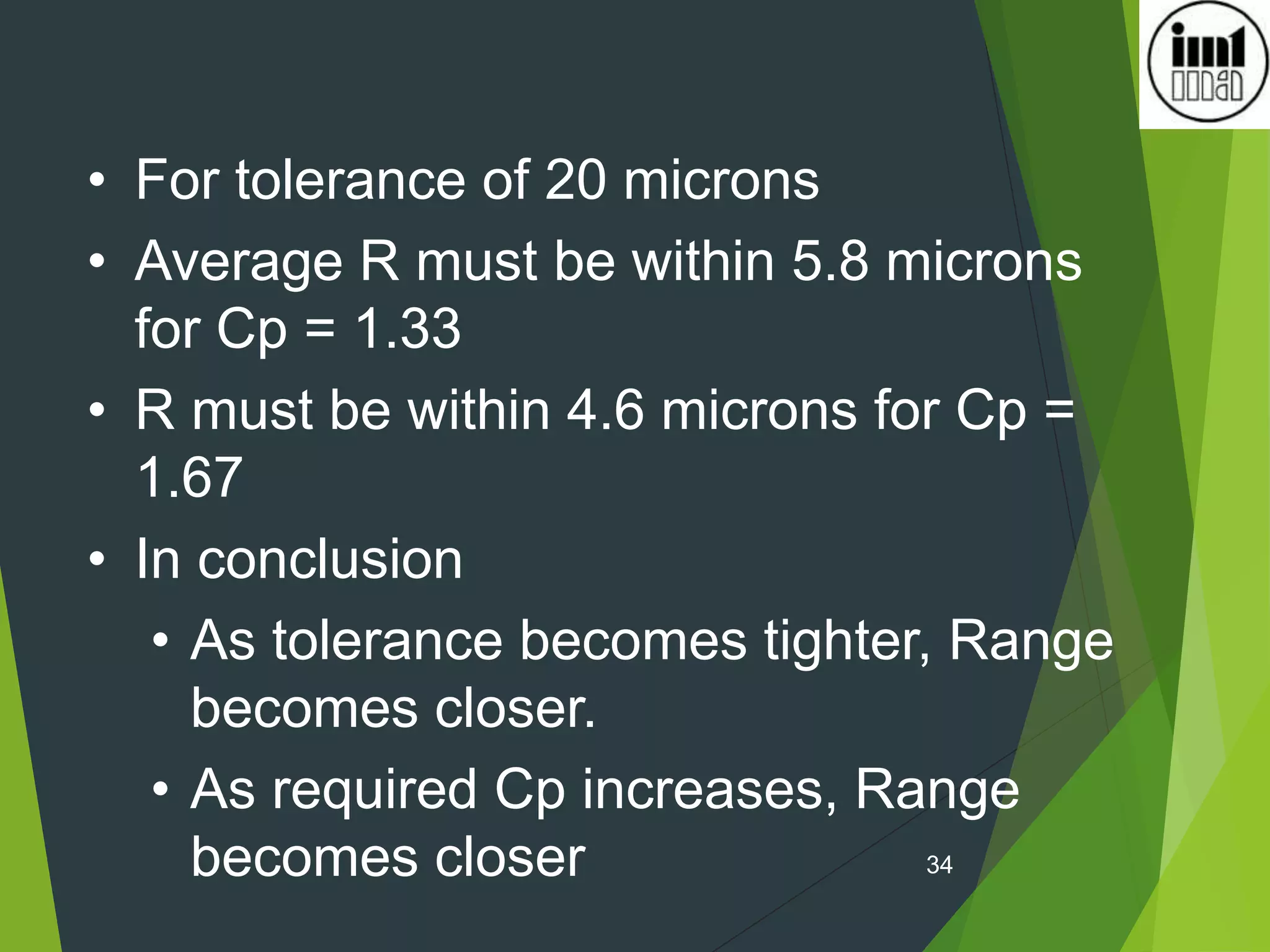

![Implication of Cpk = 1.67

Cp = 1.8

Component

tolerance

[microns]

Six Sigma

Variation

[microns]

Frequ

ency

272

(2σ)

Frequ

ency

380

(4σ)

Frequ

ency

399

(6σ)

Beyo

nd

6σ

Tot

al

40 22 7 14 22 1 400

30 16 5 10 16 1 400

20 11 3 7 11 1 400

10 5 1 3 5 1 400

47](https://image.slidesharecdn.com/day-5processcapabilityforcertificatecourseformarketingengineersonline-230721165100-44da60e7/75/Process-Capability-for-certificate-course-for-marketing-engineers-online-46-2048.jpg)