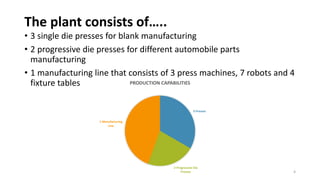

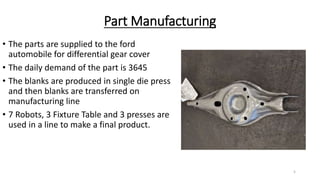

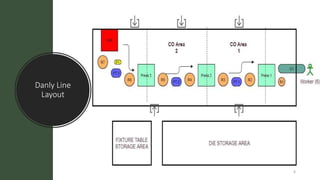

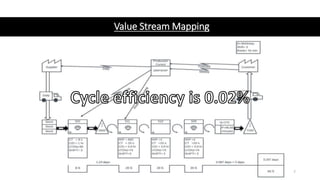

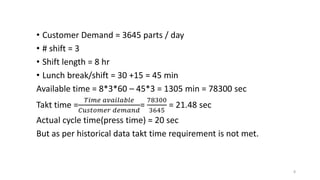

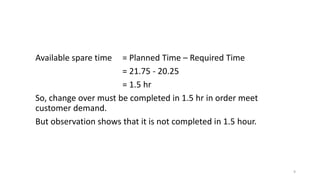

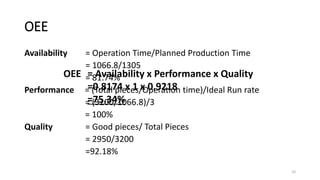

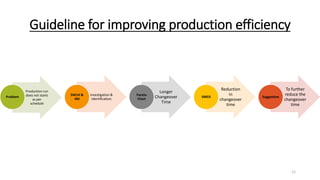

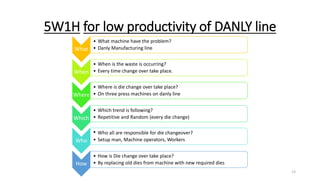

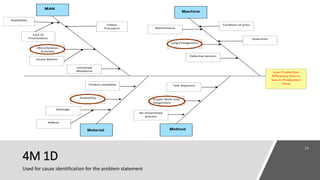

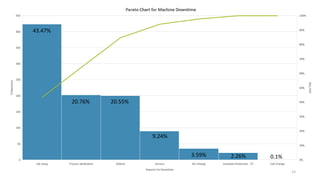

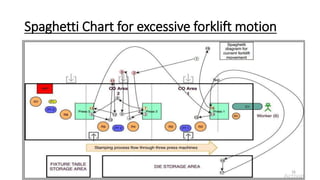

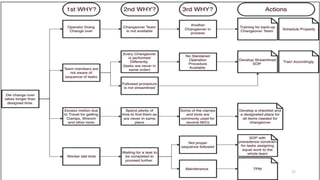

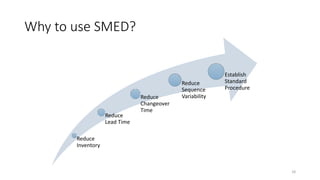

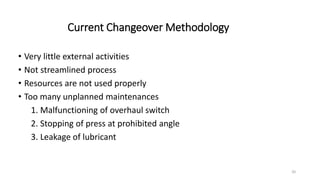

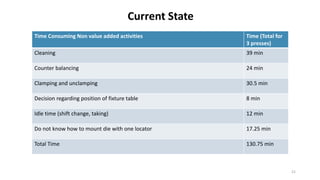

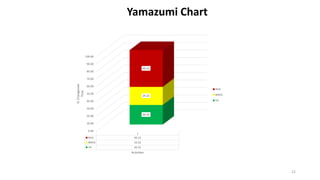

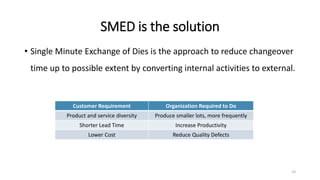

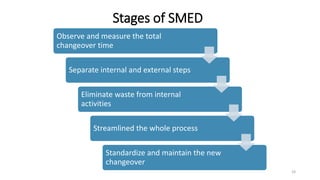

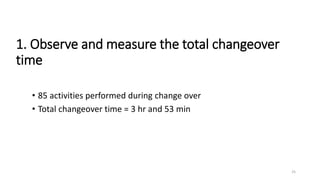

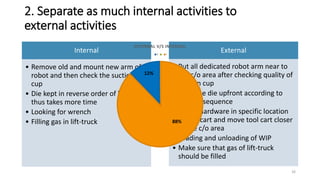

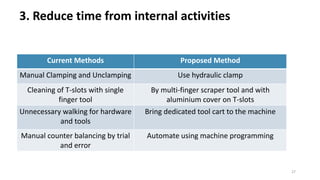

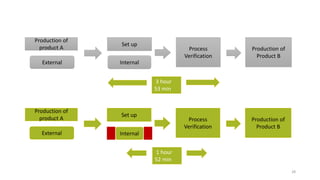

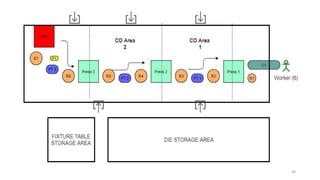

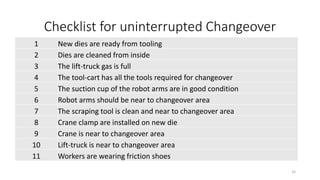

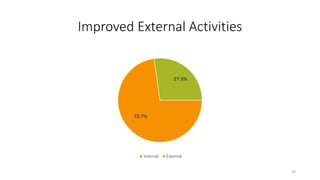

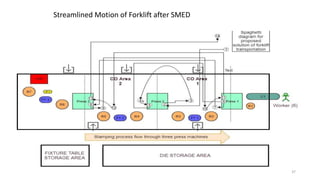

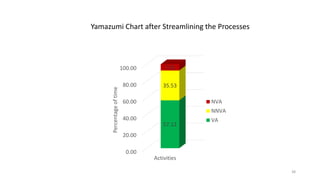

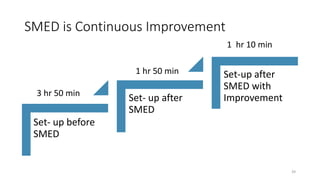

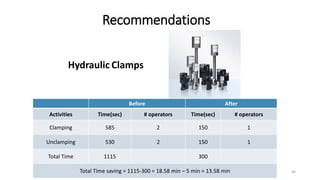

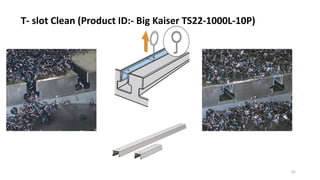

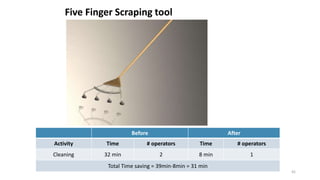

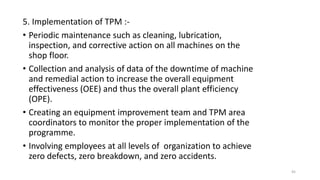

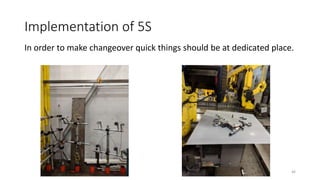

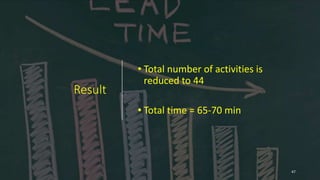

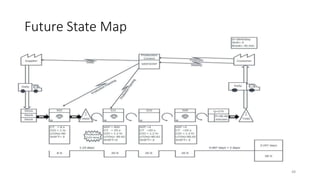

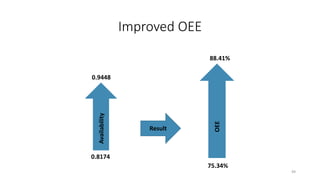

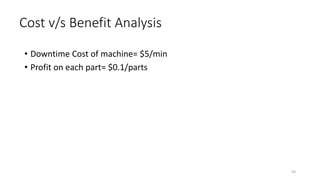

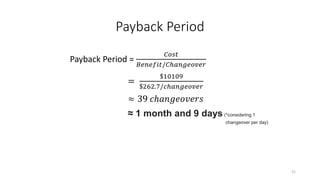

The document outlines a process improvement initiative at a Cannon automotive plant aimed at reducing die changeover time using lean tools. It highlights the current challenges, including efficiency issues and excessive time wasted during changeovers, and proposes solutions using the Single Minute Exchange of Die (SMED) methodology to streamline operations. The implementation of new procedures is expected to significantly reduce changeover time, enhance overall equipment effectiveness (OEE), and meet customer demands efficiently.