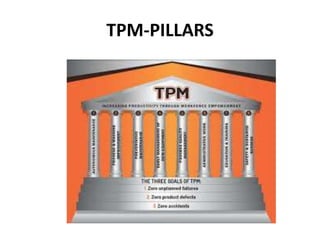

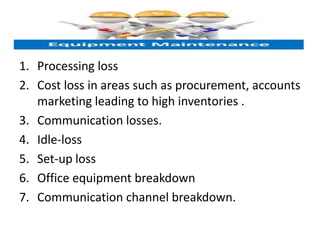

This presentation discusses Total Productive Maintenance (TPM). TPM aims to improve productivity by making processes more reliable and less wasteful through machinery, equipment, and employees. It has several objectives, including increasing production while also improving employee morale, minimizing unplanned downtime, providing a safe work environment, achieving zero defects/breakdowns/accidents, involving people at all organizational levels, and forming teams to reduce defects through self-maintenance. The presentation outlines the eight pillars of TPM which are methods for achieving its goals: autonomous maintenance, focused improvement, planned maintenance, quality maintenance, education and training, development maintenance, safety/health/environment, and office TPM.