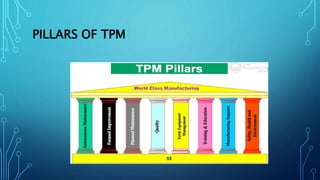

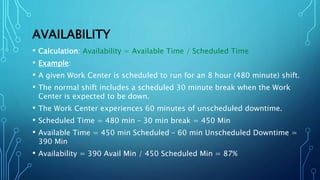

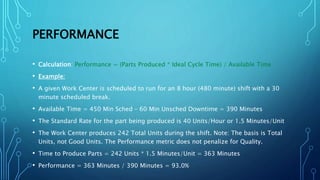

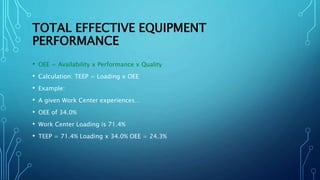

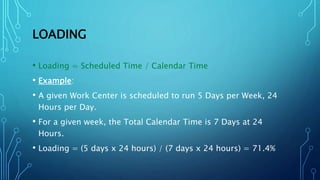

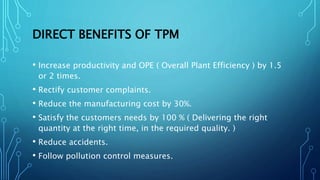

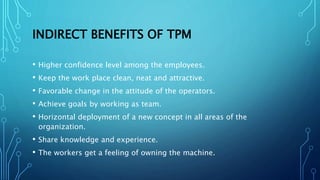

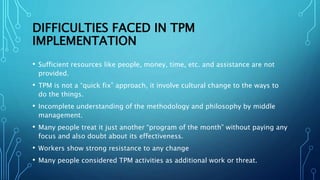

Total productive maintenance (TPM) aims to maximize equipment effectiveness through improved maintenance practices and operator involvement. It has 8 pillars including autonomous maintenance, focused improvement, and planned maintenance. TPM seeks to increase availability, performance, and quality while reducing costs. Barriers to implementation include lack of resources and resistance to cultural changes in maintenance practices.