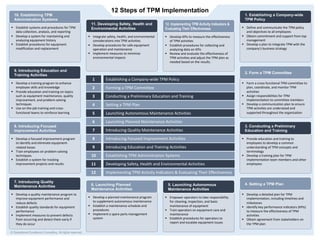

The 12 Steps of TPM Implementation Poster

- 1. 12 Steps of TPM Implementation © Operational Excellence Consulting. All rights reserved. § Define and communicate the TPM policy and objectives to all employees § Obtain commitment and support from top management § Develop a plan to integrate TPM with the company's business strategy 1. Establishing a Company-wide TPM Policy Establishing a Company-wide TPM Policy 1 Forming a TPM Committee 2 Conducting a Preliminary Education and Training 3 Setting a TPM Plan 4 Launching Autonomous Maintenance Activities 5 Launching Planned Maintenance Activities 6 Introducing Quality Maintenance Activities 7 Introducing Focused Improvement Activities 8 Introducing Education and Training Activities 9 Establishing TPM Administration Systems 10 Developing Safety, Health and Environmental Activities 11 Implementing TPM Activity Indicators & Evaluating Their Effectiveness 12 § Form a cross-functional TPM committee to plan, coordinate, and monitor TPM activities § Assign responsibilities for TPM implementation to committee members § Develop a communication plan to ensure TPM activities are understood and supported throughout the organization 2. Form a TPM Committee § Provide education and training to employees to develop a common understanding of TPM concepts and terminology § Develop a training plan for TPM implementation team members and other employees 3. Conducting a Preliminary Education and Training § Develop a detailed plan for TPM implementation, including timelines and milestones § Identify key performance indicators (KPIs) to measure the effectiveness of TPM activities § Obtain agreement from stakeholders on the TPM plan 4. Setting a TPM Plan § Establish systems and procedures for TPM data collection, analysis, and reporting § Develop a system for maintaining and analyzing equipment history § Establish procedures for equipment modification and replacement 10. Establishing TPM Administration Systems § Develop a training program to enhance employee skills and knowledge § Provide education and training on topics such as equipment maintenance, quality improvement, and problem-solving techniques § Use on-the-job training and cross- functional teams to reinforce learning 9. Introducing Education and Training Activities § Develop a focused improvement program to identify and eliminate equipment- related losses § Train employees on problem-solving techniques § Establish a system for tracking improvement projects and results 8. Introducing Focused Improvement Activities § Develop a quality maintenance program to improve equipment performance and reduce defects § Establish quality standards for equipment performance § Implement measures to prevent defects from occurring and detect them early if they do occur 7. Introducing Quality Maintenance Activities § Develop a planned maintenance program to supplement autonomous maintenance § Establish a maintenance schedule and procedures § Implement a spare parts management system 6. Launching Planned Maintenance Activities § Empower operators to take responsibility for cleaning, inspection, and basic maintenance of equipment § Train operators on equipment care and maintenance § Establish procedures for operators to report and escalate equipment issues 5. Launching Autonomous Maintenance Activities § Integrate safety, health, and environmental considerations into TPM activities § Develop procedures for safe equipment operation and maintenance § Implement measures to minimize environmental impacts 11. Developing Safety, Health and Environmental Activities § Develop KPIs to measure the effectiveness of TPM activities § Establish procedures for collecting and analyzing data on KPIs § Review and evaluate the effectiveness of TPM activities and adjust the TPM plan as needed based on the results. 12. Implementing TPM Activity Indicators & Evaluating Their Effectiveness

- 2. 12 Steps of TPM Implementation © Operational Excellence Consulting. All rights reserved. § Define and communicate the TPM policy and objectives to all employees § Obtain commitment and support from top management § Develop a plan to integrate TPM with the company's business strategy 1. Establishing a Company-wide TPM Policy Establishing a Company-wide TPM Policy 1 Forming a TPM Committee 2 Conducting a Preliminary Education and Training 3 Setting a TPM Plan 4 Launching Autonomous Maintenance Activities 5 Launching Planned Maintenance Activities 6 Introducing Quality Maintenance Activities 7 Introducing Focused Improvement Activities 8 Introducing Education and Training Activities 9 Establishing TPM Administration Systems 10 Developing Safety, Health and Environmental Activities 11 Implementing TPM Activity Indicators & Evaluating Their Effectiveness 12 § Form a cross-functional TPM committee to plan, coordinate, and monitor TPM activities § Assign responsibilities for TPM implementation to committee members § Develop a communication plan to ensure TPM activities are understood and supported throughout the organization 2. Form a TPM Committee § Provide education and training to employees to develop a common understanding of TPM concepts and terminology § Develop a training plan for TPM implementation team members and other employees 3. Conducting a Preliminary Education and Training § Develop a detailed plan for TPM implementation, including timelines and milestones § Identify key performance indicators (KPIs) to measure the effectiveness of TPM activities § Obtain agreement from stakeholders on the TPM plan 4. Setting a TPM Plan § Establish systems and procedures for TPM data collection, analysis, and reporting § Develop a system for maintaining and analyzing equipment history § Establish procedures for equipment modification and replacement 10. Establishing TPM Administration Systems § Develop a training program to enhance employee skills and knowledge § Provide education and training on topics such as equipment maintenance, quality improvement, and problem-solving techniques § Use on-the-job training and cross- functional teams to reinforce learning 9. Introducing Education and Training Activities § Develop a focused improvement program to identify and eliminate equipment- related losses § Train employees on problem-solving techniques § Establish a system for tracking improvement projects and results 8. Introducing Focused Improvement Activities § Develop a quality maintenance program to improve equipment performance and reduce defects § Establish quality standards for equipment performance § Implement measures to prevent defects from occurring and detect them early if they do occur 7. Introducing Quality Maintenance Activities § Develop a planned maintenance program to supplement autonomous maintenance § Establish a maintenance schedule and procedures § Implement a spare parts management system 6. Launching Planned Maintenance Activities § Empower operators to take responsibility for cleaning, inspection, and basic maintenance of equipment § Train operators on equipment care and maintenance § Establish procedures for operators to report and escalate equipment issues 5. Launching Autonomous Maintenance Activities § Integrate safety, health, and environmental considerations into TPM activities § Develop procedures for safe equipment operation and maintenance § Implement measures to minimize environmental impacts 11. Developing Safety, Health and Environmental Activities § Develop KPIs to measure the effectiveness of TPM activities § Establish procedures for collecting and analyzing data on KPIs § Review and evaluate the effectiveness of TPM activities and adjust the TPM plan as needed based on the results. 12. Implementing TPM Activity Indicators & Evaluating Their Effectiveness

- 3. © Operational Excellence Consulting. All rights reserved. 3 Operational Excellence Consulting is a management training and consulting firm that assists organizations in improving business performance and effectiveness. Based in Singapore, the firm’s mission is to create business value for organizations through innovative design and operational excellence management training and consulting solutions. For more information, please visit www.oeconsulting.com.sg