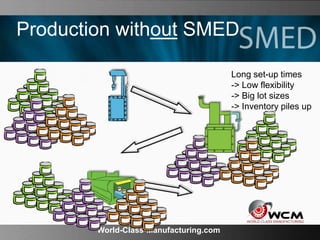

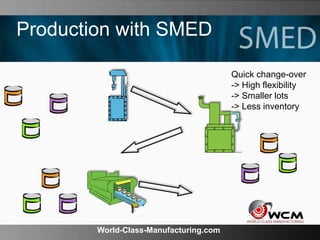

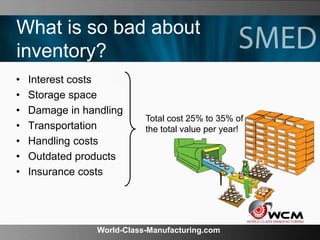

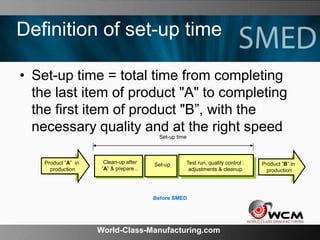

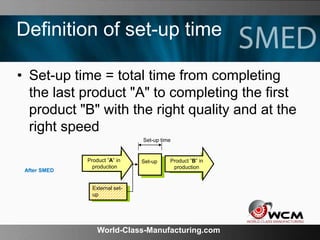

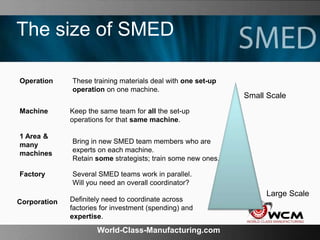

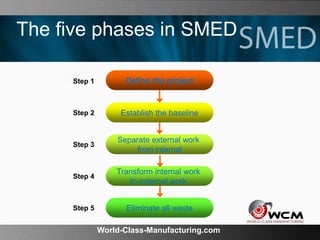

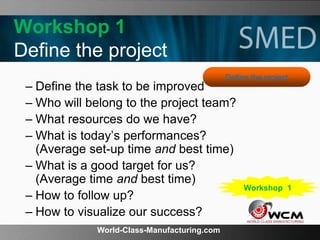

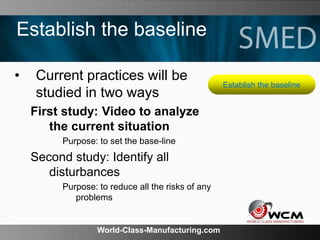

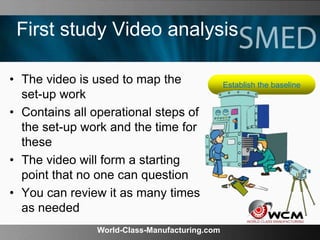

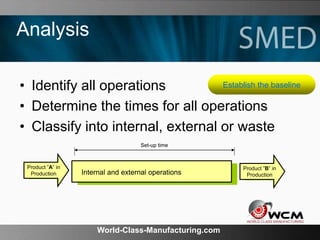

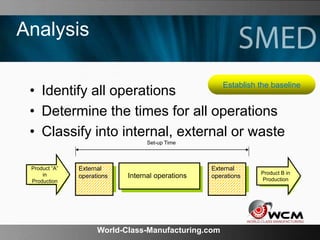

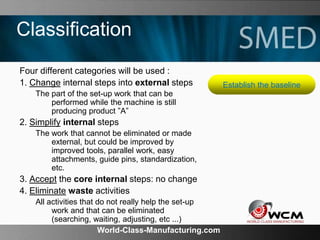

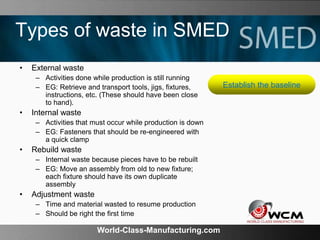

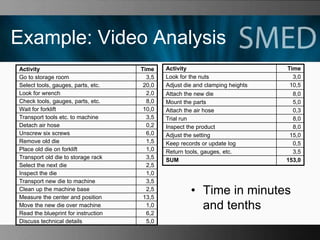

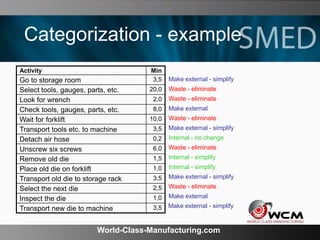

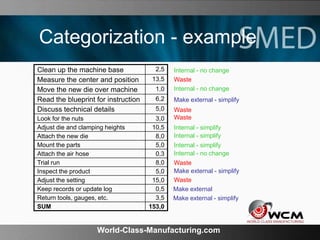

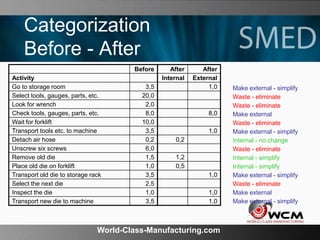

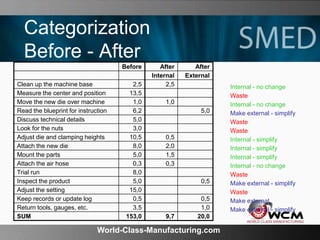

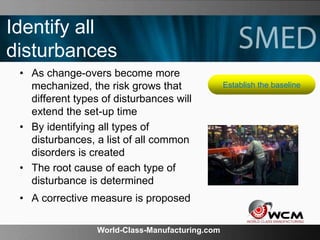

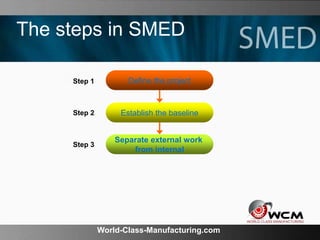

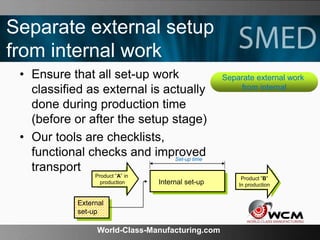

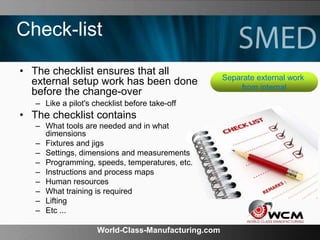

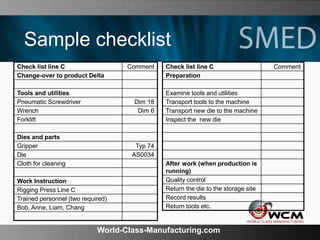

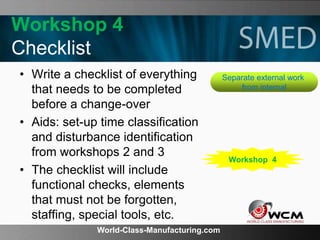

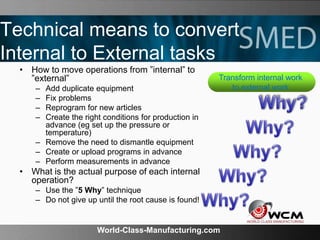

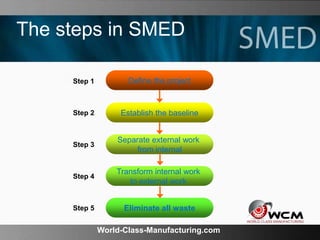

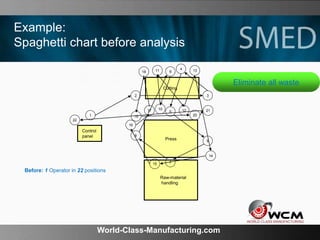

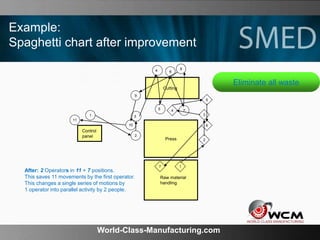

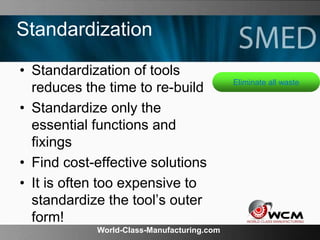

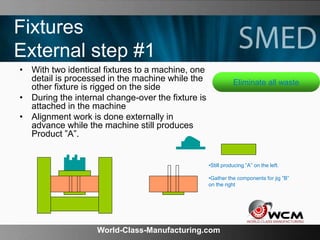

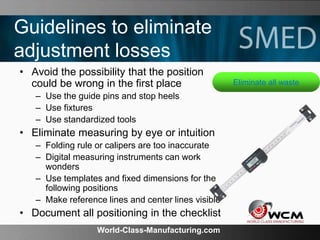

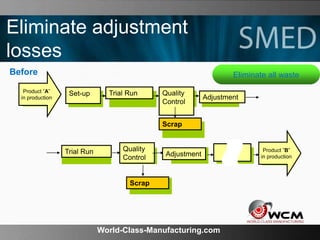

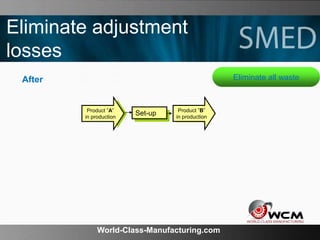

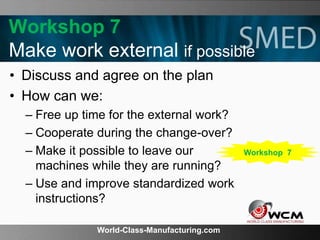

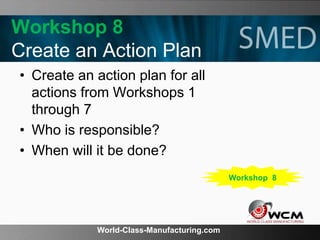

The presentation details the SMED (Single Minute Exchange of Dies) methodology, aiming to reduce set-up times in manufacturing to under nine minutes to increase efficiency and flexibility. It outlines the historical development of SMED, notable achievements, and the benefits of implementing this system, such as reduced inventory and improved delivery performance. Key steps for establishing a successful SMED project include defining the project scope, analyzing current practices, and categorizing work processes into external and internal tasks.