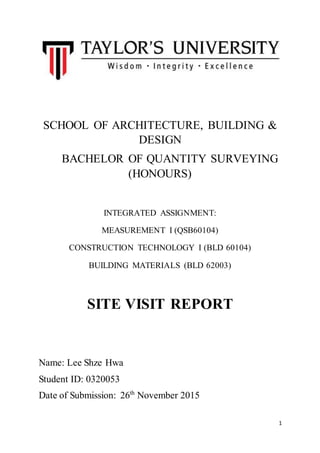

This document is a site visit report for a construction project of 96 semi-detached houses. It includes an introduction describing the site and project details. The objectives of the site visit are to observe construction processes, materials, and gain practical experience. Key observations from the site include different foundation types used - piling for some houses and pad footings for others due to soil conditions. The pad footing construction process and involved materials like rebar, formwork, and concrete are described. Photos from the site provide visual examples. The conclusion expresses what was learned from the experience.