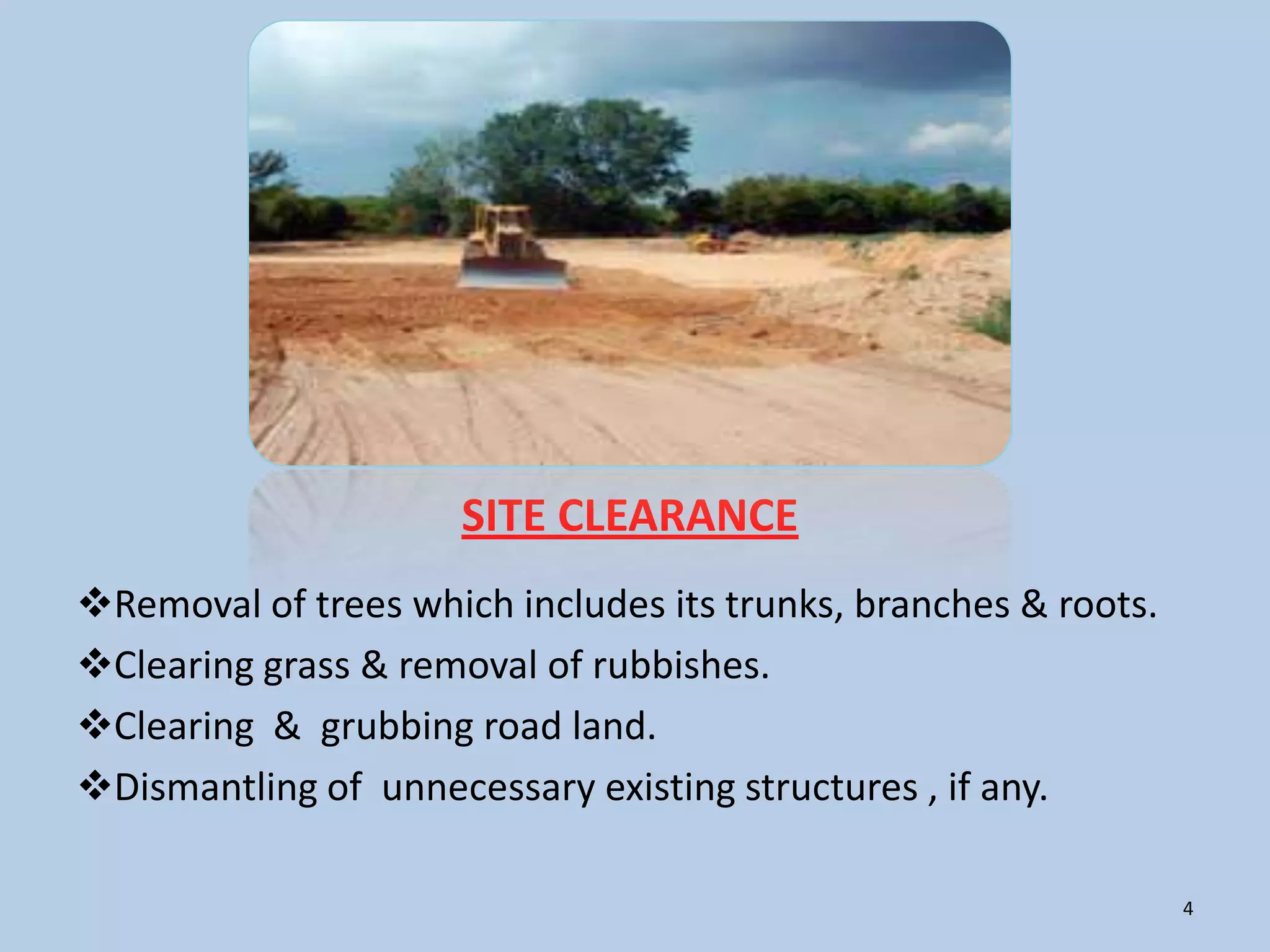

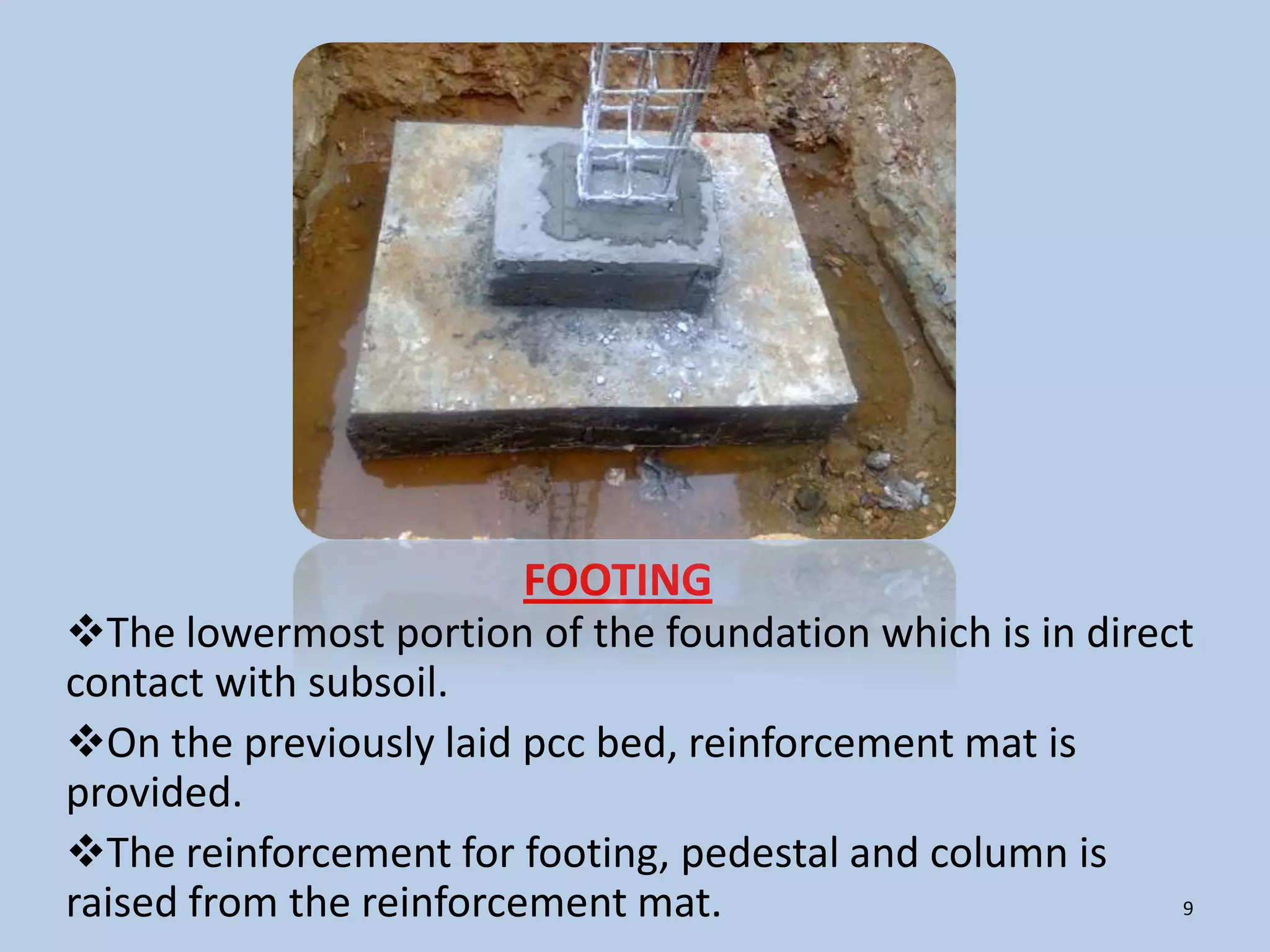

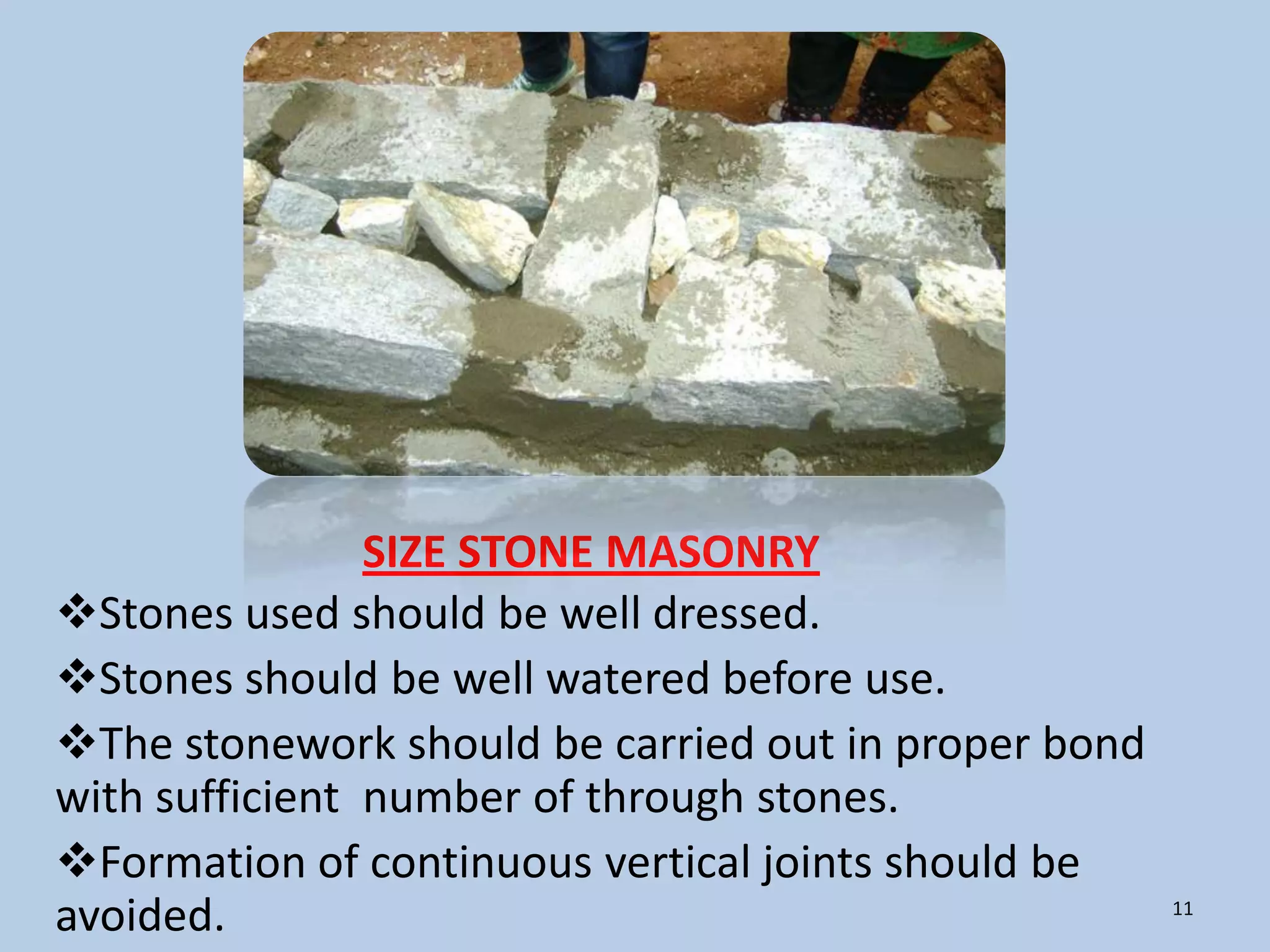

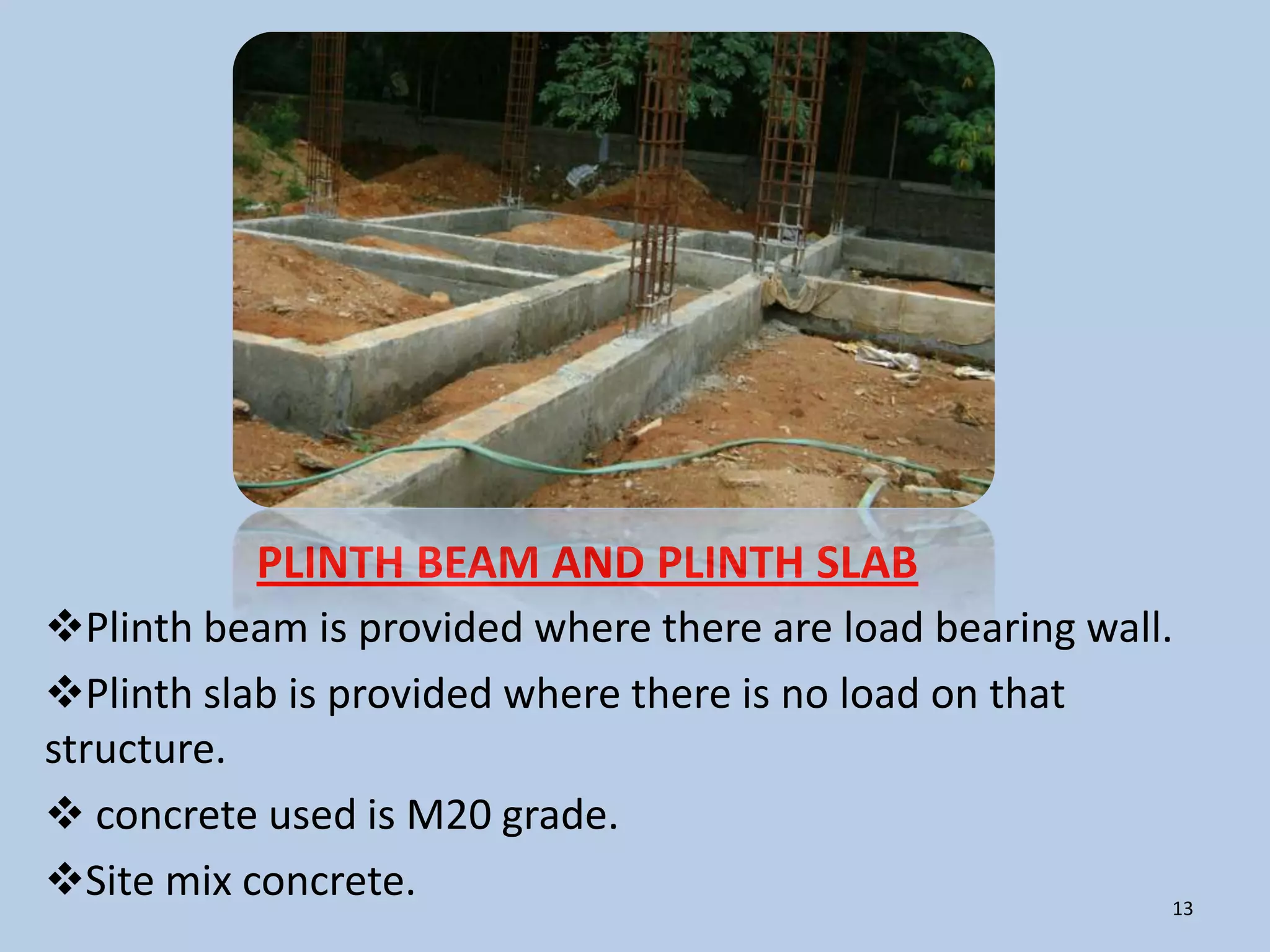

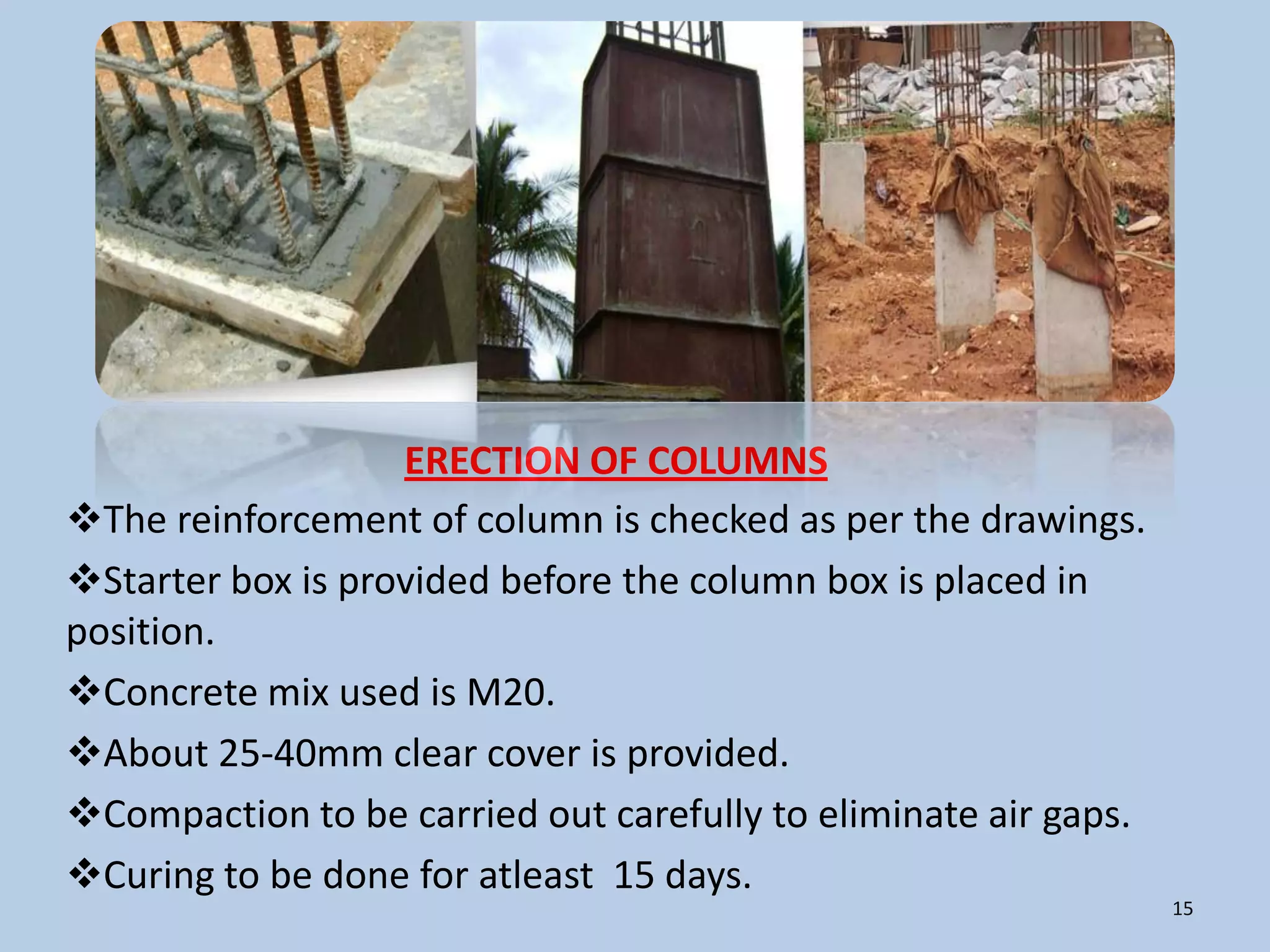

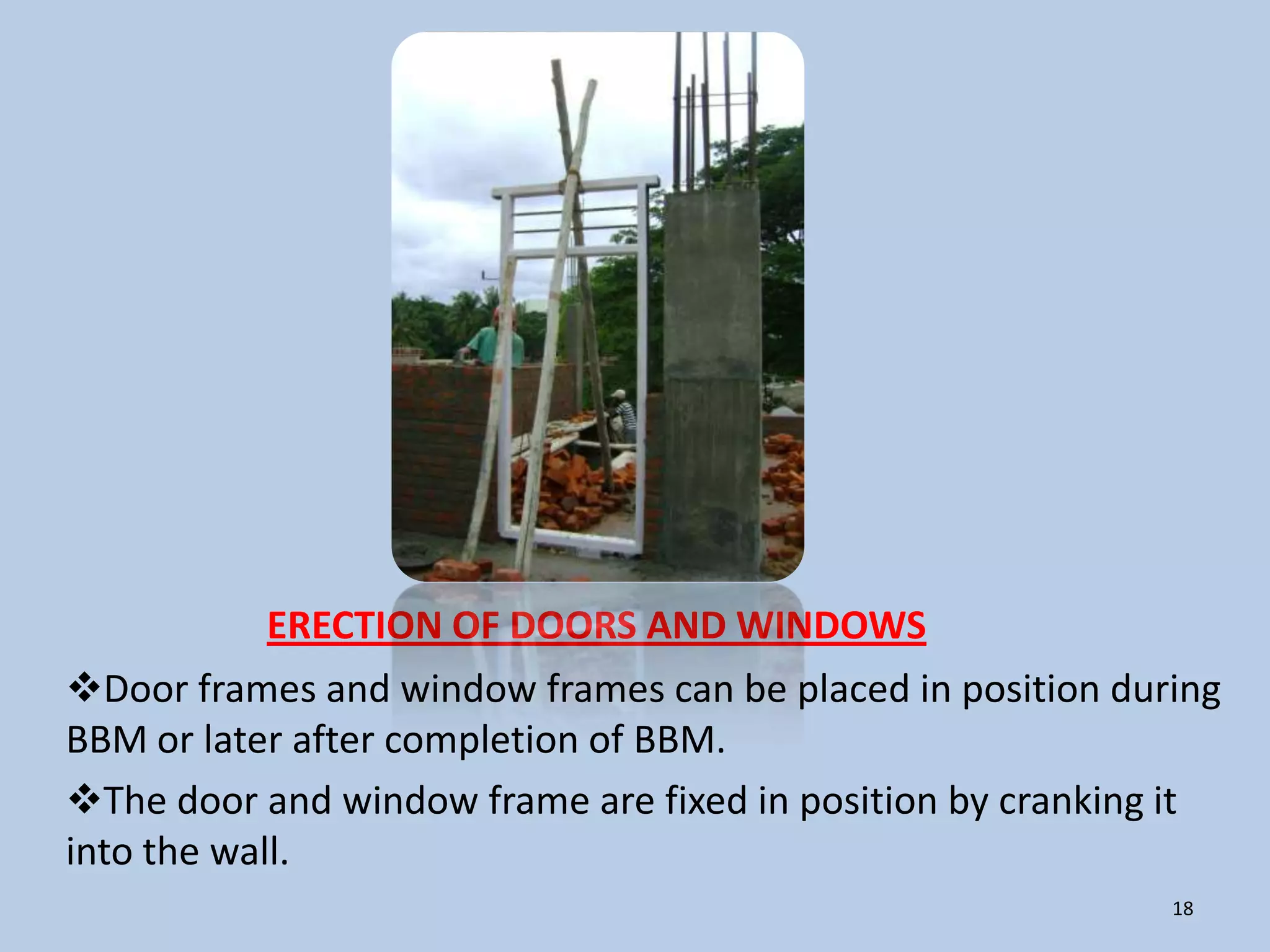

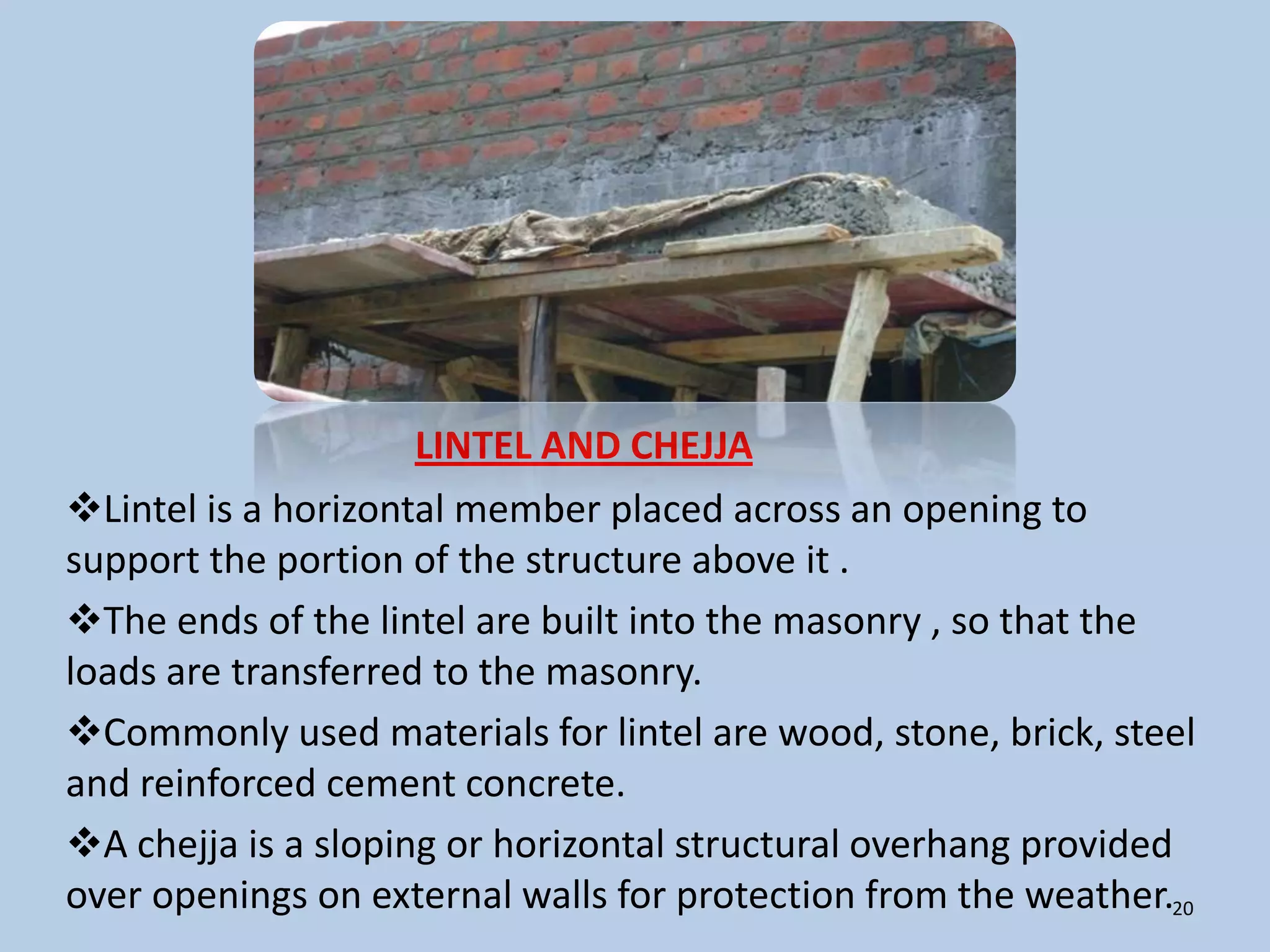

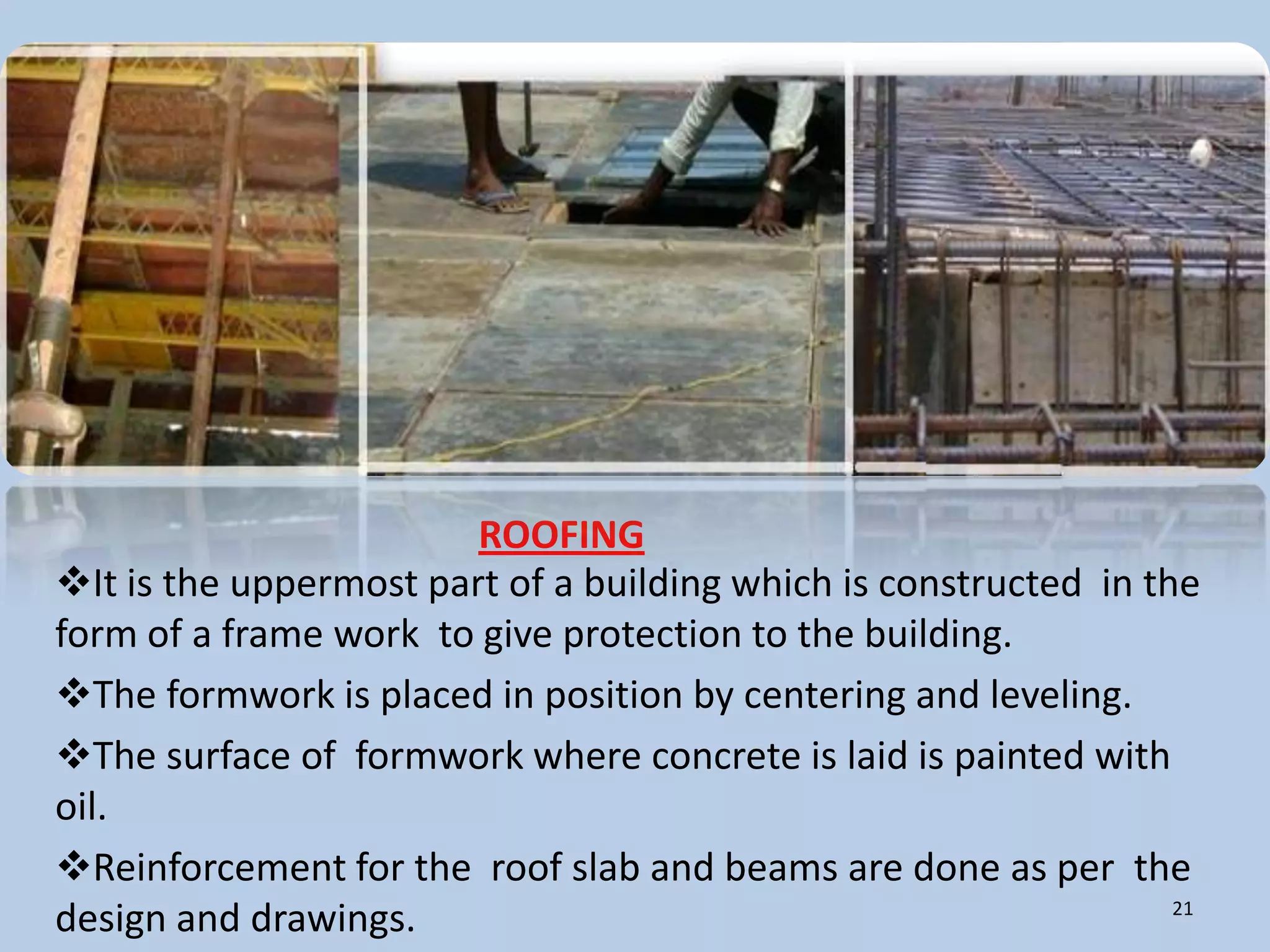

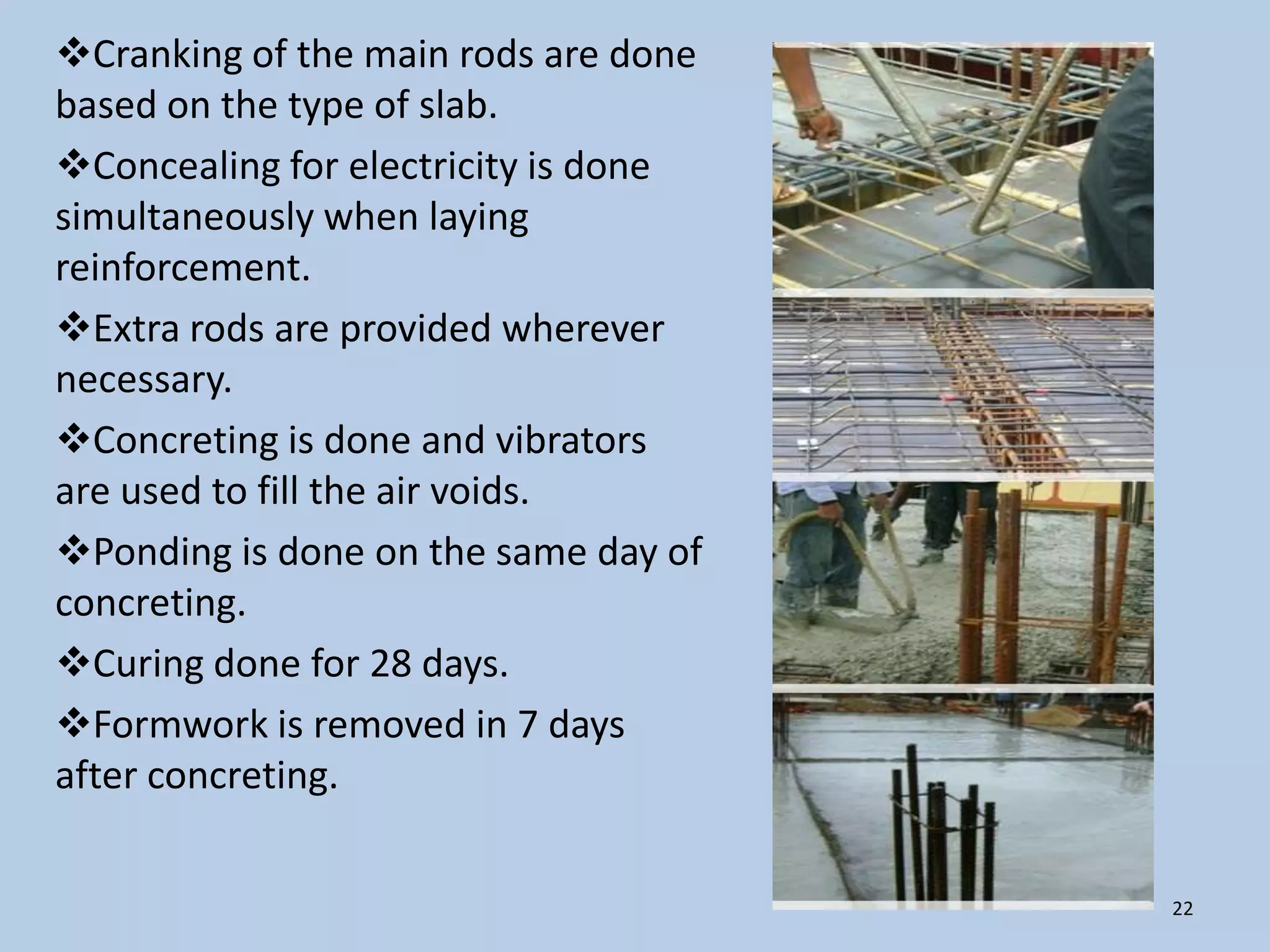

The document outlines the typical steps involved in a construction project, including site clearance, leveling, center line marking, excavation, PCC work, footing, SSM work, plinth beam and slab, erection of columns, BBM, erection of doors and windows, lintel and chejja, roofing, parapet, concealing, plastering, flooring and final finishing. It also provides details on specific construction activities like excavation, PCC work, footing, SSM work, plinth beam and slab construction, erection of columns, BBM, erection of doors and windows, lintel and chejja, roofing, parapet, concealing, plastering and ready