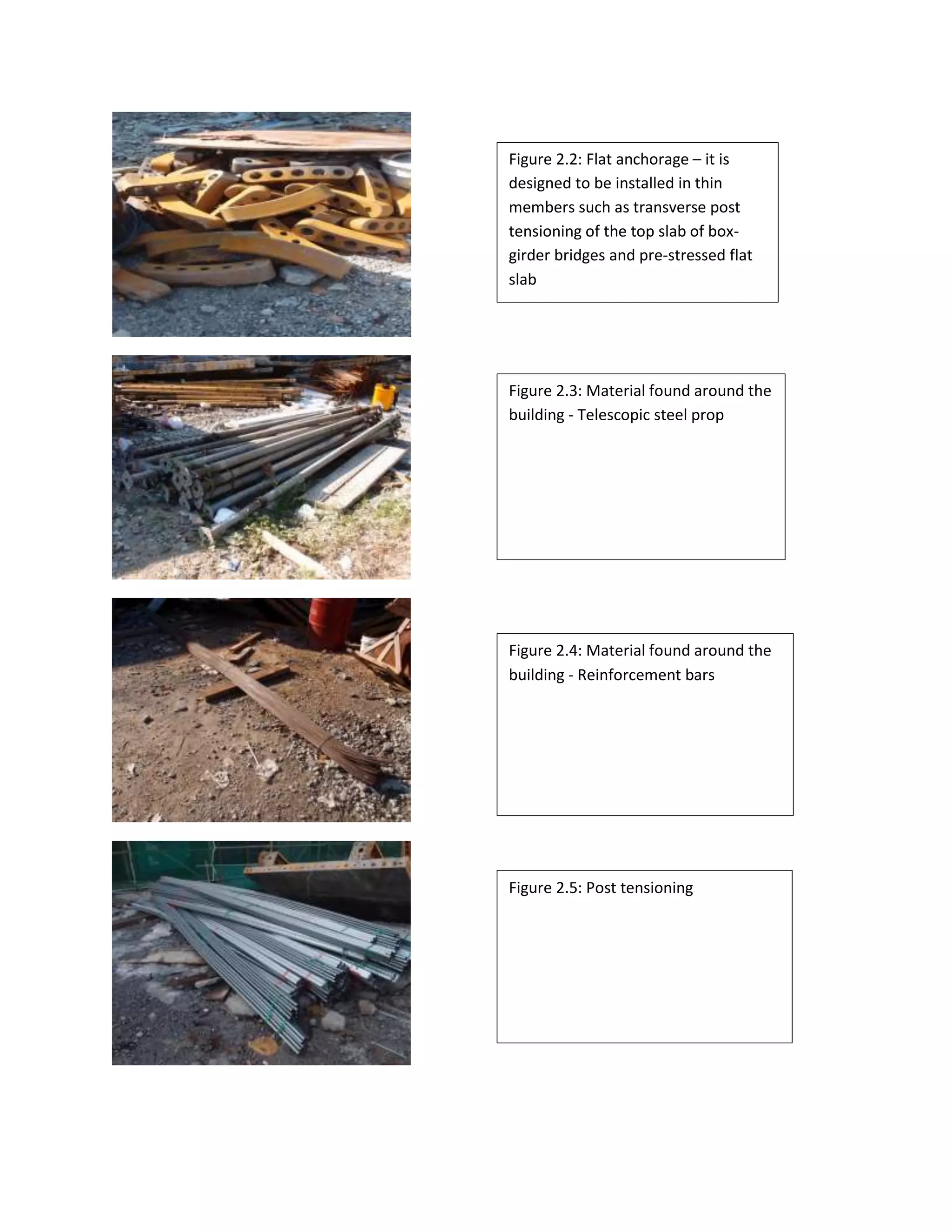

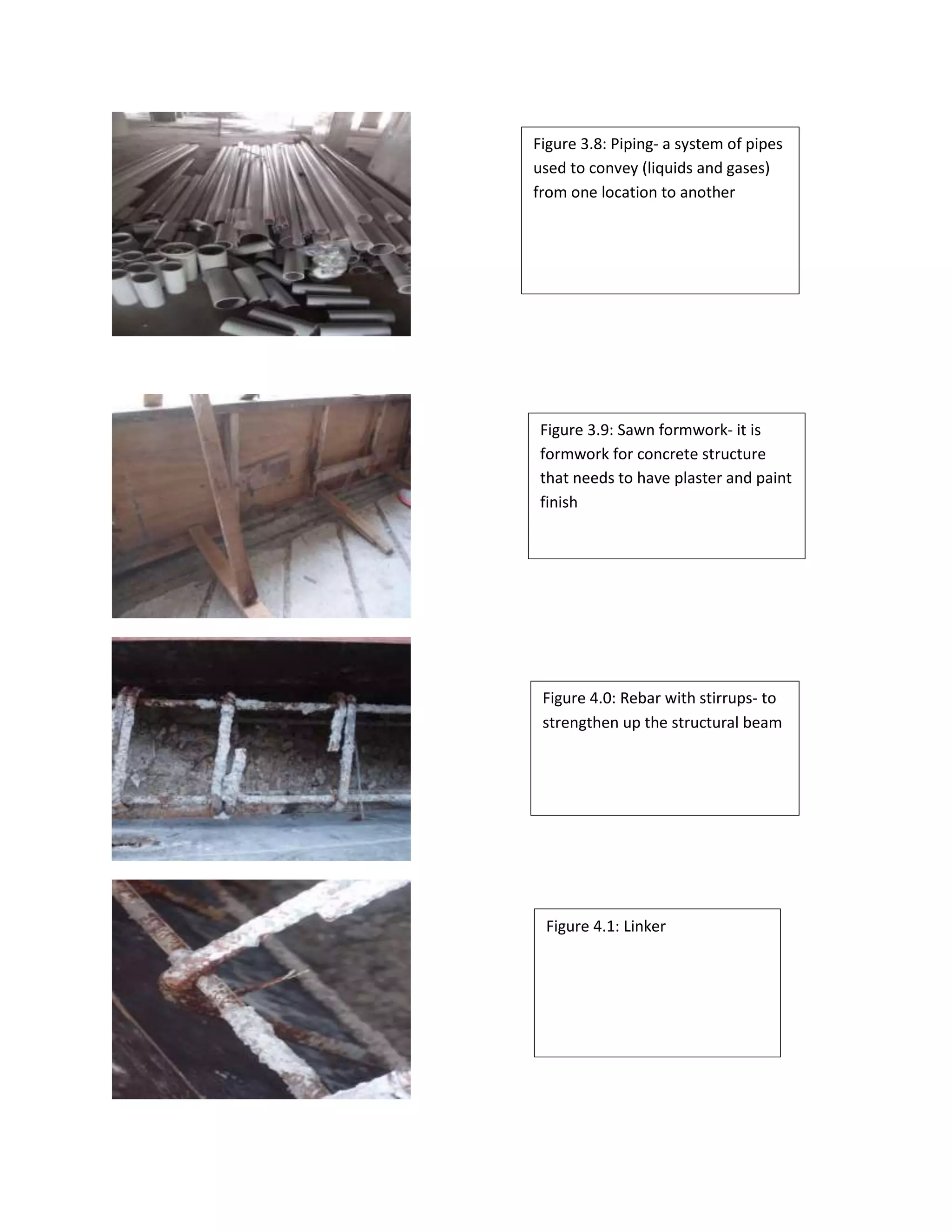

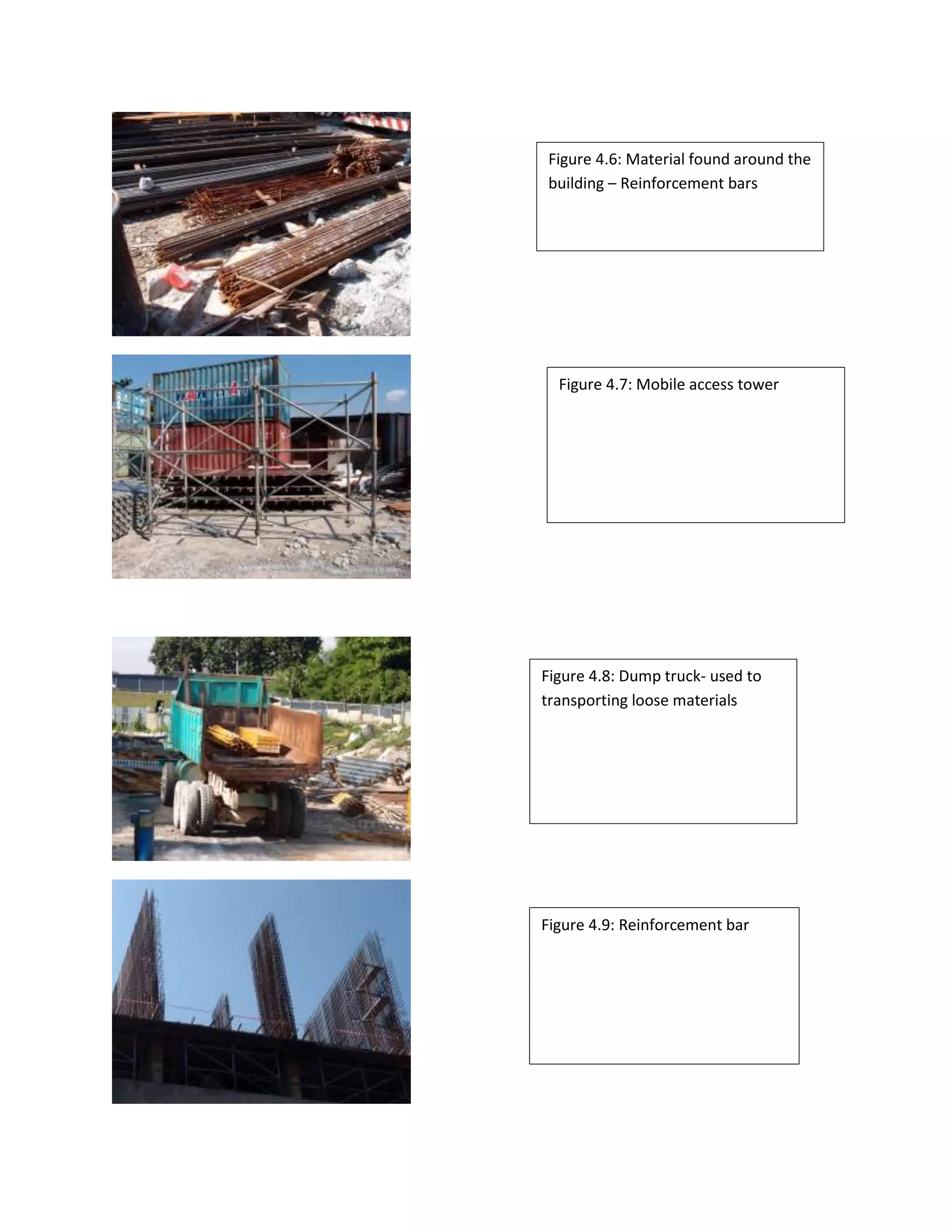

This document provides a summary of a construction site visit report for a student's course on measurement, construction technology, and building materials. The report describes the objectives of the site visit which were to understand construction sequences, building materials, safety procedures, and gain hands-on experience. Key observations from the site included different formwork and scaffolding used, materials being stored, and concrete grades being poured. The student was able to identify uses of various equipment and better understand concepts from class.

![SCHOOL OF ARCHITECTURE, BUILDING AND DESIGN

BACHELOR OF QUANTITY SURVEYING (HONOURS)

AUGUST INTAKE 2014

SEMESTER 1

[QSB 60104] MEASUREMENT 1

-Sr. Ang Fuey Lin

[BLD 60104] CONSTRUCTION TECHNOLOGY 1

-Pn. Azrina Md Yaakob

[BLD 62003] BUILDING MATERIALS

-Pn. Myzatul Aishah Kamarazaly

CONSTRUCTION SITE REPORT

INDIVIDUAL ASSIGNMENT

Yong Seen Yee (0315883)](https://image.slidesharecdn.com/pic-141203055544-conversion-gate01/75/Site-report-1-2048.jpg)