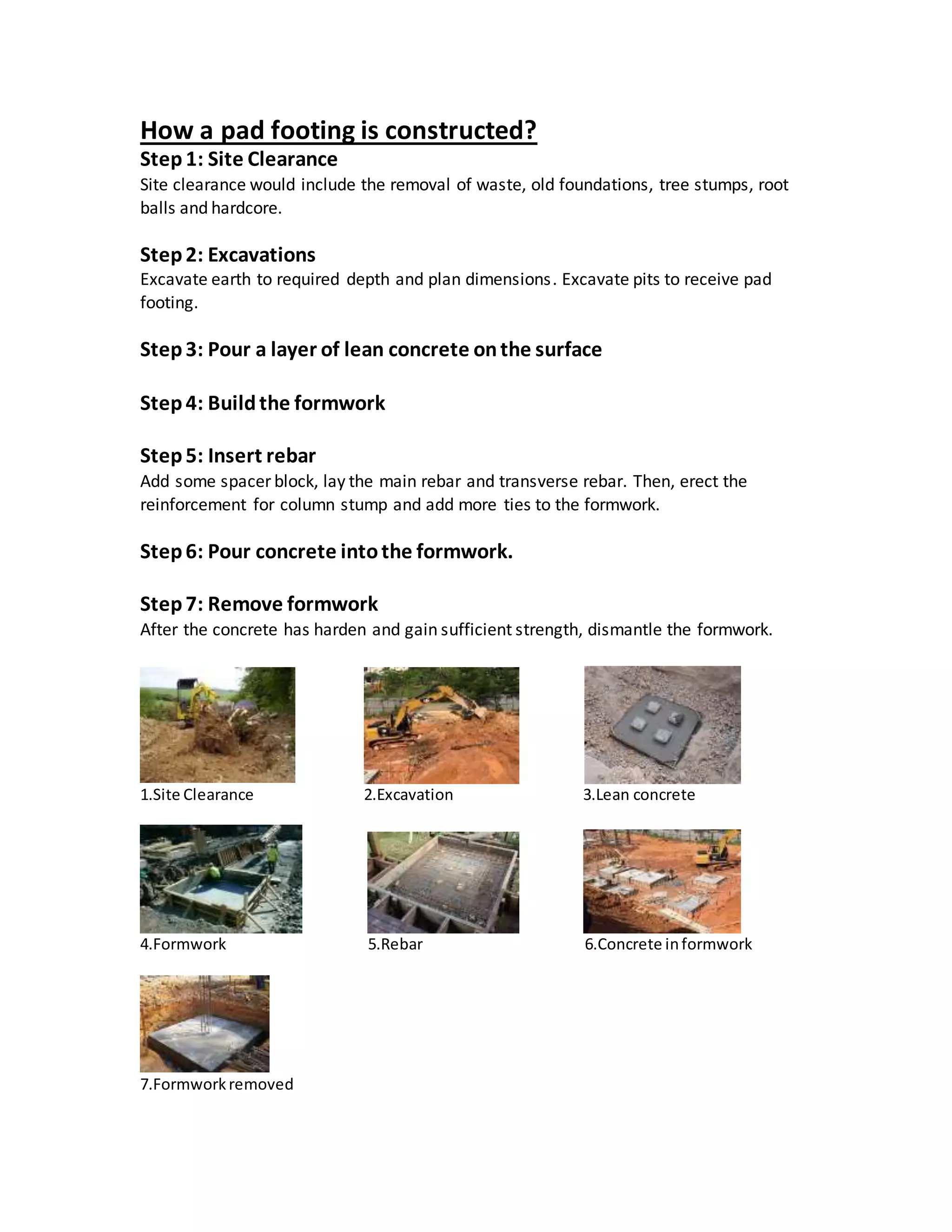

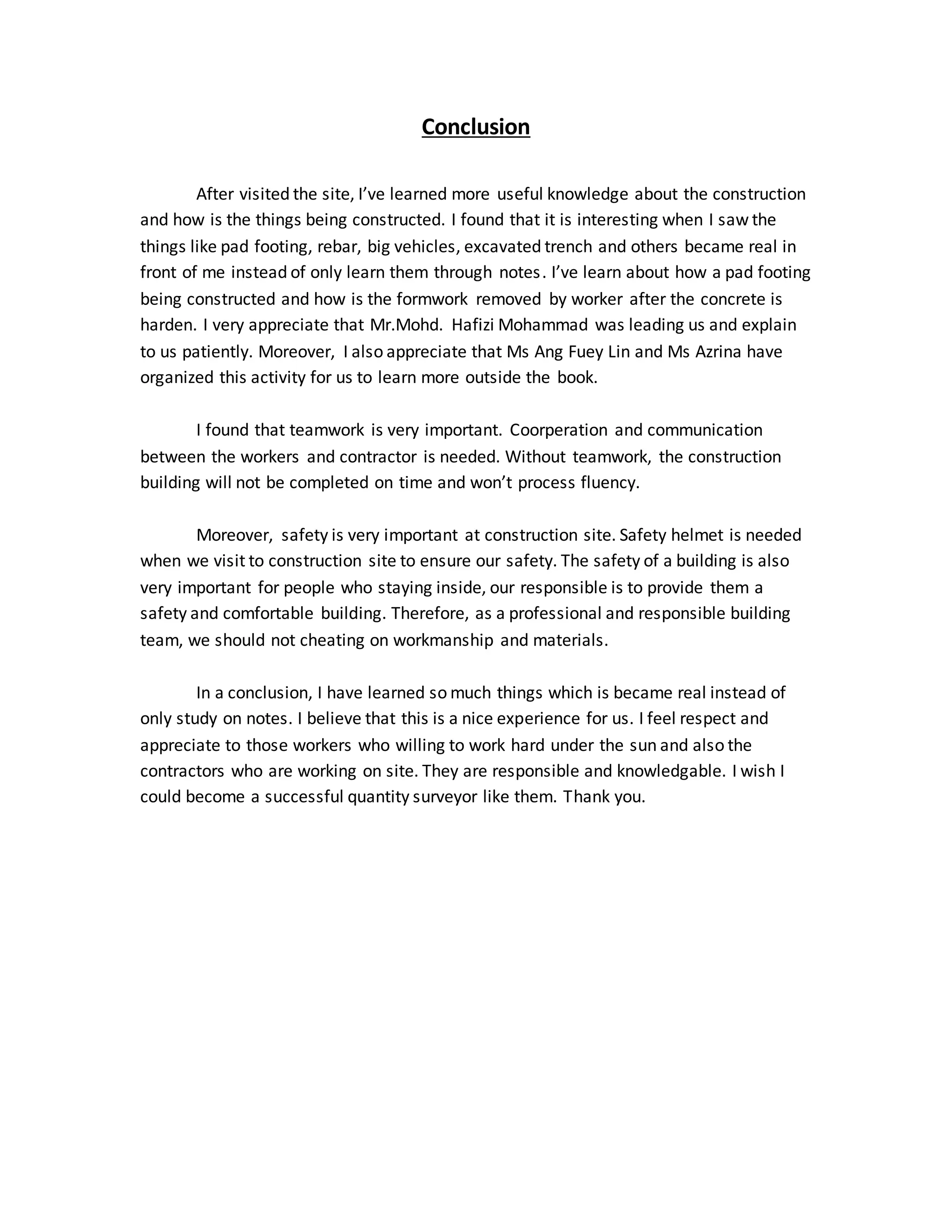

The site visit report provides details of a site visit to a construction site in Hulu Selangor where 96 units of semi-detached houses are being built. Key observations from the site include: pad footings being used to support columns, with Type 1 normal cement and high tensile steel rebar used for reinforcement. Formwork is constructed from timber and scaffolding is used. The report describes the materials and construction methods observed, including excavation, pad footing construction, and the use of formwork, rebar, concrete and other building materials. Safety procedures and documentation like the project information board were also noted.