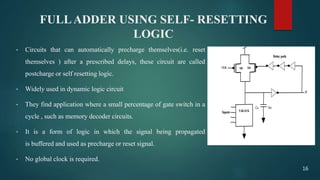

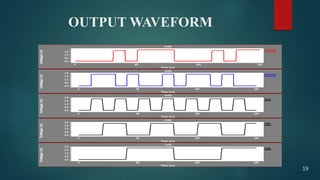

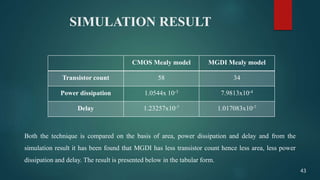

The document describes a study and performance analysis of the Modified Gate Diffusion Input (MGDI) technique. It provides details on MGDI logic, including how it overcomes limitations of the Gate Diffusion Input (GDI) technique. Various logic gates and circuits like full adders, flip-flops, and finite state machines are designed using MGDI. Simulation results show that MGDI outperforms GDI and traditional CMOS logic in terms of transistor count, power dissipation, and delay. While self-resetting logic has higher transistor count and power, it provides an alternative to dynamic logic by removing the need for a global clock.

![Literature review

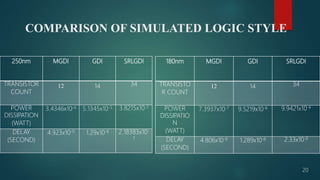

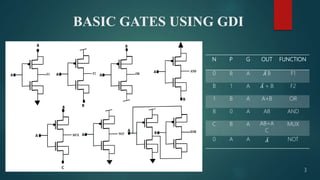

A new low power design technique, GDI has been

introduced. This technique allows implementation of a

wide range of complex logic function using only two

transistor which makes this suitable for design of fast low

power circuit, using a reduced number of transistor while

improving static power characteristics and allowing

simple top down design by using small cell library.[1]

Arkaidy Morgenshtein et

al. (2002)

Massimo Alioto et al.

(2003)

Another technique for high speed low power circuit was implemented which was

based on mixing different logic styles to implement arithmetic circuit. Here fast full

adders chains without driving capability interrupted by full adders with driving

capability are considered and optimized for minimum delay.[2]

8](https://image.slidesharecdn.com/shubhamjha-copy2-180719064335/85/Modified-Gate-Diffusion-Input-MGDI-10-320.jpg)

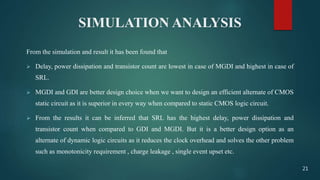

![D-FF was implemented by using GDI technique [1]. Performance comparison with

other D-FF design was done with respect to gate area, delay and power dissipation and

the proposed structures showed upto 45% reduction in PDP and the reduction in gate

area.[3]

Arkaidy Morgenshtein et

al. (2004)

Massimo Alioto et al.

(2007)

Adder was designed using mixed topology [2] and compared it with single topology

for technology spanning five technology nodes( from 90 nm to 0.35 um). Results show

that the mixed topology is very efficient over single topology and its advantage

increases as down-scaling the technology.[4]

Based on mixed topology full adder based on mixed GDI has been designed. As

compared to the previous [1] here GDI full adders are followed by inverters in the

long full adder chains to alleviate the problem of signal degradation during

propagation through long chain.[5]

Adarsh Kumar Agarwal

et al. (2009)

9](https://image.slidesharecdn.com/shubhamjha-copy2-180719064335/85/Modified-Gate-Diffusion-Input-MGDI-11-320.jpg)

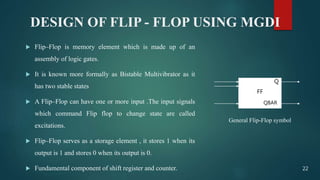

![4-Bit full adder was designed using SRL, here SRL is compared with dynamic logic at

gate level and performance comparison.Dynamic logic lacks in the application of

clock distribution grid and routing to dynamic gates that presents a problem to CAD

tools and introduces issues of delay and skew into the circuit design process, this is

solved by SRL. The only deficit is that it occupies more Si area.[6]

R. Uma (2011)

R. Uma et al. (2012)

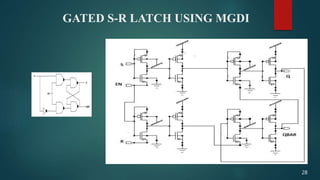

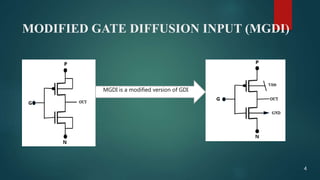

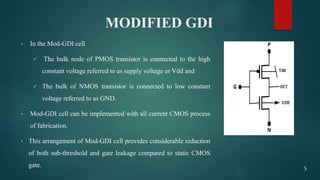

Modified-GDI is introduced , earlier GDI can be fabricated only in twin well CMOS

process or SOI process to realize a chip, this increases the complexity as well as the

cost of fabrication. But MGDI can be fabricated in any standard CMOS fabrication

process.[7]

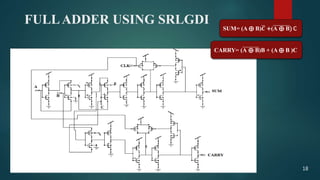

Here the nMOS block of conventional SRL[6] is replaced by the Mod-GDI block.

This structure reduces the transistor count and dynamic power dissipation. In

conventional CMOS the upper pMOS and the lower nMOS stack is connected to VDD

and GND , which provides a low impedance path between VDD and gnd. This situation

is eliminated in this logic. So by combining SRL and MGDI the circuit produces high

speed and low power output.[8]

R. Uma et al. (2012)

10](https://image.slidesharecdn.com/shubhamjha-copy2-180719064335/85/Modified-Gate-Diffusion-Input-MGDI-12-320.jpg)

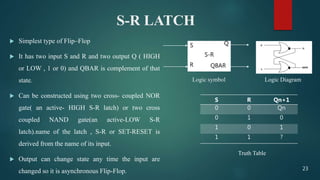

![Three low power full adders are designed with full swing AND, OR and XOR gates

to alleviate threshold voltage problem which is commonly encountered in Gate Diffusion

Input (GDI) logic. The enhanced driving capability also facilitates lower voltage and

faster operation which leads to less energy consumption. The performance of the

proposed designs is compared with the other full adder designs, namely CMOS, CPL,

hybrid and GDI through SPICE simulations using 45 nm technology models.[10]

Mrs. K.Kalaiselvi et al.

(2014)

Mohan Shoba et al.

(2016)

In the proposed paper the adder circuits is designed in Self resetting logic and the

number of transistors in the modified design is reduced. The goal is to obtain a family

of adders that could simplify the implementation of fast processing circuit which

overcomes the restriction due to the pulses being elongated and shortened as signal

traverse the logic stages. The circuits are designed in 120nm processing CMOS

processing technology. [9]

R. Uma et al.

(2017)

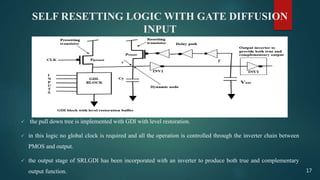

Design of low power adder is done using SRLGDI.In the proposed design structure , the

pull down tree is implemented with (GDI) with level restoration which apparently

eliminates the conductance overlap between nMOS and pMOS devices which was

encountered in the case of conventional SRL [6], thereby reducing the short circuit

power dissipation and providing High Output Voltage.[11]

11](https://image.slidesharecdn.com/shubhamjha-copy2-180719064335/85/Modified-Gate-Diffusion-Input-MGDI-13-320.jpg)