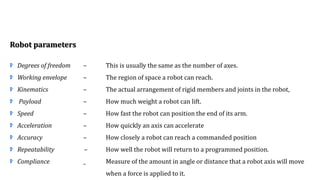

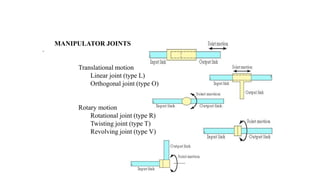

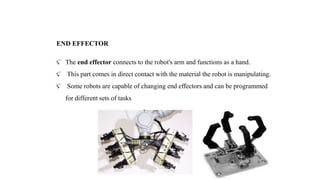

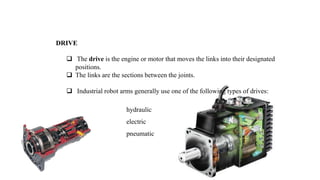

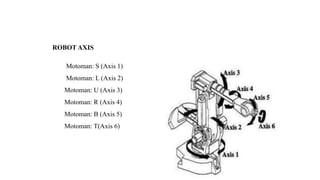

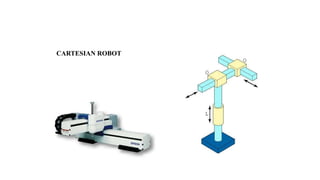

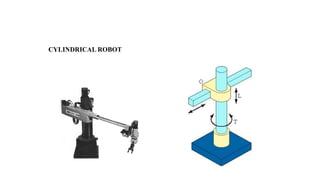

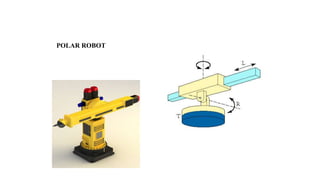

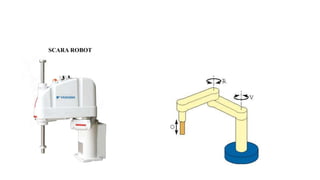

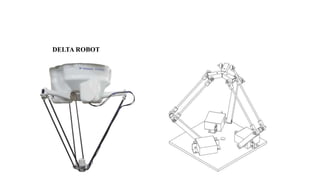

This document provides information on industrial robotics. It discusses various types of industrial robots including articulated, Cartesian, polar, cylindrical, SCARA, and delta robots. It also outlines common robot components like the controller, manipulator, end effector, drive system, and sensors. Finally, it lists some key applications of industrial robots like robotic handling, welding, assembly, and dispensing.