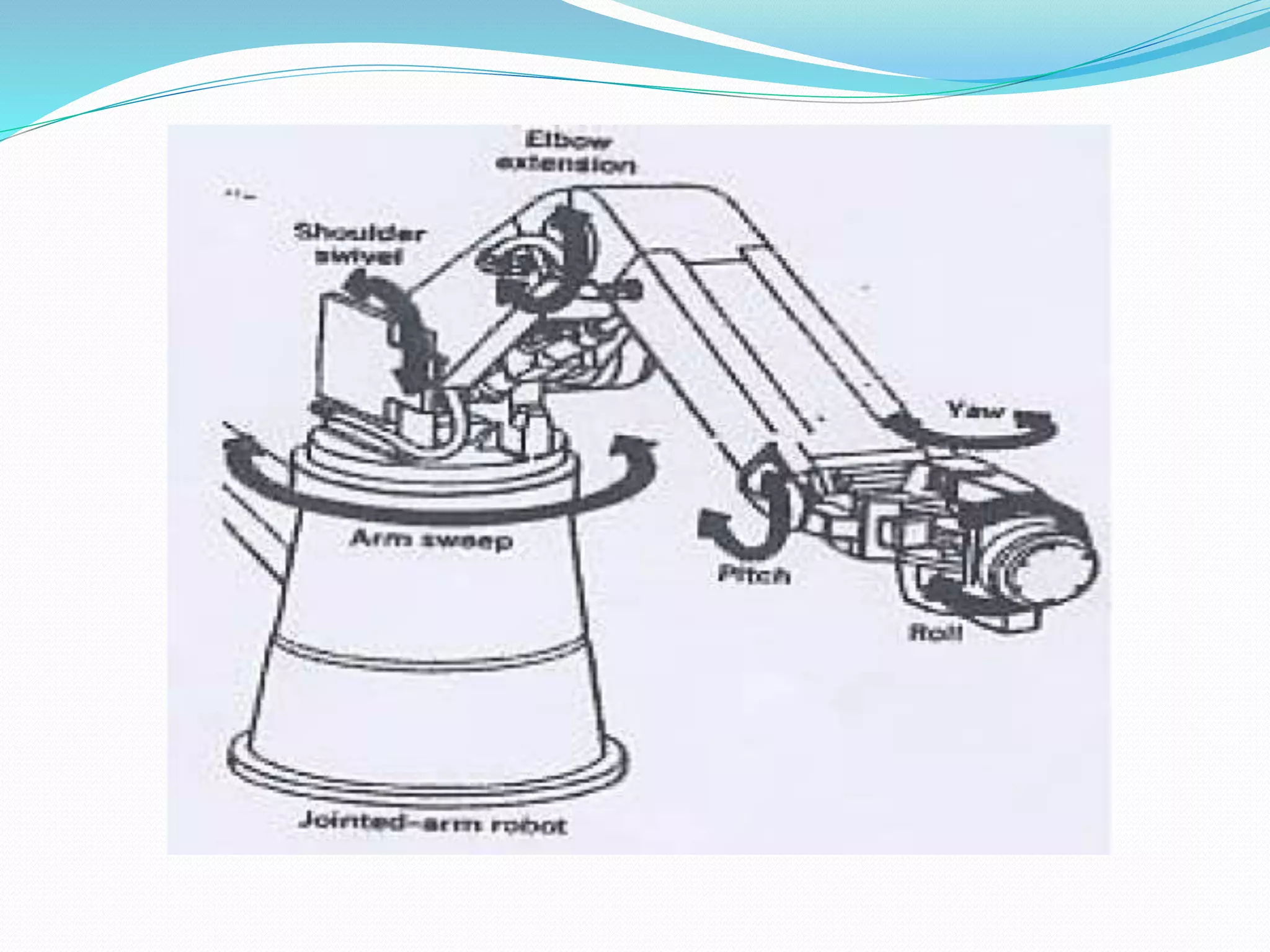

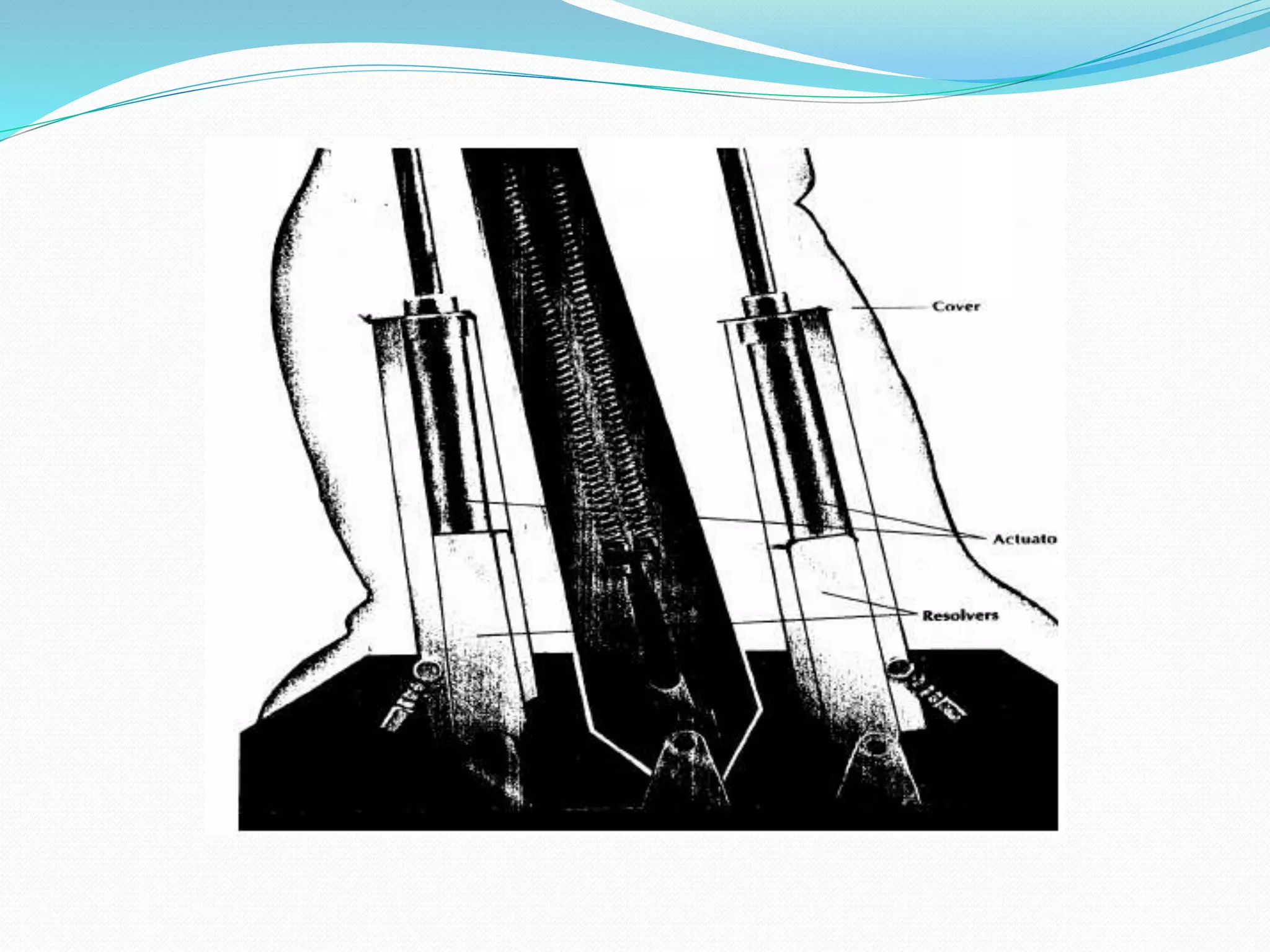

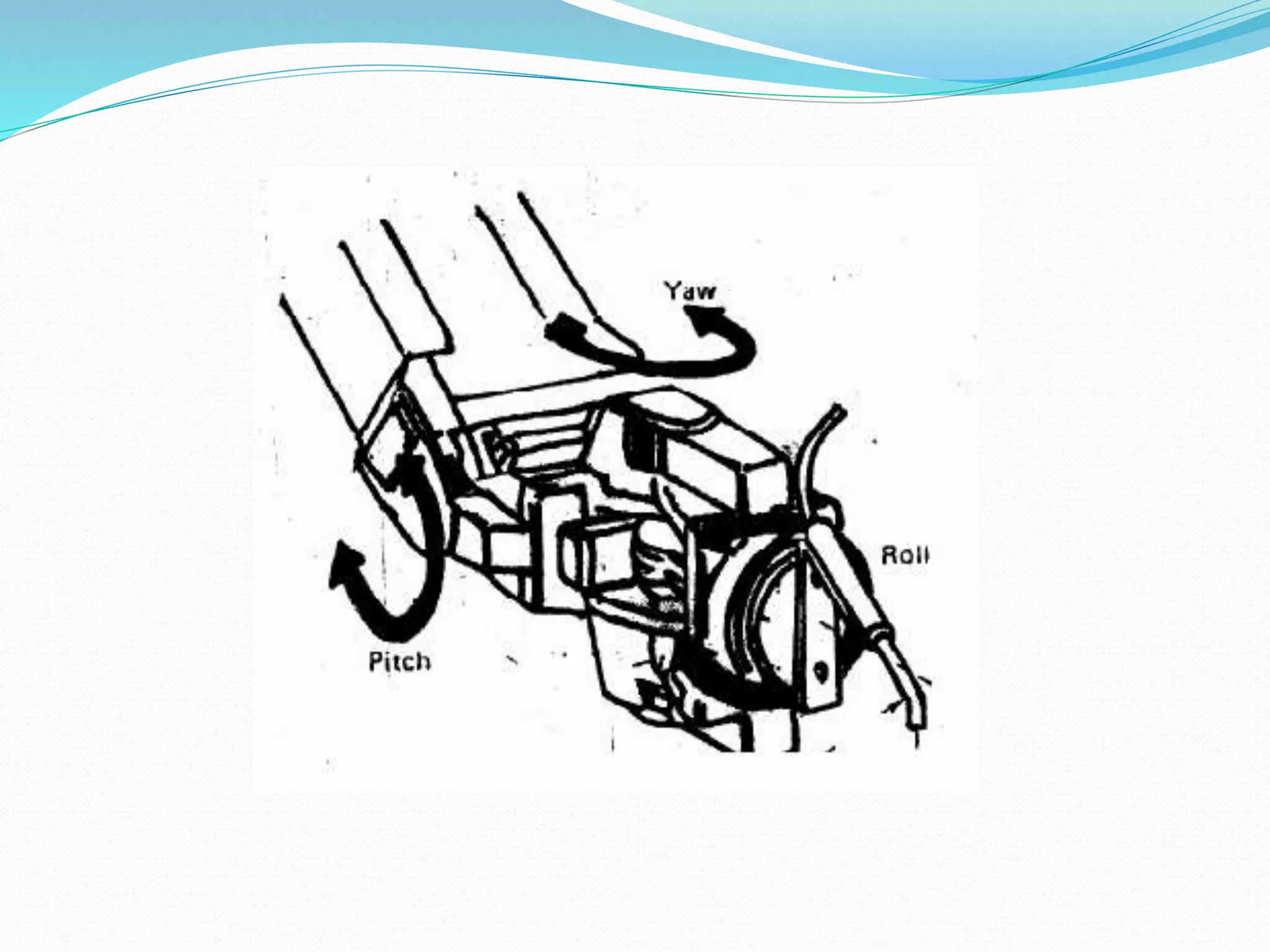

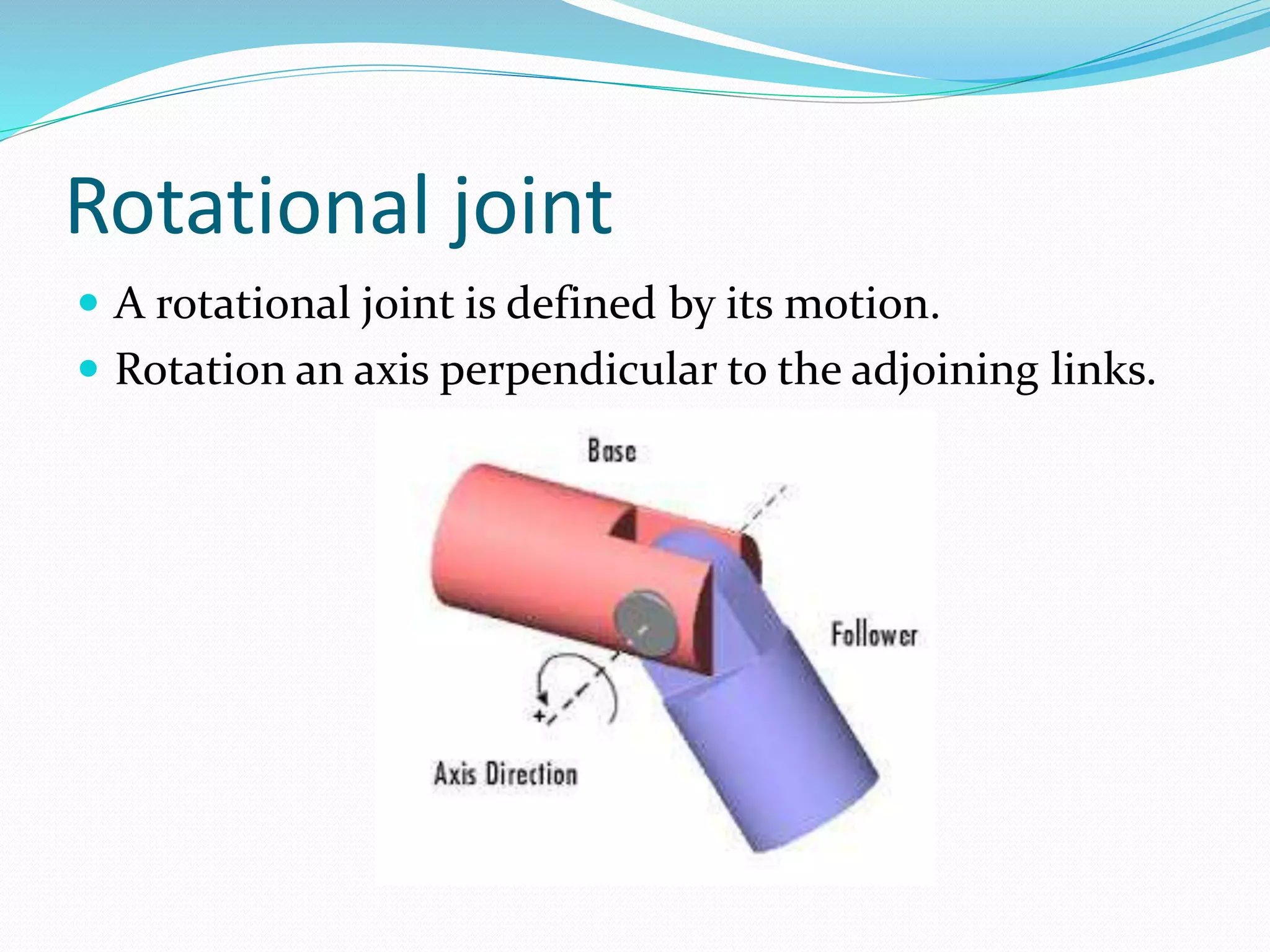

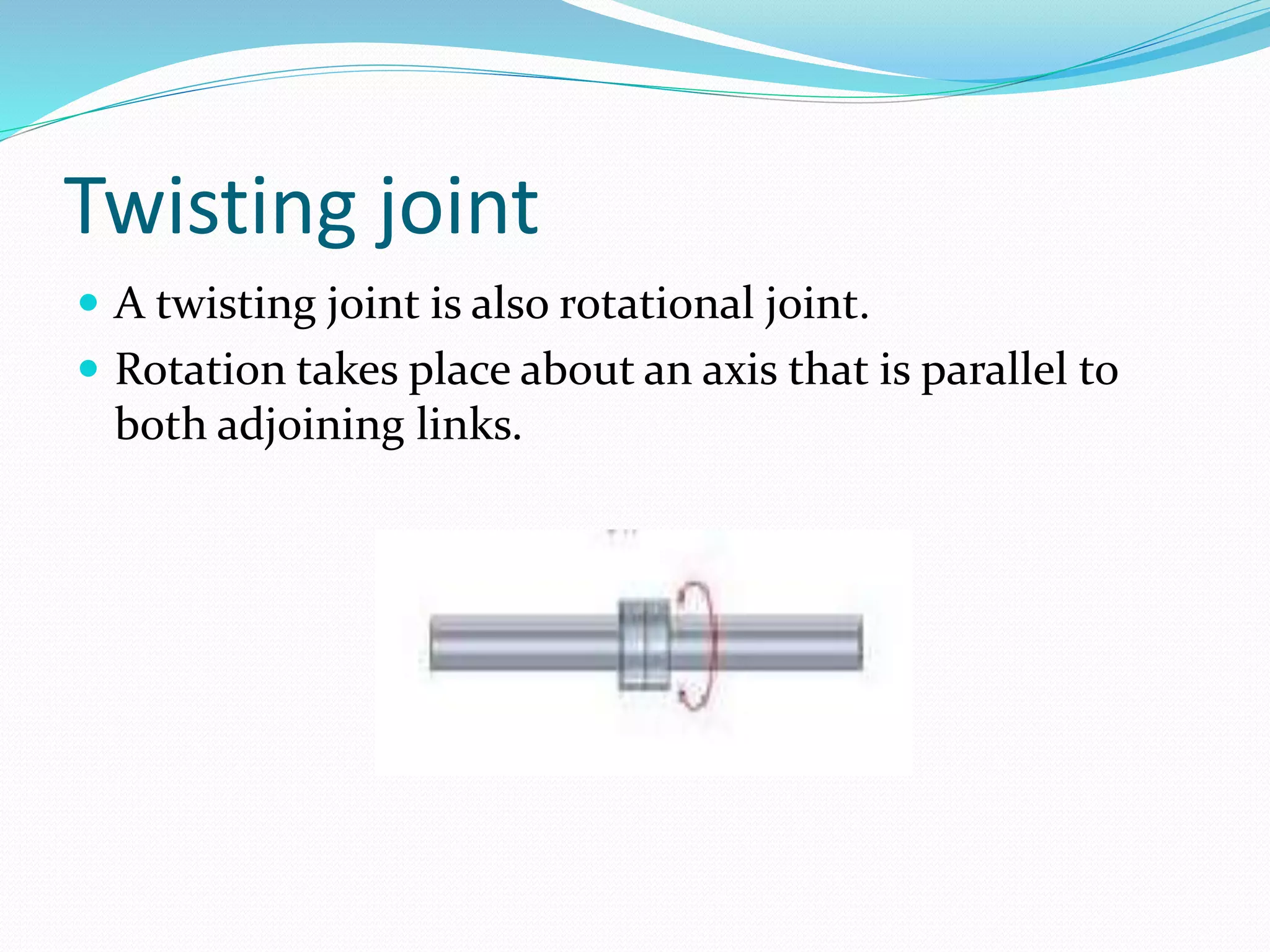

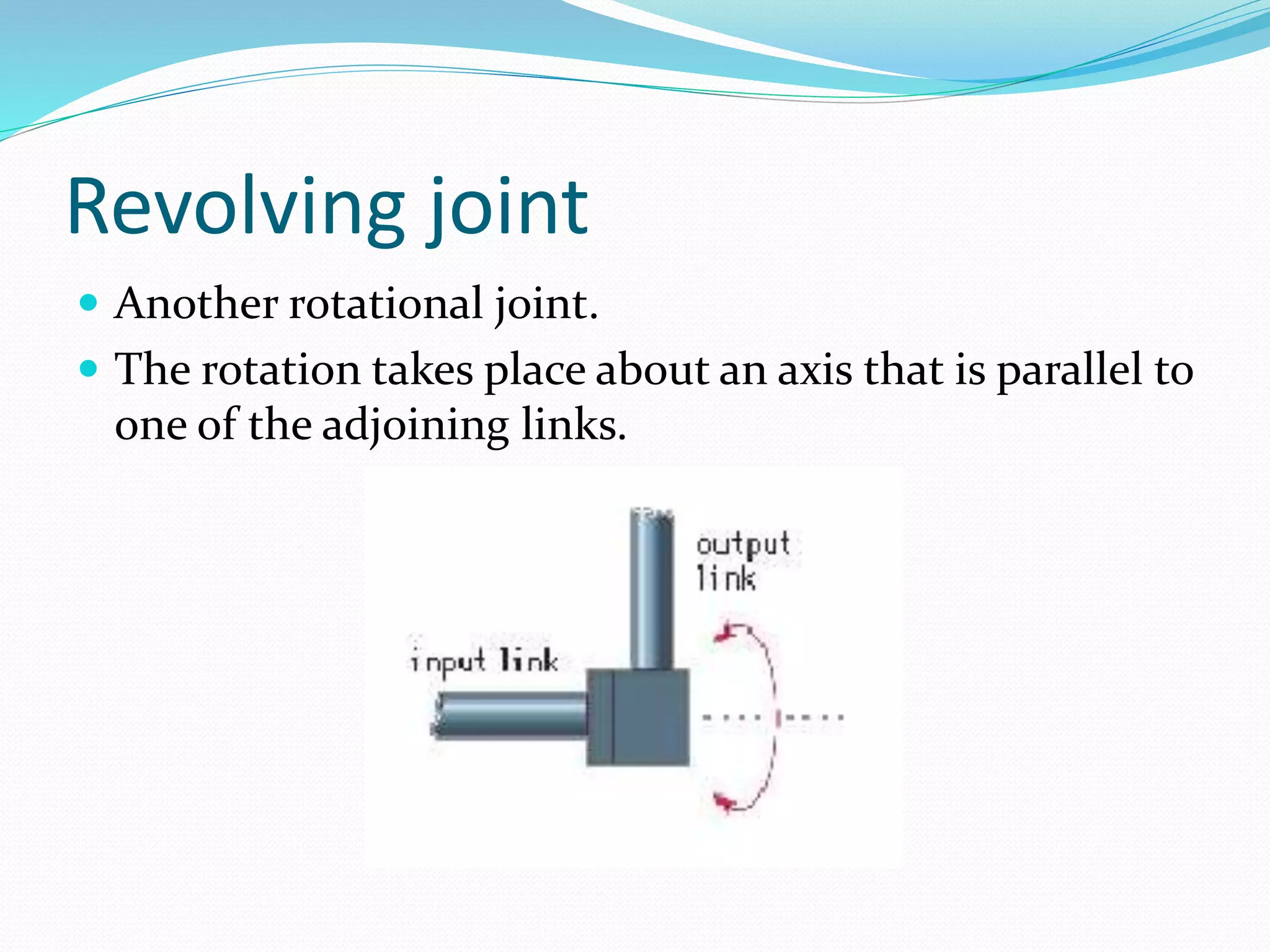

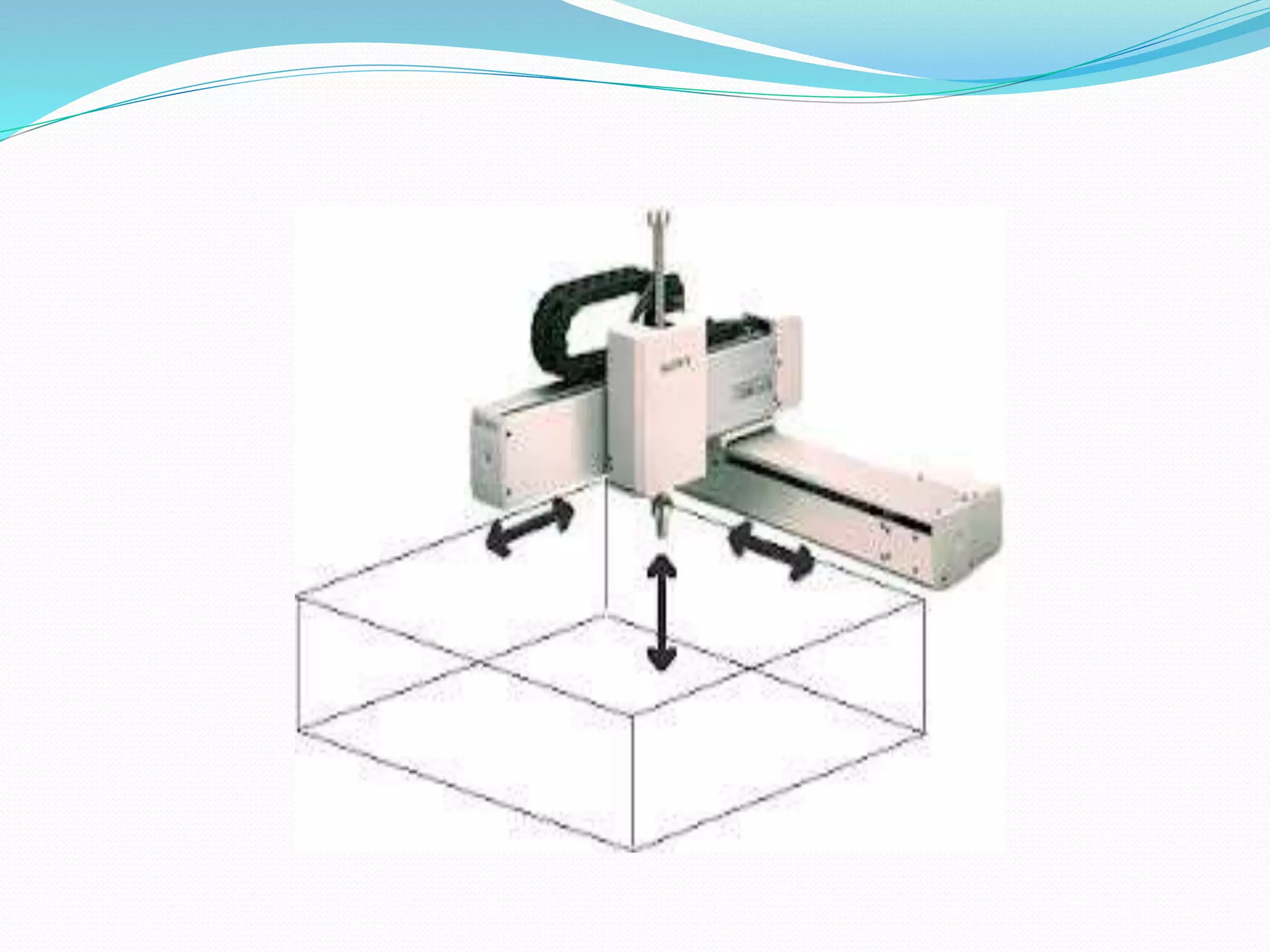

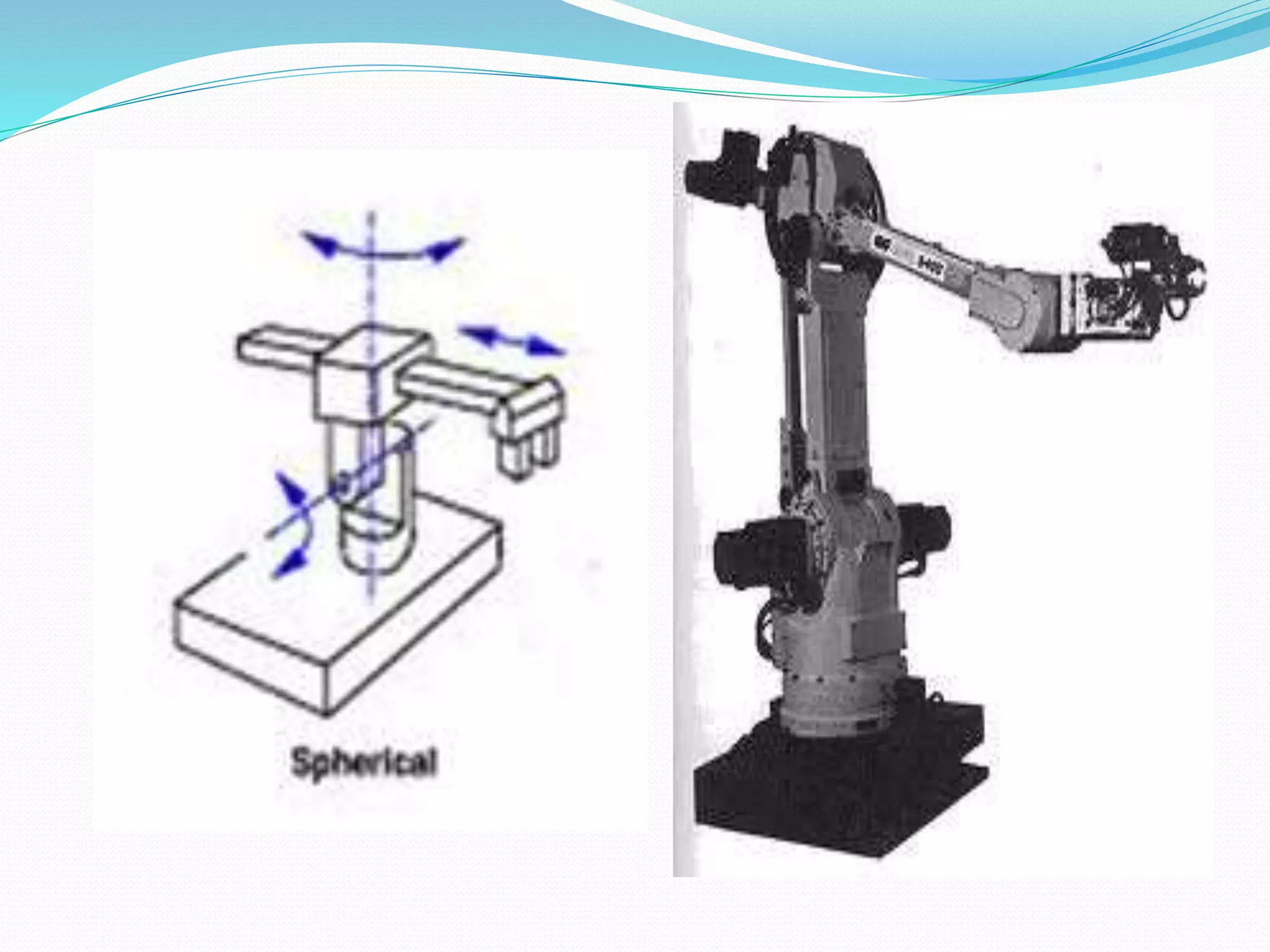

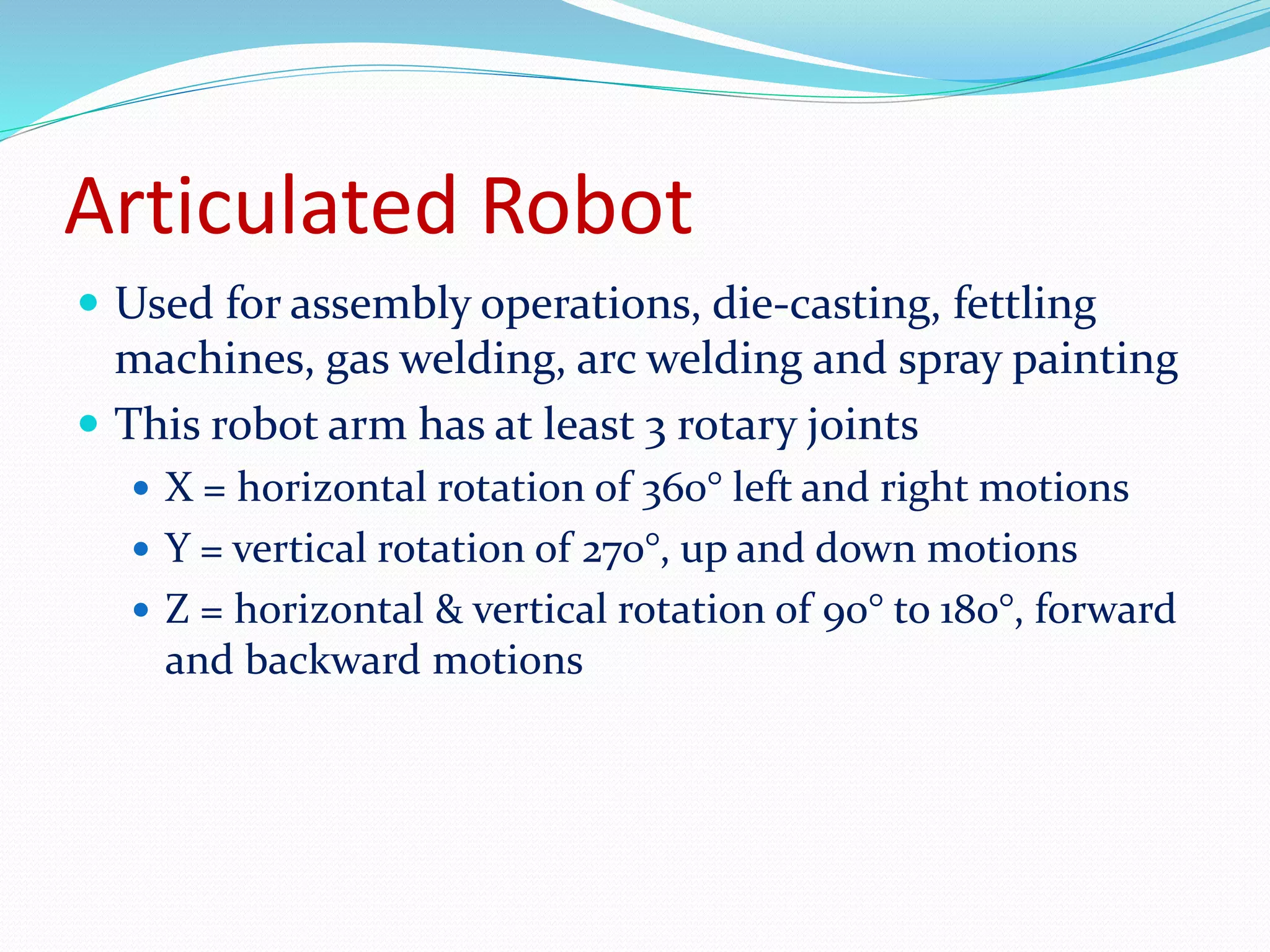

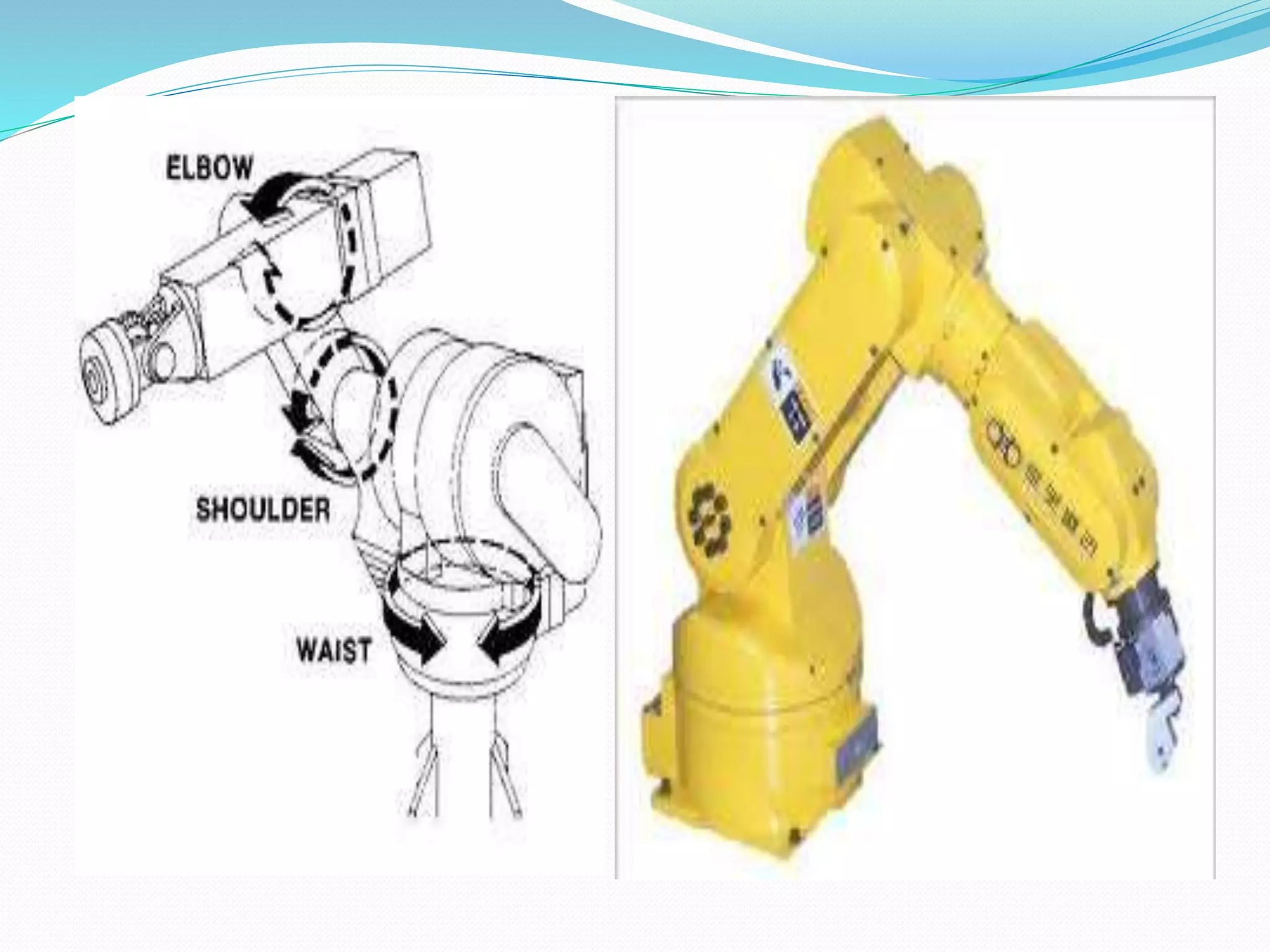

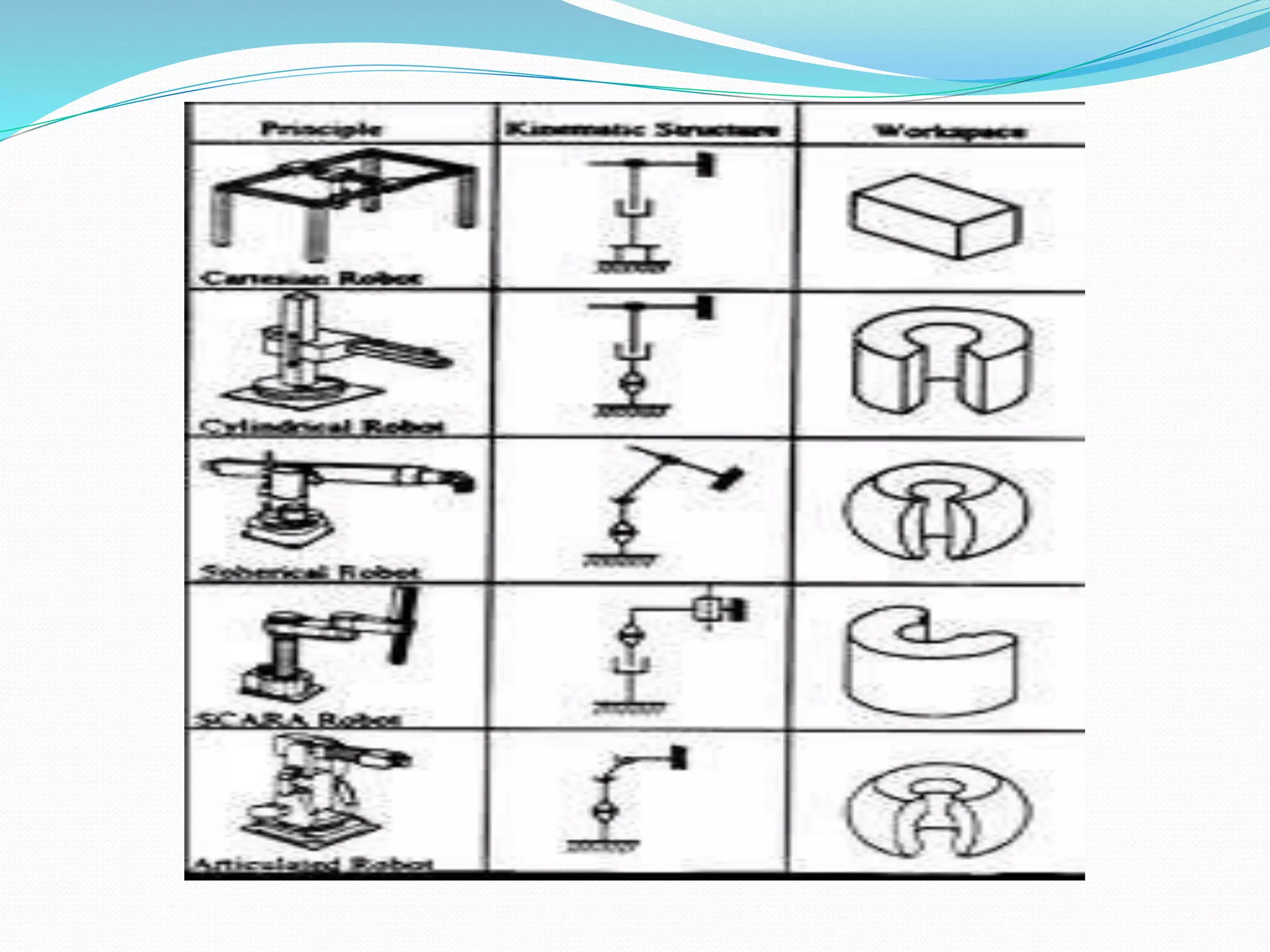

This document provides an introduction to industrial robot automation. It defines a robot and outlines the typical components of a robot including the controller, manipulator, actuator, end-effector, and sensors. The document also discusses the advantages and disadvantages of robot automation, lists the six main types of robots, and explains some common applications of robot automation in production systems such as welding, assembly, and material handling.