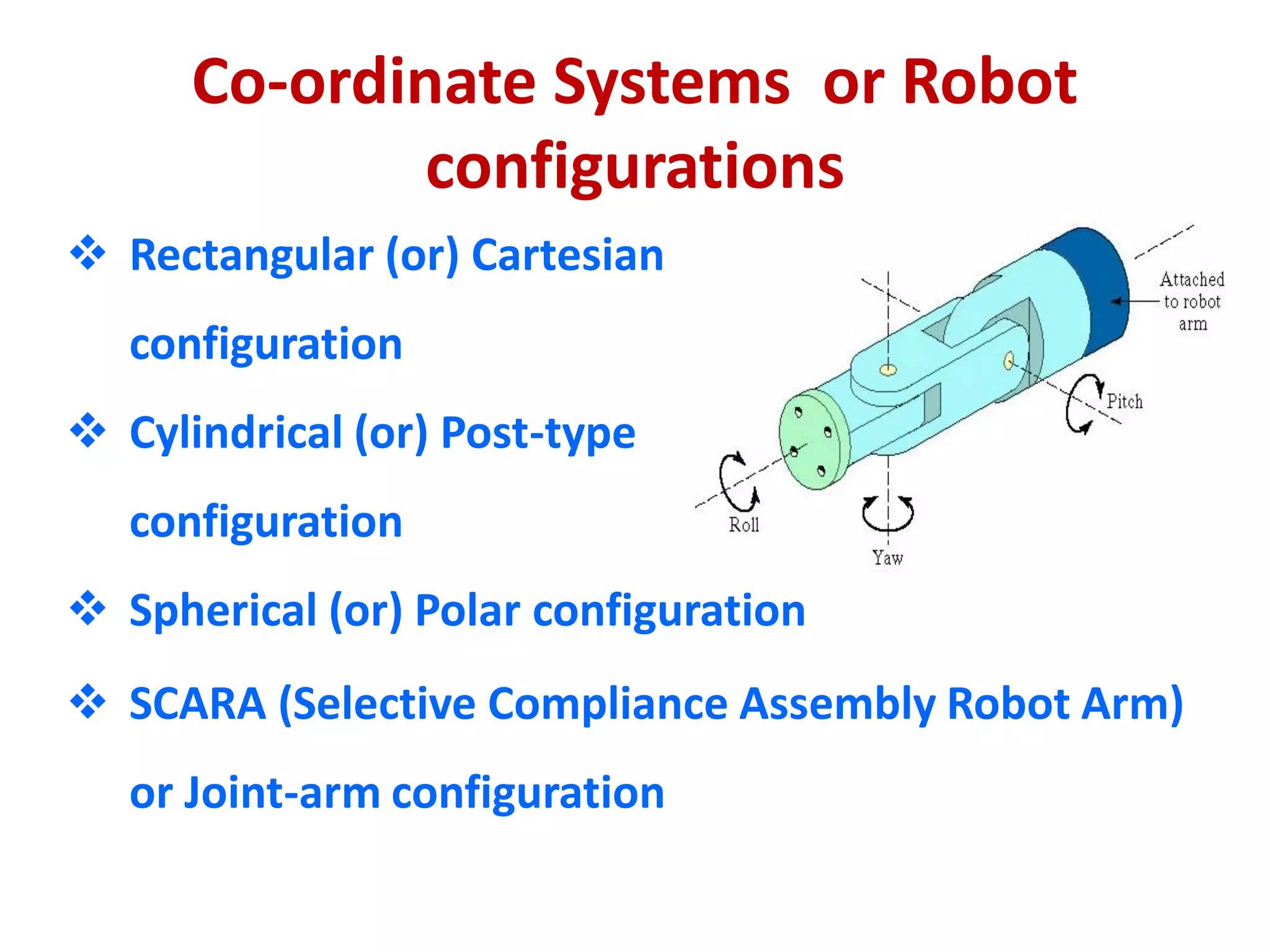

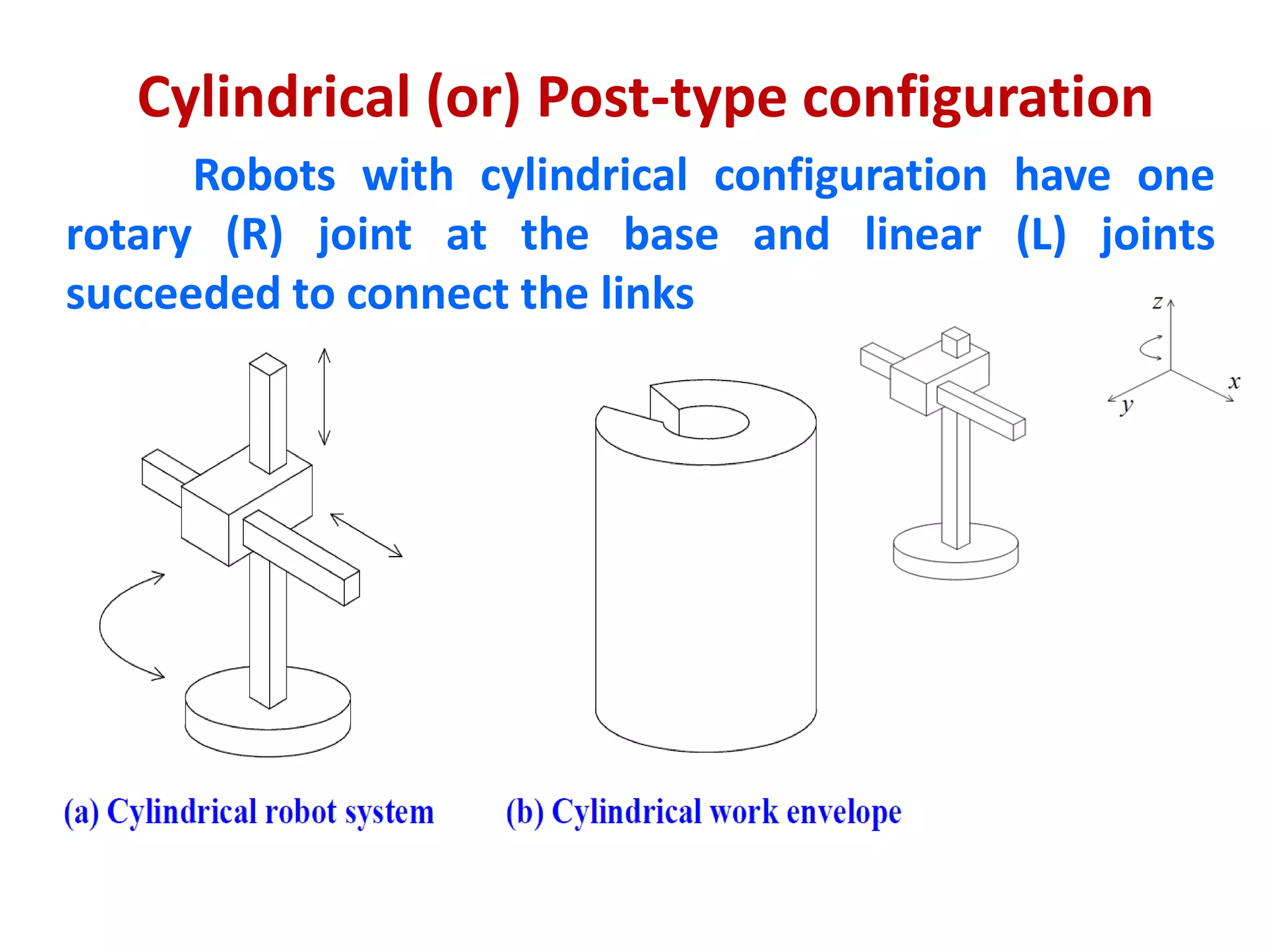

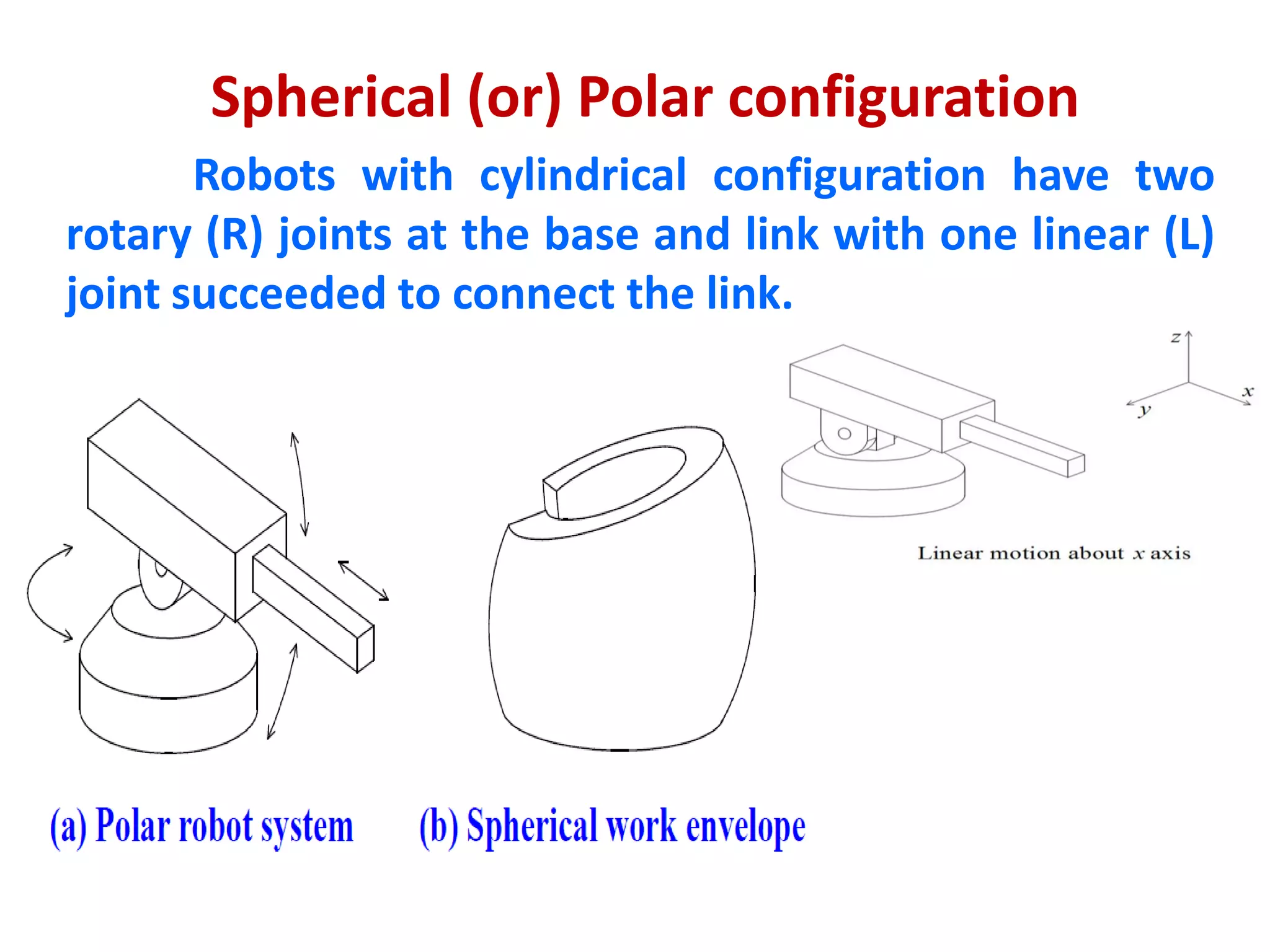

This document provides an overview of robotics and robots. It begins with definitions of a robot and discusses the history and development of robotics. It then covers the three laws of robotics proposed by Isaac Asimov. The document describes the main components of a robotic system including the robotic arm, end effector, sensors, and control computer. It discusses different robot configurations, specifications, applications, and the needs and disadvantages of robots.