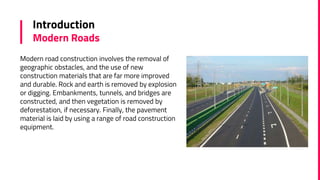

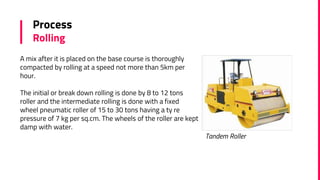

This document summarizes the process of constructing a 200m long, 8m wide paved road in Soran University campus in Soran, Iraq. It describes surveying the location, designing the road profile and cross-sections, and calculating the cost at 117,200,000 IQD. The construction process involves preparing the subgrade, sub-base, and base layers, laying the wearing course in layers, compacting with rollers, and constructing shoulders. Quality control checks aggregate grading, bitumen grade and mixing/laying temperatures. Finally, the document discusses completing all steps to open the road for public use according to international standards.