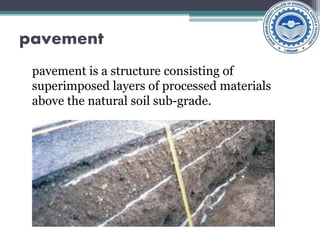

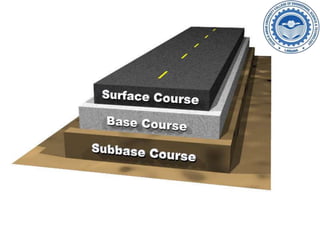

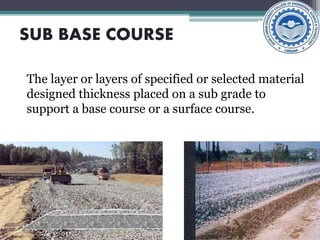

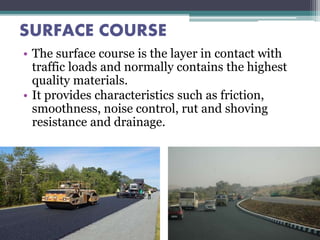

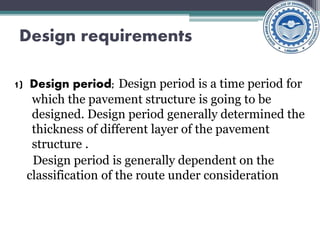

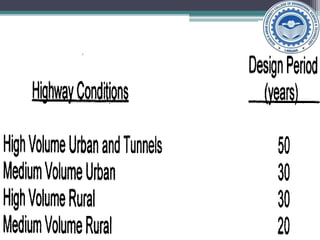

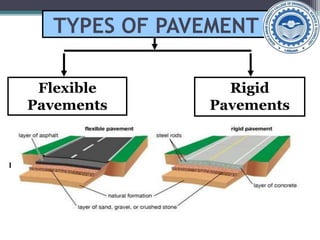

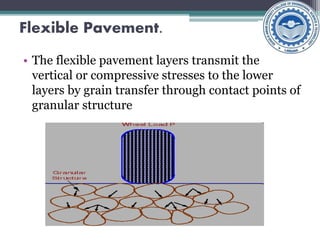

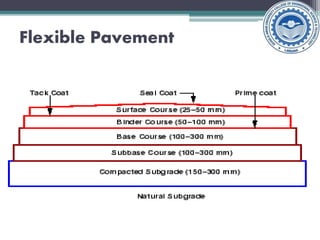

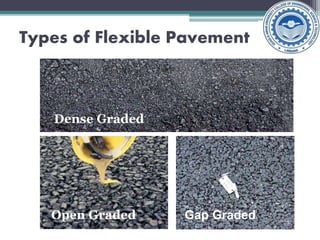

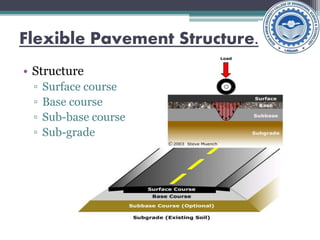

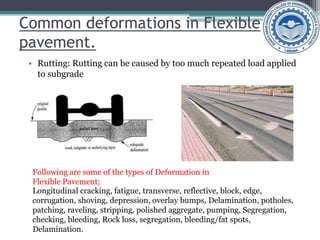

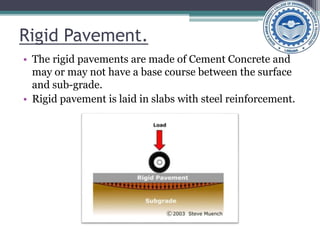

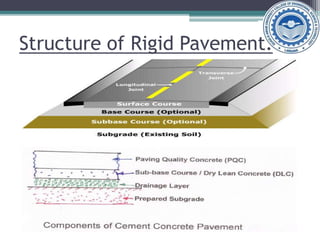

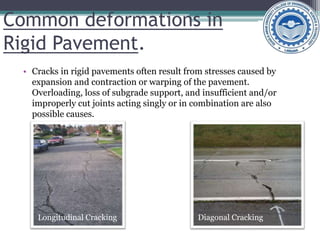

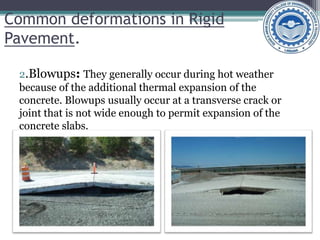

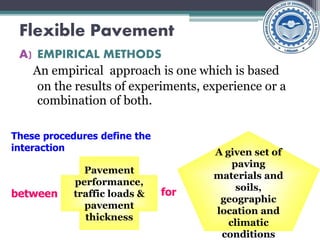

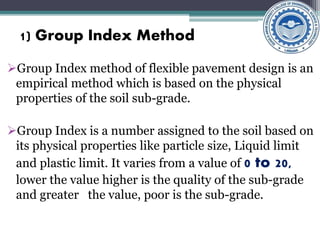

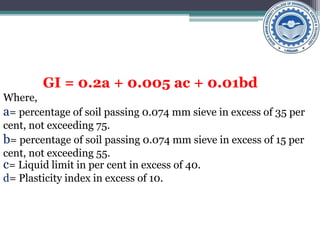

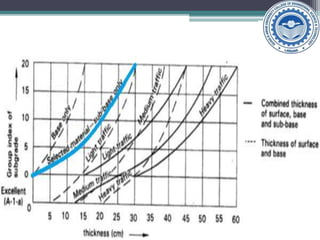

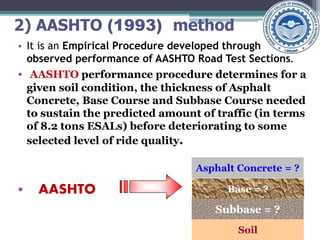

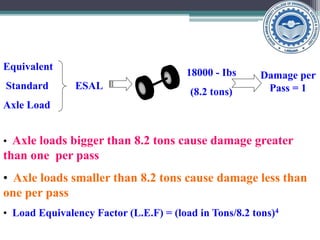

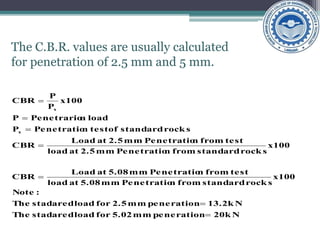

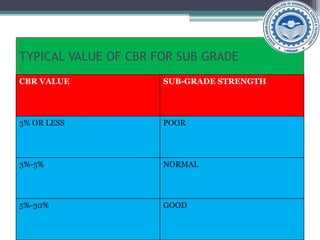

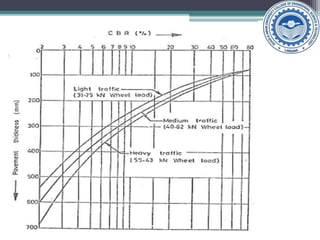

The document outlines the design and structure of pavements, detailing flexible and rigid pavements, their components, and the effects of traffic and drainage on pavement longevity. It covers various pavement design methods, including empirical and mechanistic-empirical approaches, and discusses key performance factors like load-bearing capacity and deformation issues. Additionally, the document explains the California Bearing Ratio (CBR) test used to evaluate pavement thickness and subgrade strength.