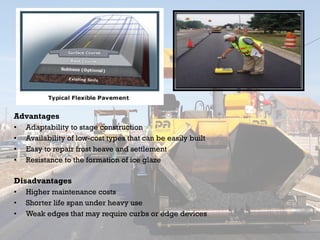

The document presents an overview of road construction, focusing on flexible and rigid pavements, their advantages and disadvantages, and selected projects illustrating both types. It details the construction processes, time and cost analyses, and environmental impacts associated with each pavement type. The conclusions emphasize the importance of initial costs in pavement decision-making, the economic considerations for large-scale projects, and the viability of concrete for certain road types.