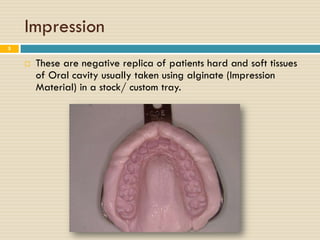

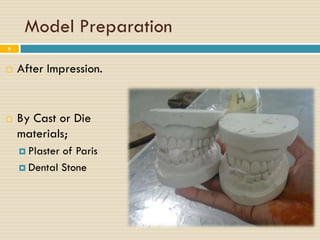

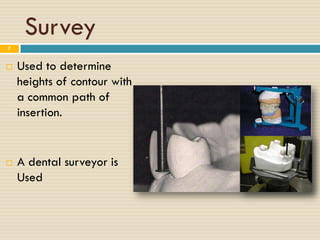

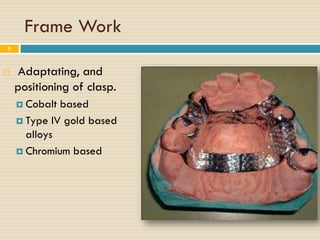

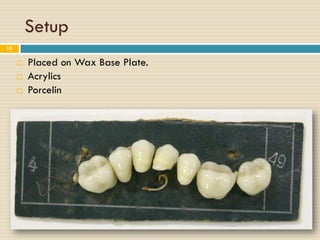

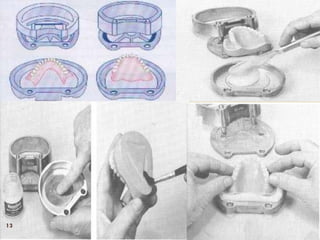

A removable partial denture is made by taking an impression of the patient's mouth, preparing a model, designing a metal framework with clasps to hold the denture in place, adding artificial teeth, curing it in a flask, and finishing/polishing. The process takes 3-6 weeks and involves multiple appointments for impressions, fittings, and adjustments.