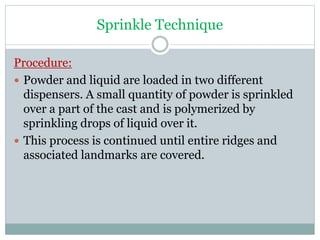

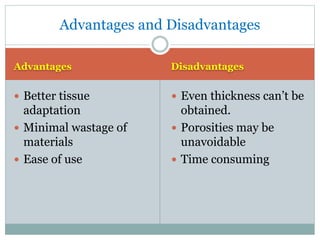

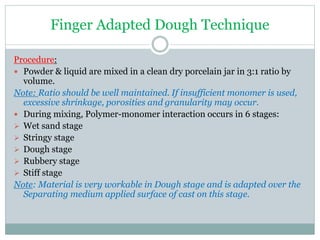

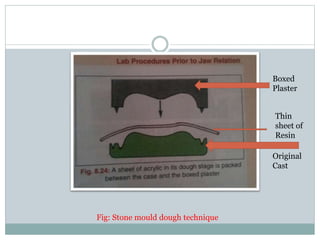

A temporary denture base is used to support artificial teeth during procedures like determining jaw relations and tooth arrangement. It aims to resemble the final denture. Common materials used are auto-polymerizing resins, heat cure resin, thermoplastics, and shellac. Self-cure acrylic resin is a popular option that can be manipulated using techniques like the sprinkle technique, finger-adapted dough technique, or stone mould dough technique to adapt to the cast. The temporary denture base should adequately support teeth, adapt to tissues, and be stable, rigid, and non-reactive in the mouth.