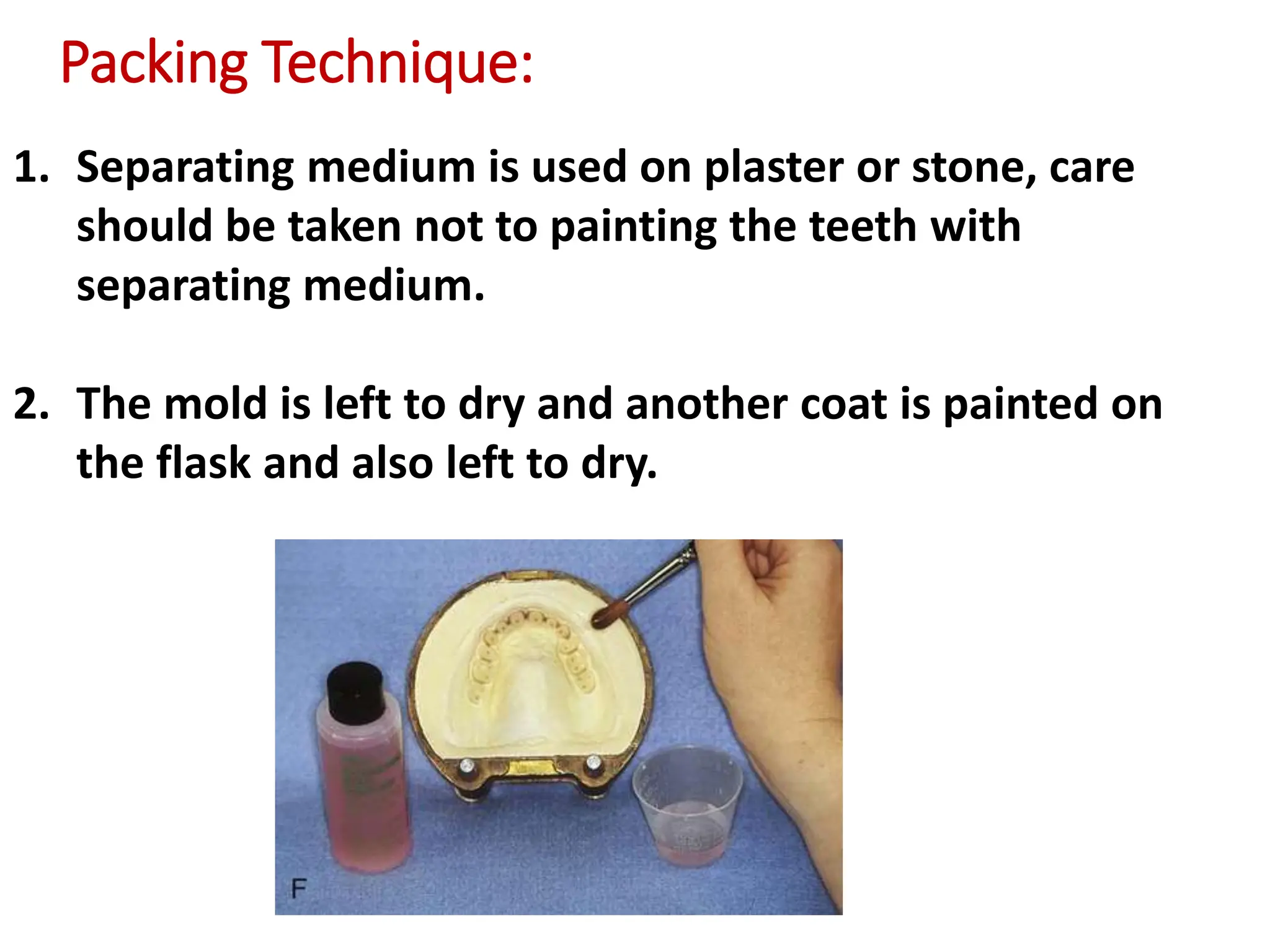

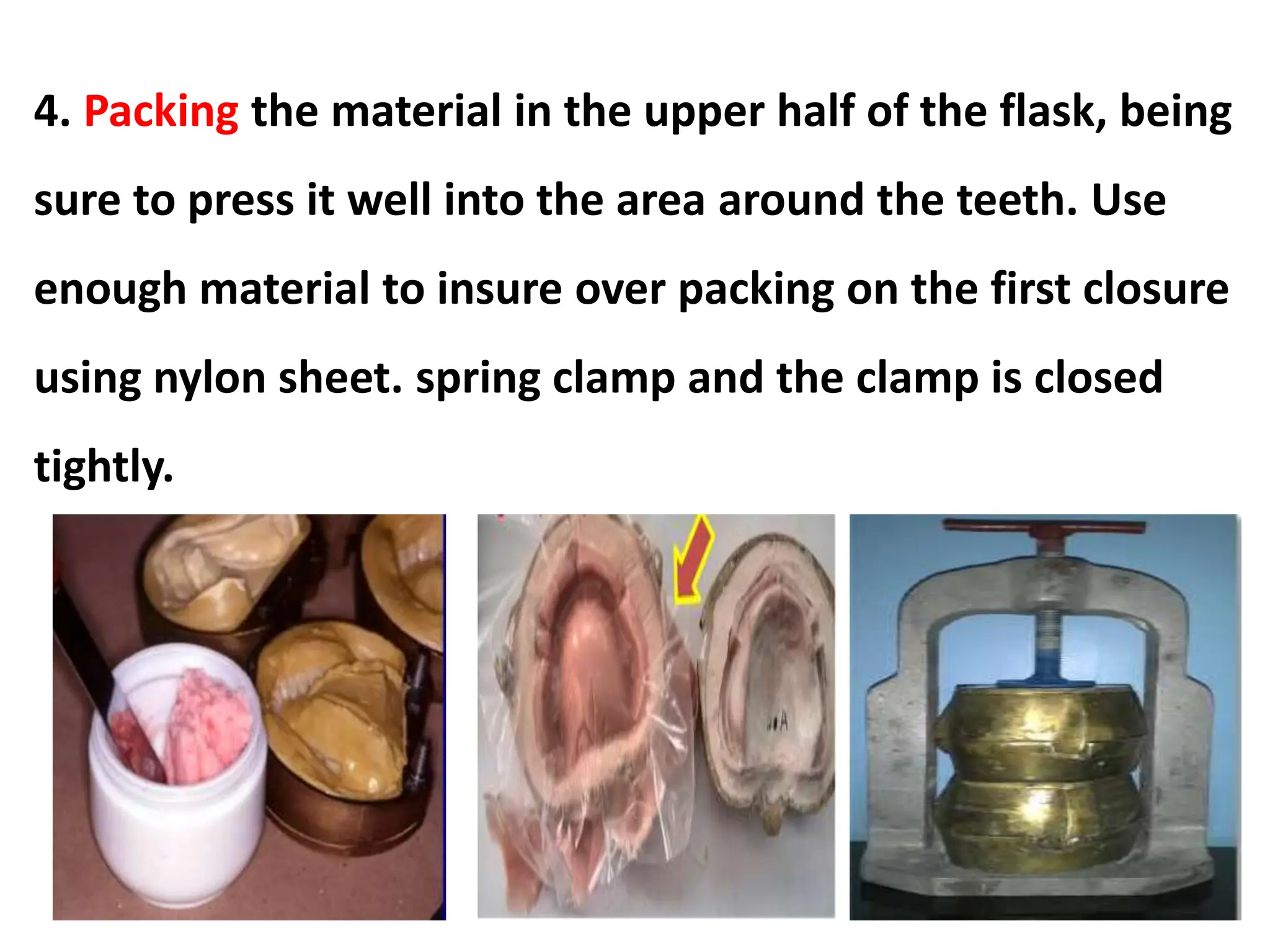

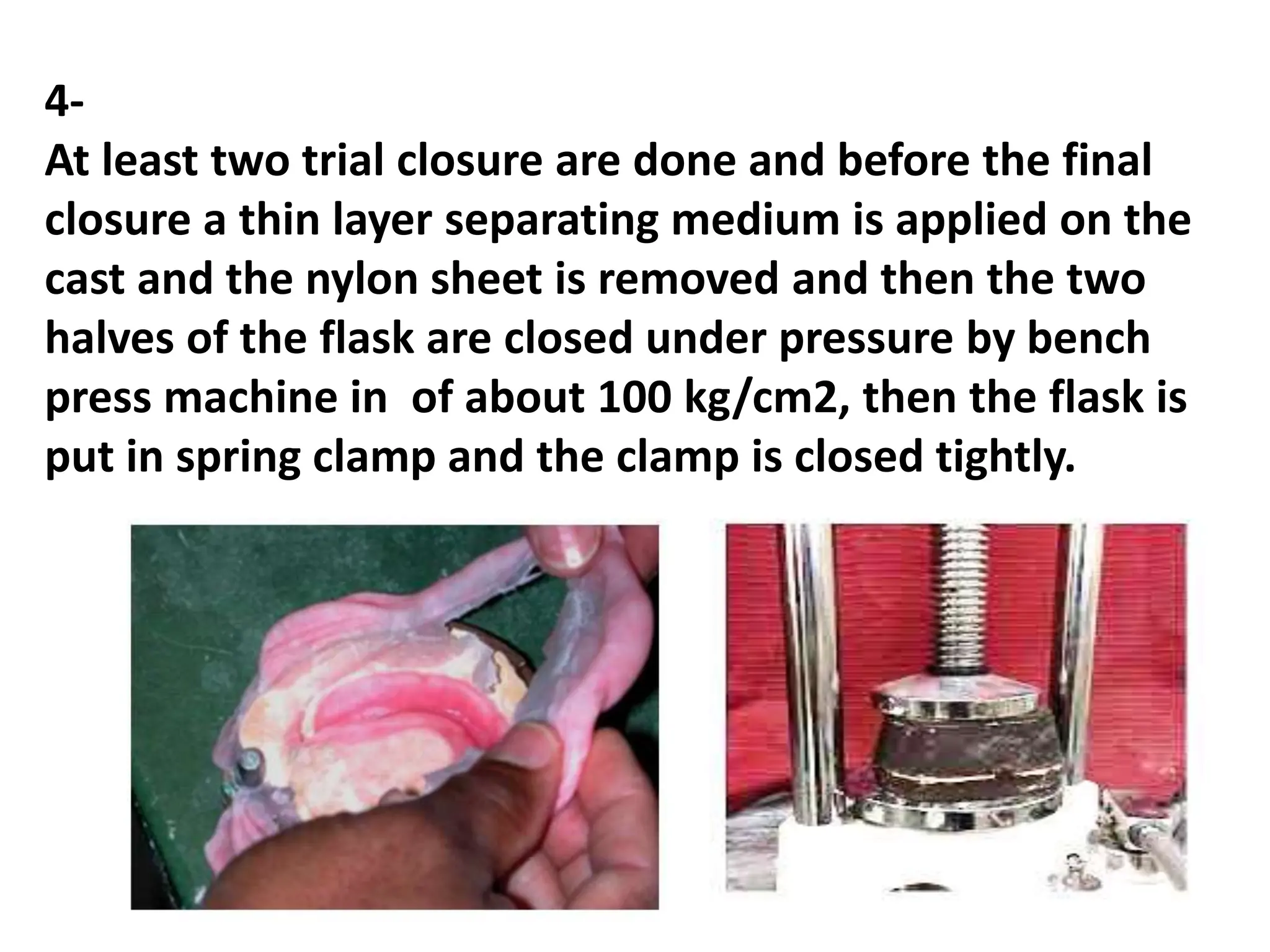

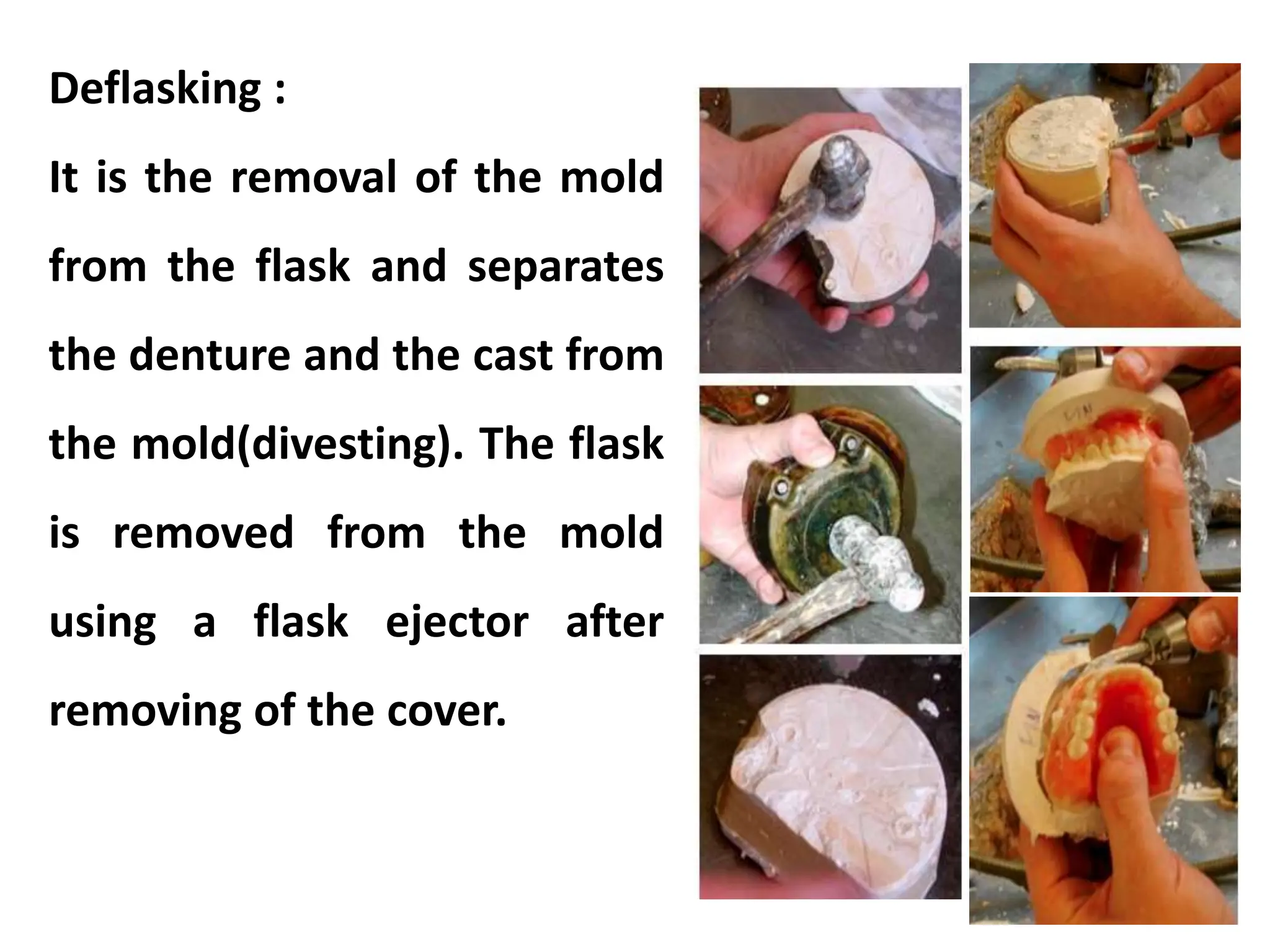

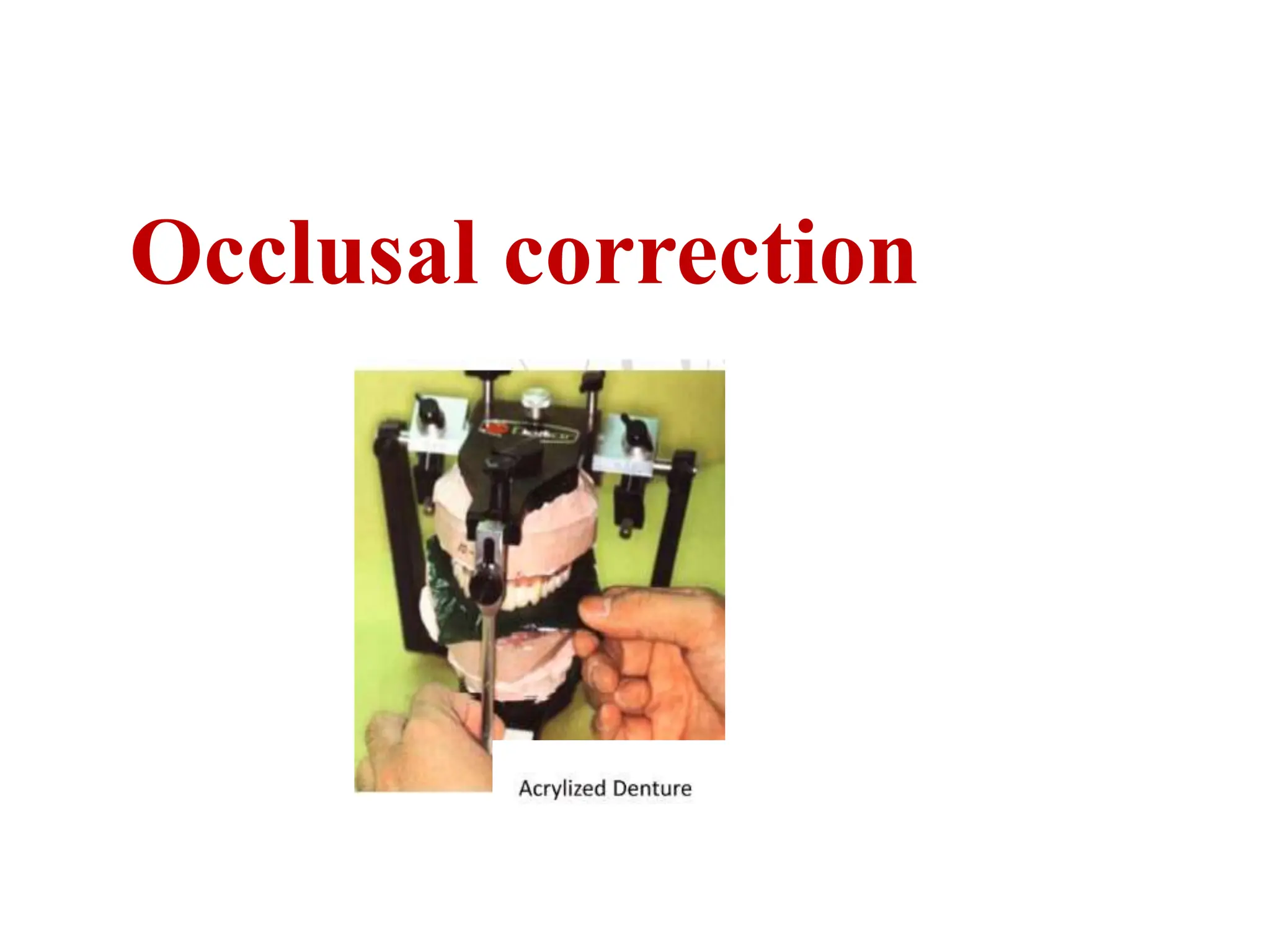

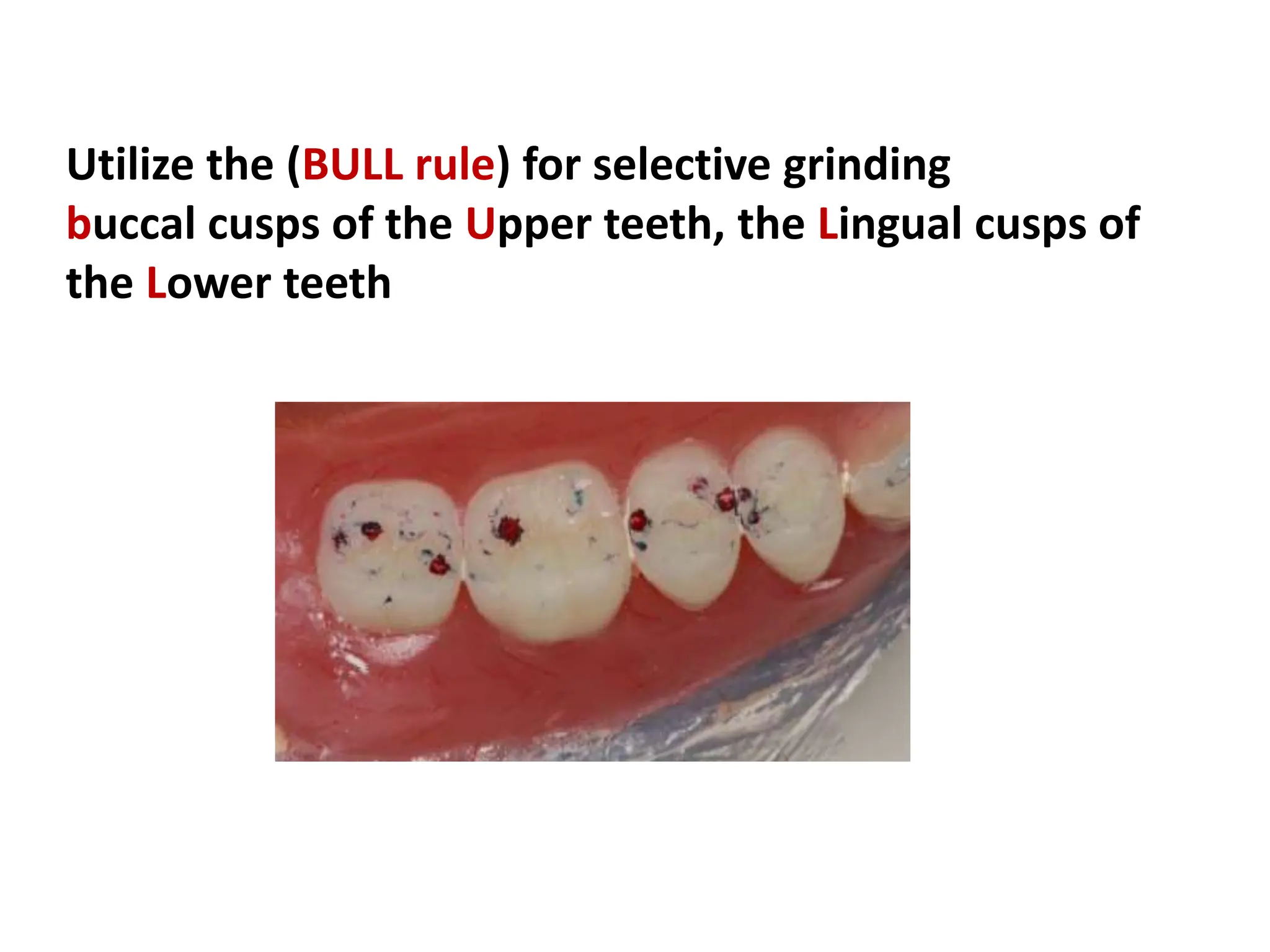

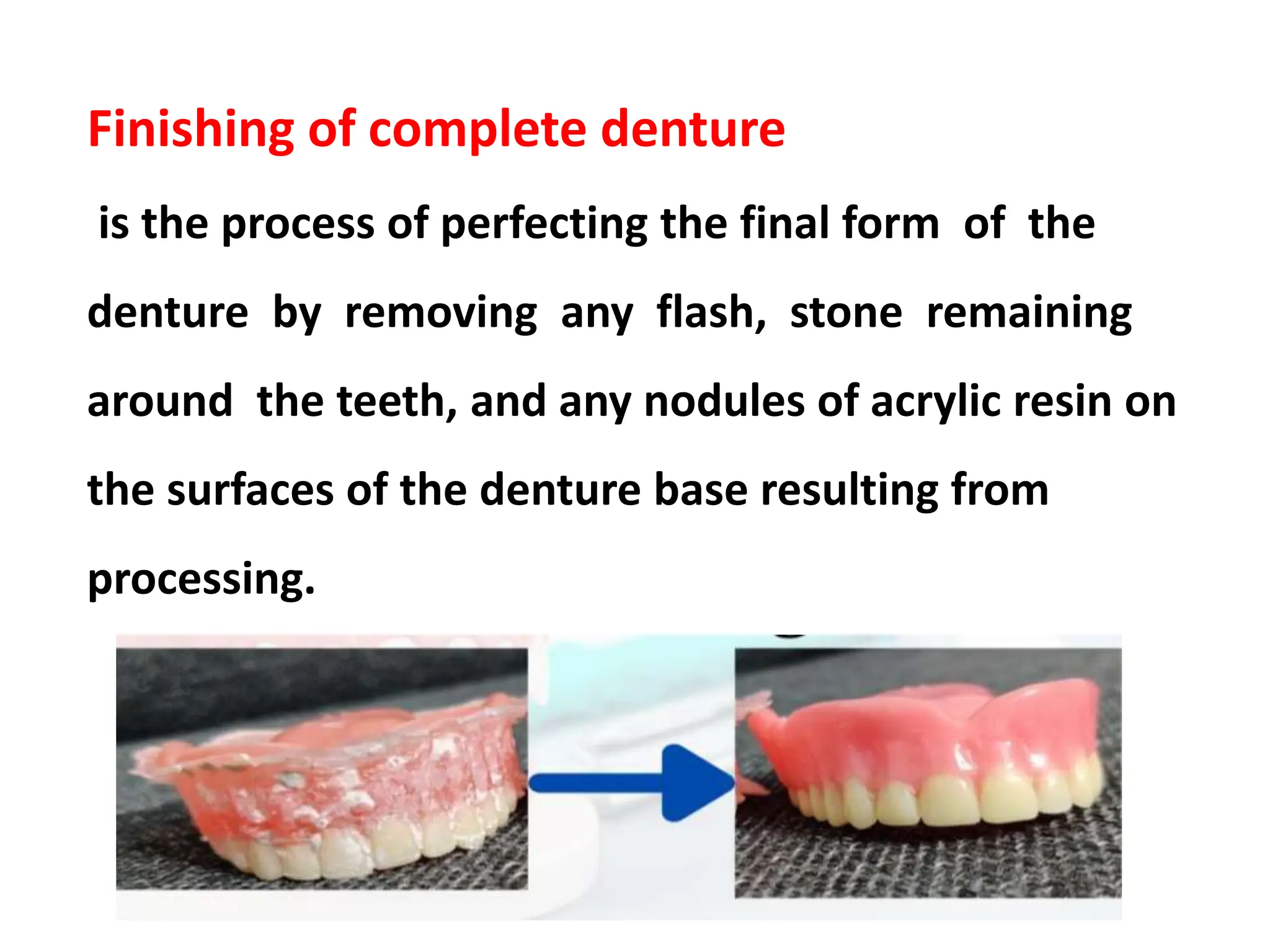

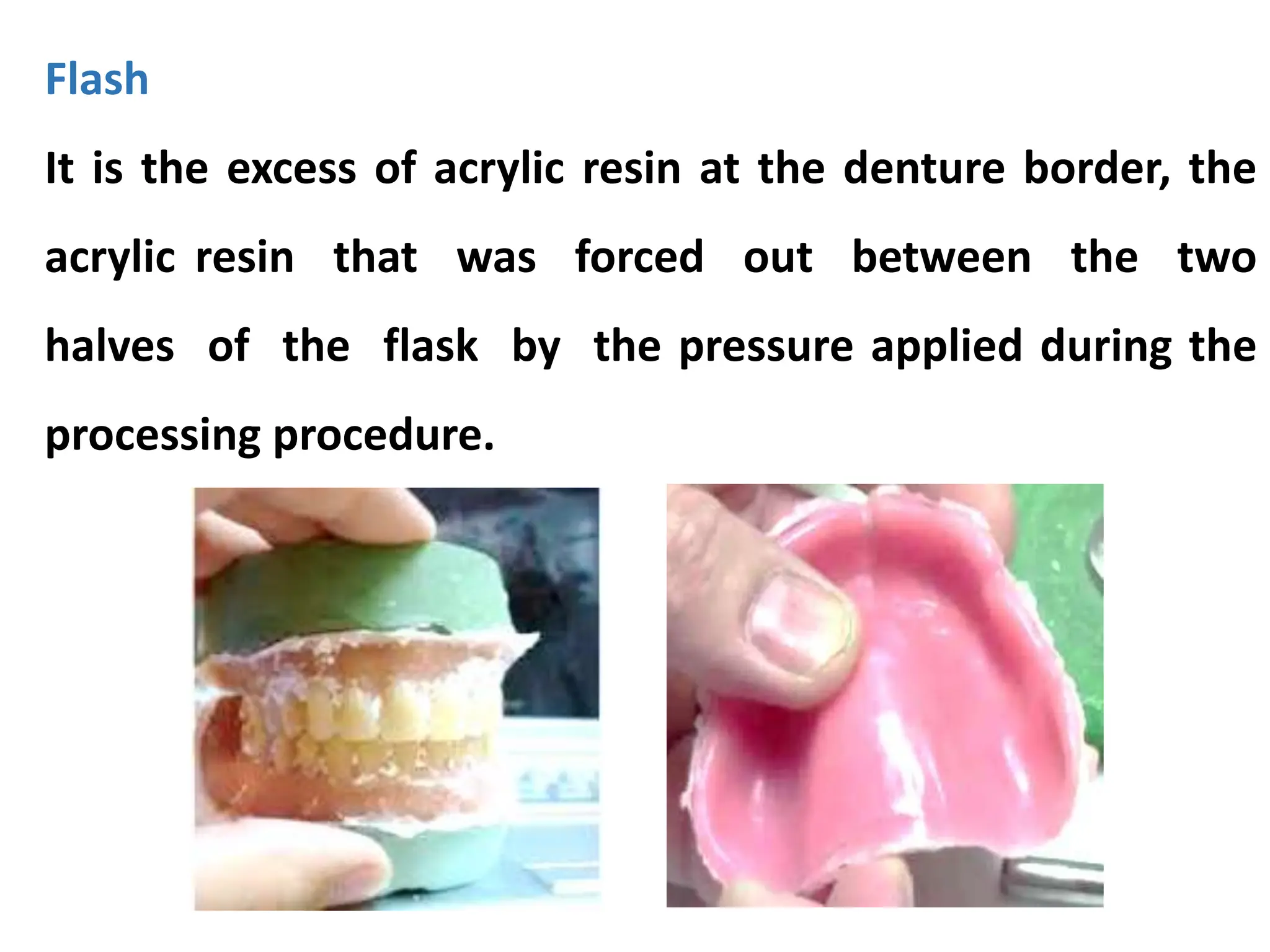

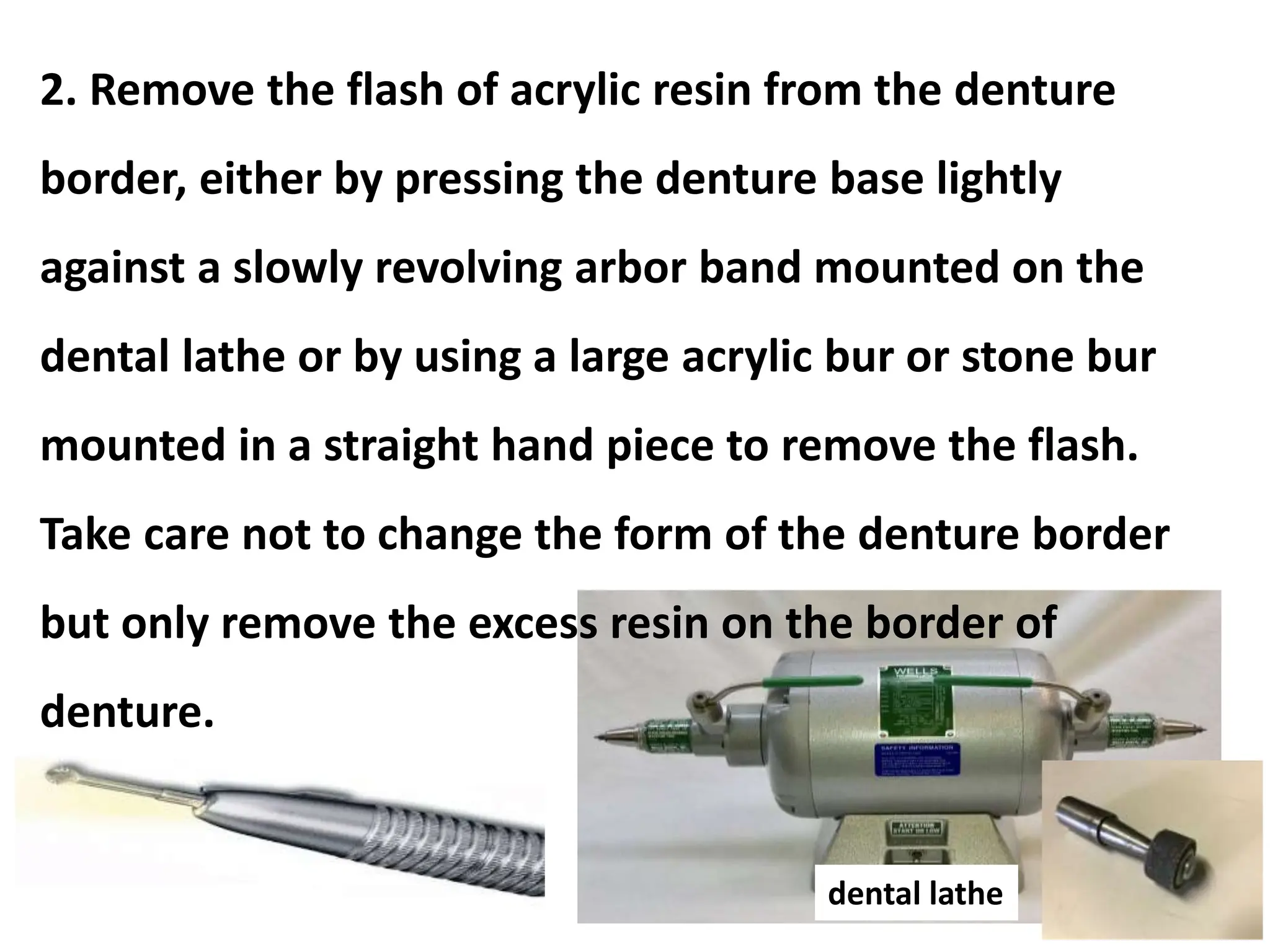

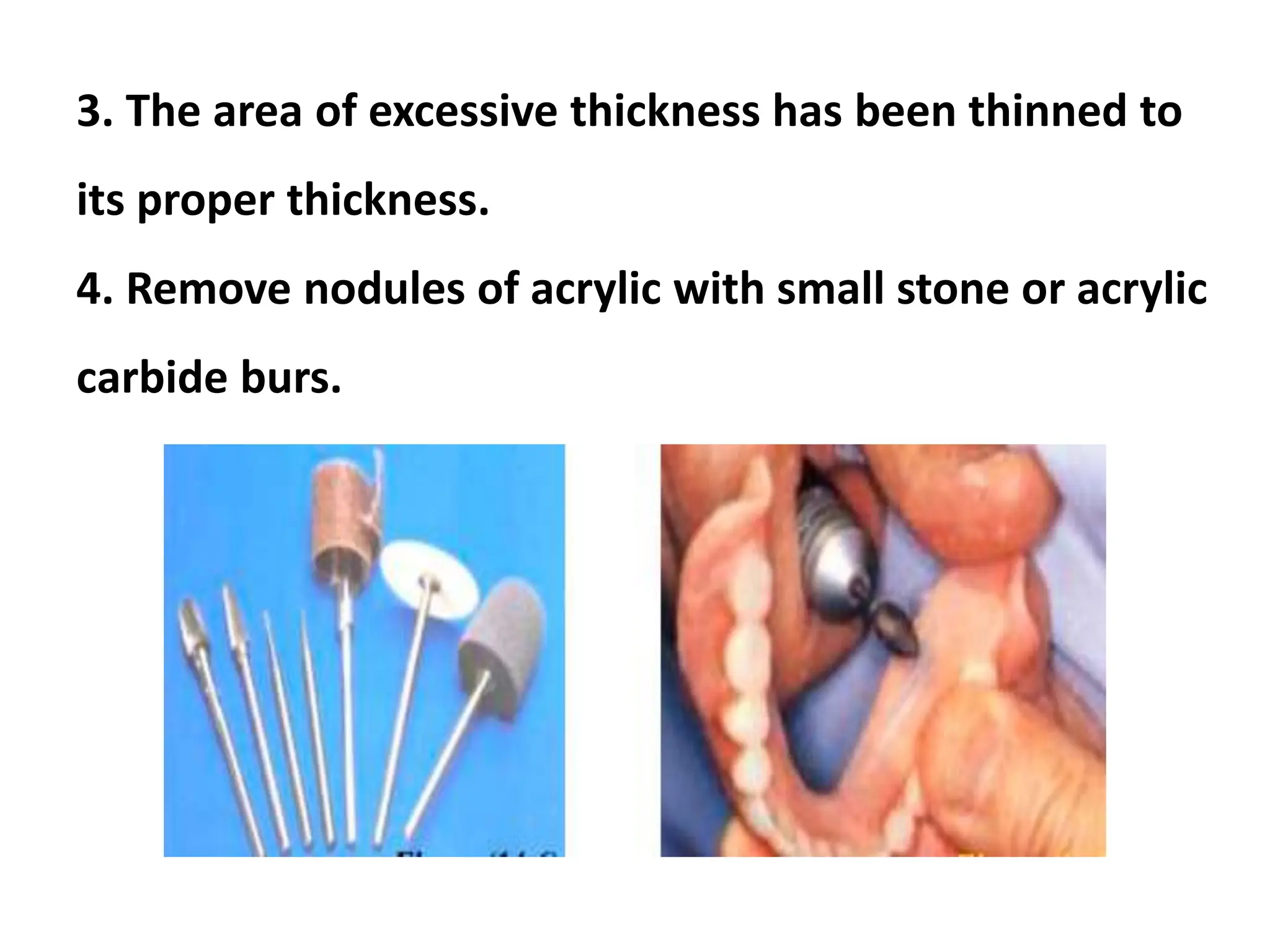

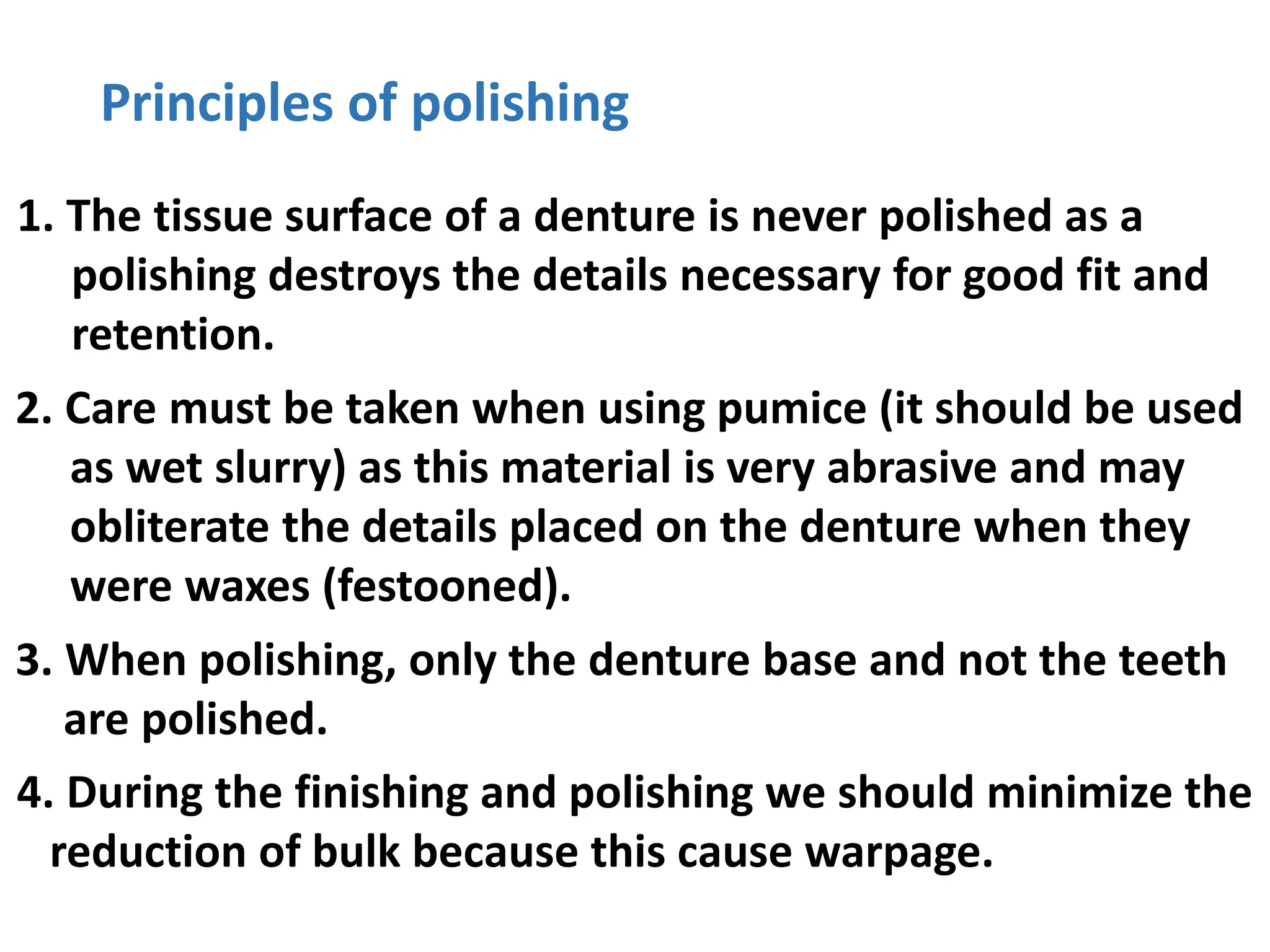

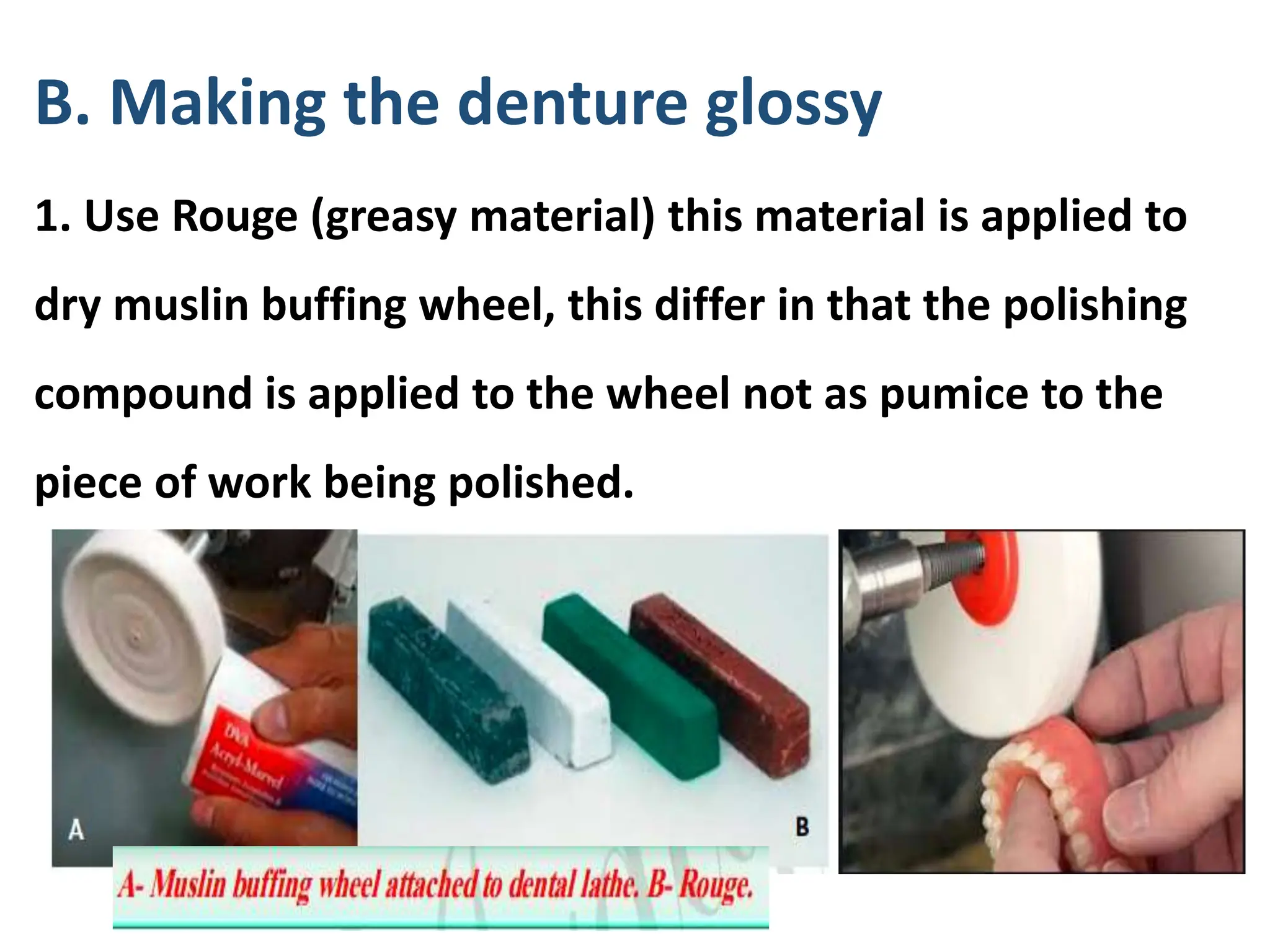

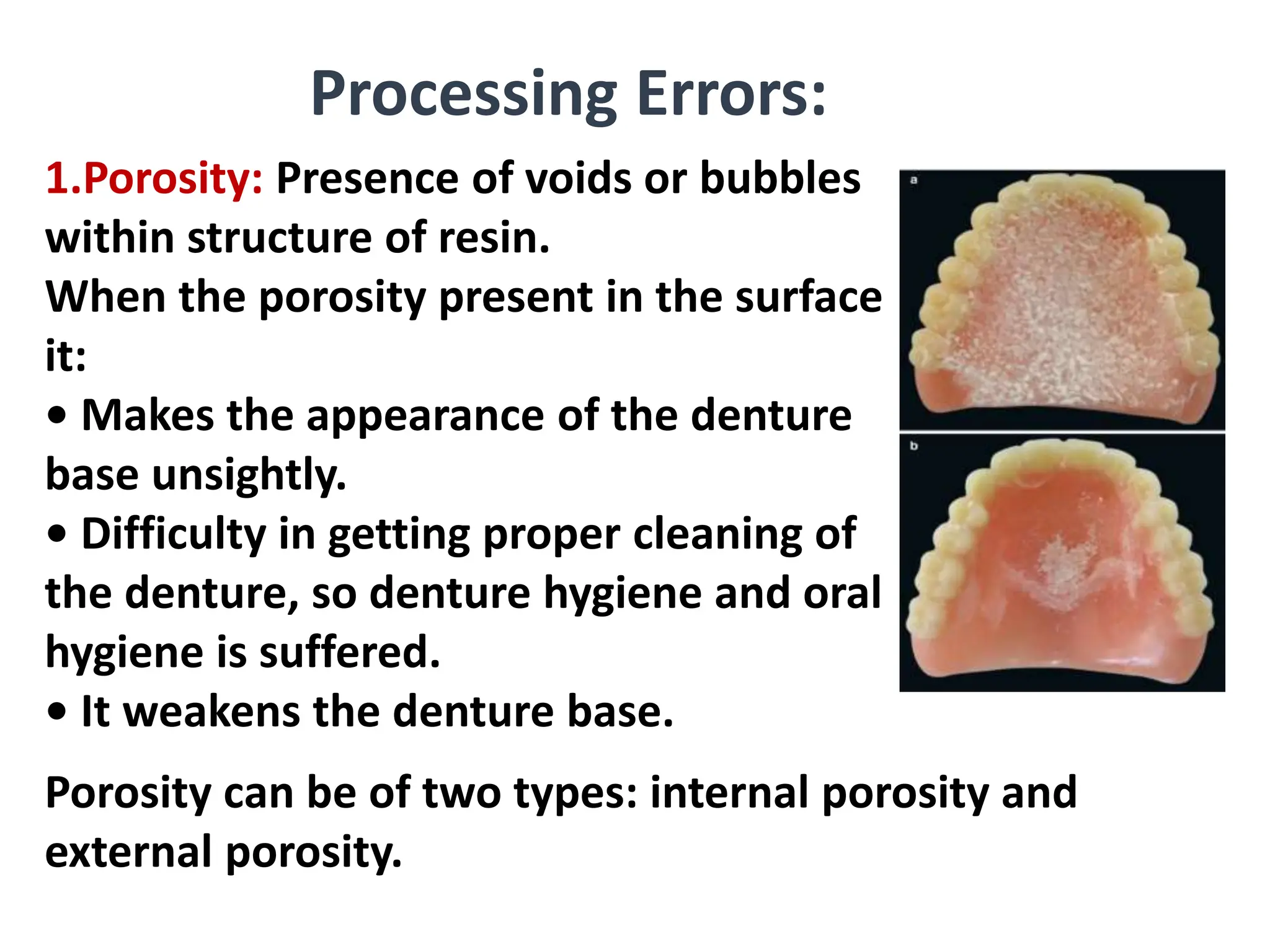

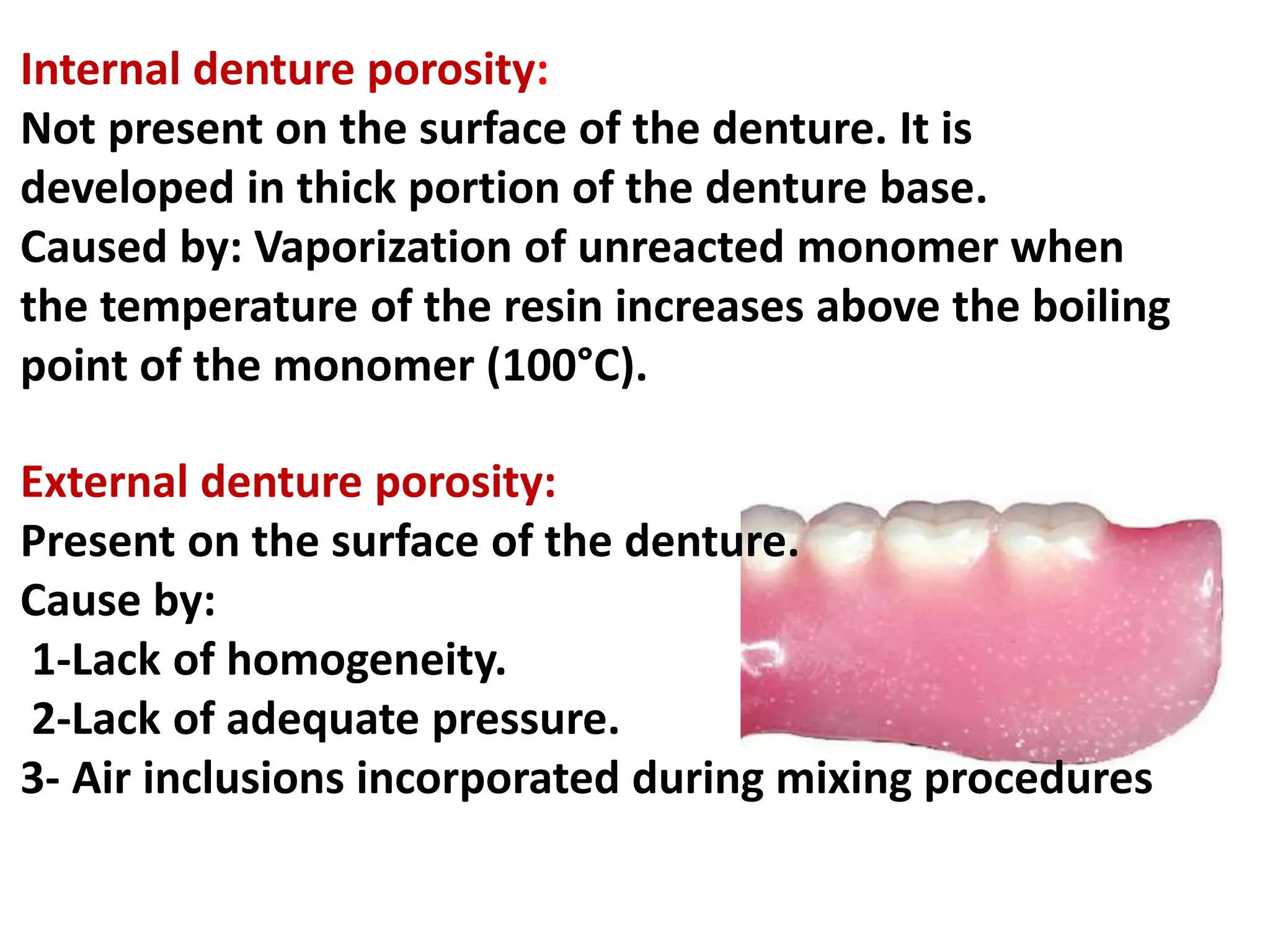

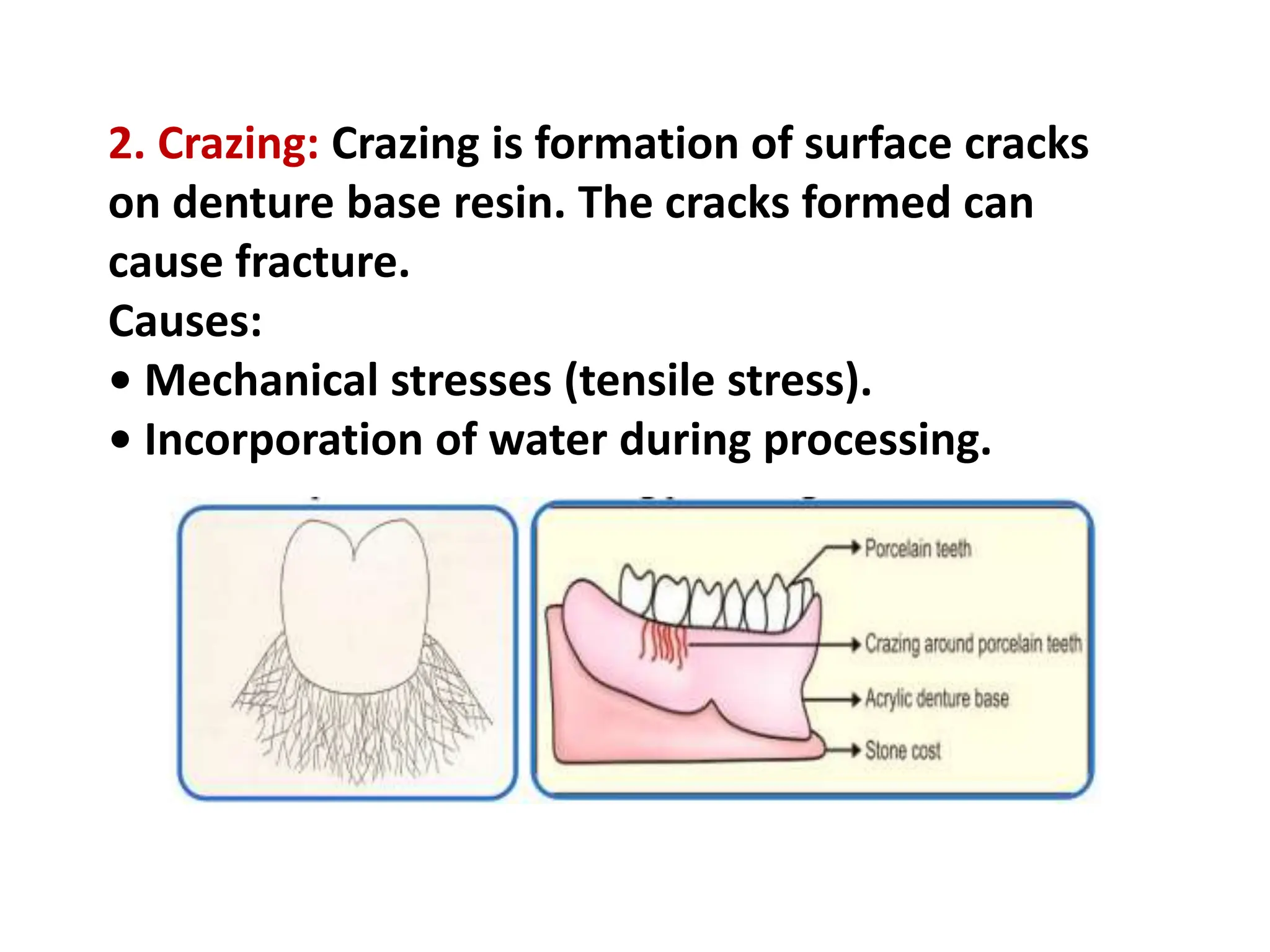

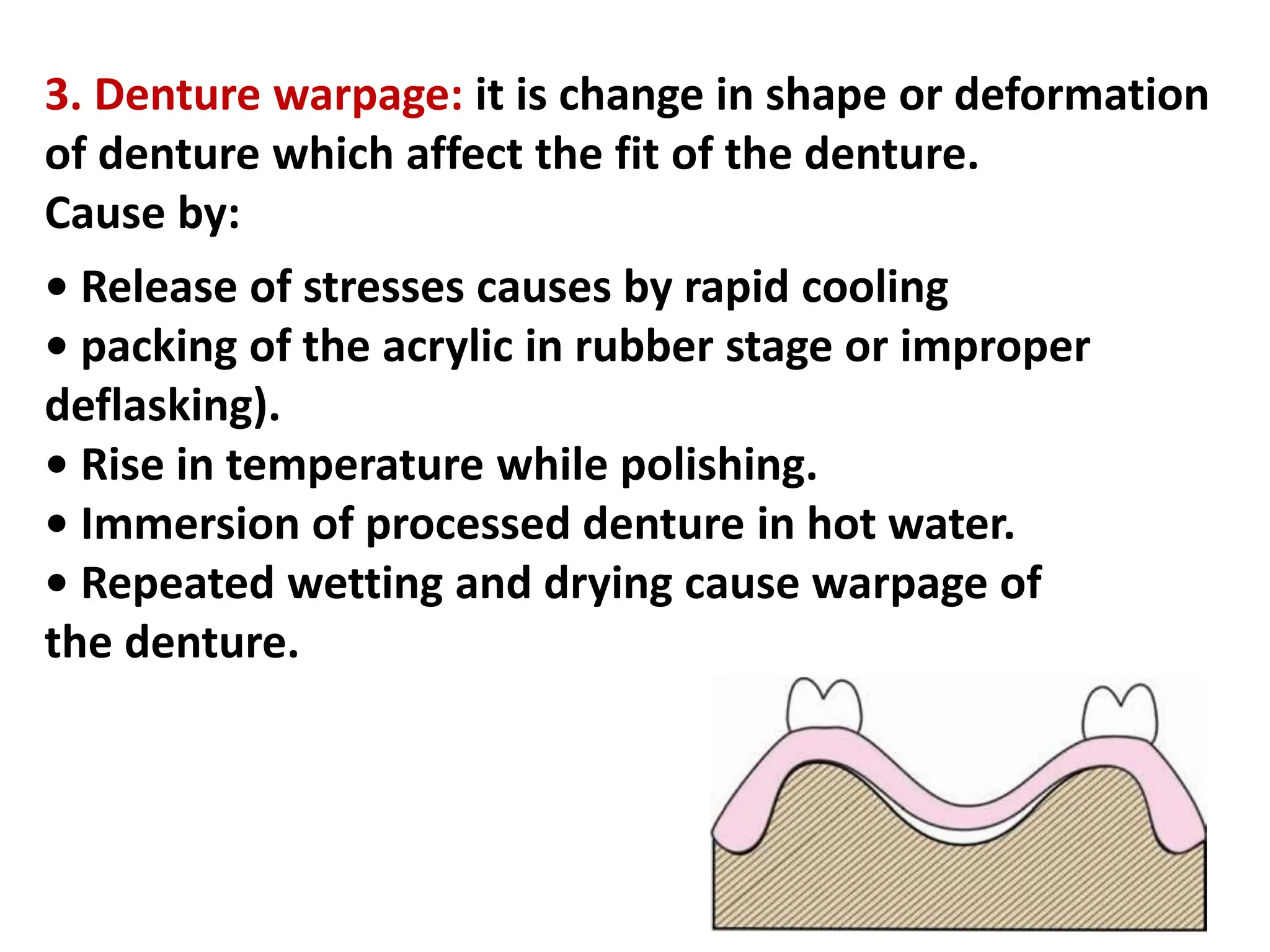

The document details the procedure for packing, curing, deflasking, finishing, and polishing dentures, highlighting crucial steps such as using the correct amounts of acrylic, ensuring proper temperature control during curing, and performing selective grinding for occlusal correction. It emphasizes the importance of minimizing porosity, crazing, and warpage in the finished product. Additionally, it describes polishing techniques to achieve a smooth and glossy surface while maintaining the necessary details for fit and retention.