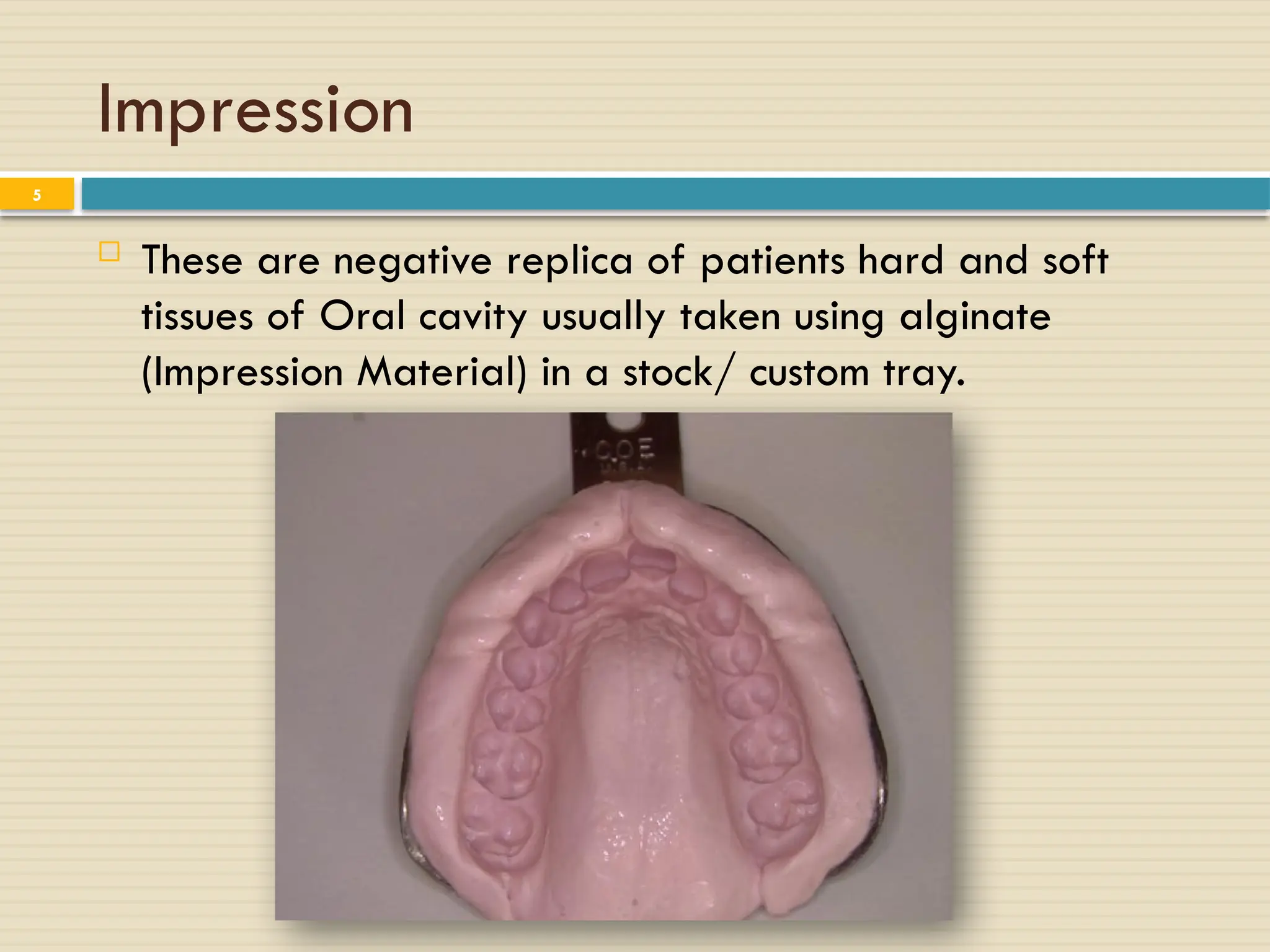

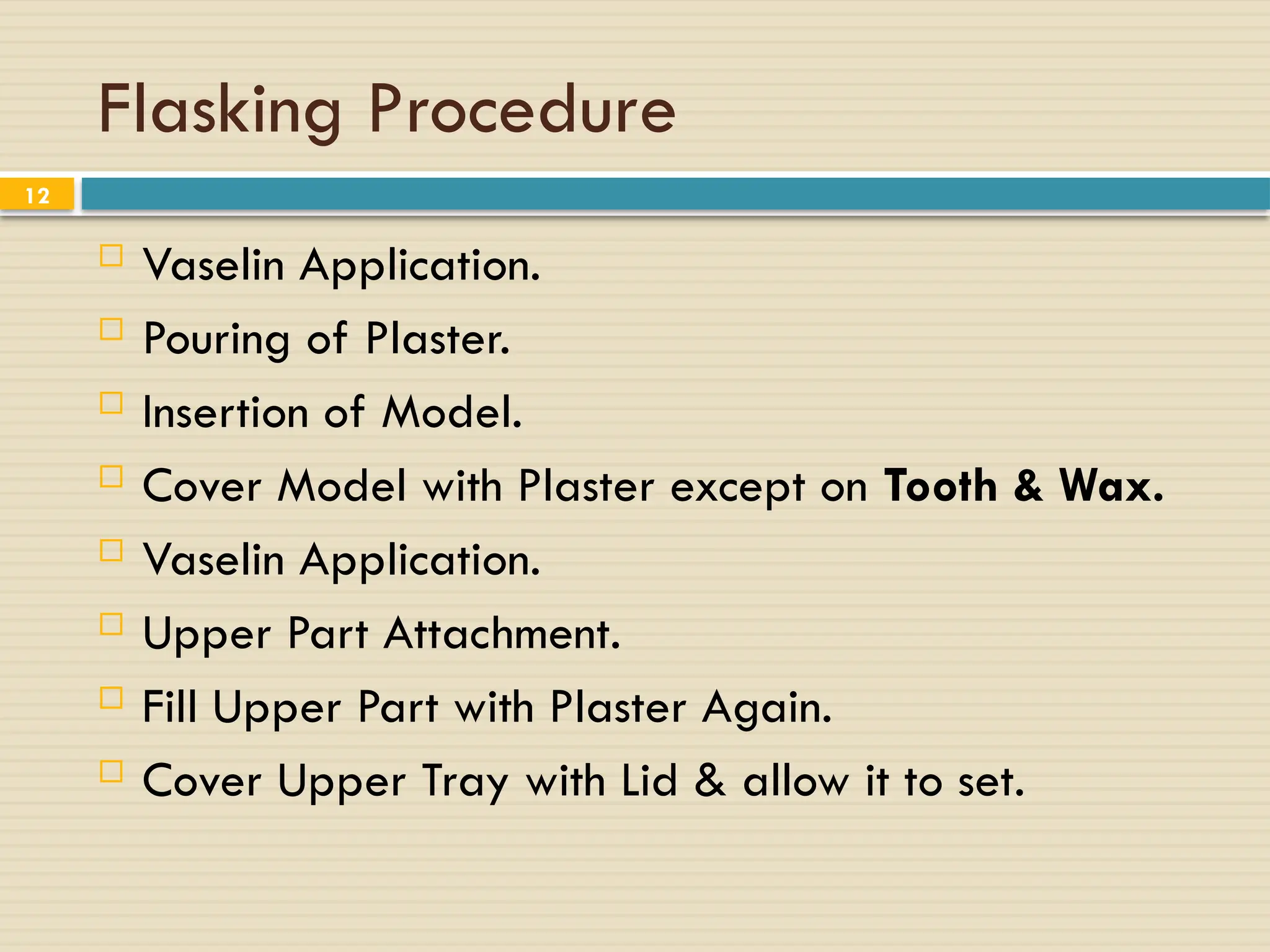

The document outlines the steps involved in creating removable partial dentures, detailing the process from initial impressions to final polishing. Key steps include model preparation, framework adaptation, and curing of materials, taking approximately three to six weeks to complete. It emphasizes the importance of precision throughout the various stages including articulation, waxing, and deflasking.