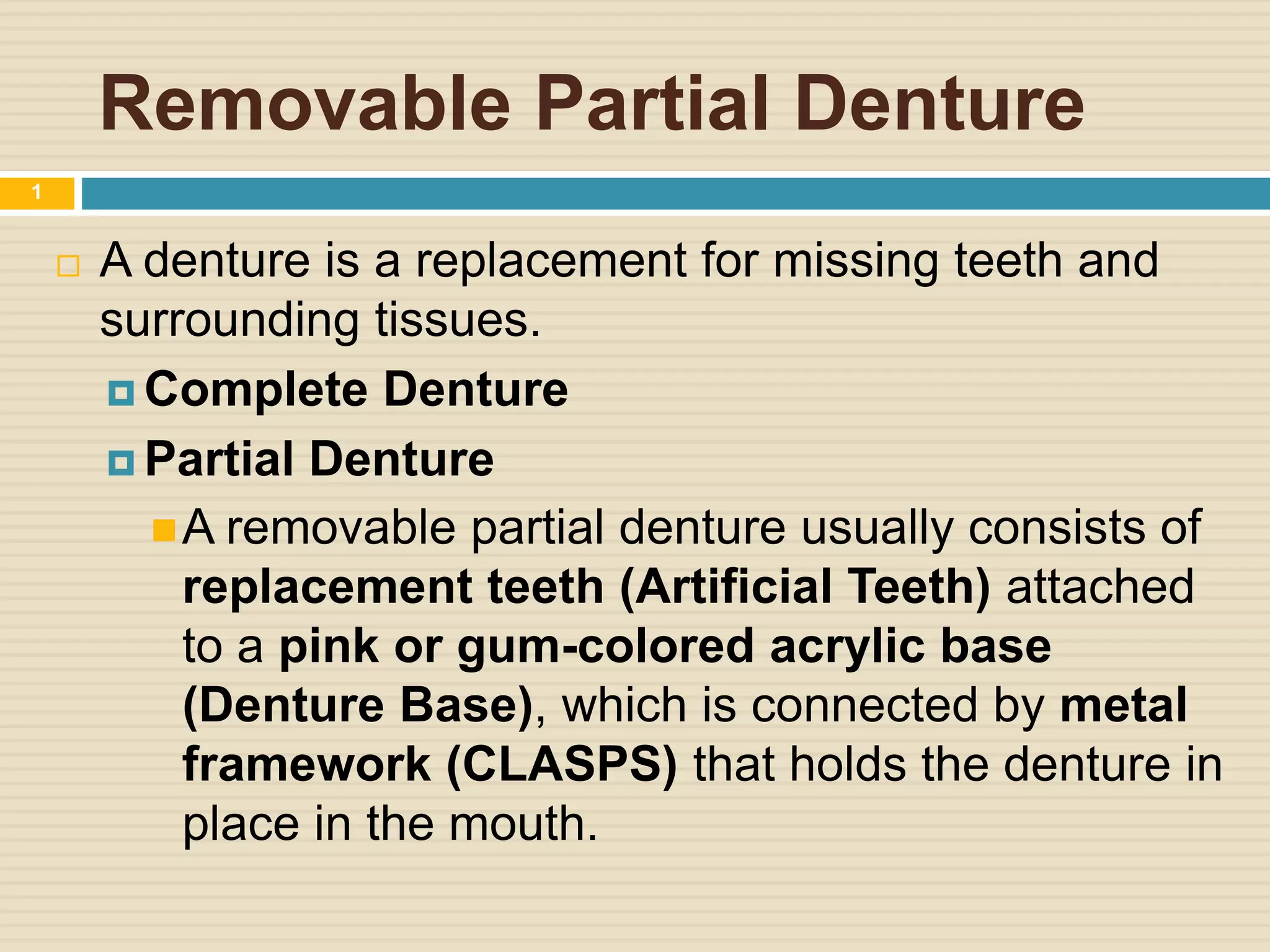

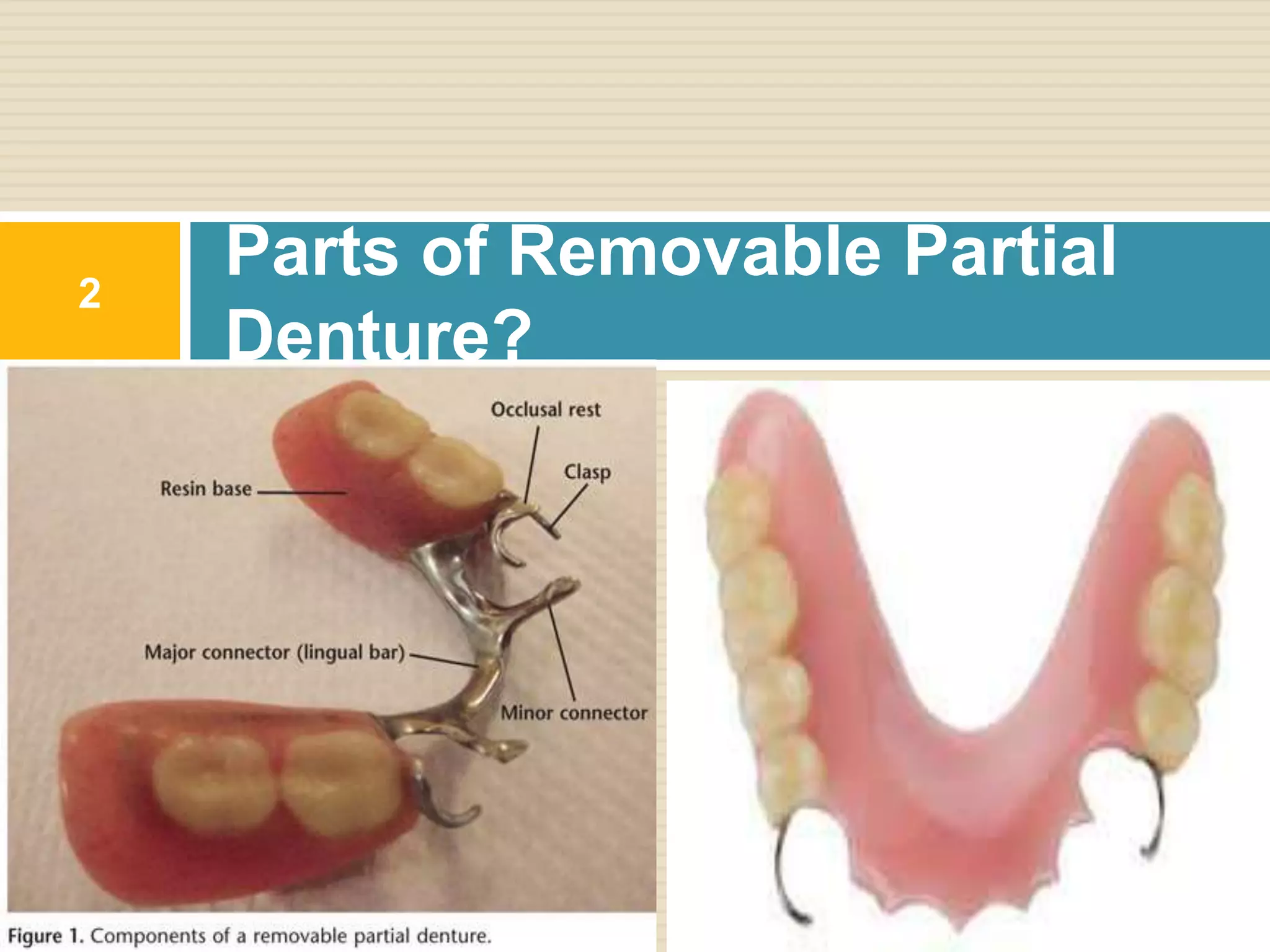

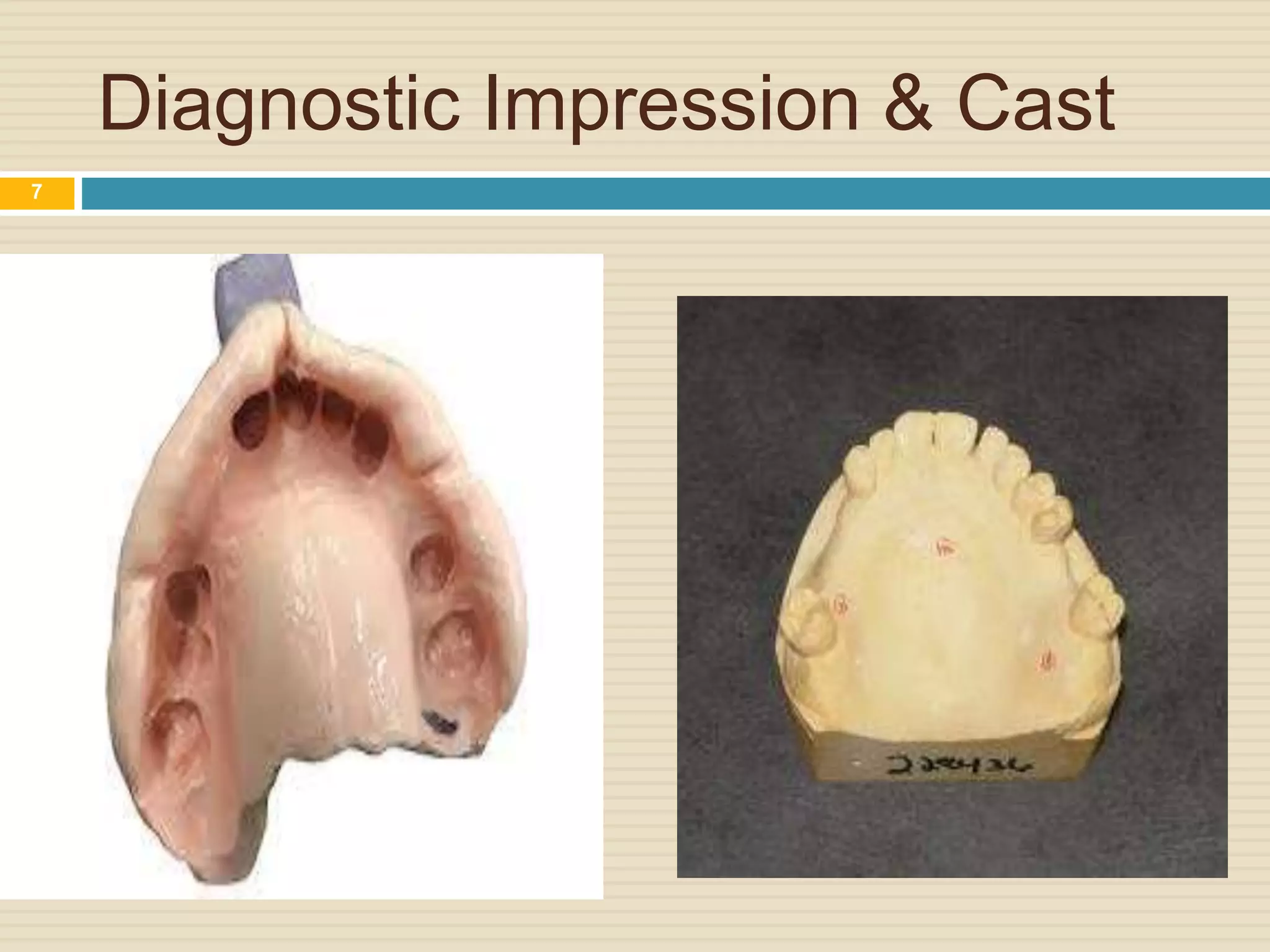

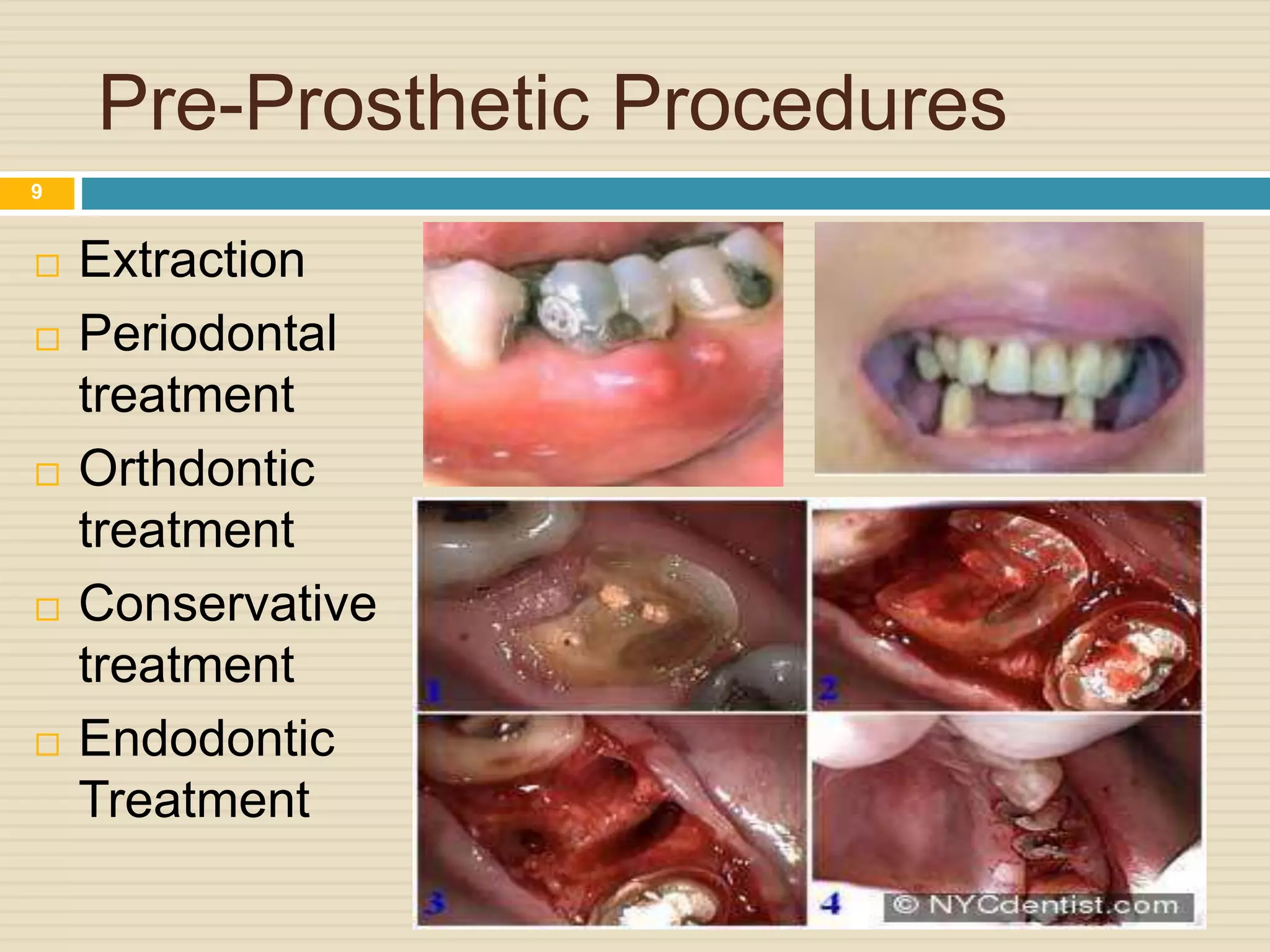

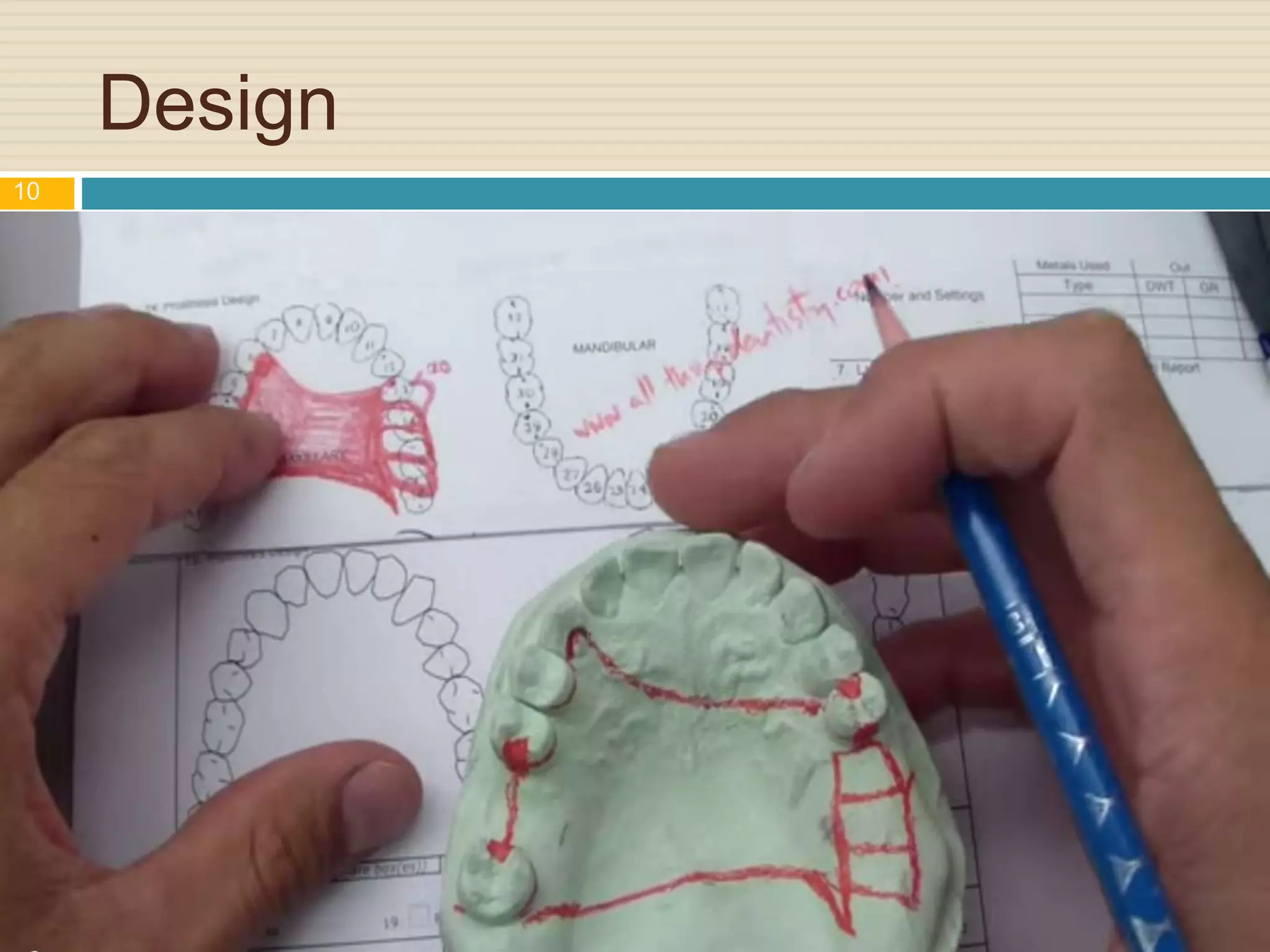

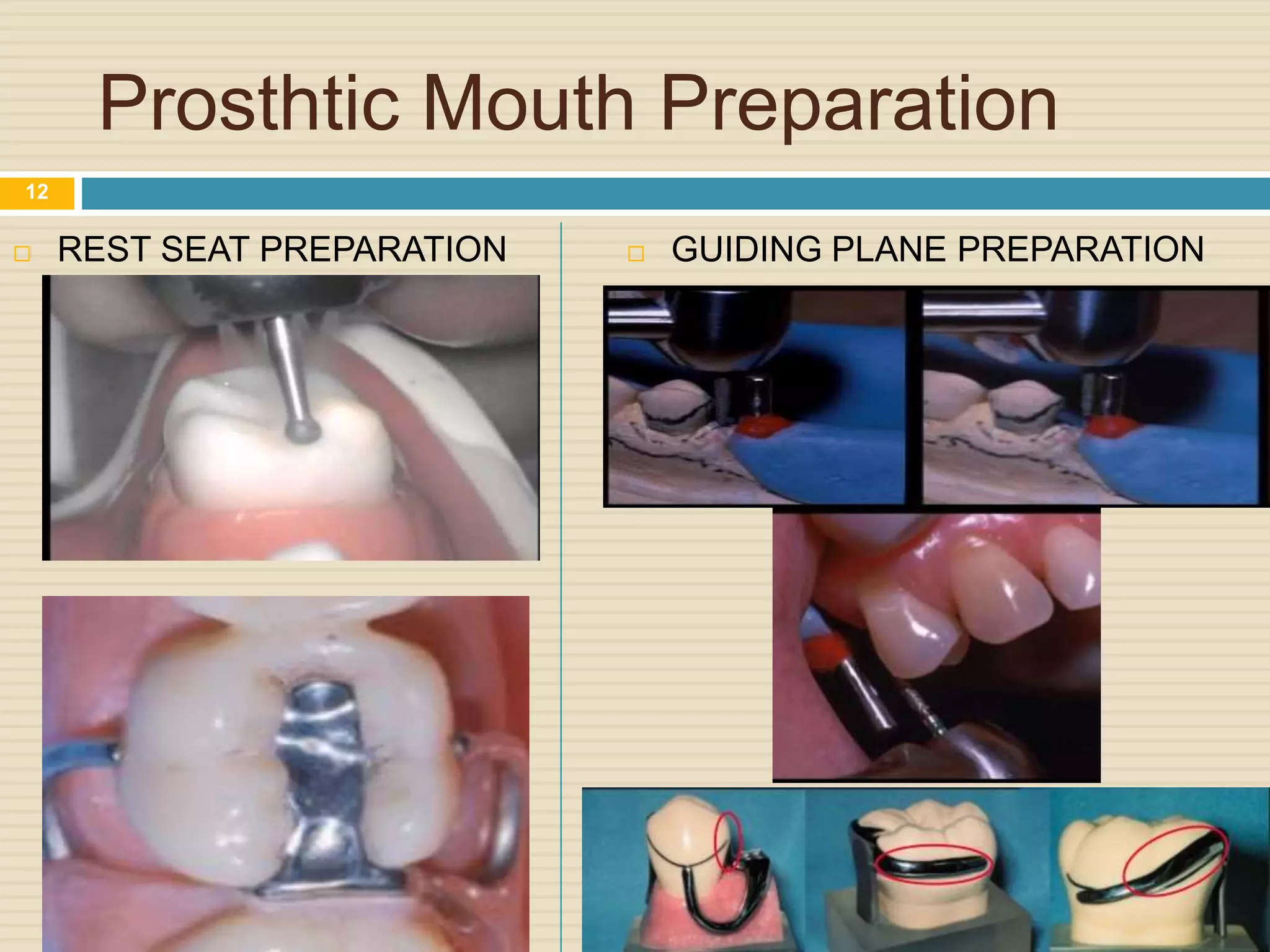

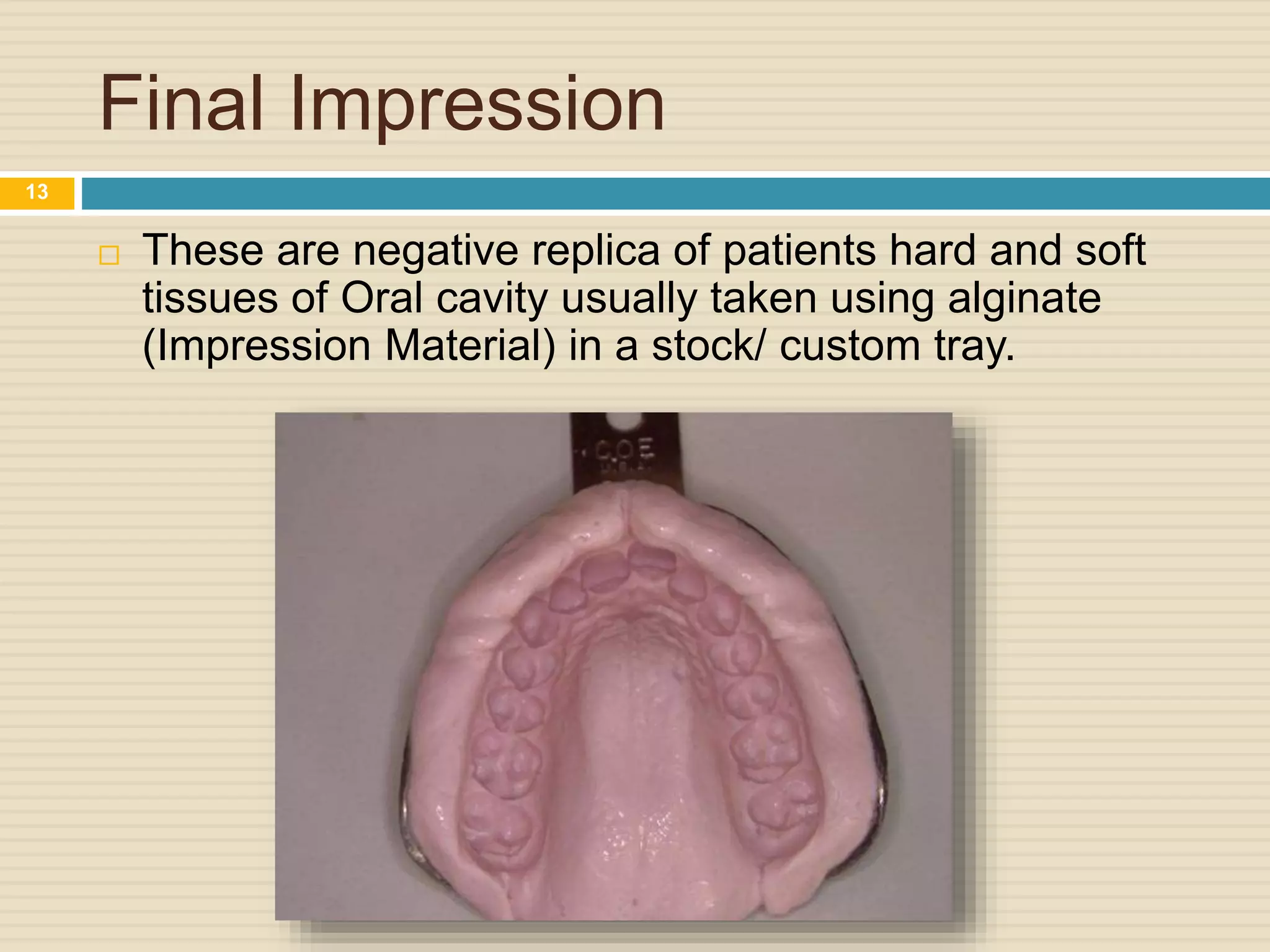

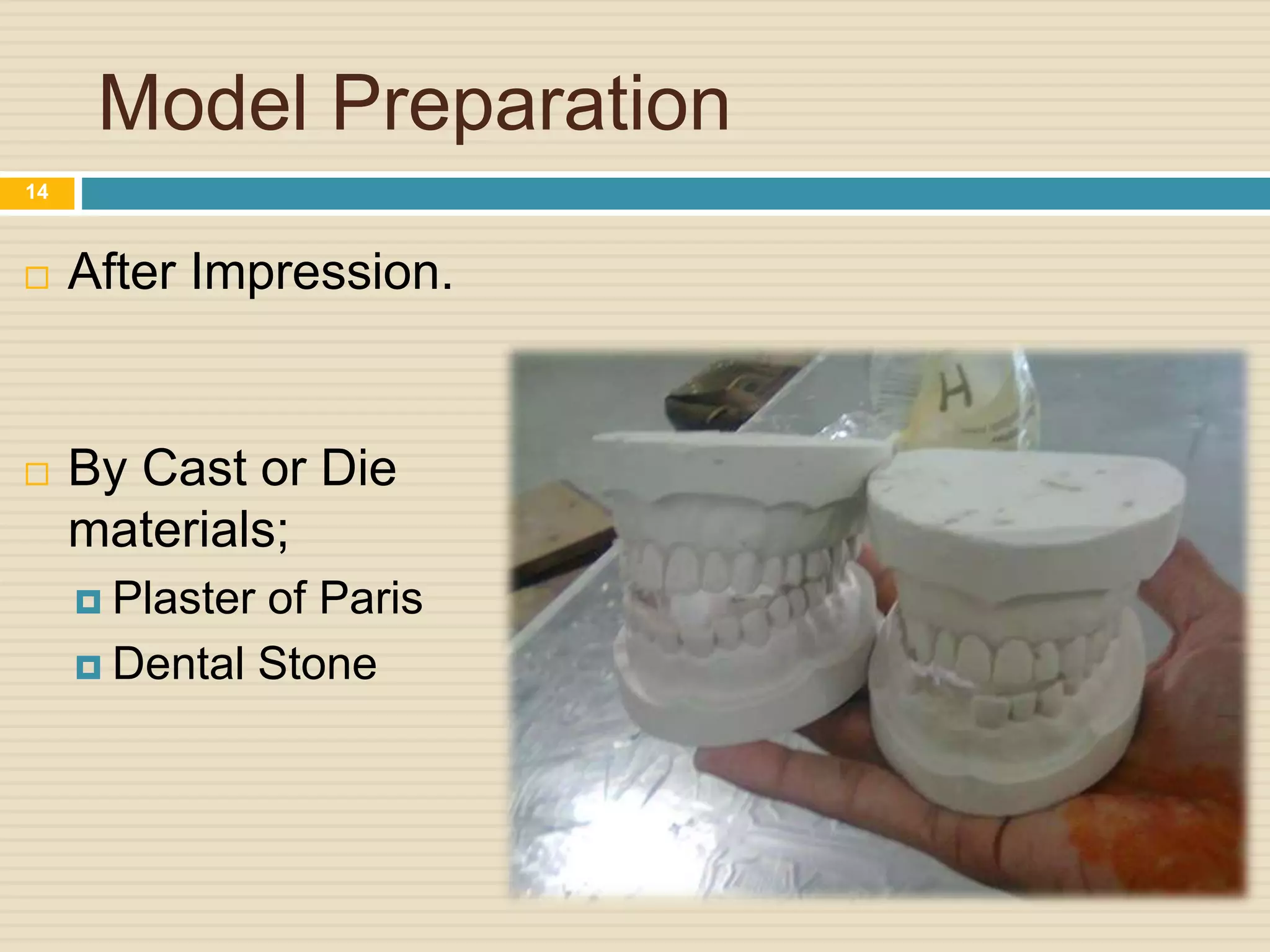

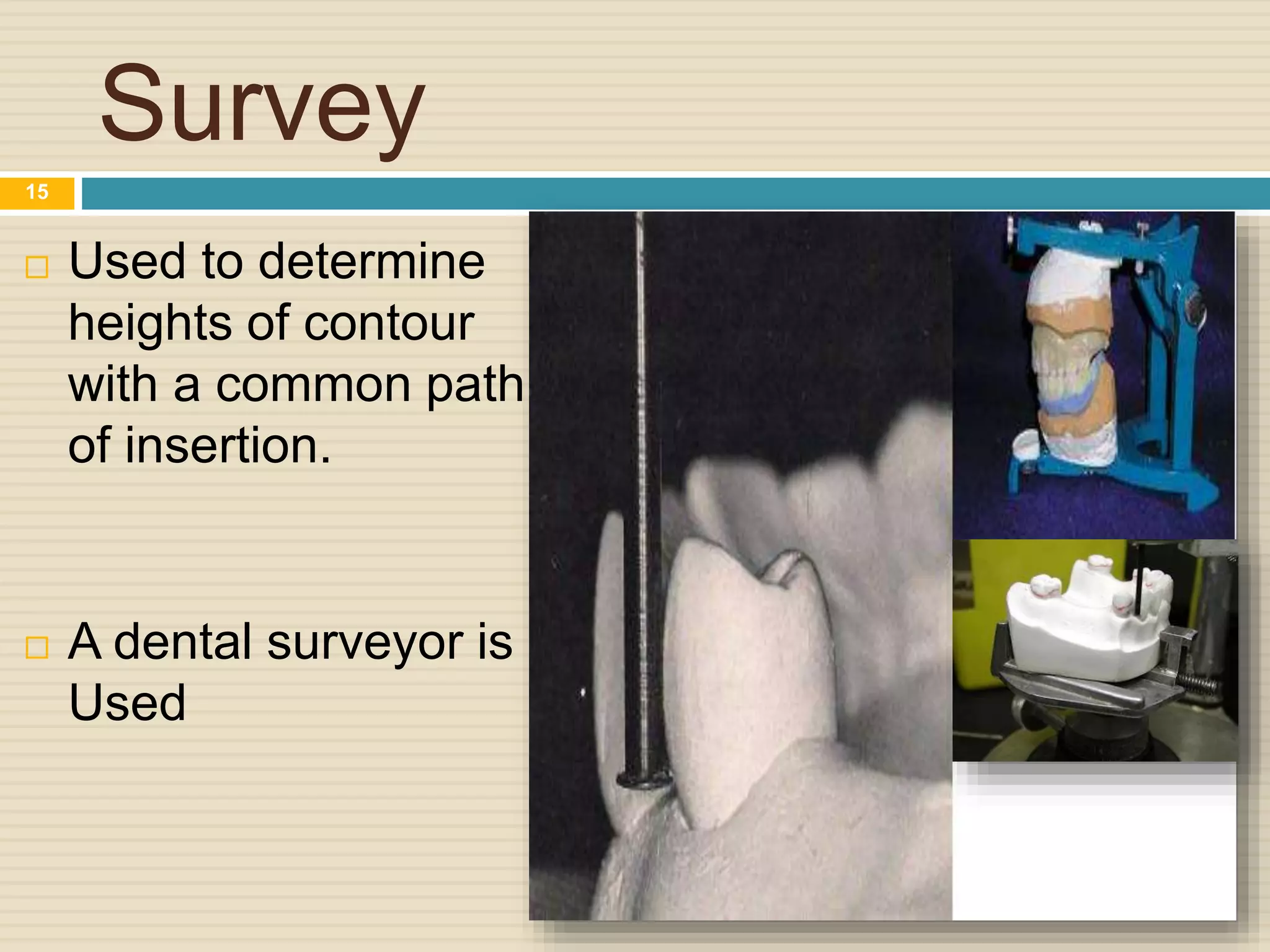

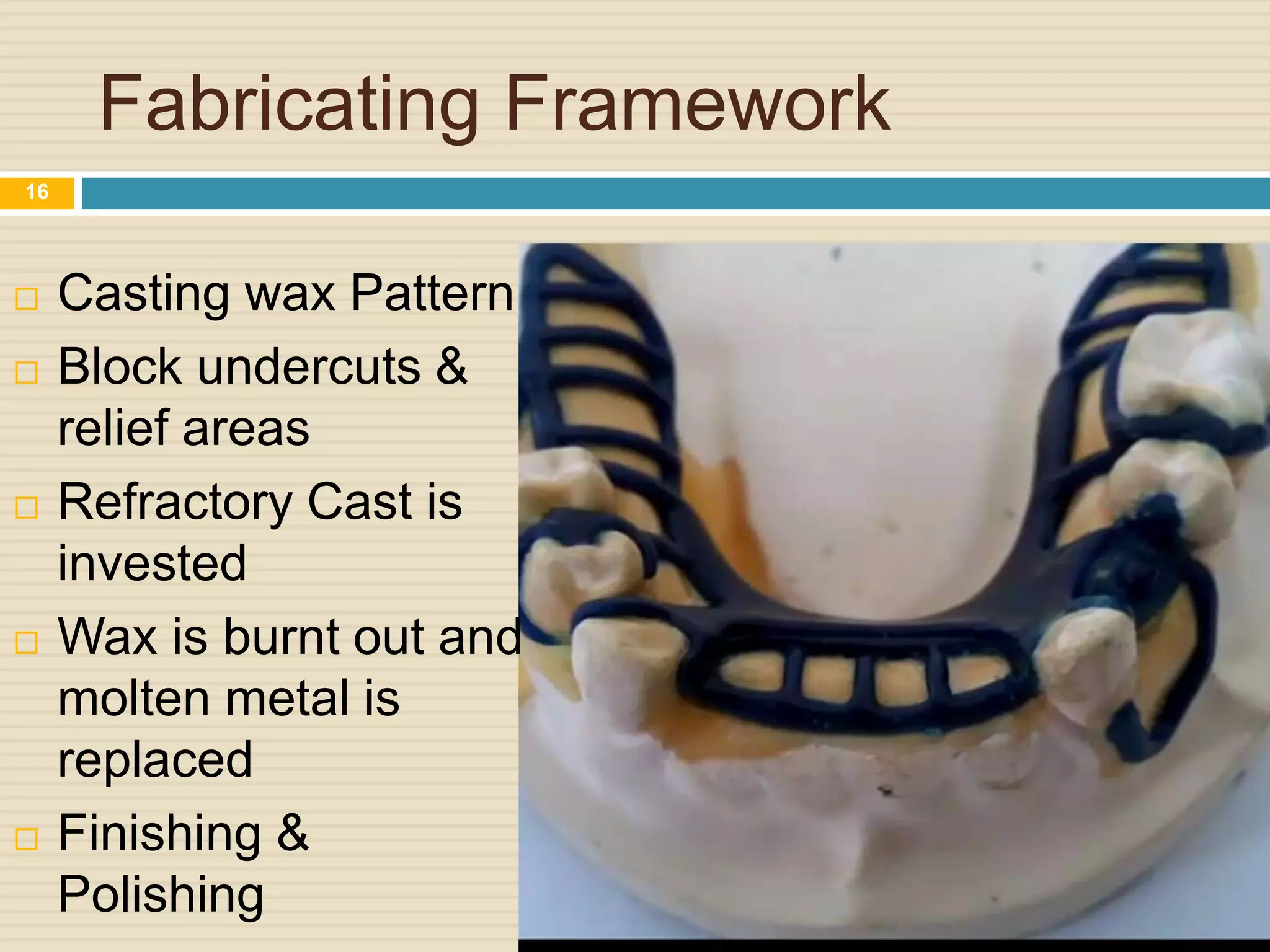

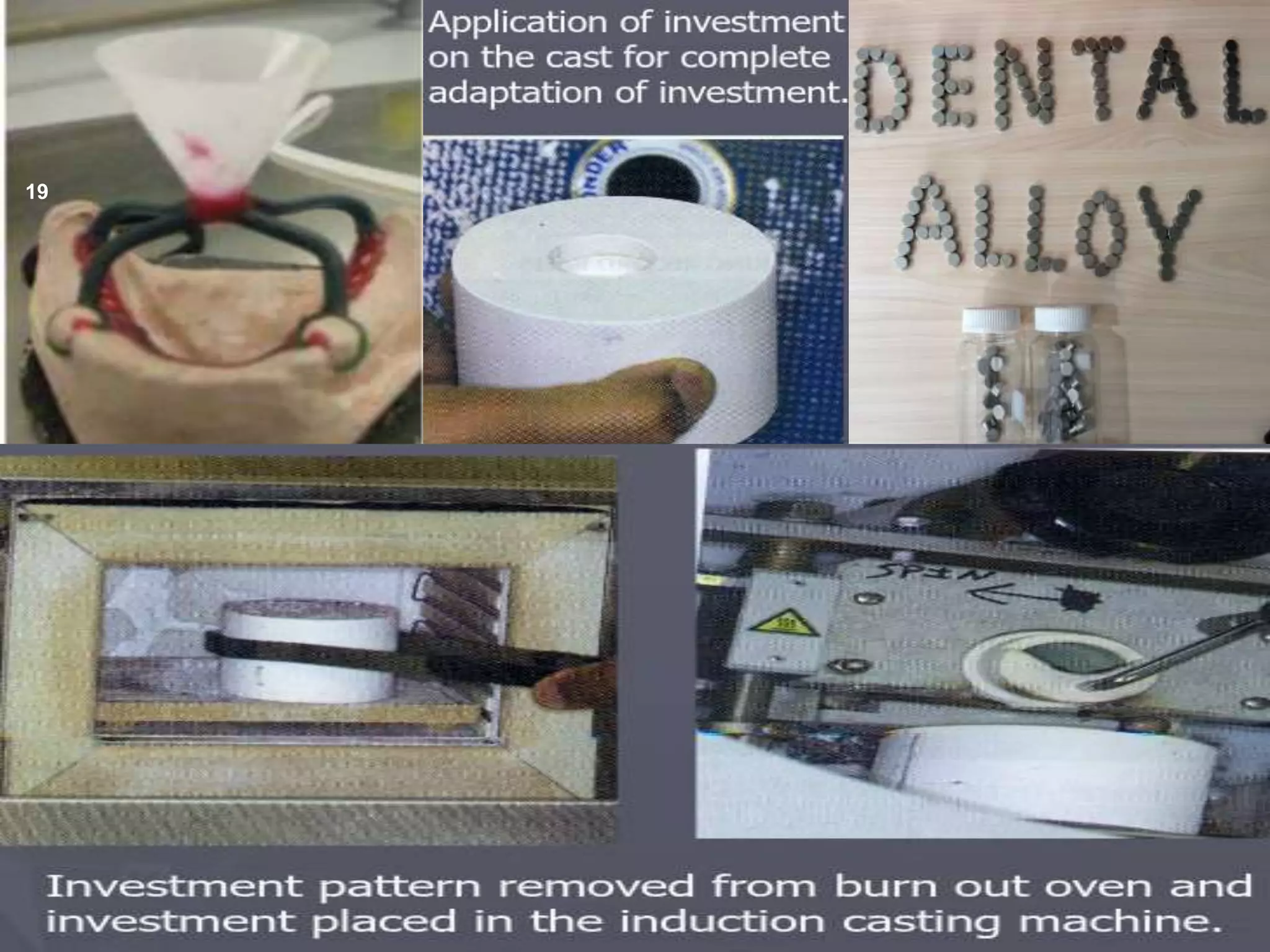

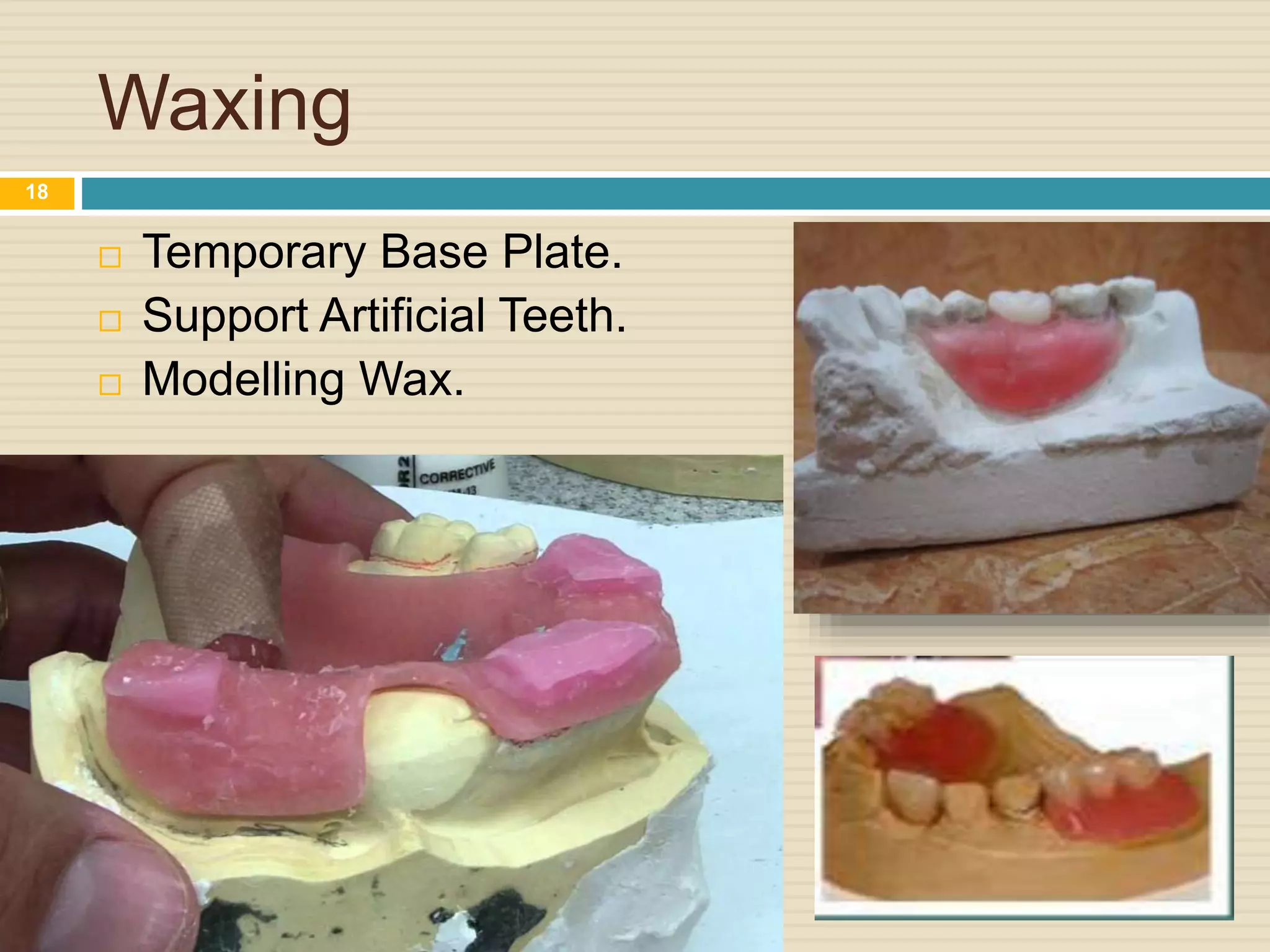

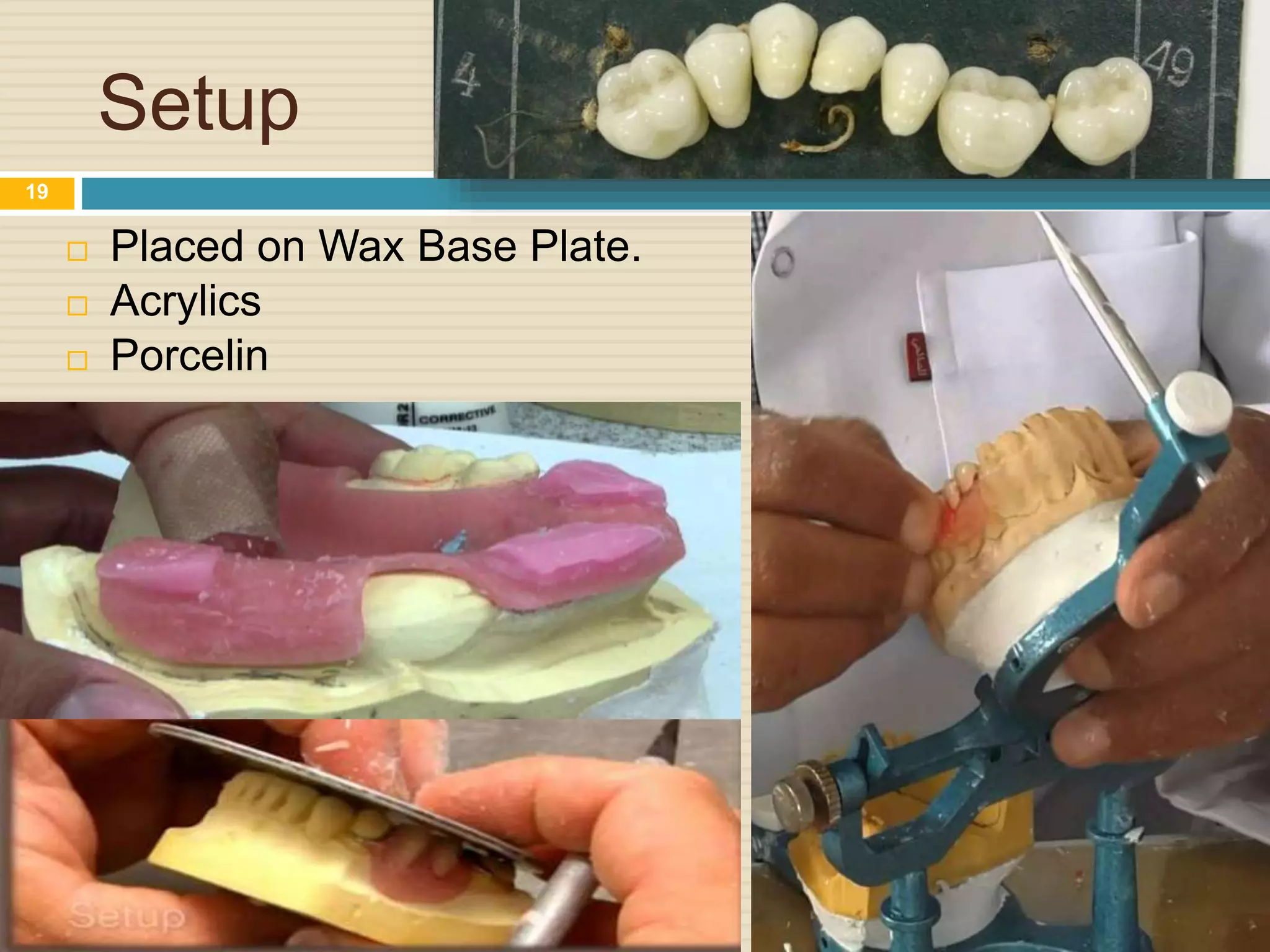

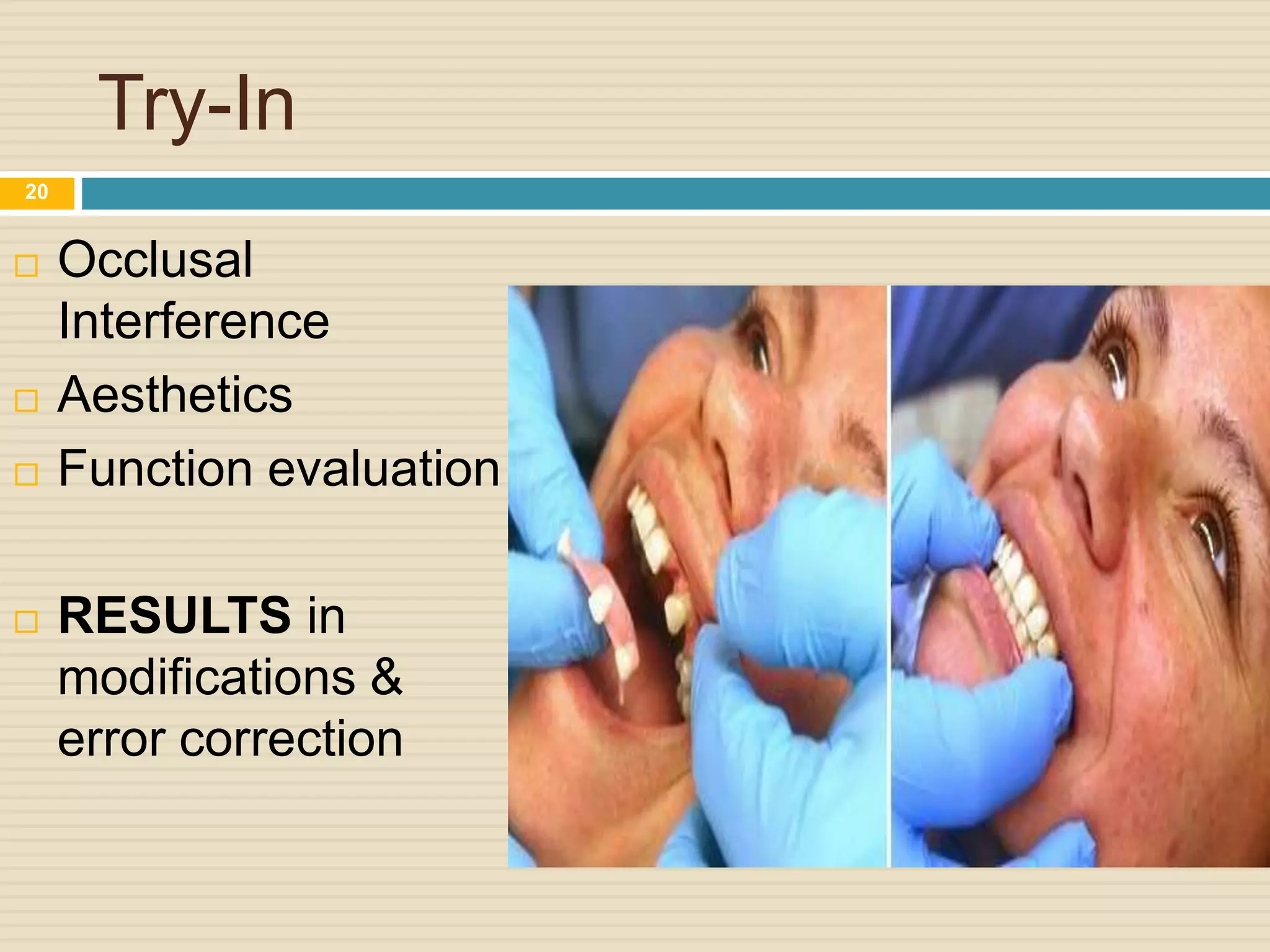

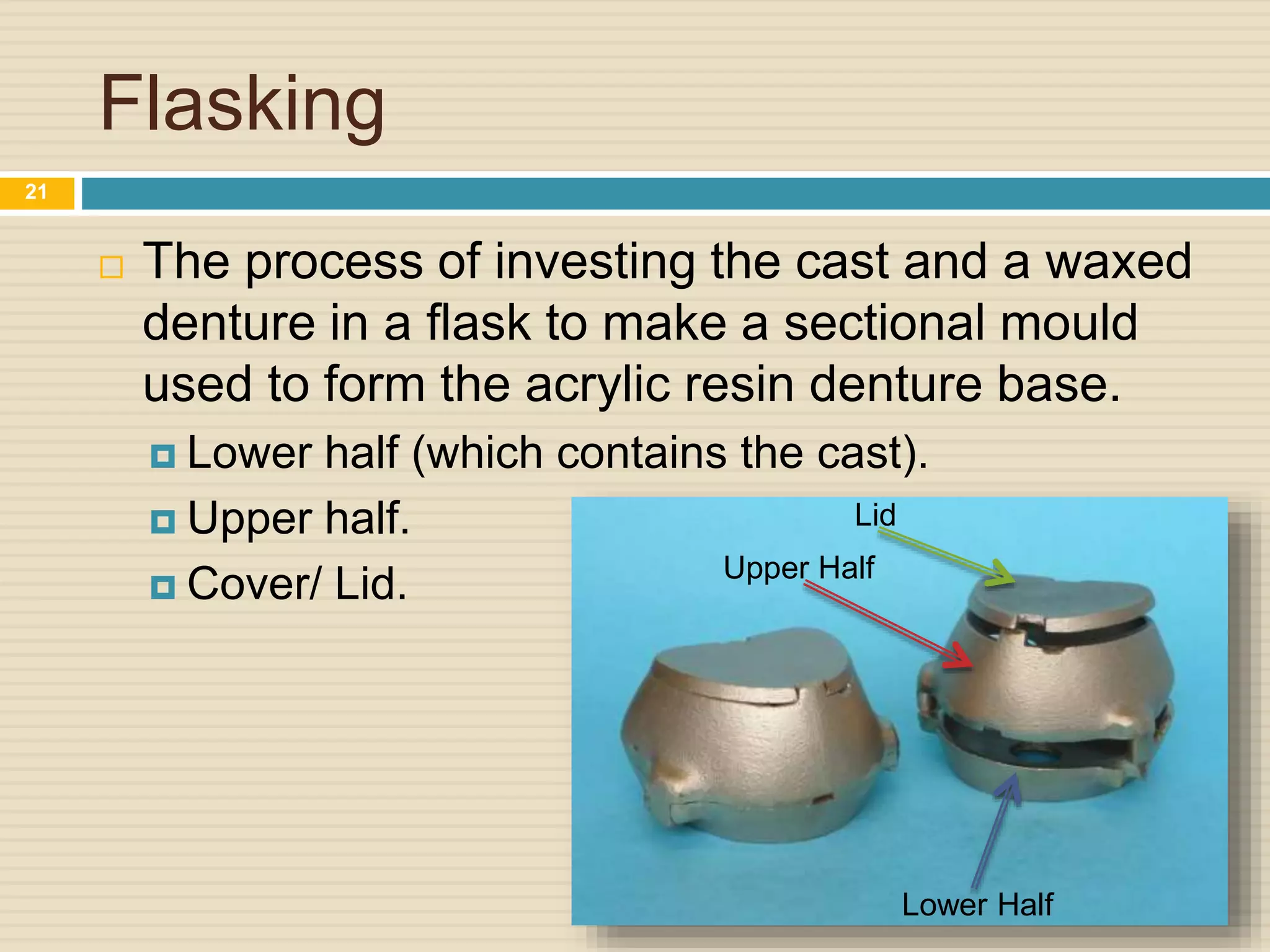

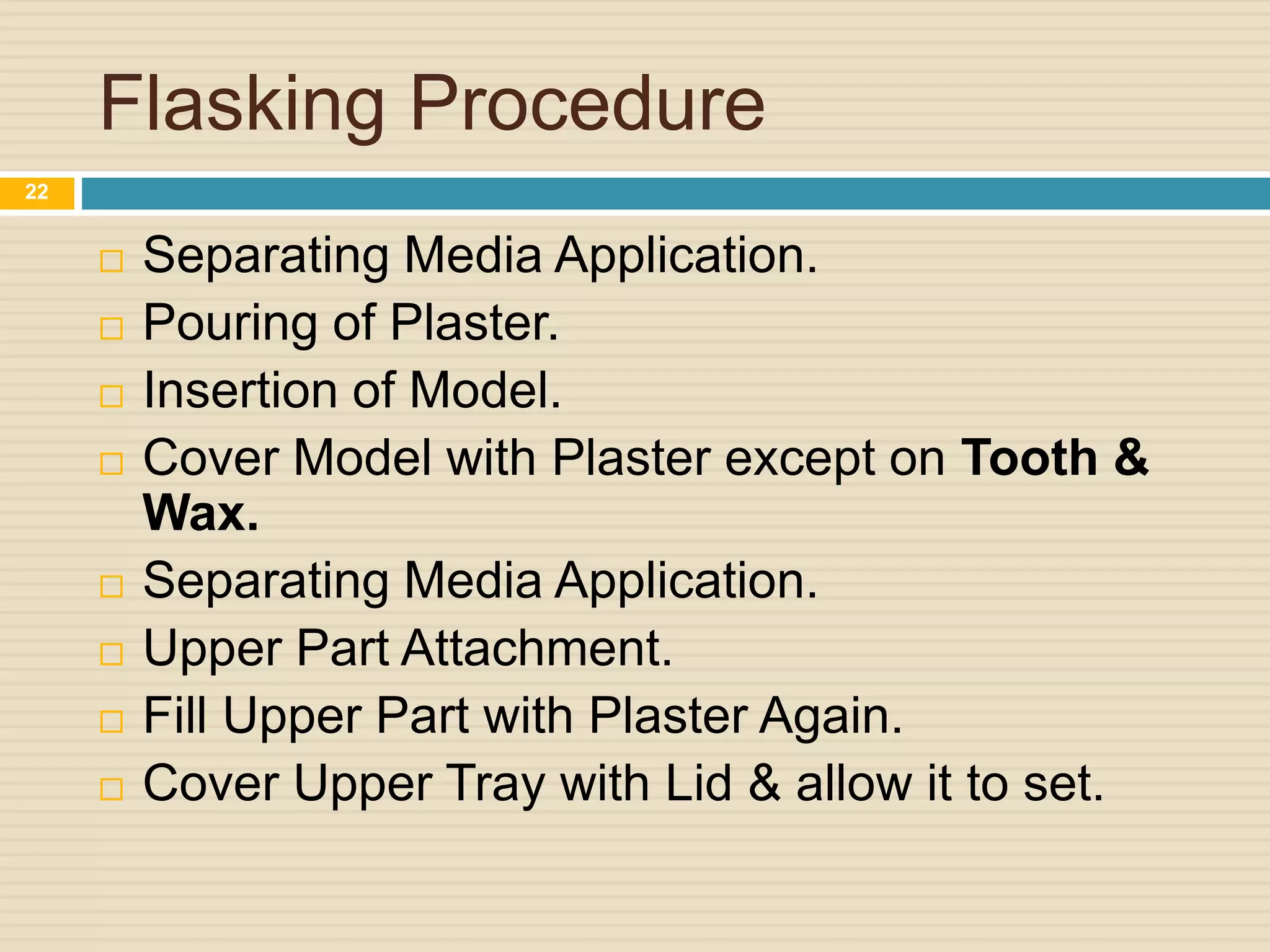

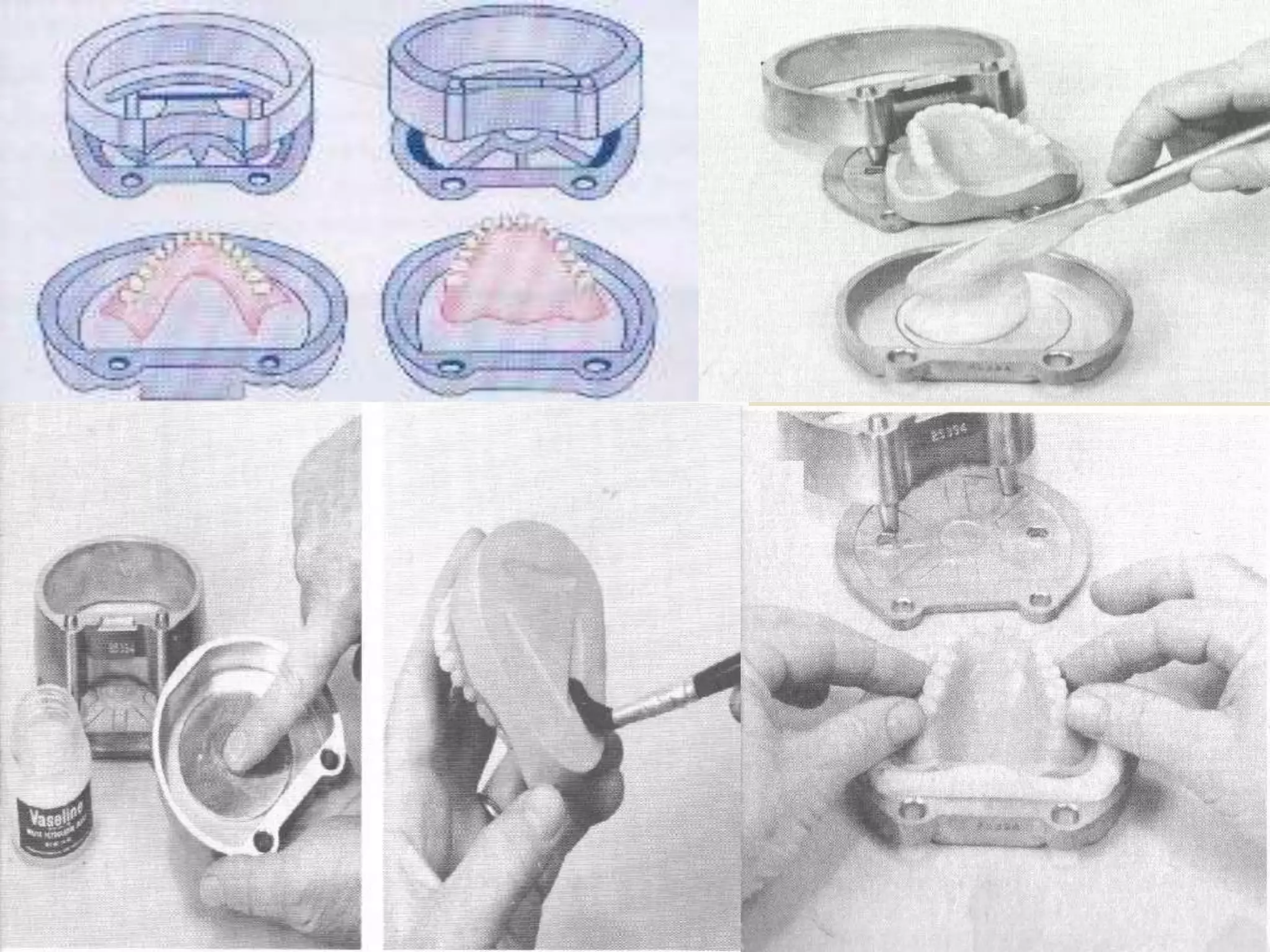

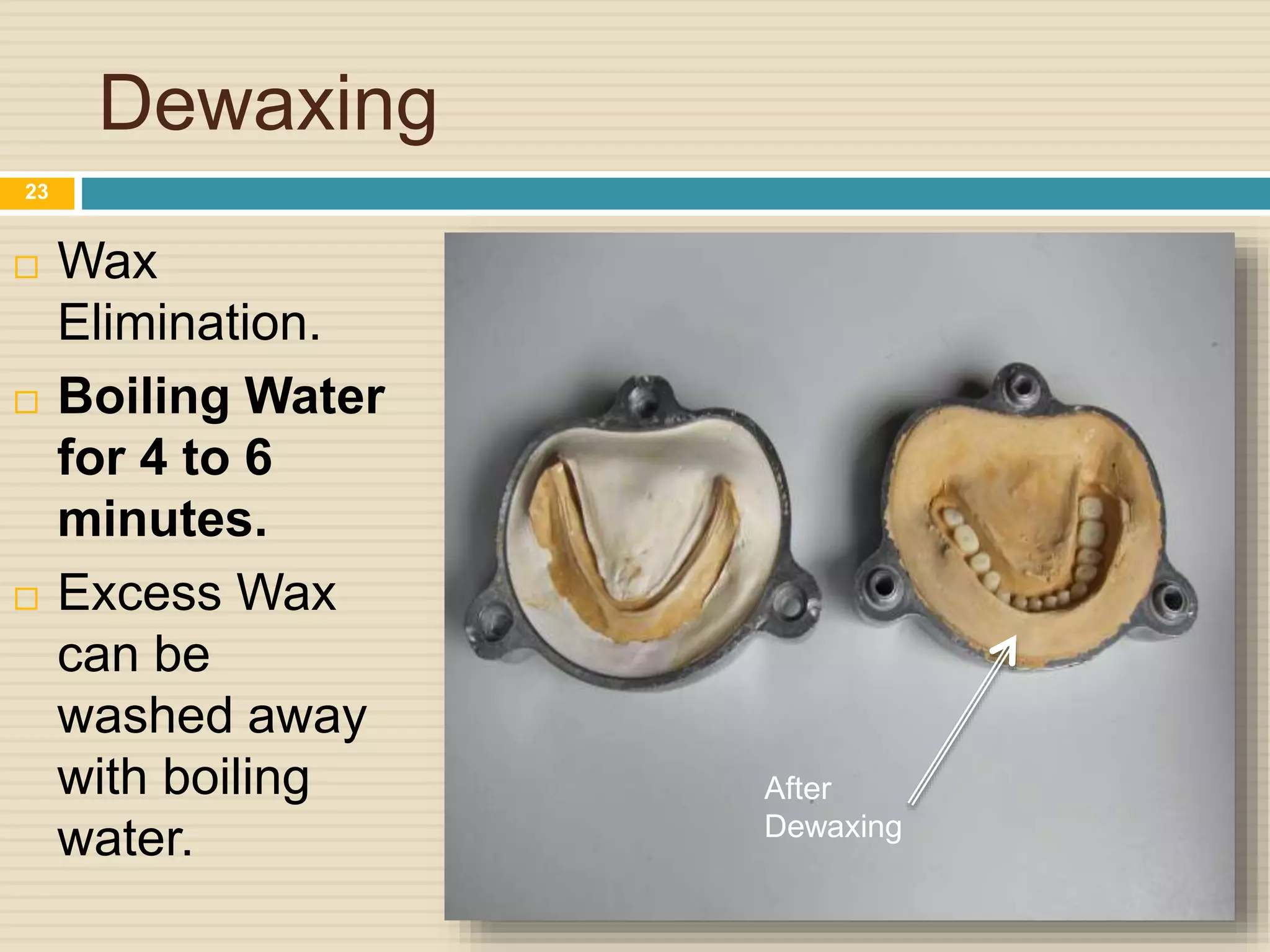

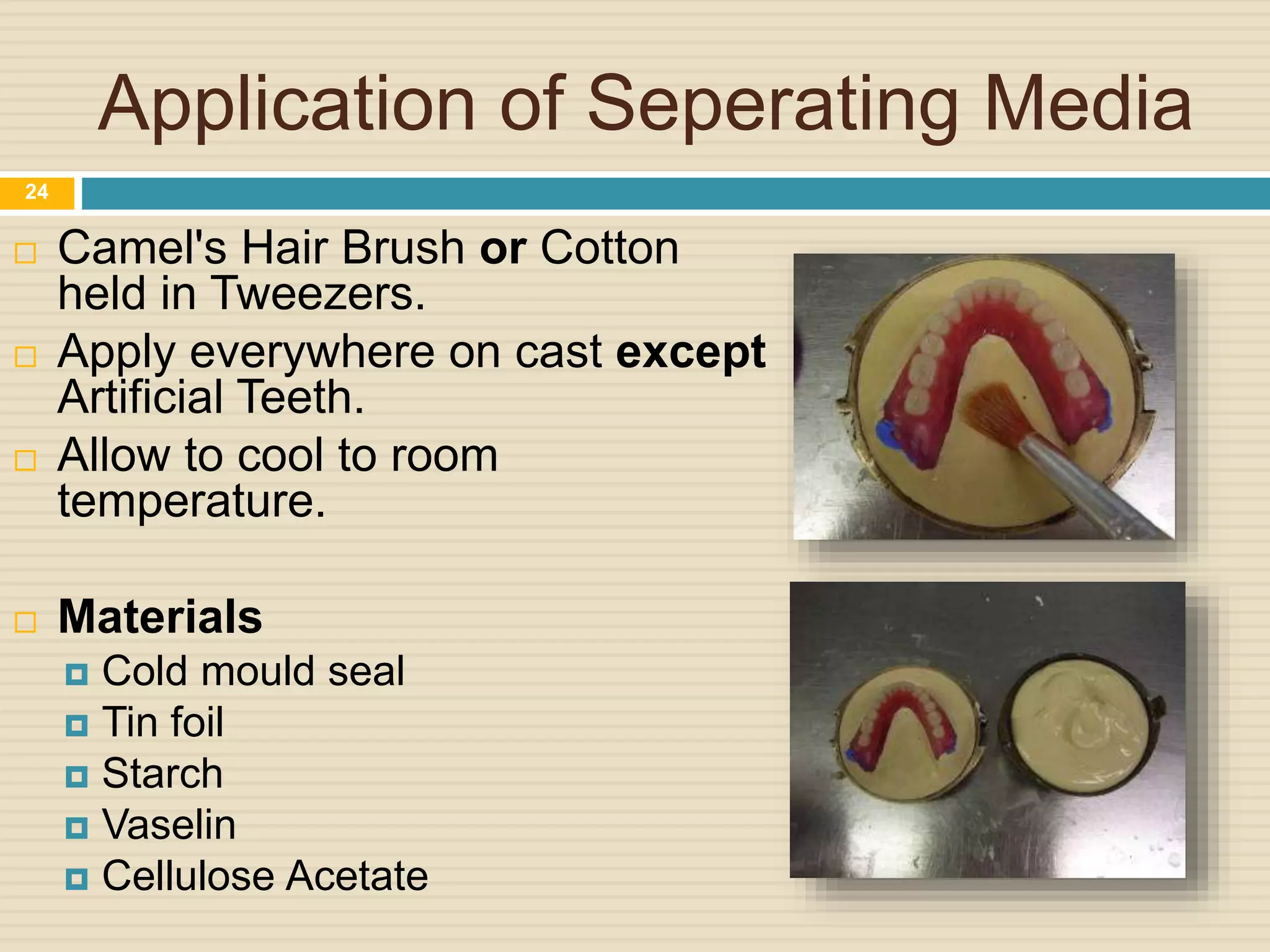

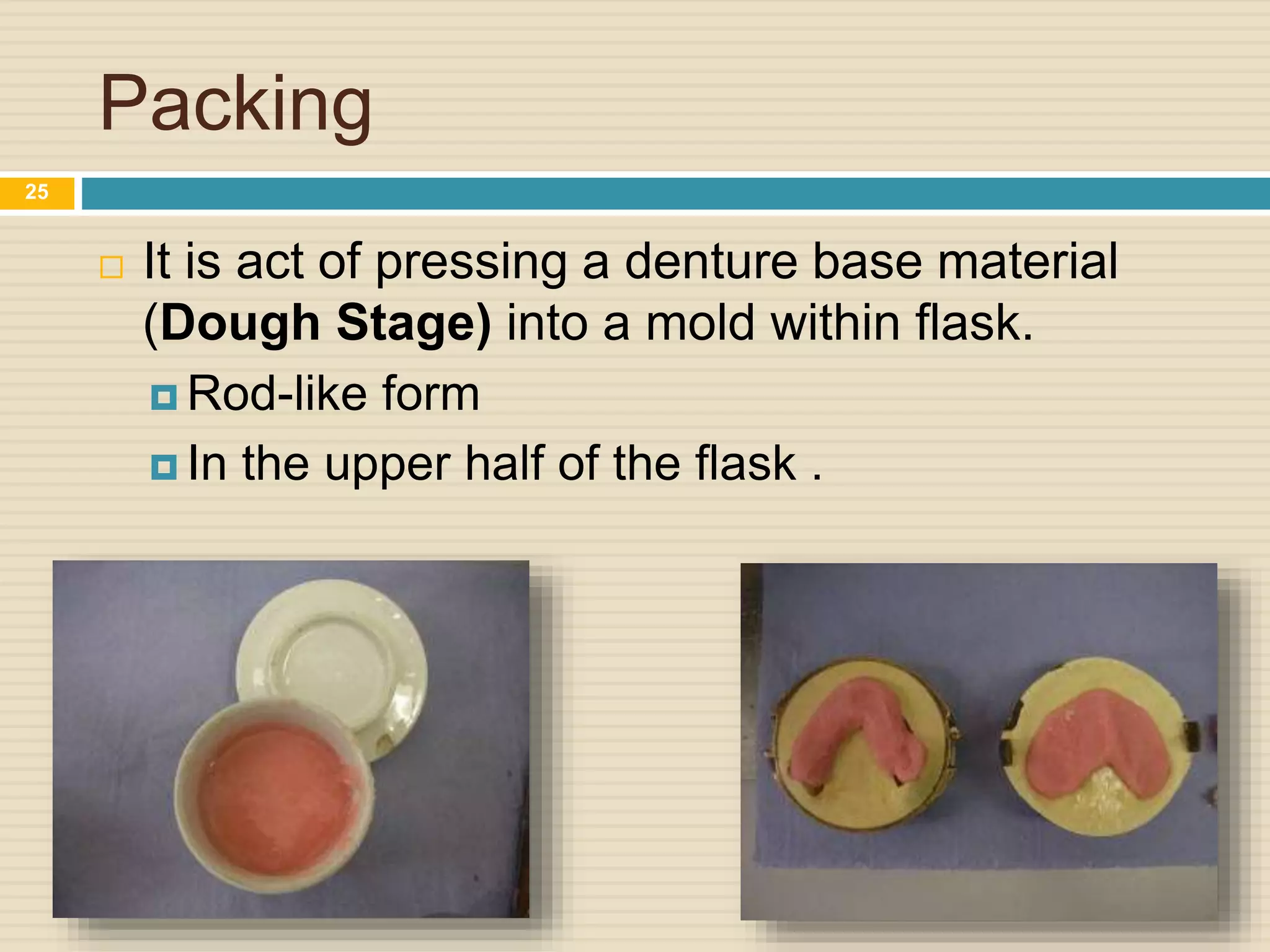

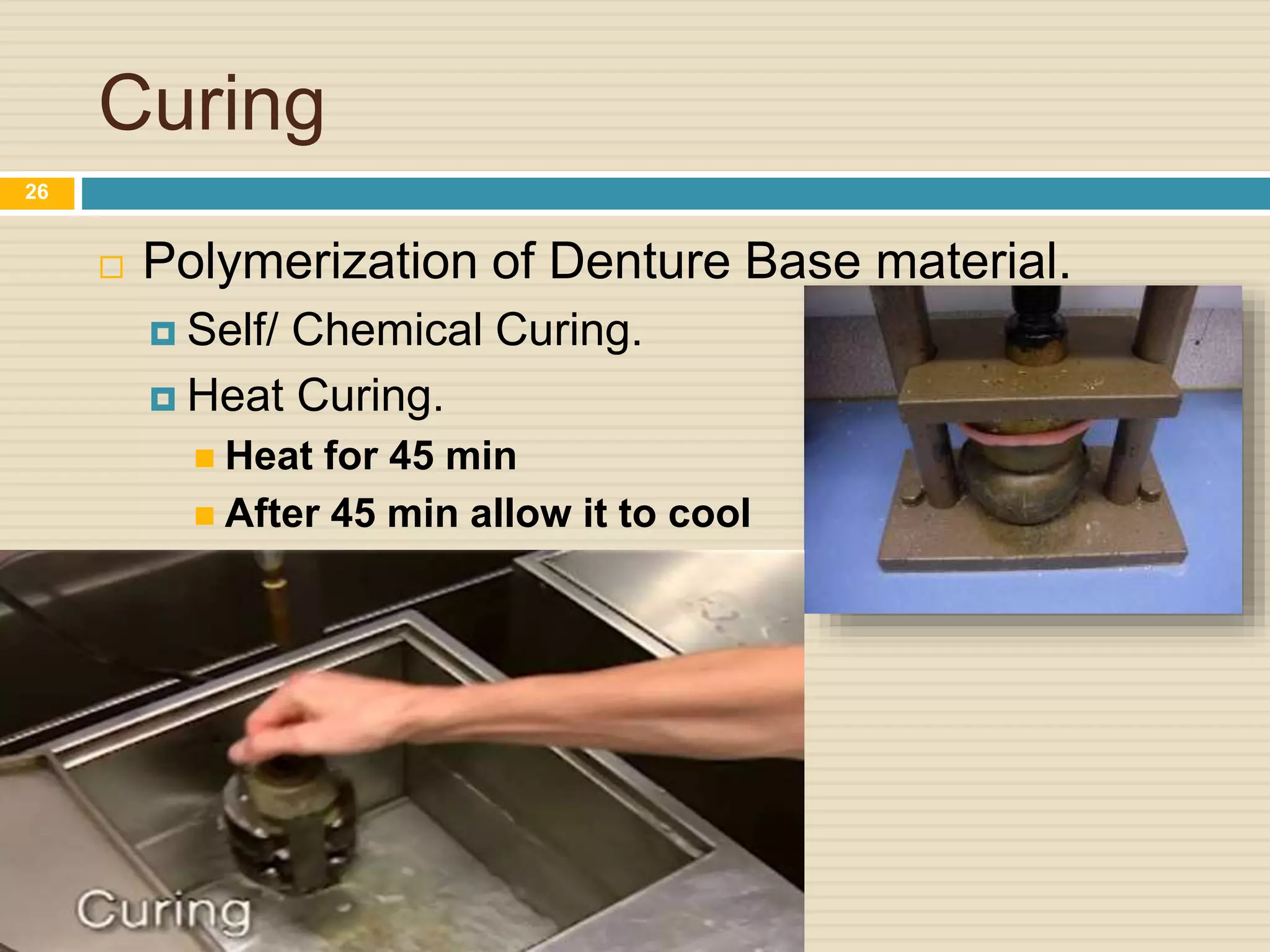

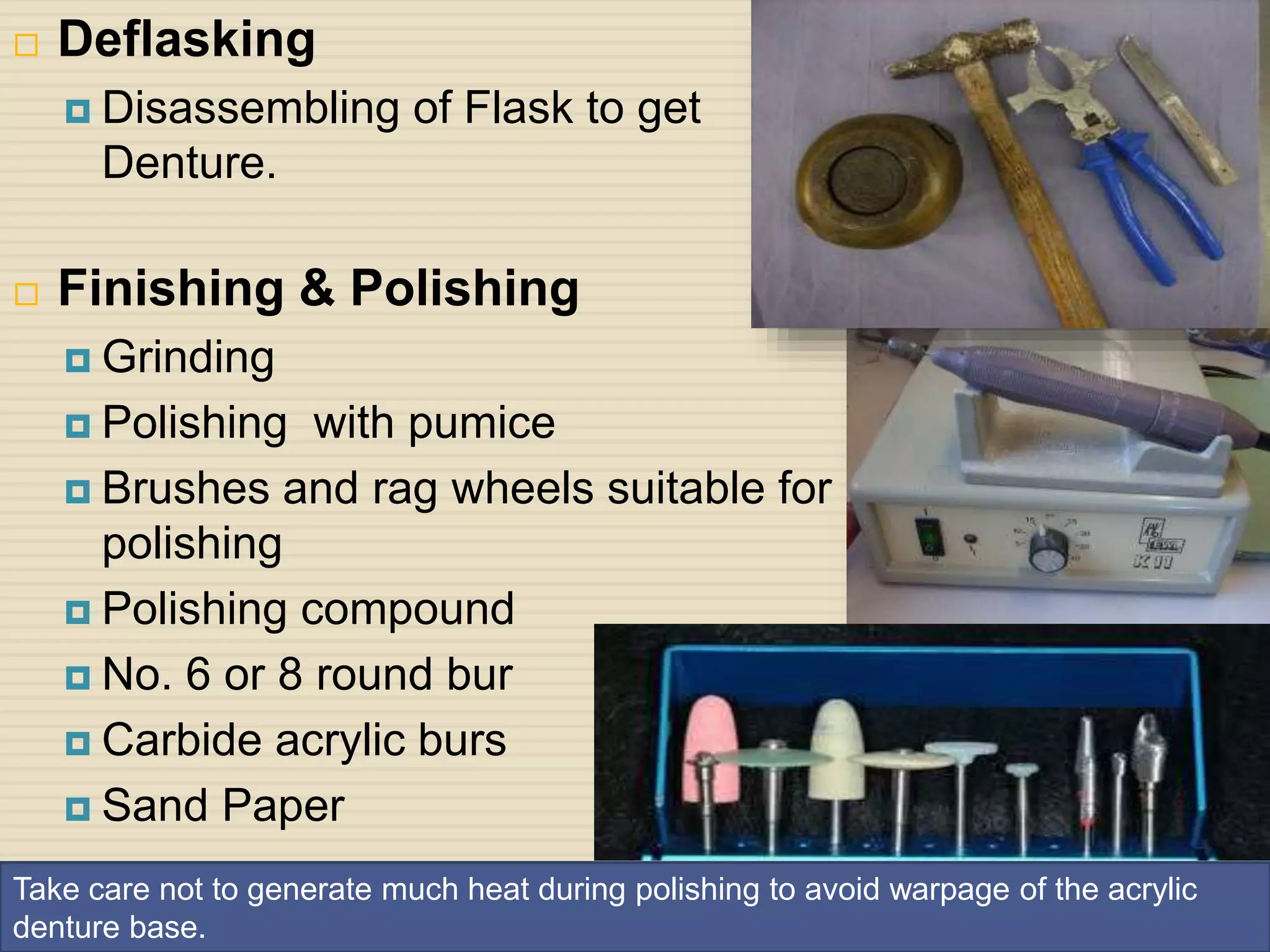

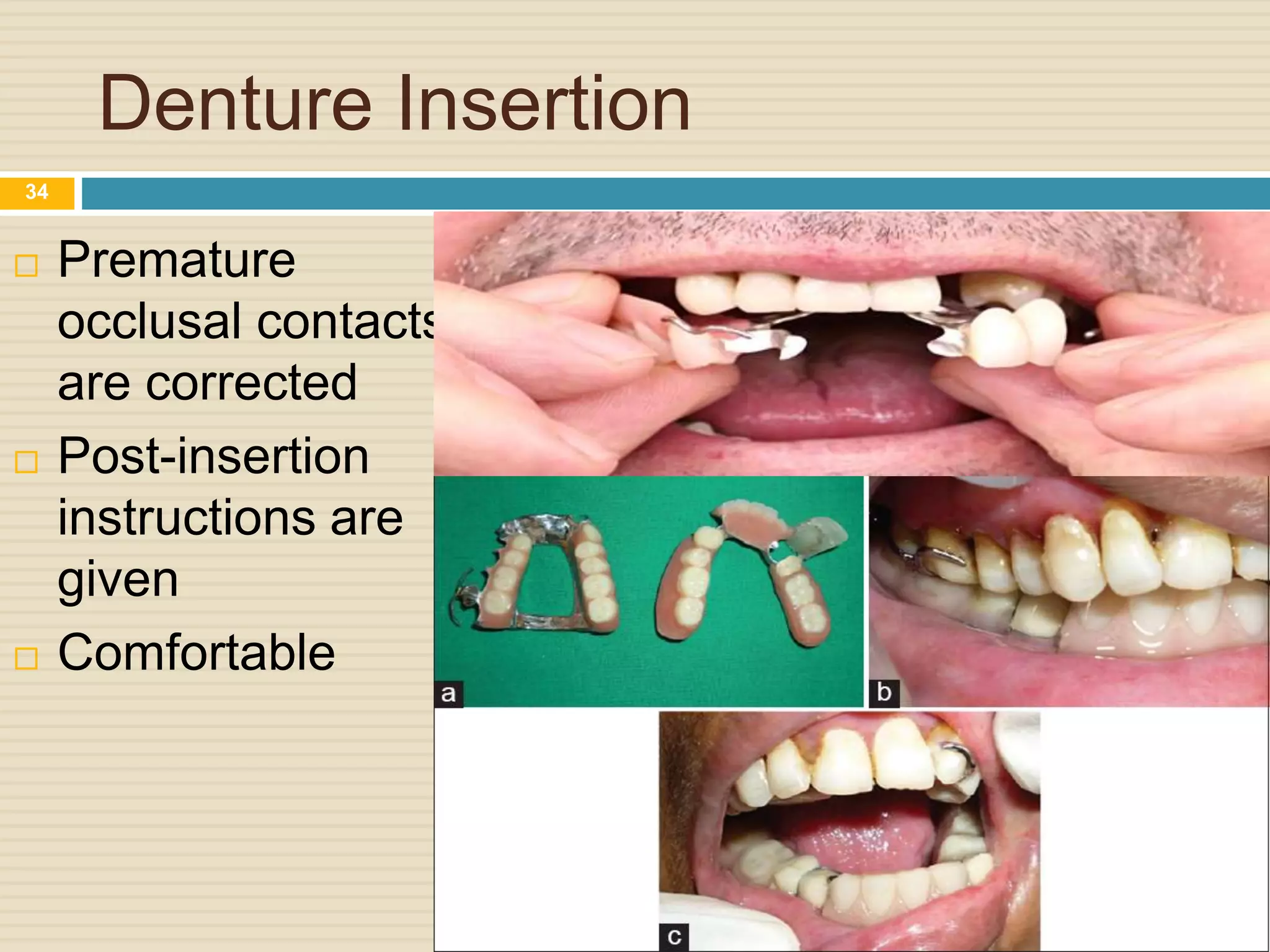

The document outlines the steps involved in fabricating a removable partial denture, which includes both clinical and laboratory steps. The clinical steps include diagnosis, treatment planning, impressions, framework try-in, and denture insertion. The laboratory steps involve model preparation, surveying, framework fabrication, waxing, flasking, curing, and finishing. Key steps include diagnostic impressions to create study models, designing the prosthesis framework, final impressions, packing denture base material into the mold, curing, and inserting the final denture.